Patents

Literature

36results about How to "Constant control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

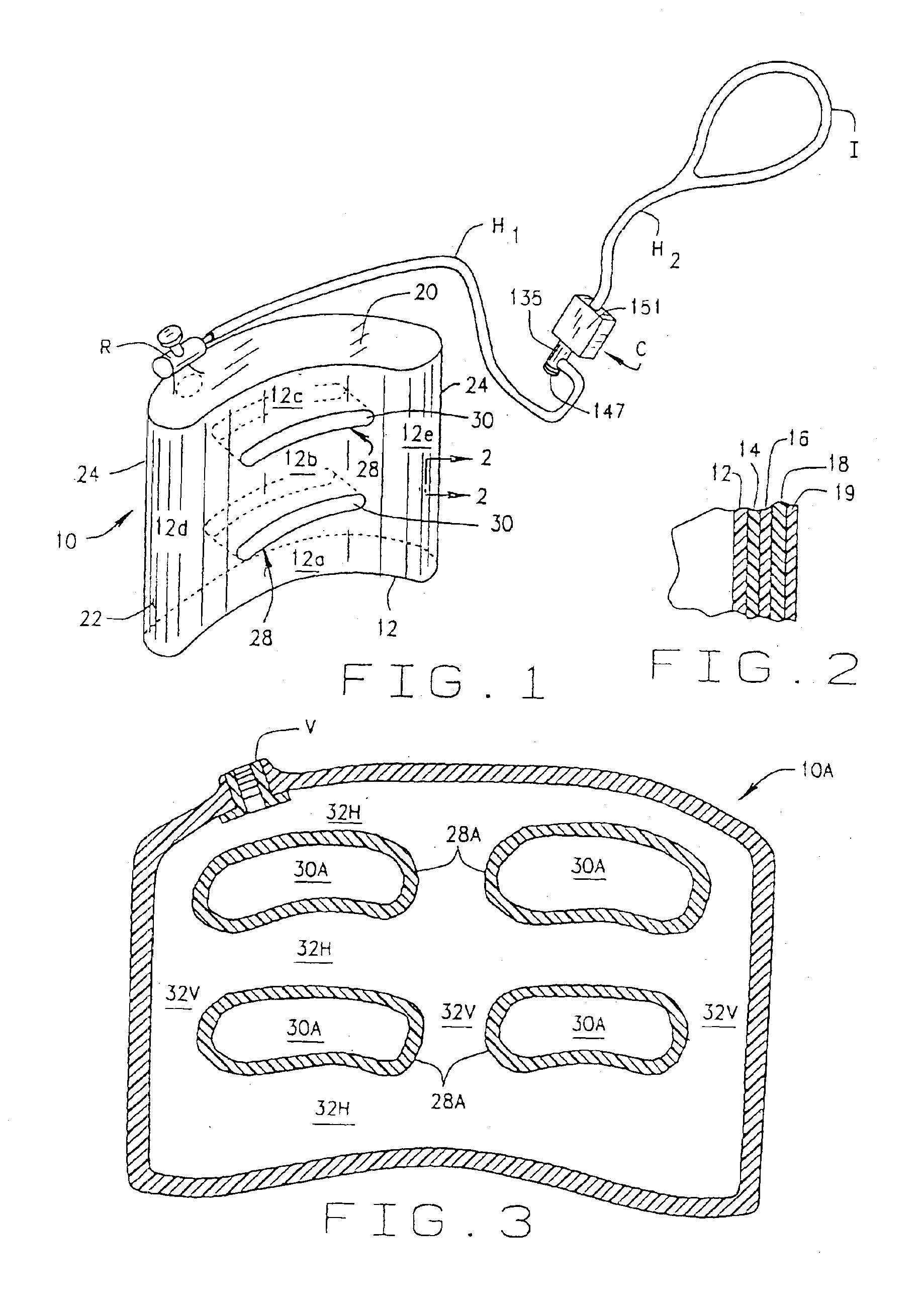

Infusion pumps

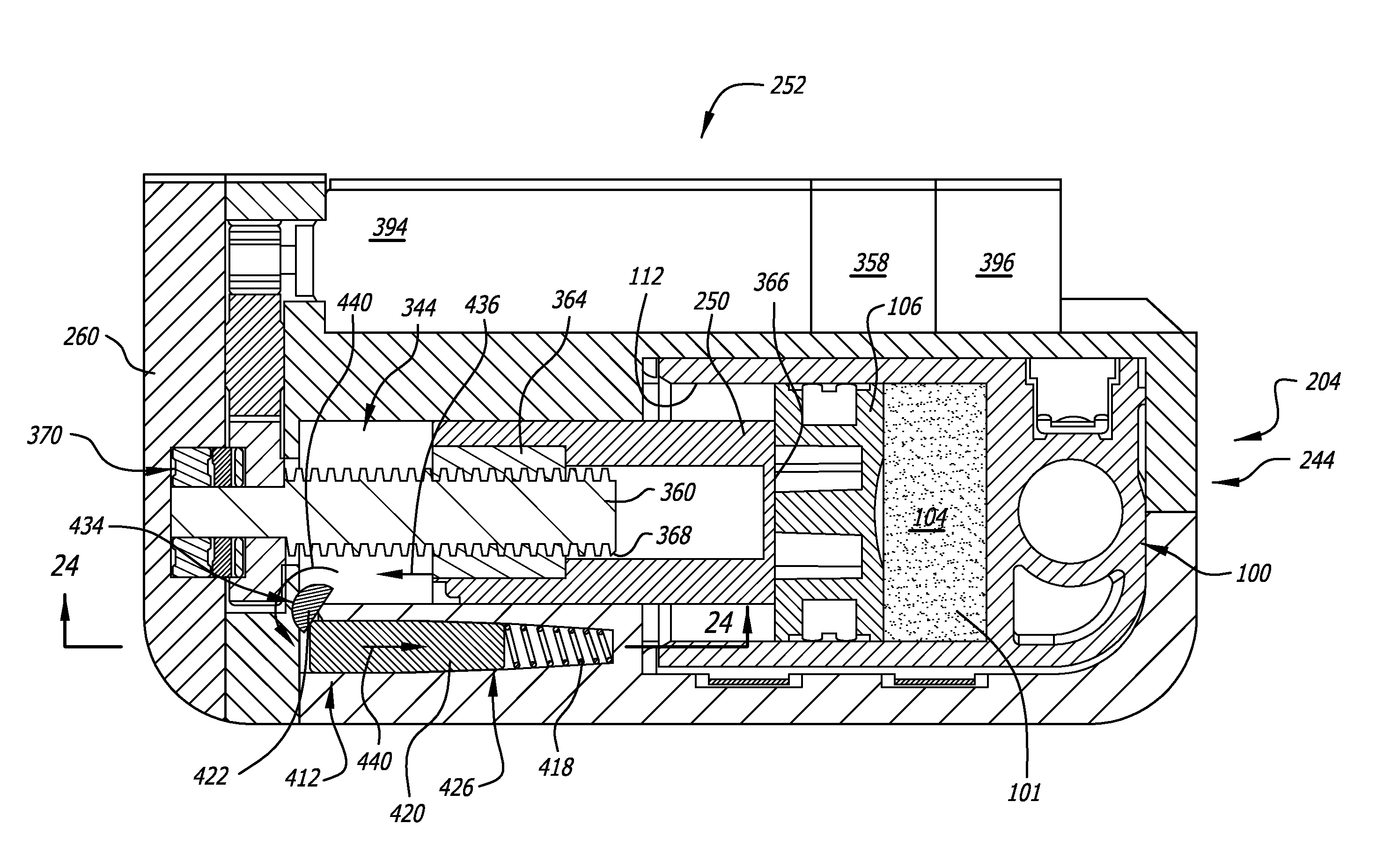

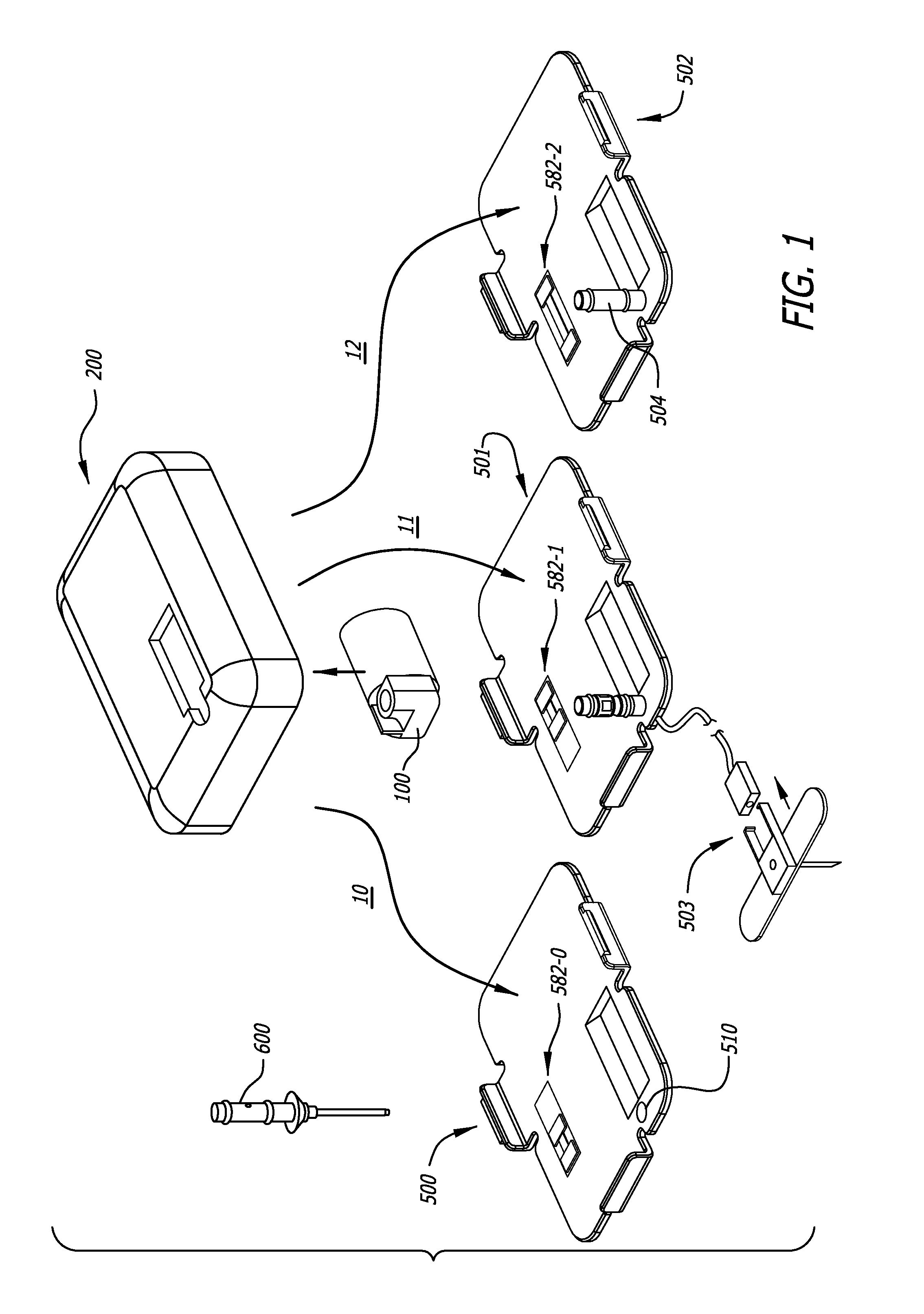

ActiveUS20120078181A1Constant controlAccurate distanceDiagnosticsSurgeryBiomedical engineeringAmbulatory infusion pumps

Ambulatory infusion pumps, pump assemblies, cartridges, baseplates, cannulas, insertion tools, and related components as well as combinations thereof and related methods.

