Denitrification filler and method for deep denitrification of municipal sewage

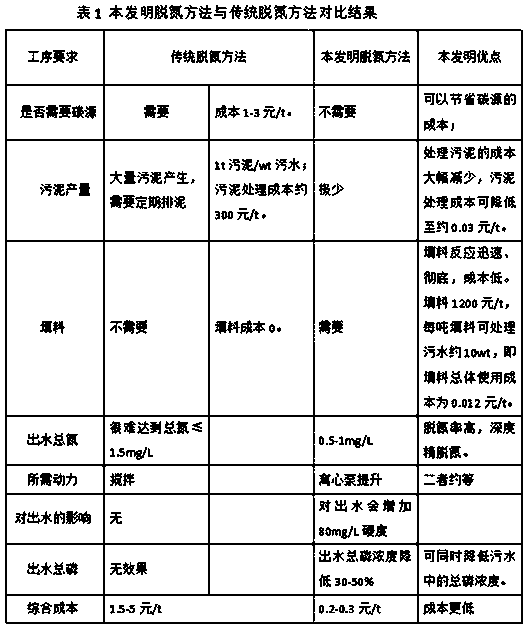

A technology for denitrification and raw materials, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of poor process control, complex process, large sludge output, etc. The effects of rich raw material sources, simple preparation methods and low environmental adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: A denitrification filler prepared from the following raw materials in terms of weight percentage: 1% aluminum powder, 10% aluminum hydroxide, 5% sulfur powder, 20% sodium thiosulfate, and 2% sodium silicate , calcium hydroxide 50%, wood chips 2%, water 10%.

Embodiment 2

[0025] Embodiment 2: A kind of denitrification filler, the difference from Embodiment 1 is that it is prepared from the following raw materials in terms of weight percentage: 1.5% aluminum powder, 11% aluminum hydroxide, 4% sulfur powder, thio Sodium sulfate 23%, sodium silicate 2.5%, calcium hydroxide 48%, wood chips 2%, water 8%.

Embodiment 3

[0026] Embodiment 3: A kind of denitrification filler, the difference with embodiment 1 is that, by weight percentage, it is prepared from the following raw materials: aluminum powder 1%, aluminum hydroxide 9%, sulfur powder 5%, thio Sodium sulfate 25%, sodium silicate 3%, calcium hydroxide 45%, wood chips 3%, water 9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com