Yarn guide plate for patternbars of warp knitting machine

A yarn guide plate and machine flower technology, which is applied in the directions of warp knitting, textiles, papermaking, knitting, etc., can solve the problem of unfavorable flower combs and high-speed operation of the yarn guide needles of the flower combs, failure of subsequent processing, assembly and use of parts after one molding Process limitations and other problems, to achieve the effect of obvious cost reduction, comprehensive processing cost reduction, and single piece weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in combination with specific embodiments.

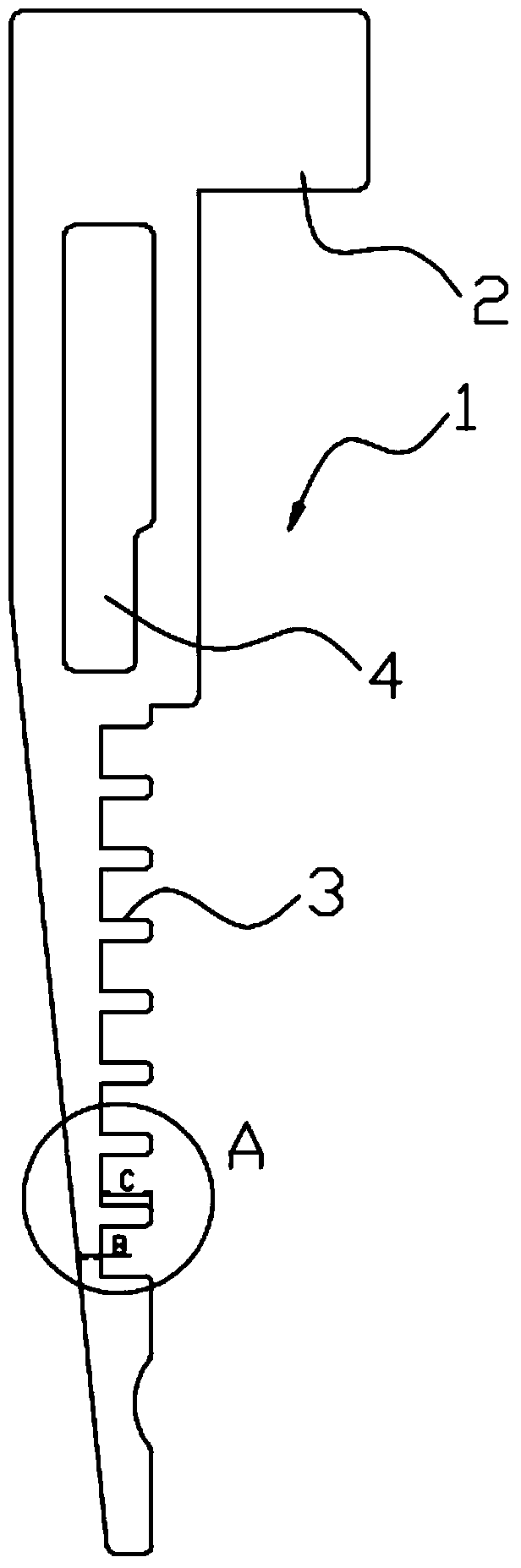

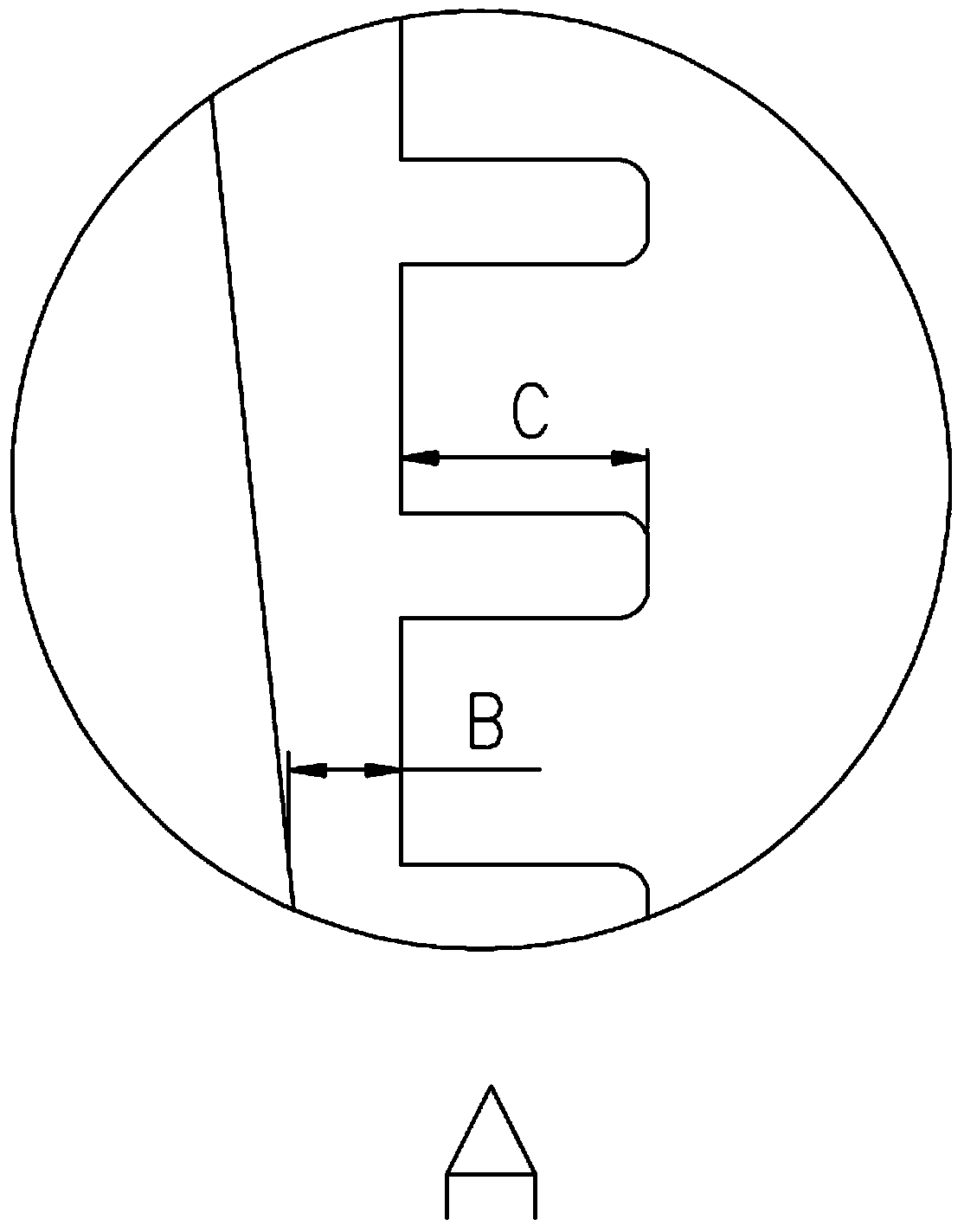

[0027] Such as figure 1 As shown, a yarn guide plate for warp knitting machine combing in one embodiment of the present invention includes a yarn guide base 2 and a track 3 arranged on the yarn guide base 2, and the yarn guide base 2 and the track 3 are One-piece overall structure, the material of the yarn guide plate 1 is light magnesium alloy. The yarn guide plate 1 is integrally formed without secondary processing of the rail 3, effectively avoiding the warping or deformation of the yarn guide plate 1 caused by secondary processing, with better stability and effectively prolonging the service life. The yarn guide plate 1 is made of lightweight magnesium alloy. Compared with similar aluminum profiles, the weight of a single piece is reduced, not only the cost of a single piece is reduced, but also the overall processing cost is also reduced to a certain extent. will be ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com