Owner:MEDTRONIC MIMIMED INC

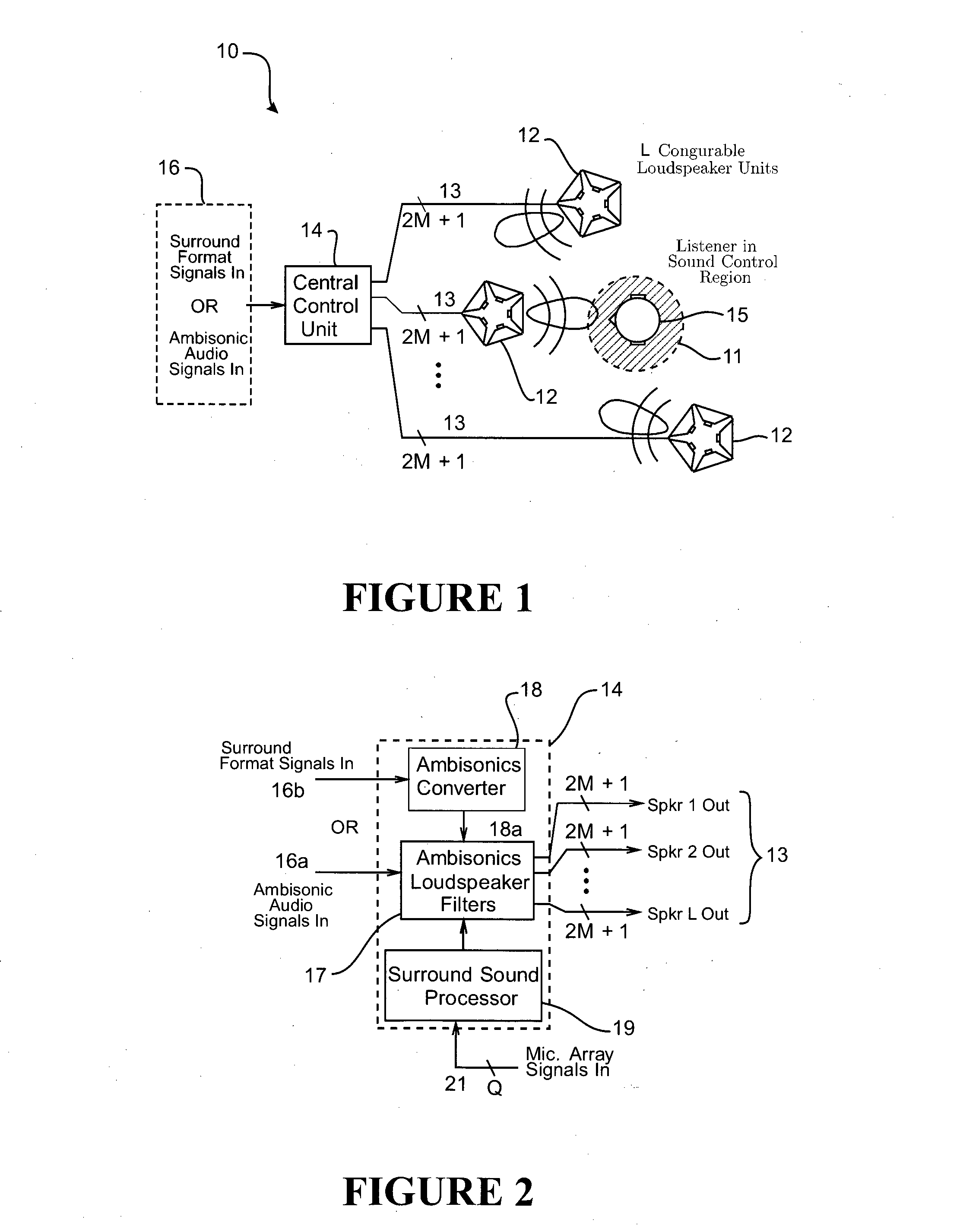

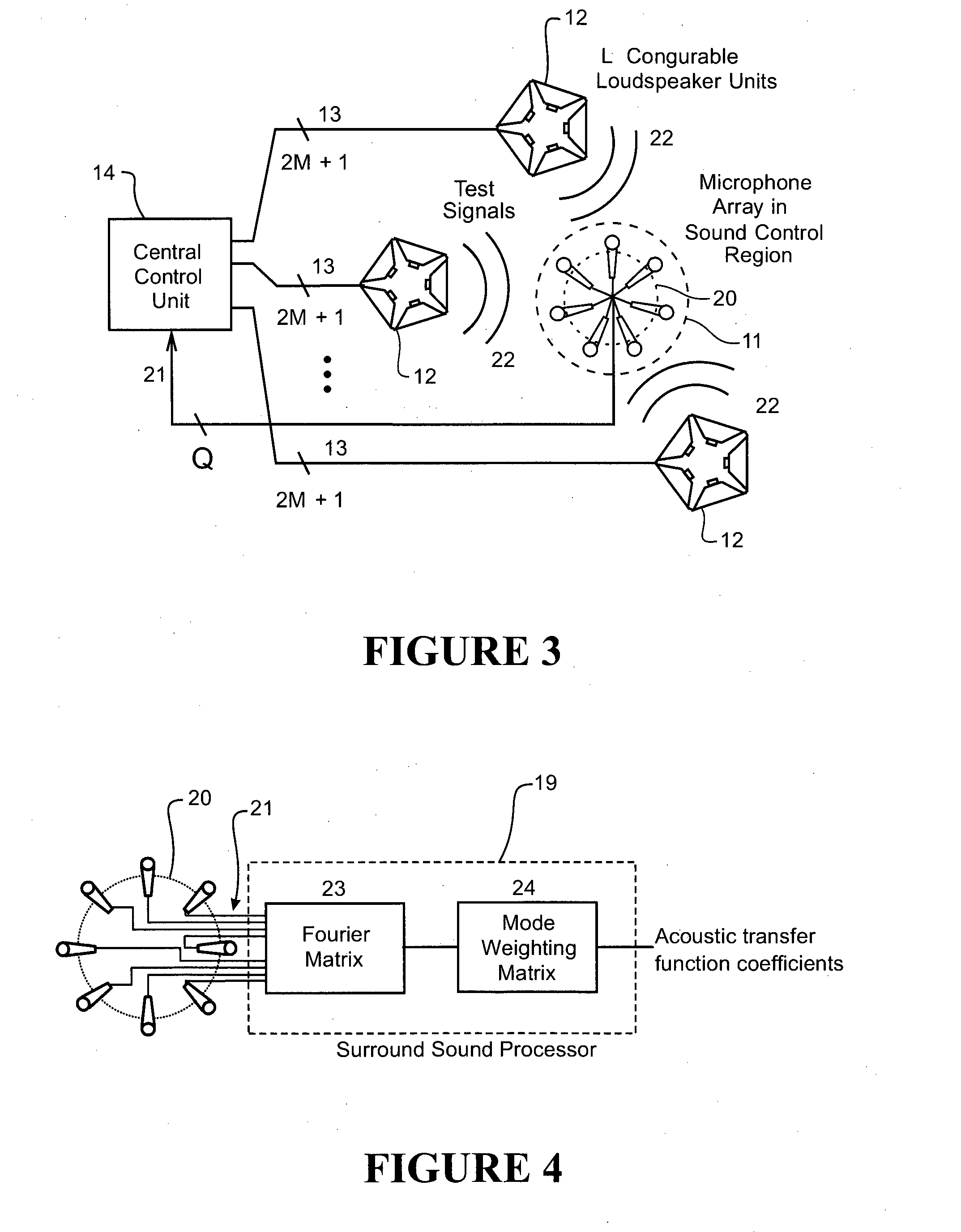

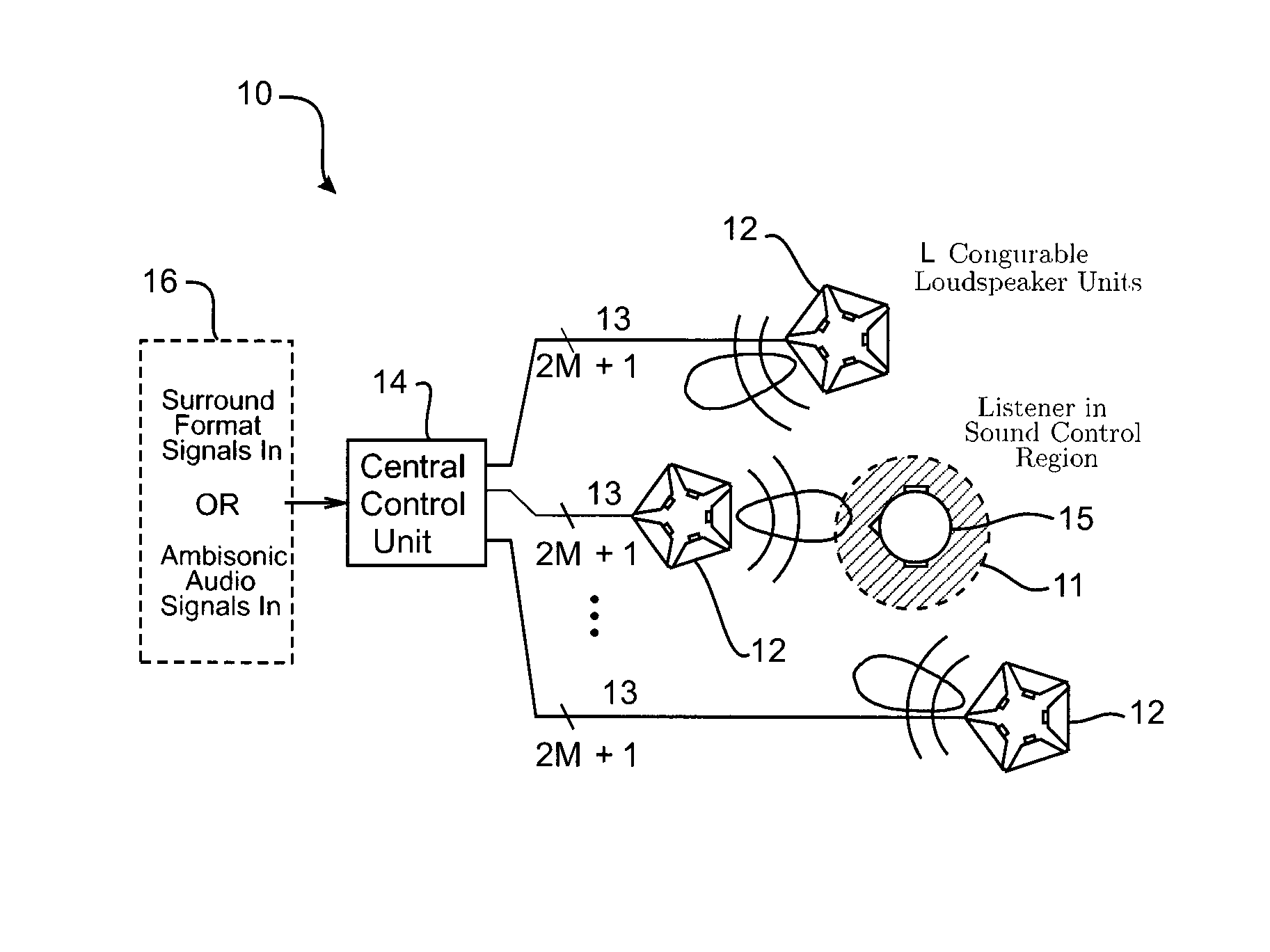

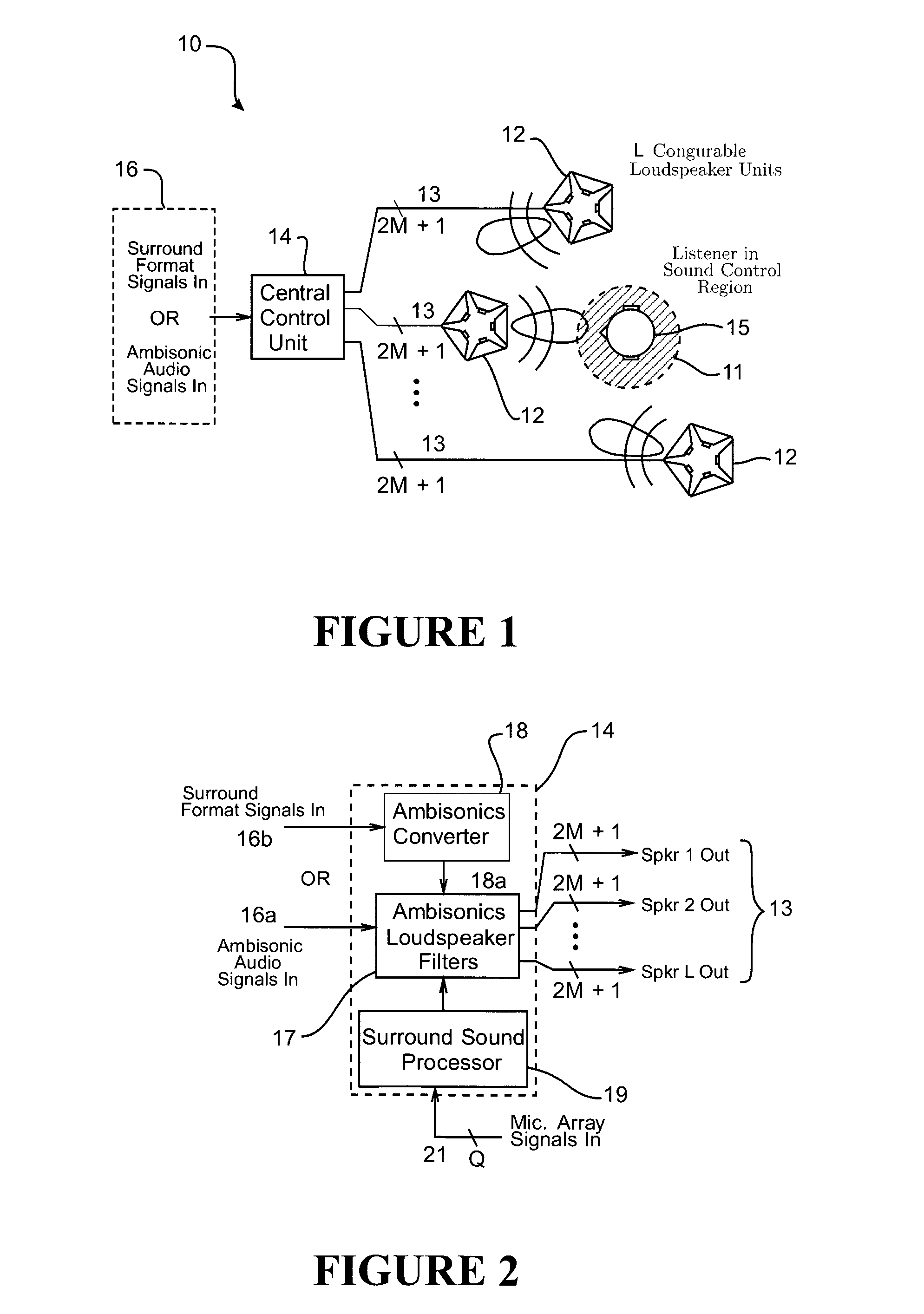

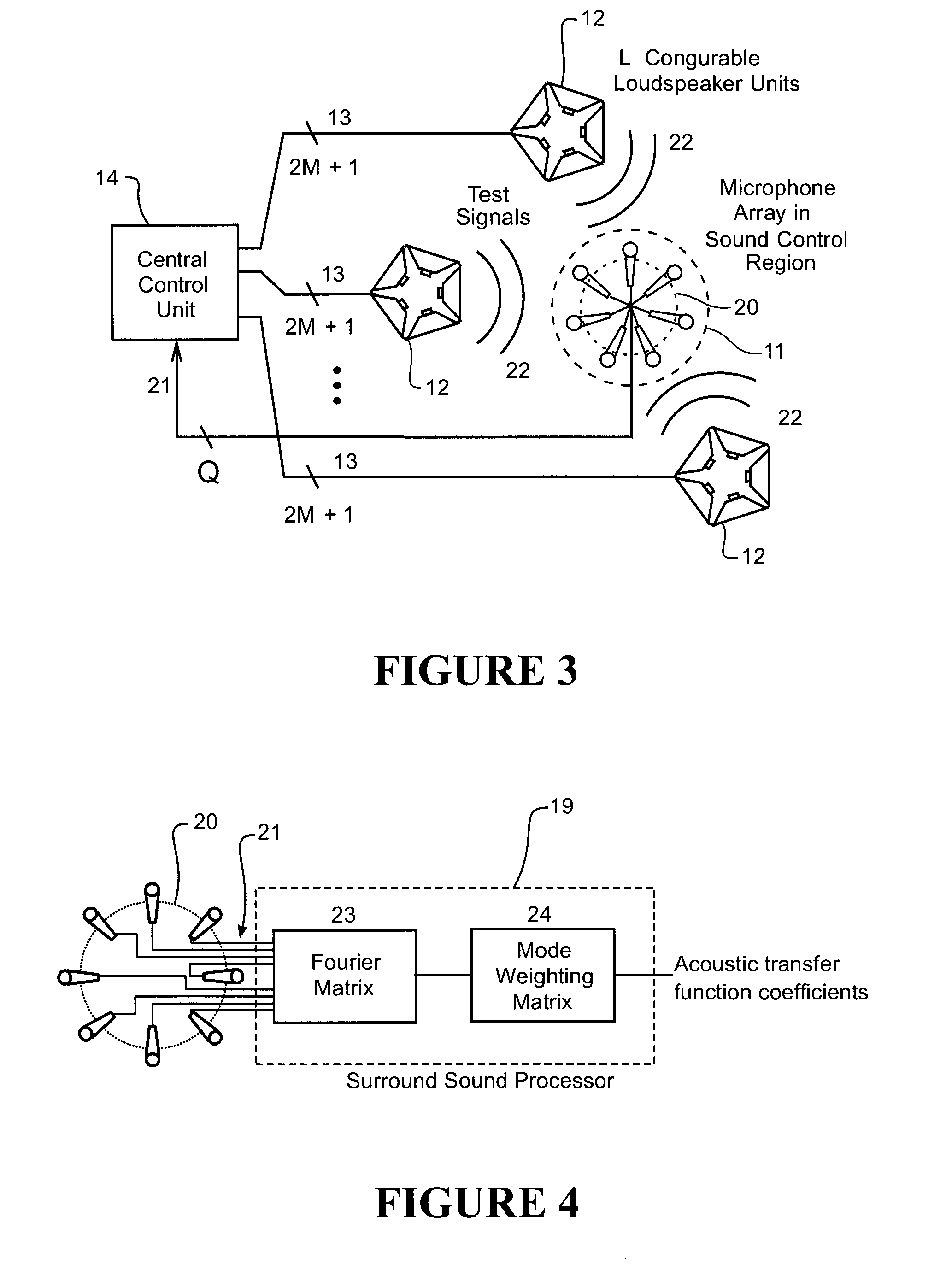

Surround Sound System

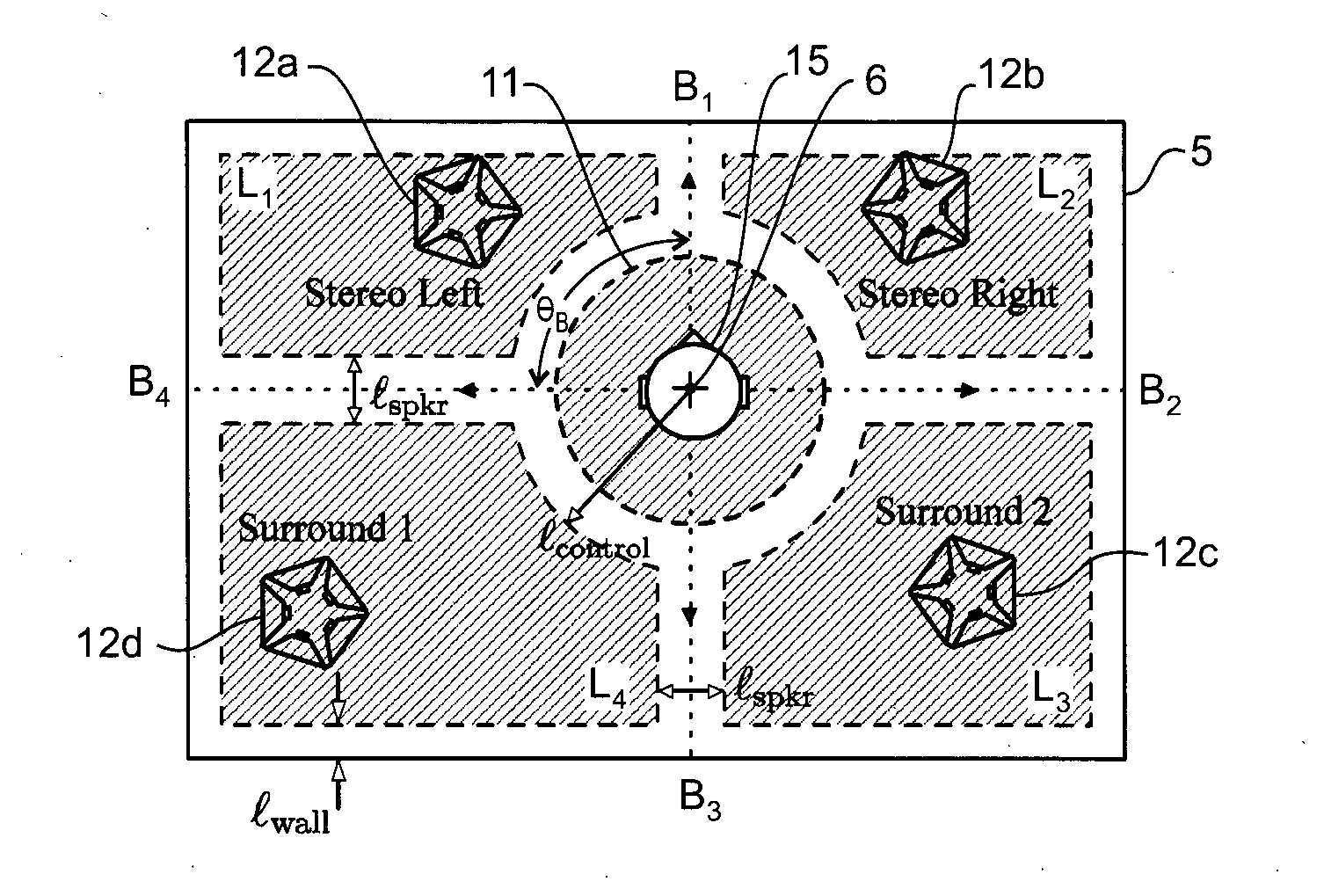

ActiveUS20130223658A1Constant controlSpeech analysisStereophonic systemsAcoustic transfer functionVocal tract

A surround sound system for reproducing a spatial sound field in a sound control region within a room having at least one sound reflective surface. The system uses multiple steerable loudspeakers located about the sound control region, each loudspeaker having a plurality of different individual directional response channels being controlled by respective speaker input signals to generate sound waves emanating from the loudspeaker with a desired overall directional response. A control unit connected drives each of the loudspeakers and has pre-configured filters based on measured acoustic transfer functions for the room for filtering the input spatial audio signals to generate the speaker input signals for all the loudspeakers to generate sound waves with co-ordinated overall directional responses that combine together at the sound control region in the form of either direct sound or reflected sound from the reflective surface(s) of the room to reproduce the spatial sound field.

