Efficient backwashing-free filtering clarification tank

A technology for backwashing, filtration and clarification, which is used in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. and other problems, to achieve the effect of good adsorption and temperature resistance, convenient operation control and production management, and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

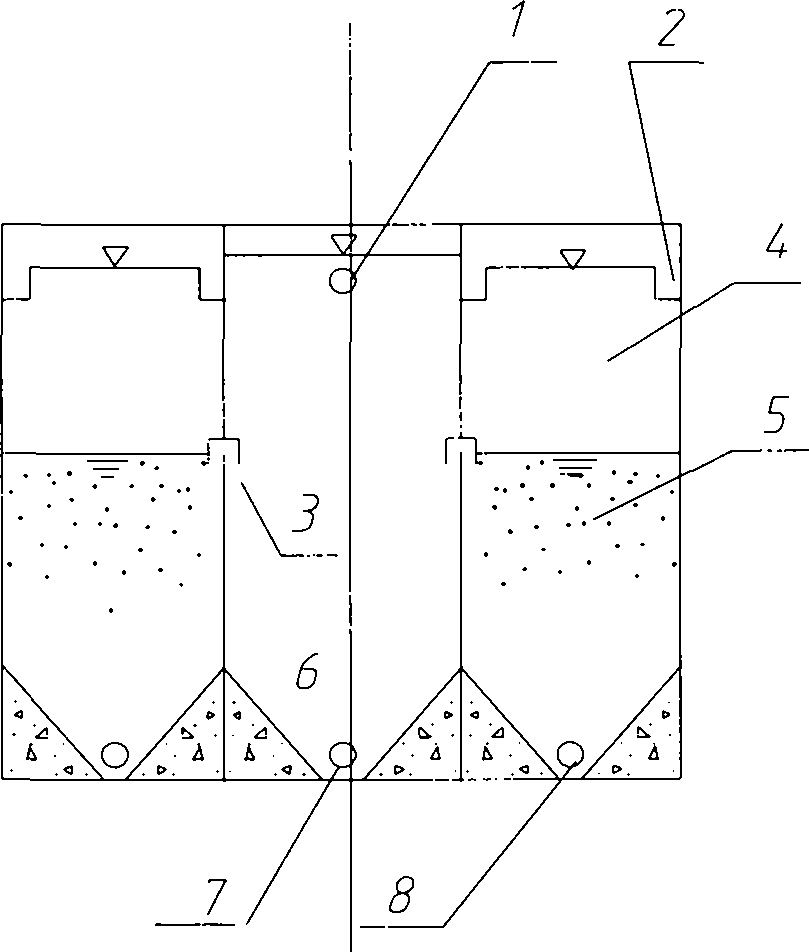

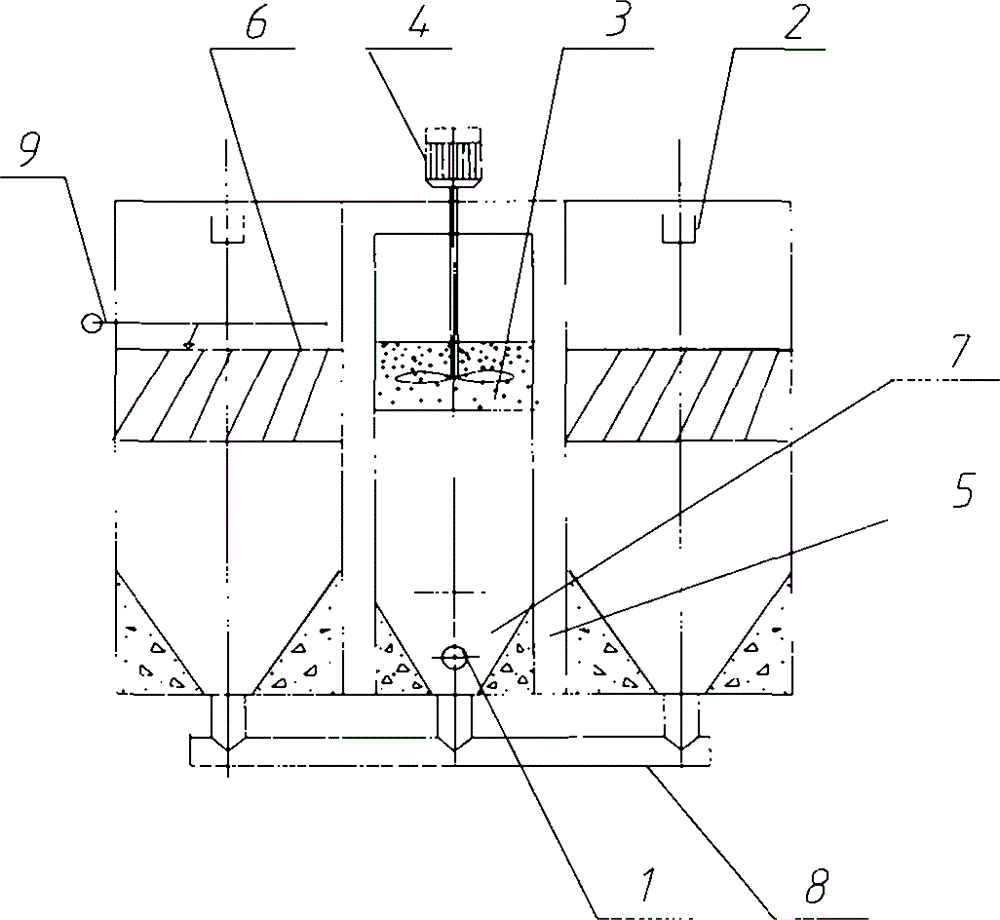

[0012] The water inlet main pipe enters from the middle and lower part of the reaction chamber cone, and the treated water enters the reaction chamber tangentially through the distribution pipe (1). A suspension filter device is set in the middle of the cylindrical section of the reaction chamber, and figure 2 The device frame shown in (3) is filled with suspension filter material, and the mixer is installed at the position of part number (4) in the figure. The diversion chamber (5) enters the lower part of the clarification chamber through the lower part of the diversion chamber. In the clarification chamber, the water flows from bottom to top, and through the contact and separation of the honeycomb inclined pipe (6), the clean water flows out of the clarification tank through the outlet water distribution tank (2), and the sludge settles down and enters the sludge concentration chamber (7). Then enter the mud collecting bucket and the mud collecting main pipe (8), and fina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com