Owner:CALLAGHAN INNOVATION

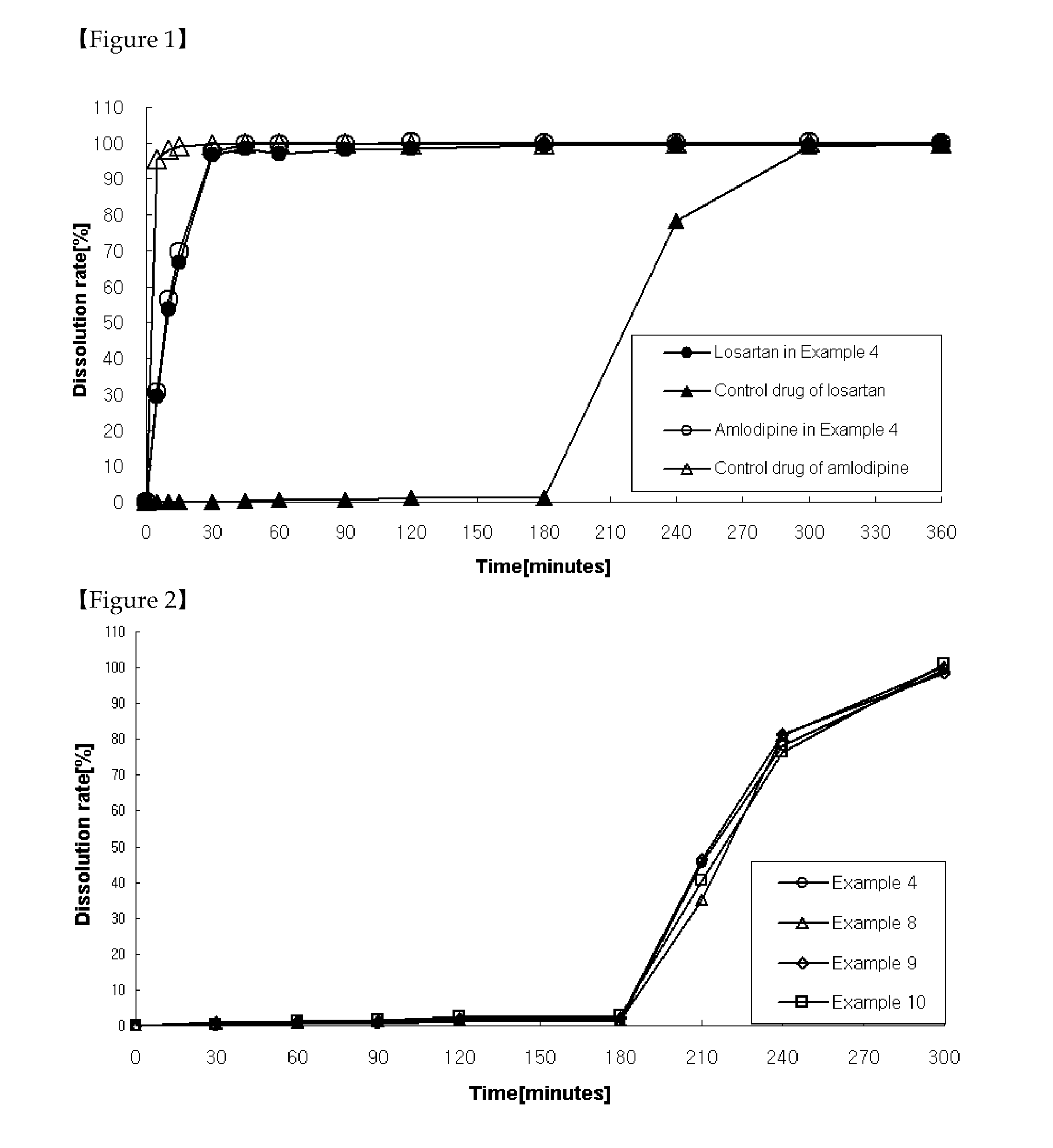

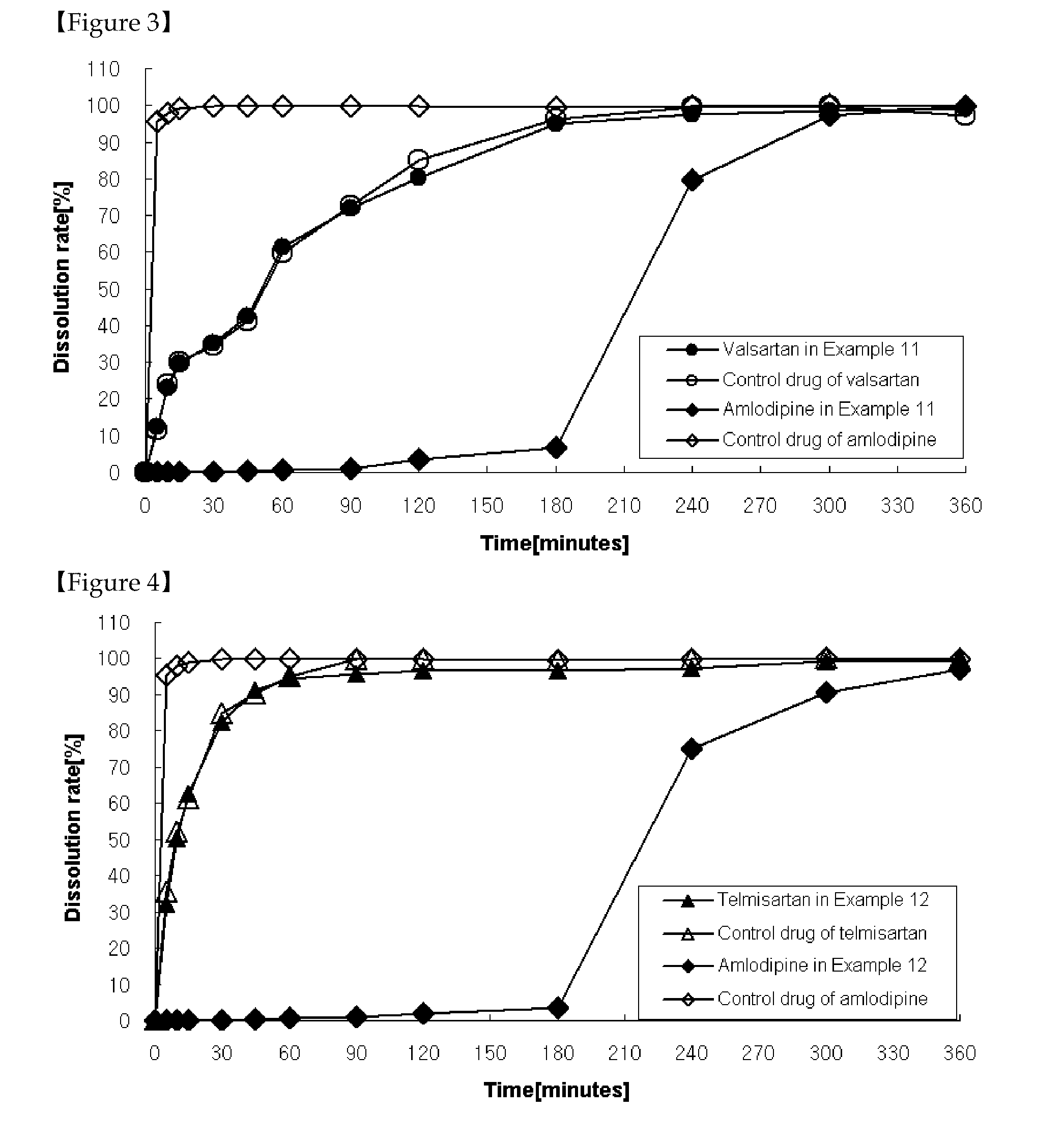

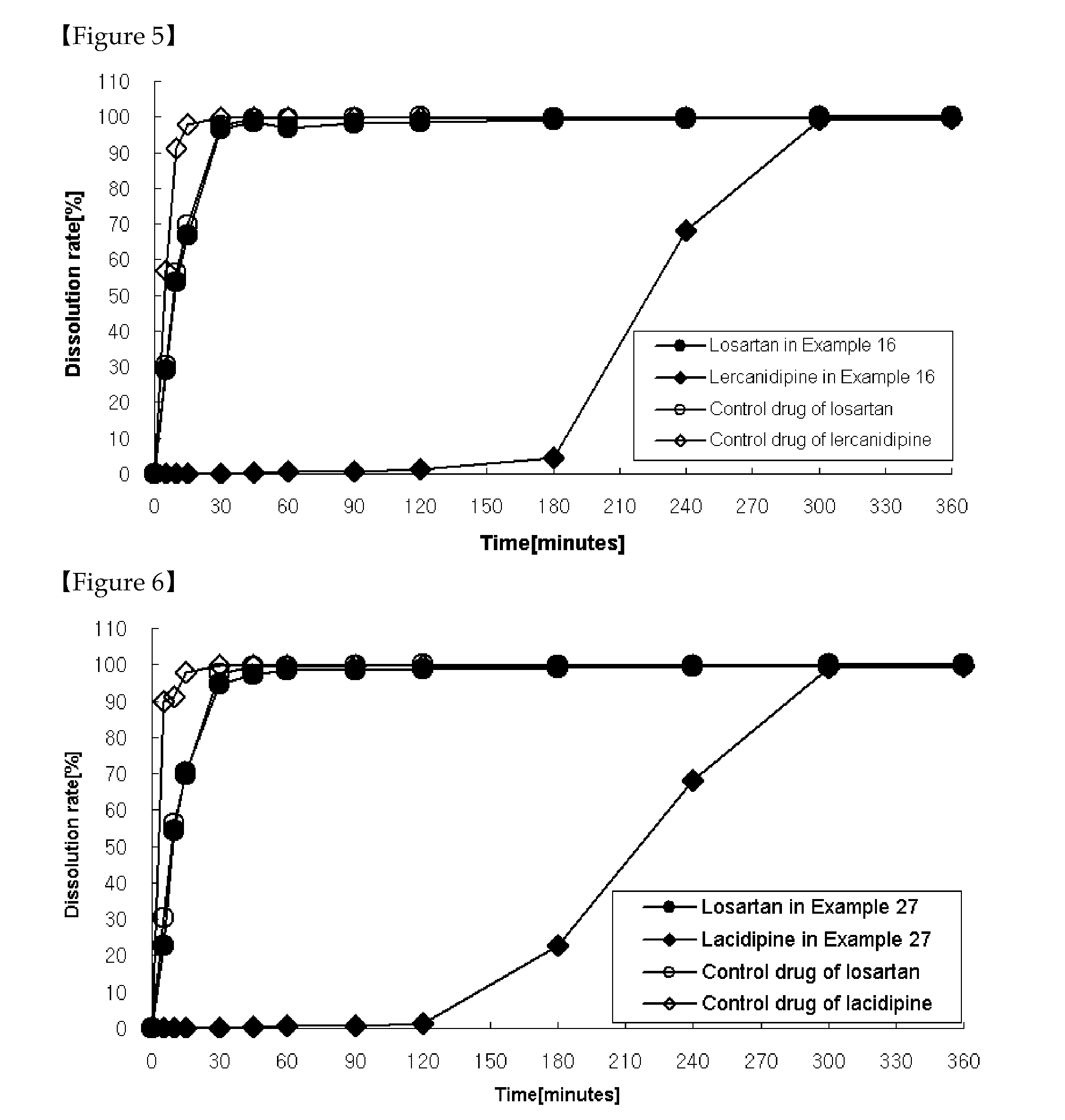

Combined preparation for the treatment of cardiovascular diseases based on chronotherapy theory

InactiveUS20100047341A1Improve Medication AdherenceConstant controlBiocideAnimal repellantsCo administrationSide effect

The present invention relates to a functional combination preparation comprising a dihydropyridine-based calcium channel blocker such as amlodipine and an ARB (Angiotensin-2 receptor blocker) such as losartan. In particular, the present invention relates to a chronotherapeutical combination pharmaceutical formulations with controlled-release for the prevention or treatment of cardiovascular disease, which is formulated in accordance with xenobiotics and chronotherapy for enabling the two drugs to be chronotherapeutically released, thereby improving the therapeutic activity as compared to the co-administration of each drug in the form of a single pill, while reducing side effects and maintaining the therapeutic activity as high as possible at the time of day when the risk of a complication of cardiovascular disease is highest.

Owner:HANALL PHARMA CO LTD

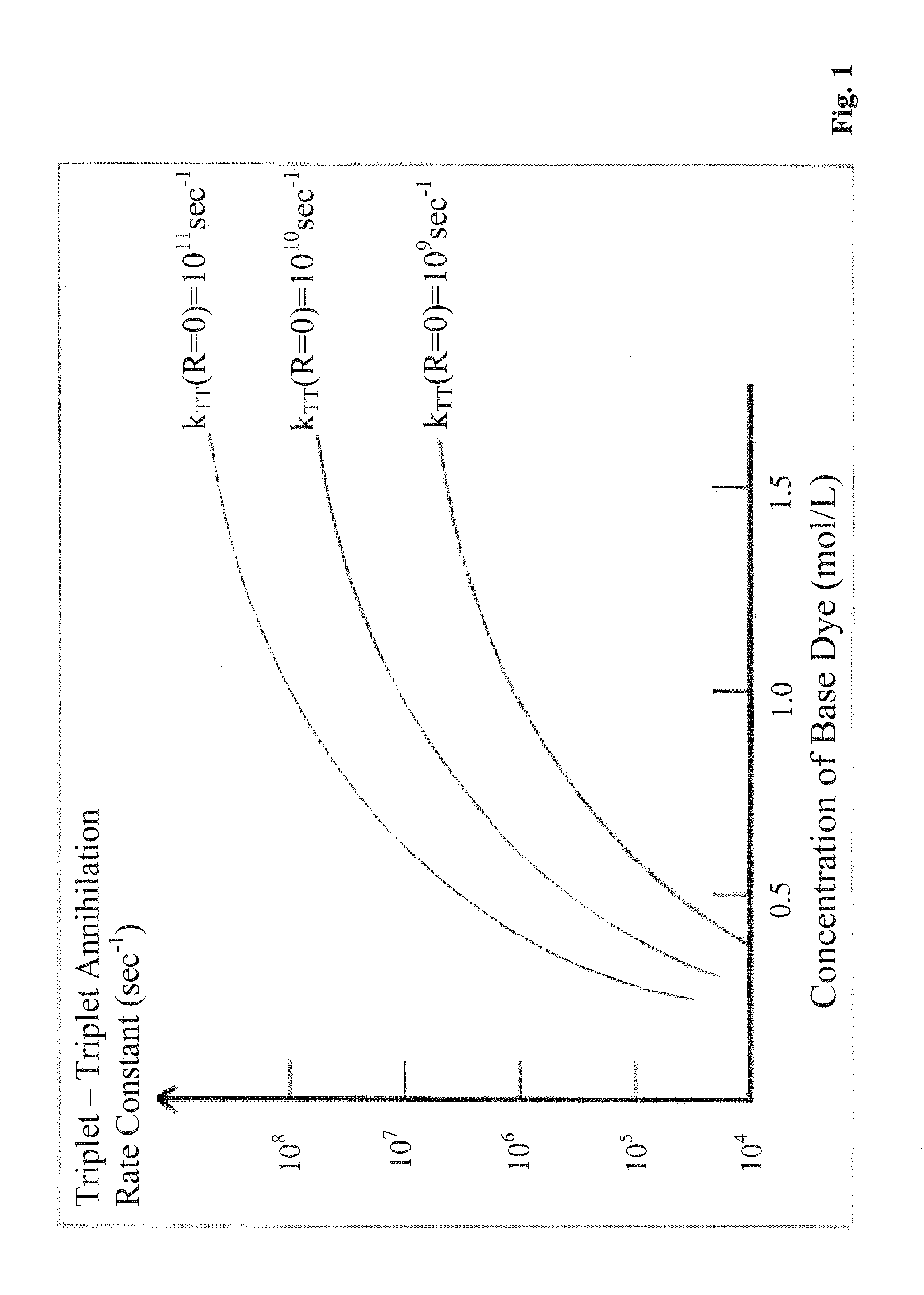

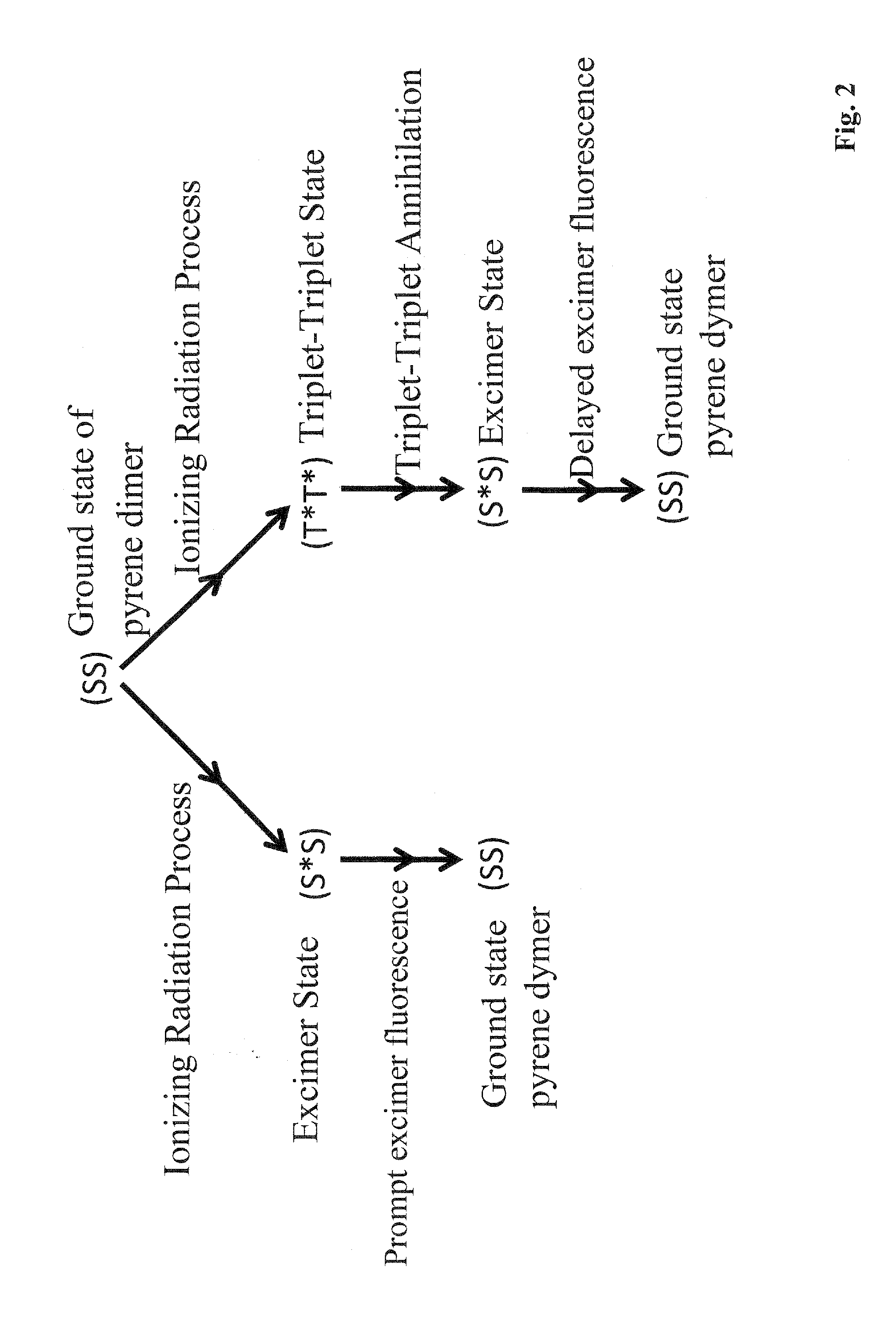

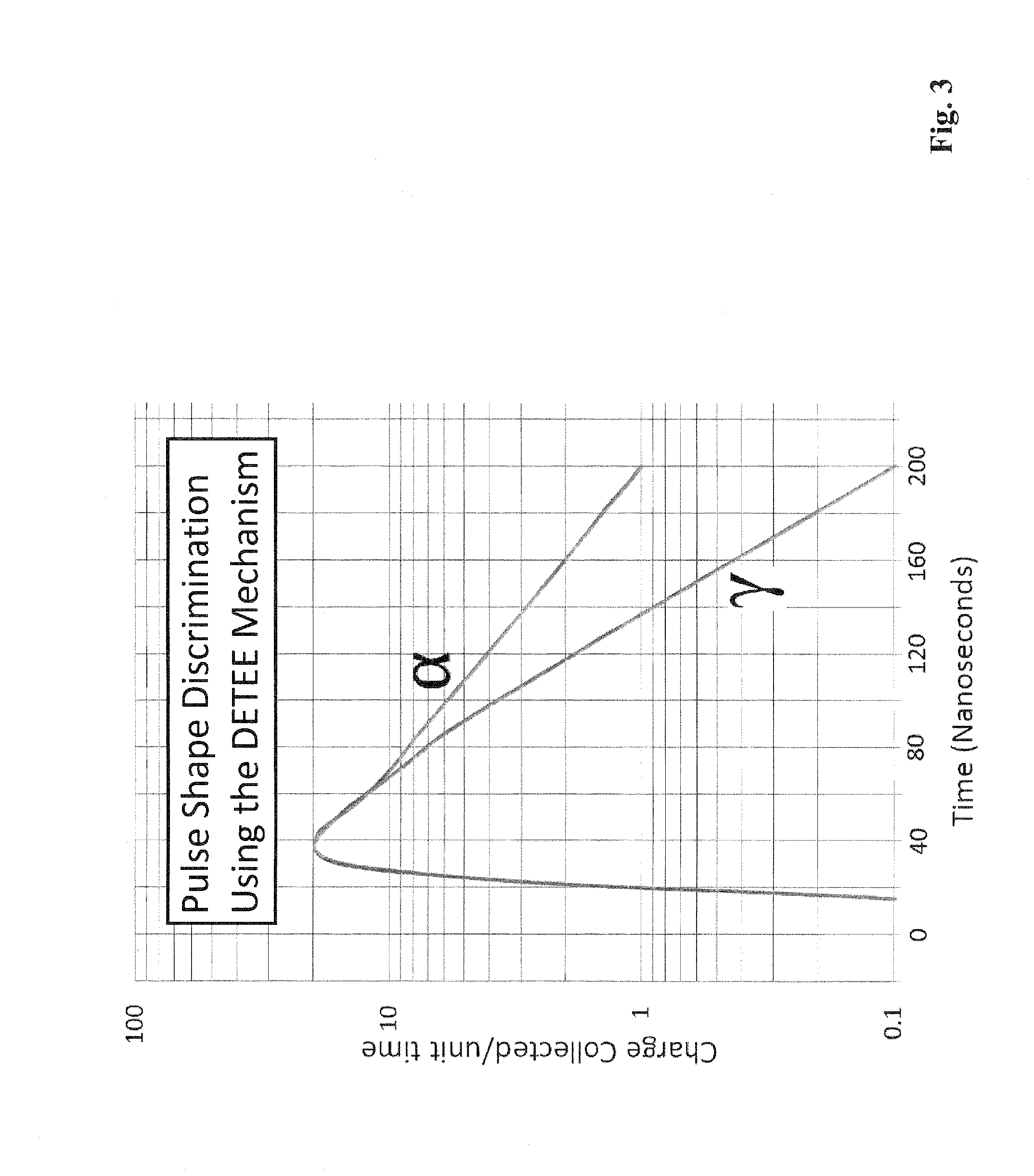

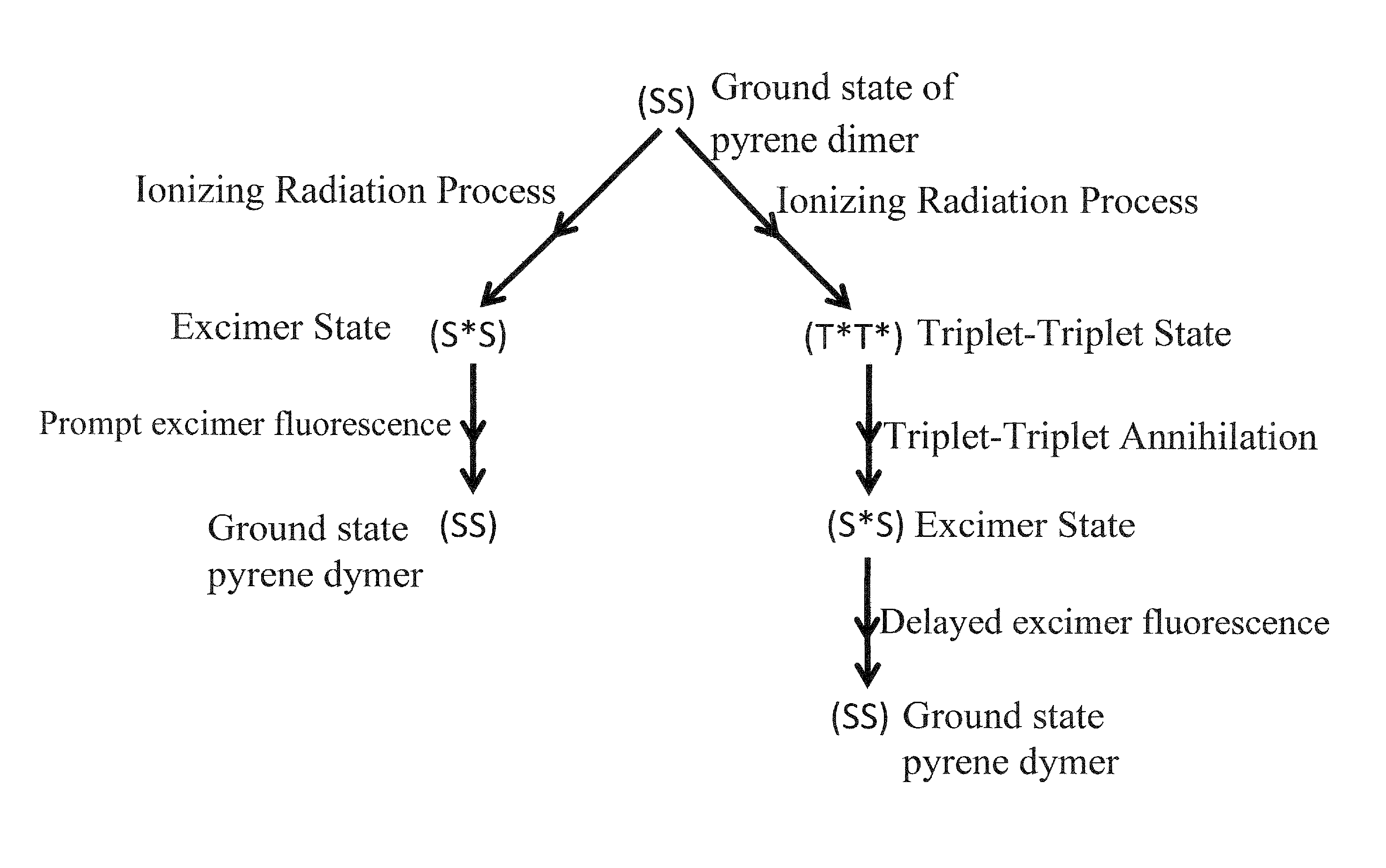

Materials, method, and apparatus for detecting neutrons and ionizing radiation

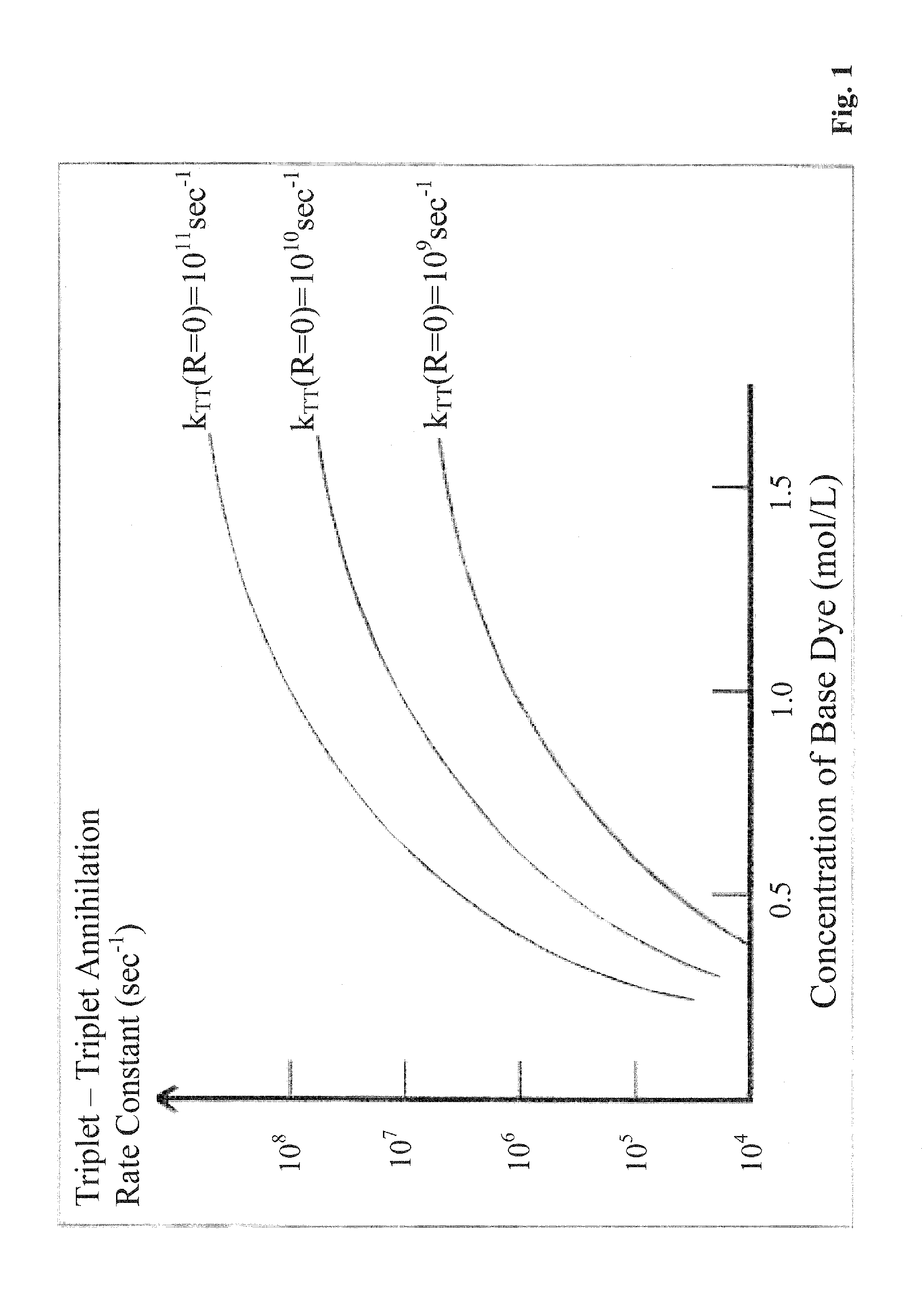

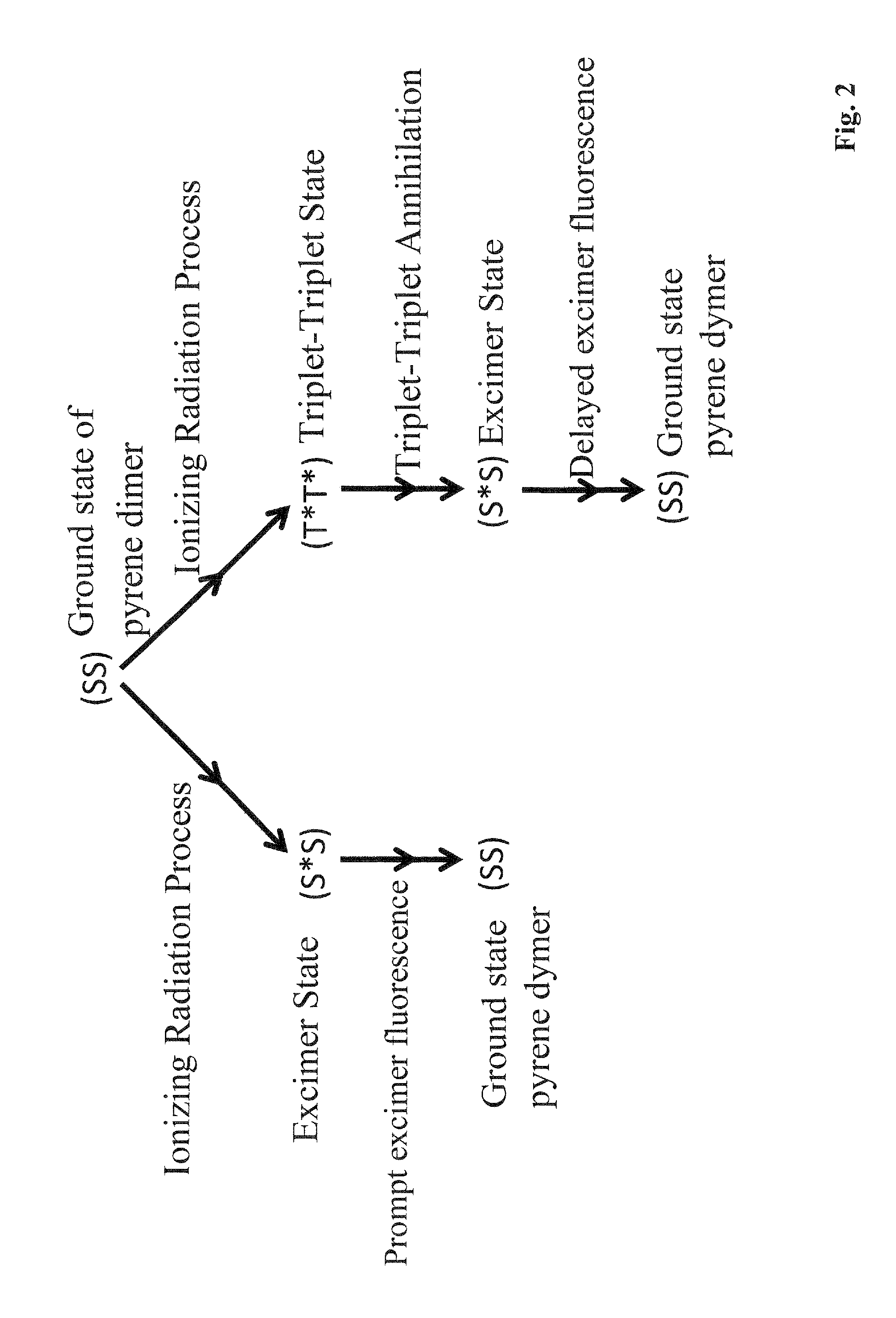

InactiveUS20120241630A1Improve solubilityImprove radiation resistanceMeasurement with scintillation detectorsMaterial analysis by optical meansCalorescenceDiffusion

Embodiments of the invention provide a scintillator material, a scintillator system, and / or a method of detecting incident radiation using a scintillator material, or scintillator system, comprising a polymer material that comprises chromophores. Additional embodiments provide a scintillator material, scintillator system, and / or a method of detecting incident radiation using a scintillator material, or scintillator system, comprising a polymer material having one, two, three, or more, organic dyes dissolved therein wherein the polymer material having the one, two, three, or more dyes dissolved therein comprises chromophores. At least one of the dyes, termed the base dye, has a concentration in the range 0.5 to 3.5 mol / L. In a specific embodiment, the base dye has a concentration in the range 1.0 to 3.0 mol / L. This base dye concentration is high enough to achieve a substantial triplet-triplet state annihilation rate despite the negligible diffusion of the dye in the rigid polymer matrix.

Owner:NANOPTICS

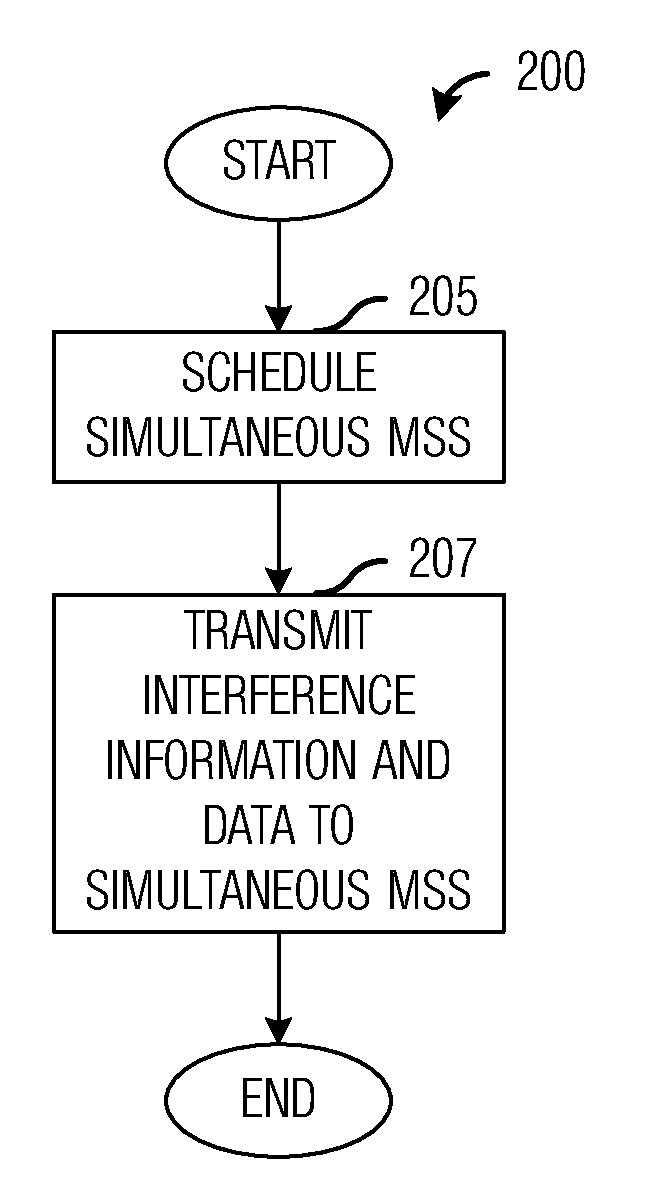

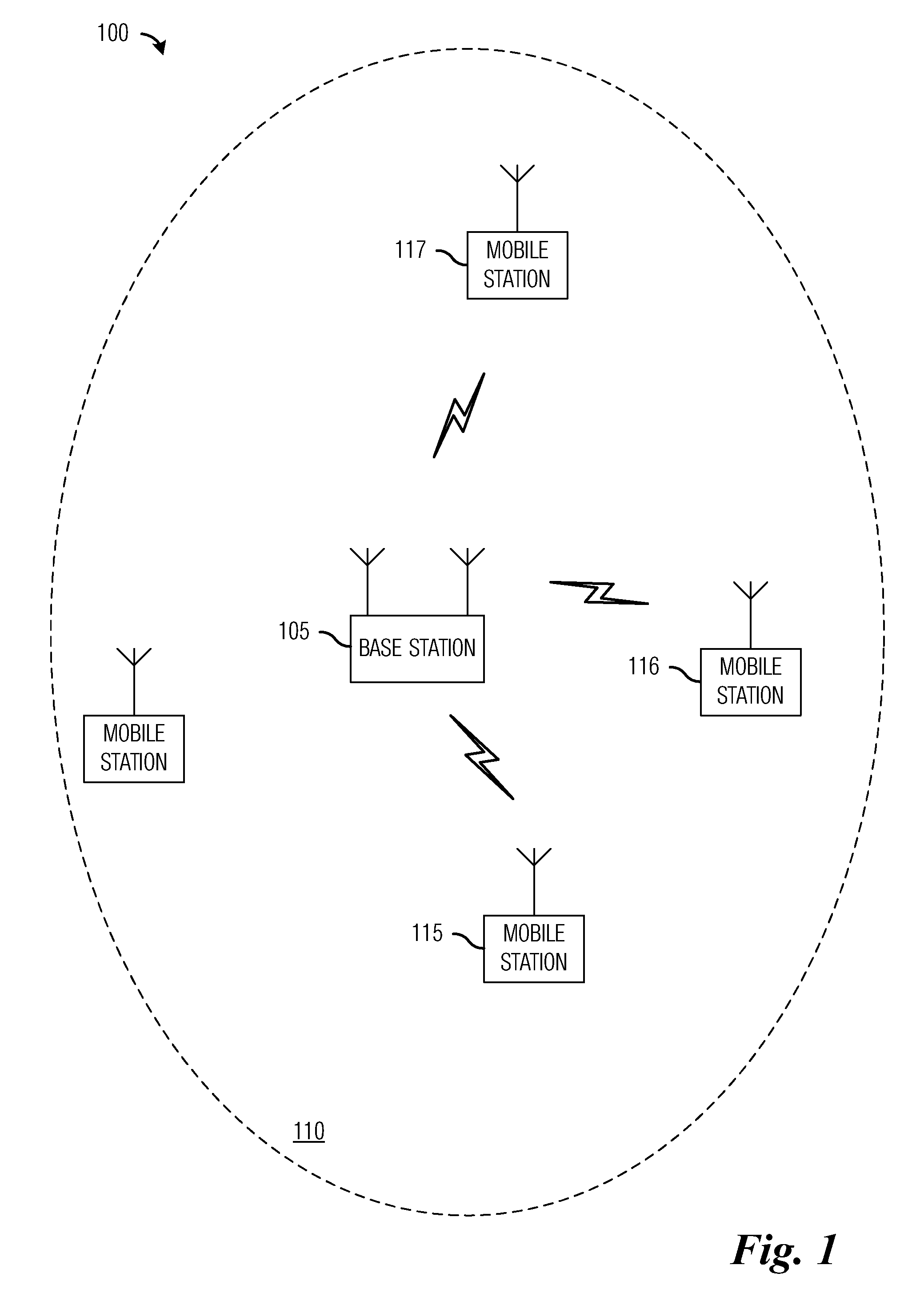

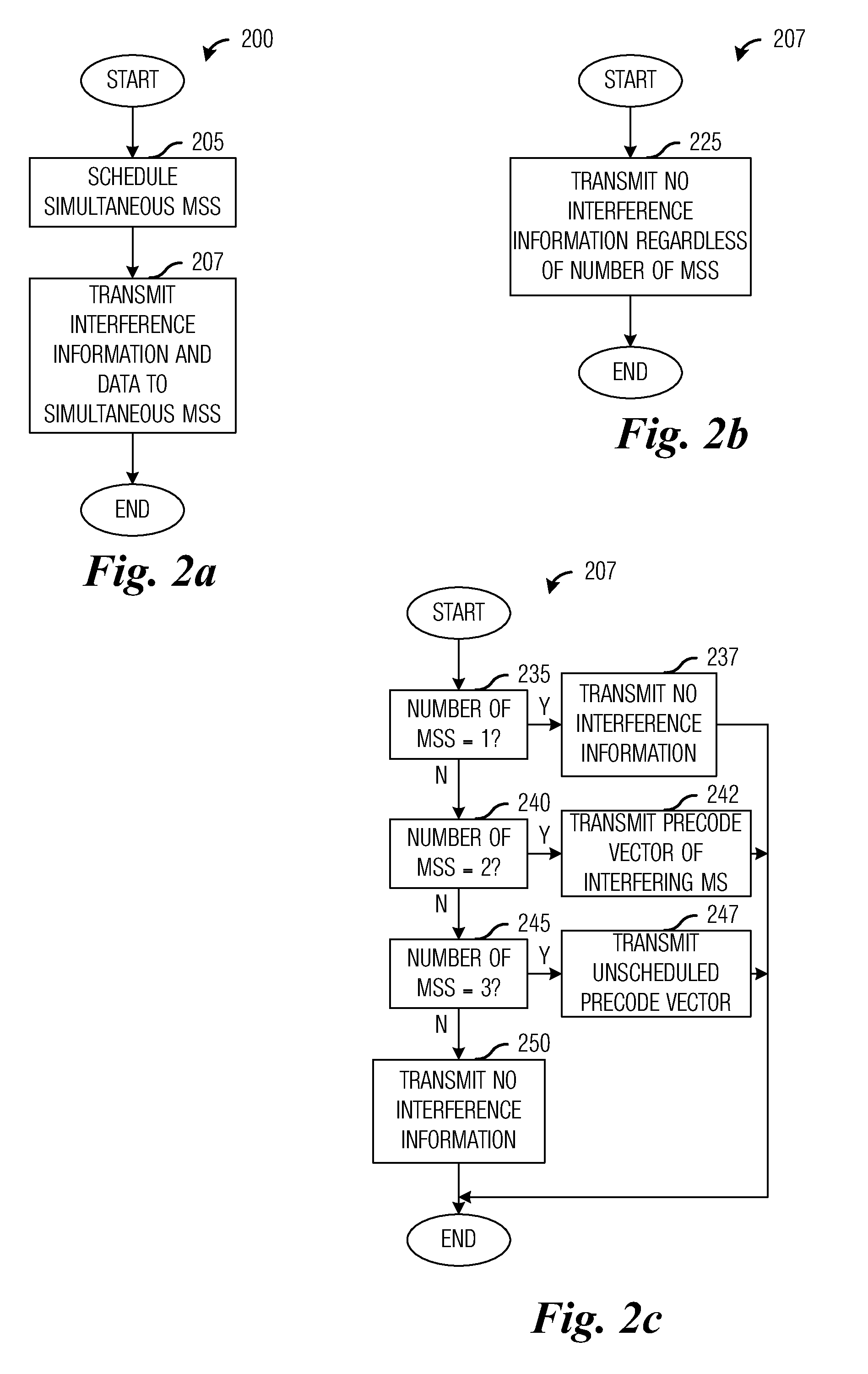

System and method for downlink control signal structure for multi-user MIMO

ActiveUS8194602B2Reduce overheadConstant controlNetwork traffic/resource managementAssess restrictionControl signalMobile station

A system and method for downlink control signal structure for multi-user MIMO is provided. A method comprises selecting a set of mobile stations (MSs) to receive substantially simultaneously transmitted transmissions, and transmitting interference control information and data to each mobile station (MS) in the set of MSs. A number of MSs in the set of MSs is less than a maximum allowable number of simultaneously scheduled MSs, and an amount of interference control information and a type of interference control information transmitted is based on the number of MSs in the set of MSs and the maximum allowable number of simultaneously scheduled MSs.

Owner:FUTUREWEI TECH INC

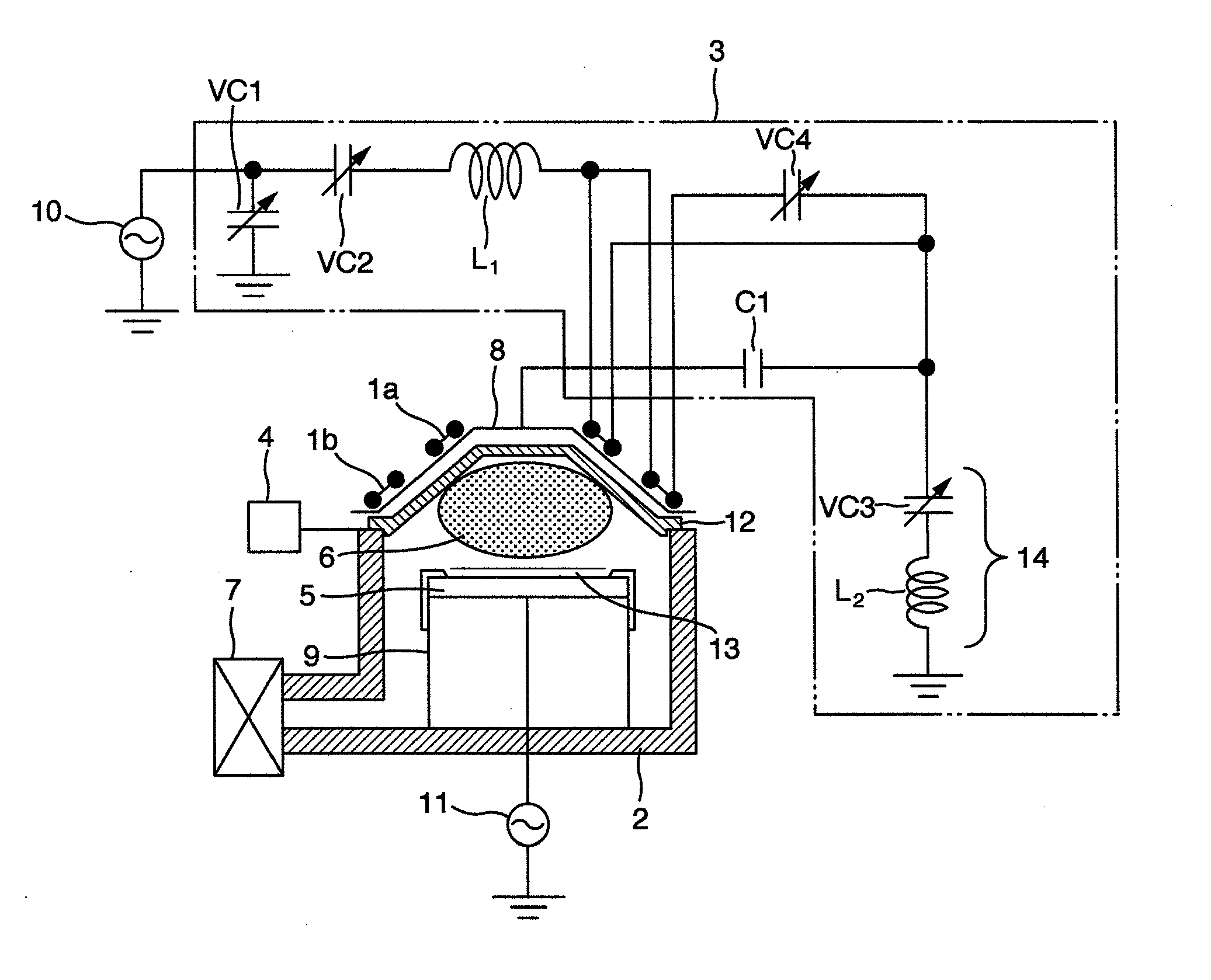

Plasma processing apparatus

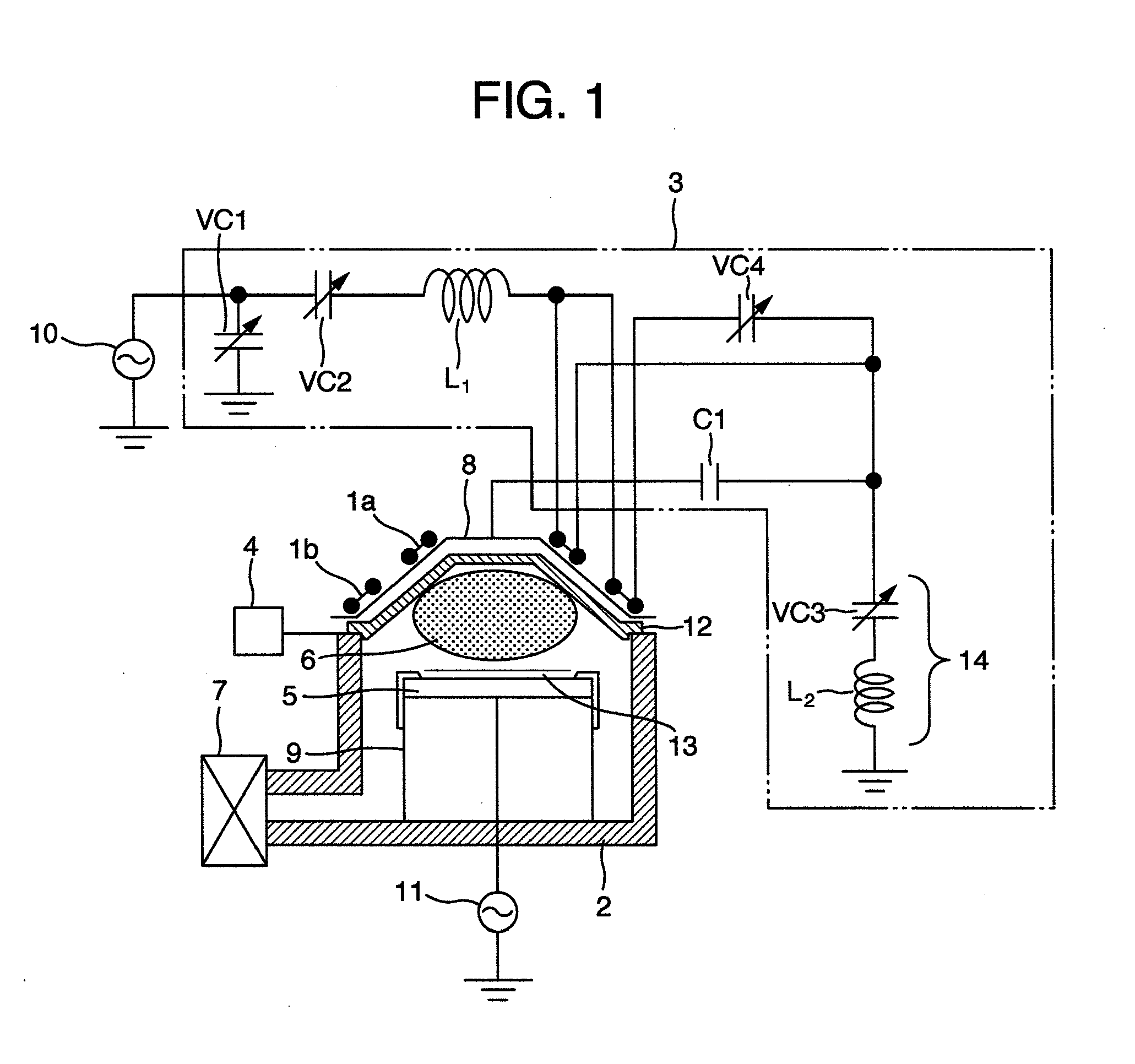

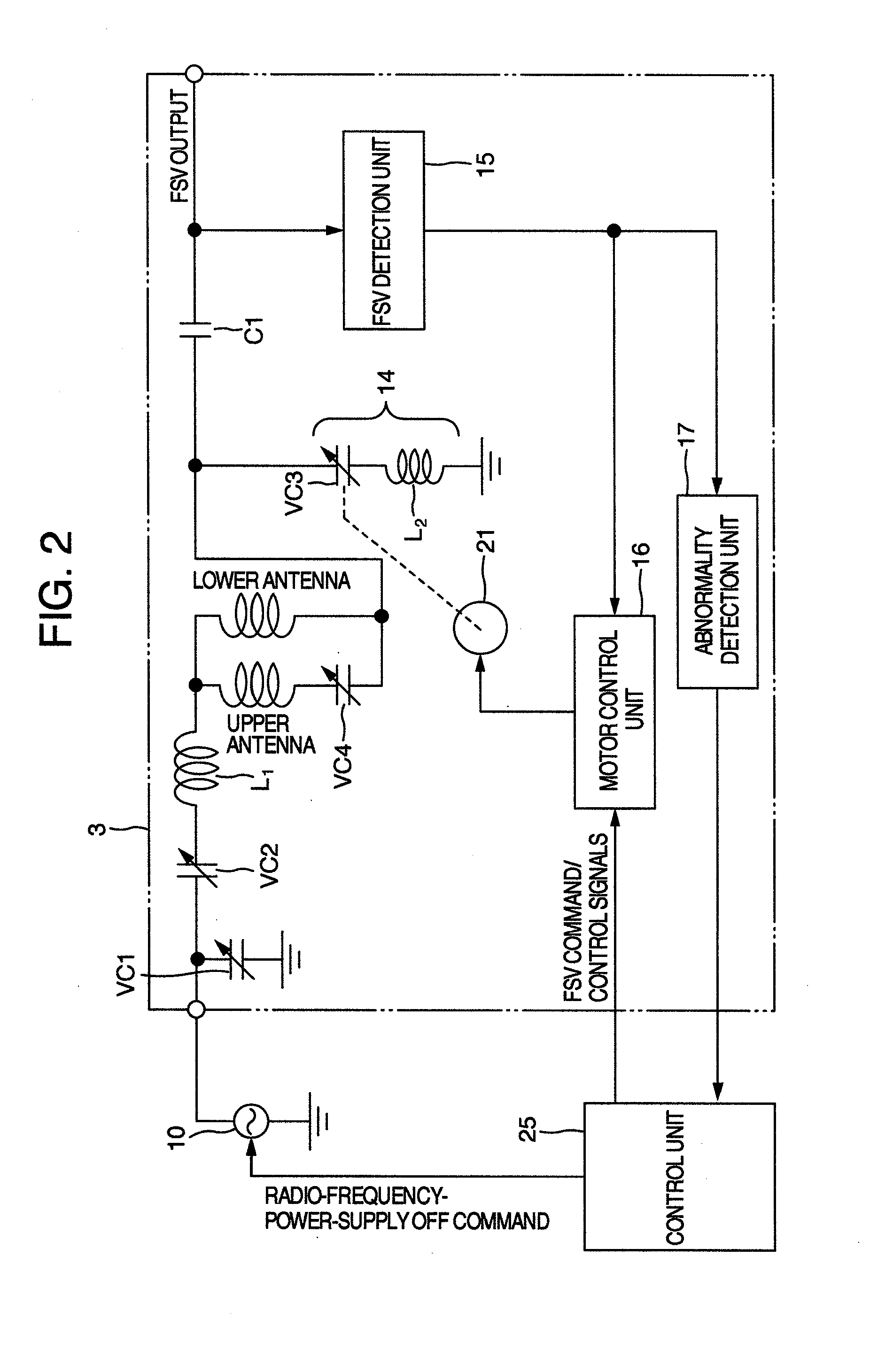

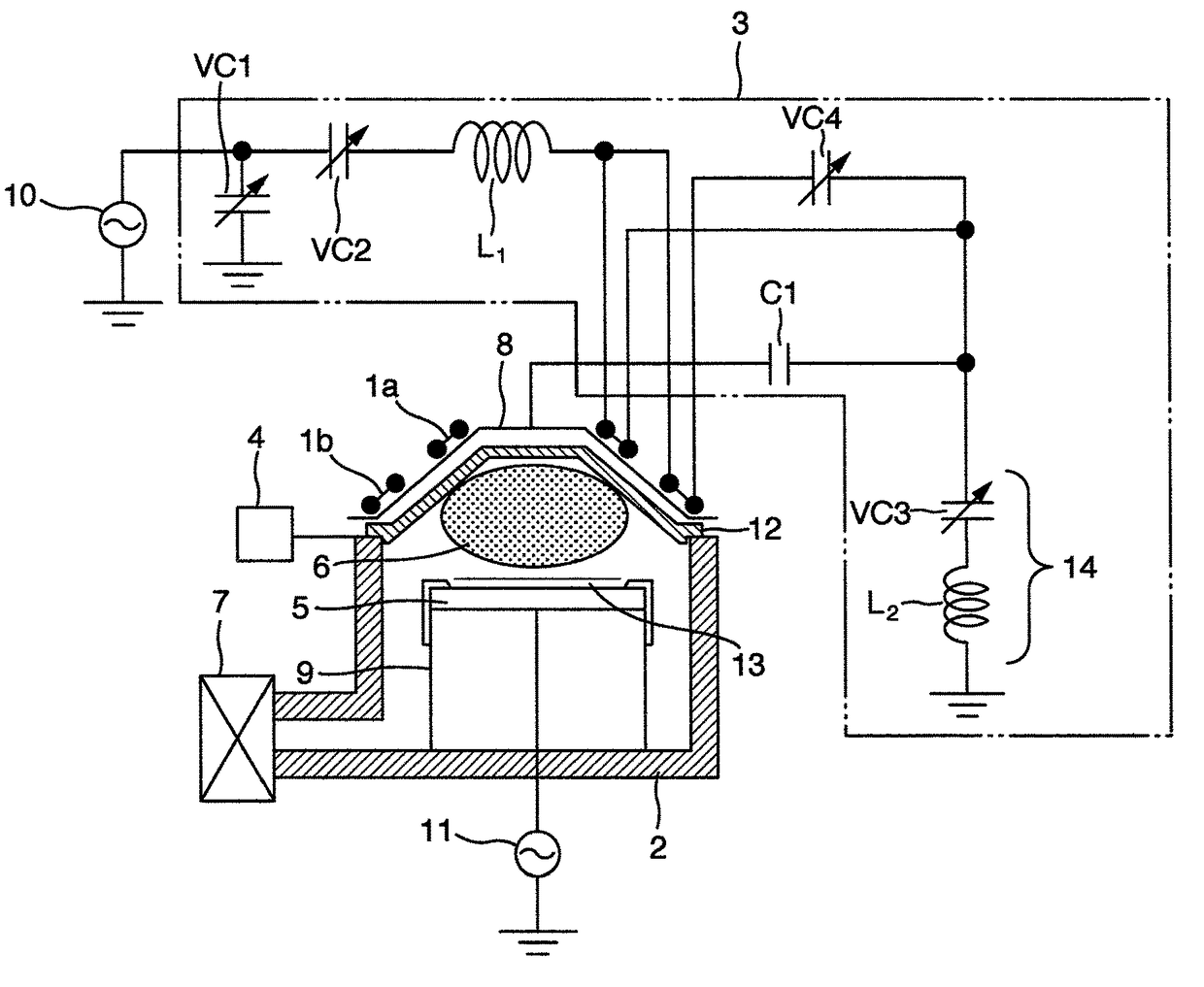

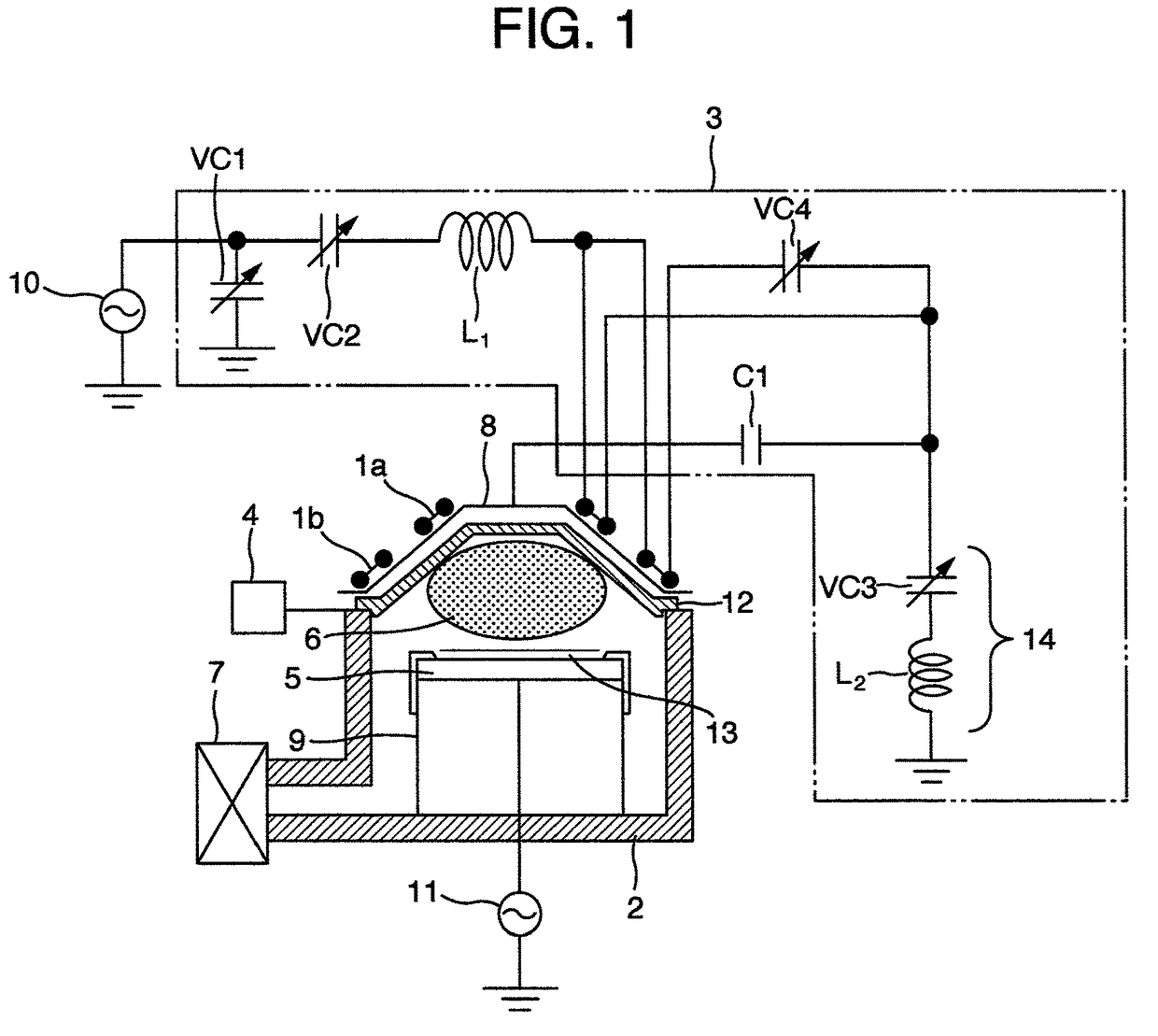

ActiveUS20120145322A1Improve accuracyConstant controlElectric discharge tubesSemiconductor/solid-state device manufacturingRadio frequencyInductor

In the present invention, there is provided a plasma processing apparatus including a vacuum processing chamber for applying a plasma processing to a sample, a sample stage deployed inside the vacuum processing chamber for mounting the sample thereon, induction antennas provided outside the vacuum processing chamber, a radio-frequency power supply for supplying a radio-frequency power to the induction antennas, and a Faraday shield which is capacitively coupled with the plasma, a radio-frequency voltage being applied to the Faraday shield from the radio-frequency power supply via a matching box, wherein the matching box includes a series LC circuit including a variable capacitor and an inductor, a motor control unit for controlling a motor for the variable capacitor, and a radio-frequency voltage detection unit for detecting the radio-frequency voltage applied to the Faraday shield, the matching box executing a feedback control over the radio-frequency voltage applied to the Faraday shield.

Owner:HITACHI HIGH-TECH CORP

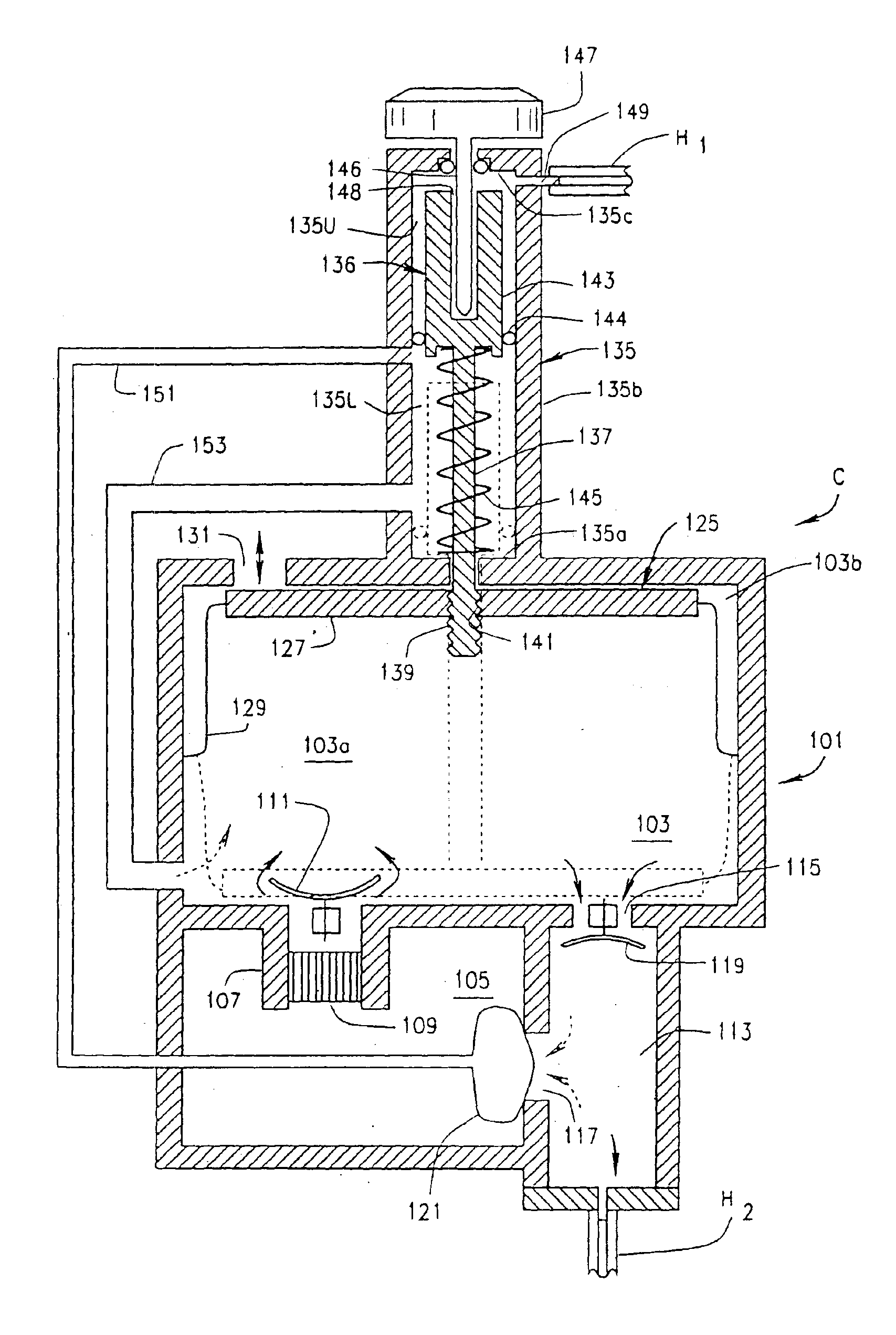

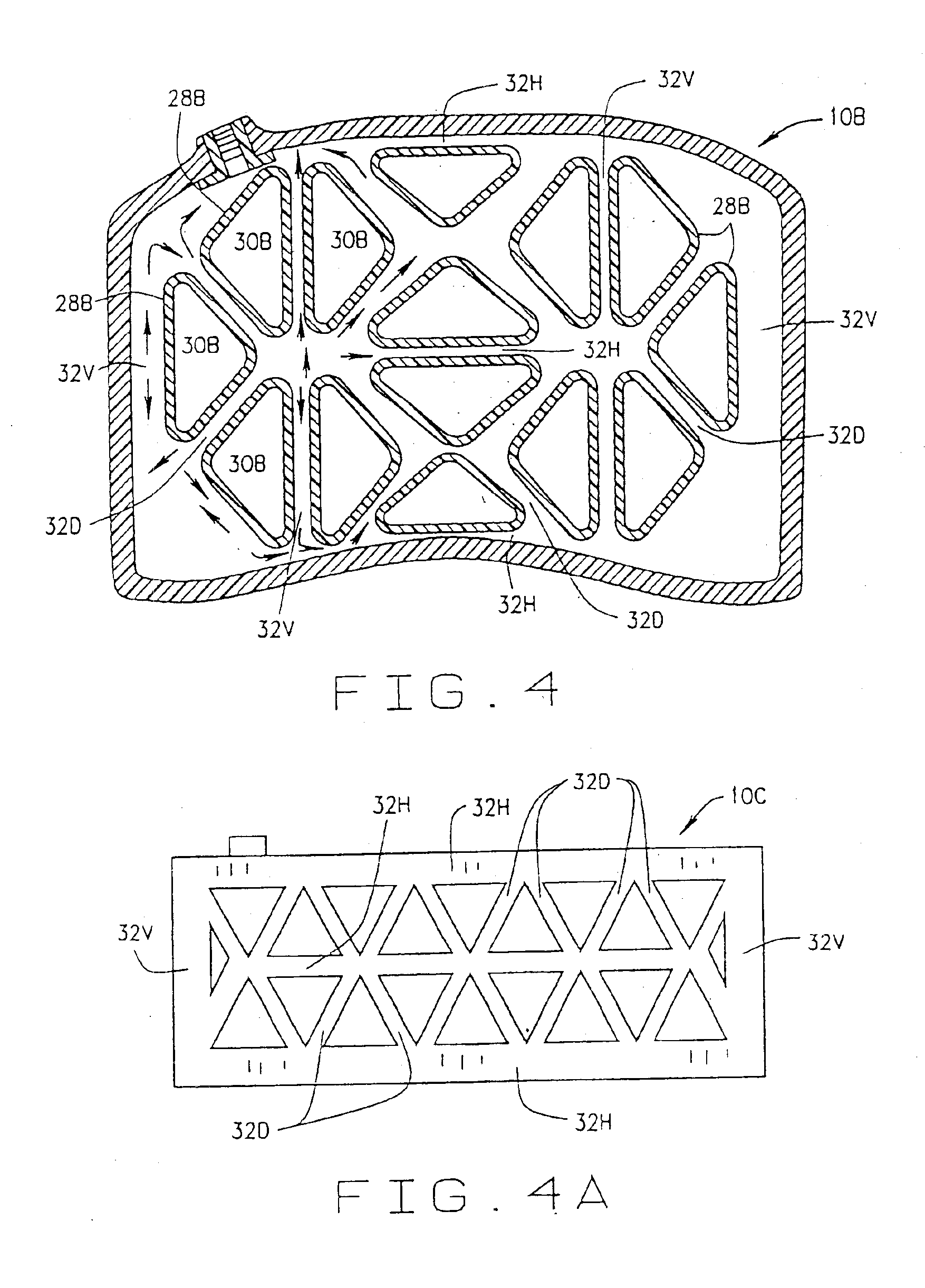

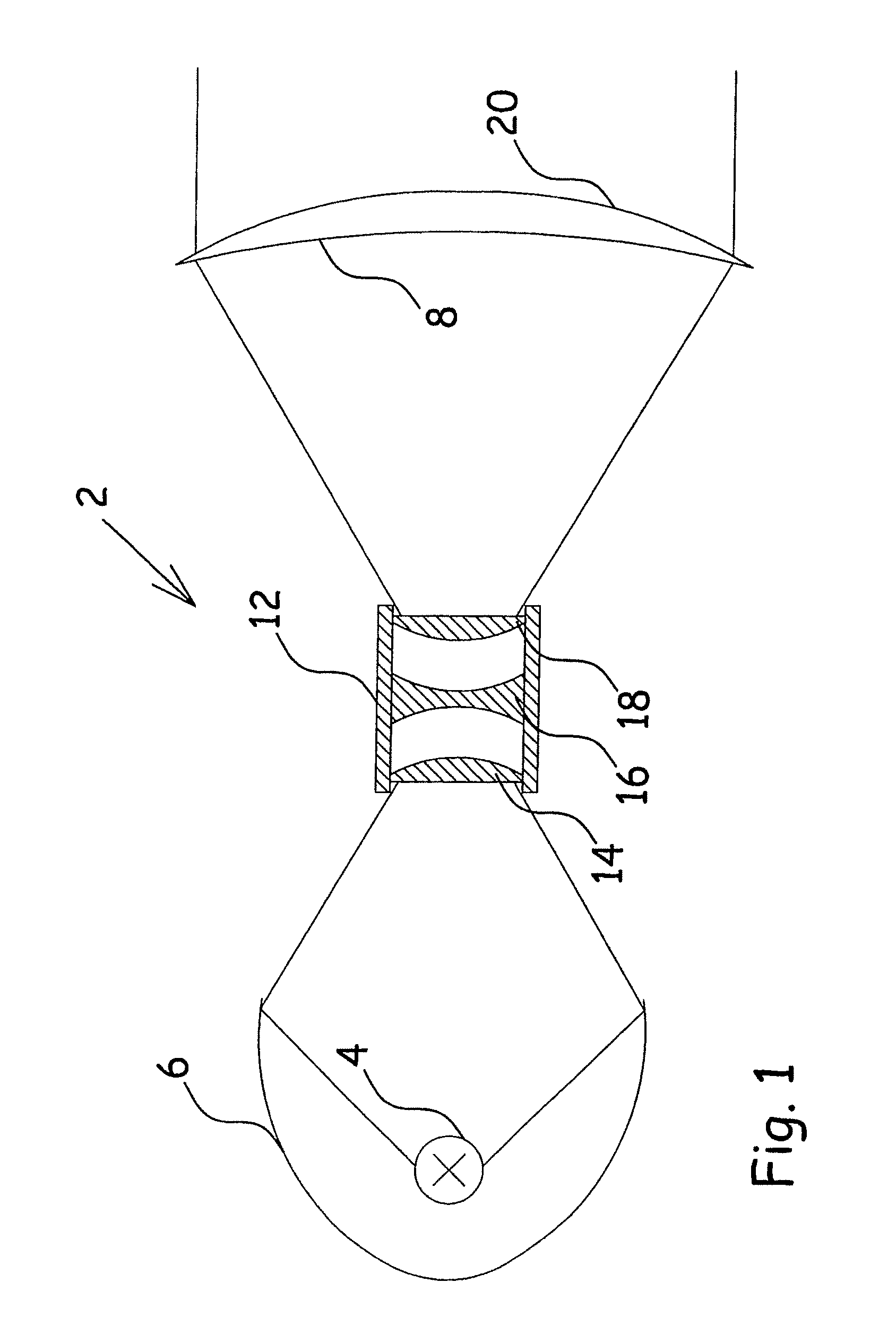

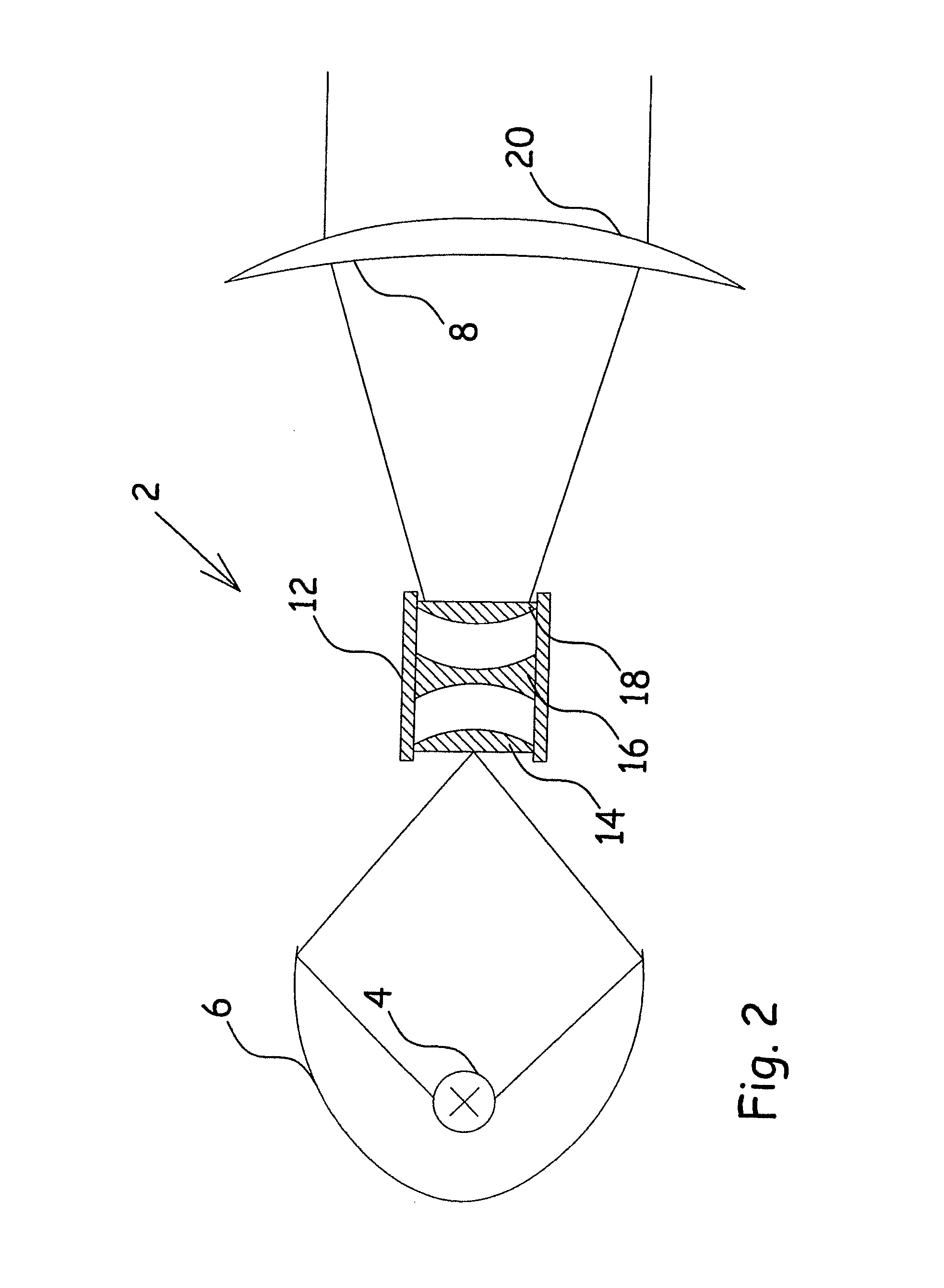

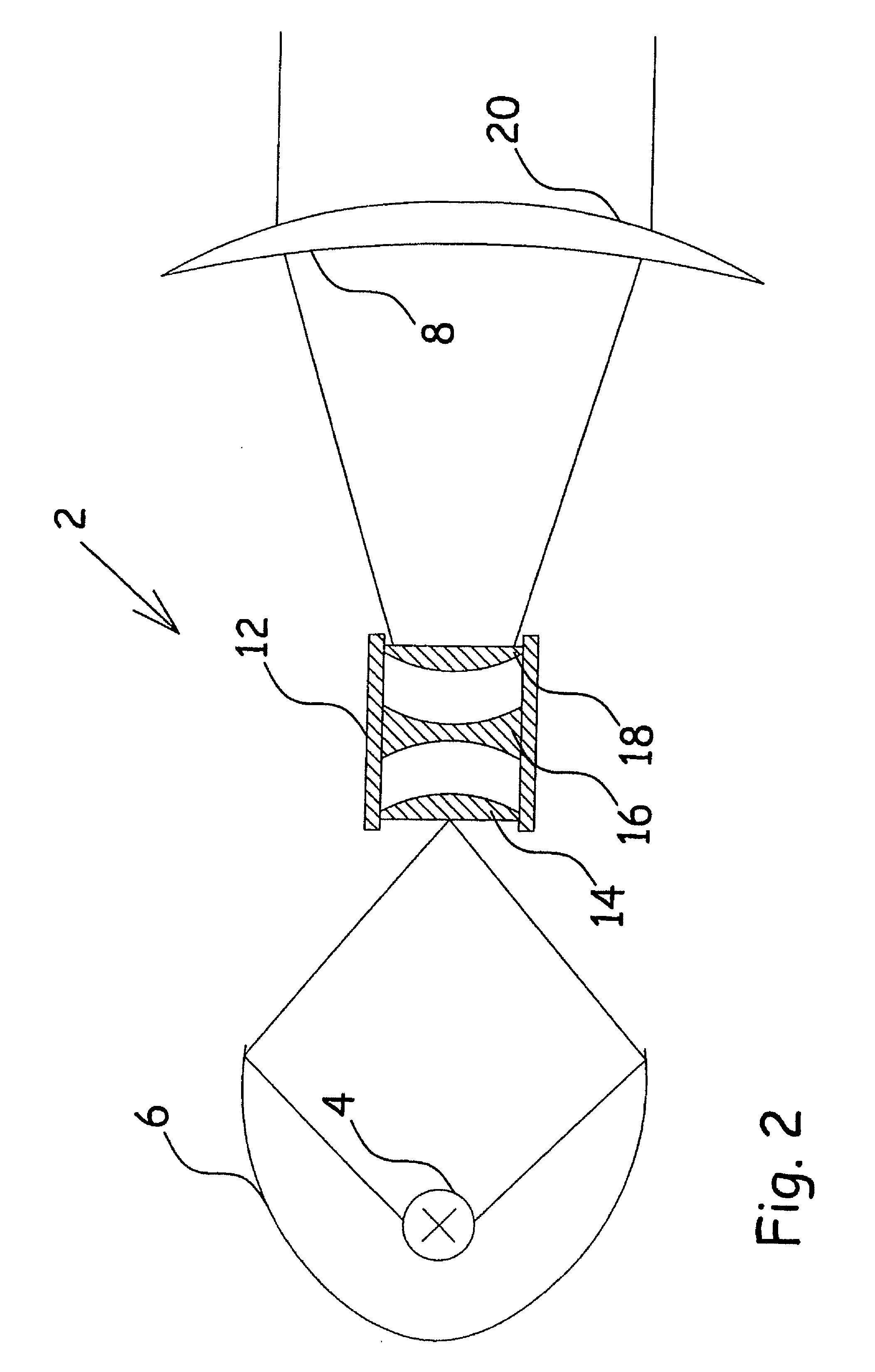

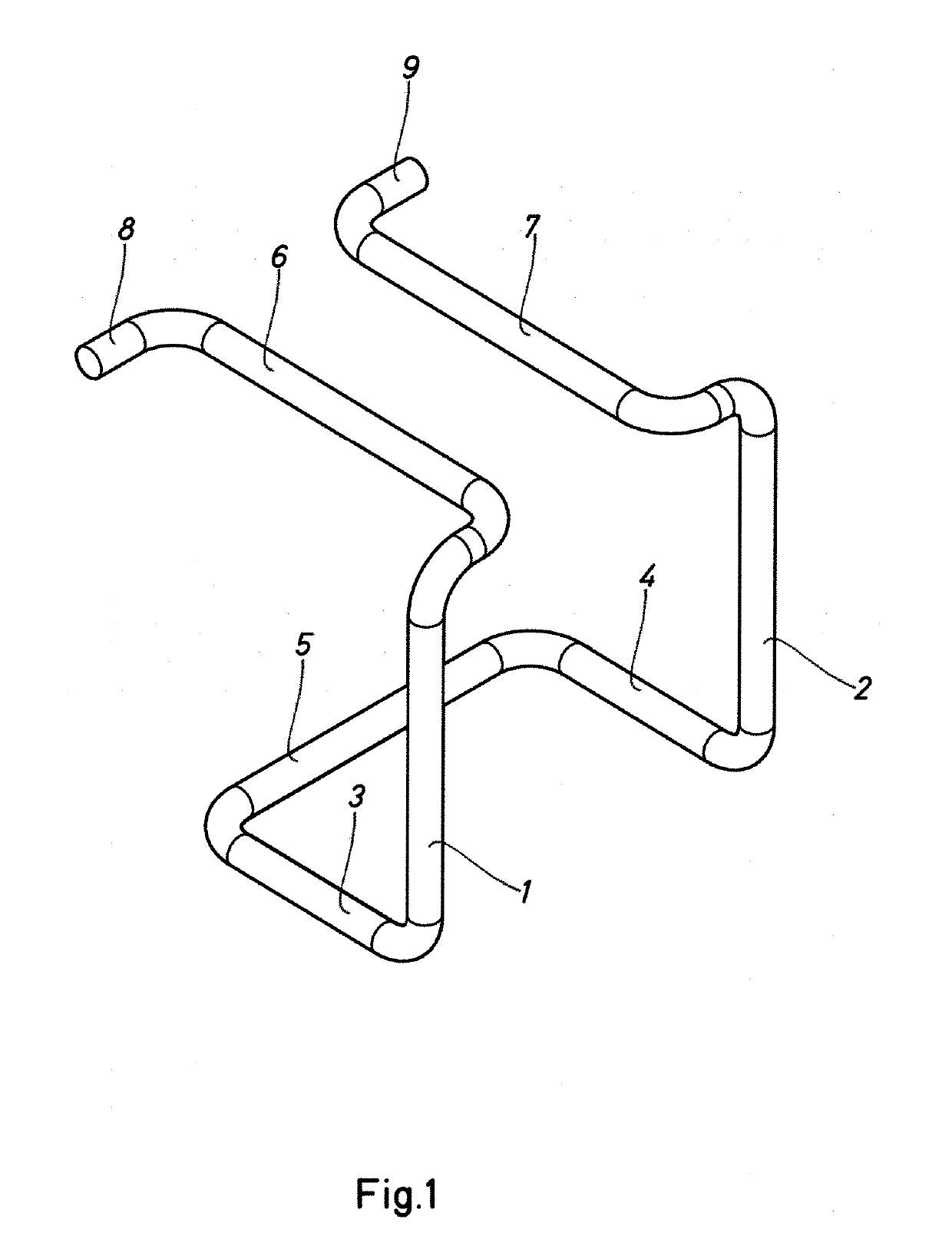

Conserver for pressurized gas tank

InactiveUS6866042B2Assures geometrical integrityAmplify tensileBreathing masksGas handling applicationsFiberProduct gas

A pressurized gas supply system includes a pressurized container which expands and contracts. The container includes a one-piece liner molded from a polymer which is reinforced by a high tensile fiber such as KEVLAR®. A valve is molded into the liner, and a regulator is connected to the valve. A hose, having a conserver positioned therealong, extends between the regulator and a fitting allowing a user to inhale gas from the container. The container is carried in a carrying bag, which can be in the form of a carrying case, a purse, or a back-pack.

Owner:IZUCHUKWU JOHN I

Surround sound system

ActiveUS9319794B2Constant controlSpeech analysisLoudspeaker spatial/constructional arrangementsAcoustic transfer functionVocal tract

A surround sound system for reproducing a spatial sound field in a sound control region within a room having at least one sound reflective surface. The system uses multiple steerable loudspeakers located about the sound control region, each loudspeaker having a plurality of different individual directional response channels being controlled by respective speaker input signals to generate sound waves emanating from the loudspeaker with a desired overall directional response. A control unit connected drives each of the loudspeakers and has pre-configured filters based on measured acoustic transfer functions for the room for filtering the input spatial audio signals to generate the speaker input signals for all the loudspeakers to generate sound waves with coordinated overall directional responses that combine together at the sound control region in the form of either direct sound or reflected sound from the reflective surface(s) of the room to reproduce the spatial sound field.

Owner:CALLAGHAN INNOVATION

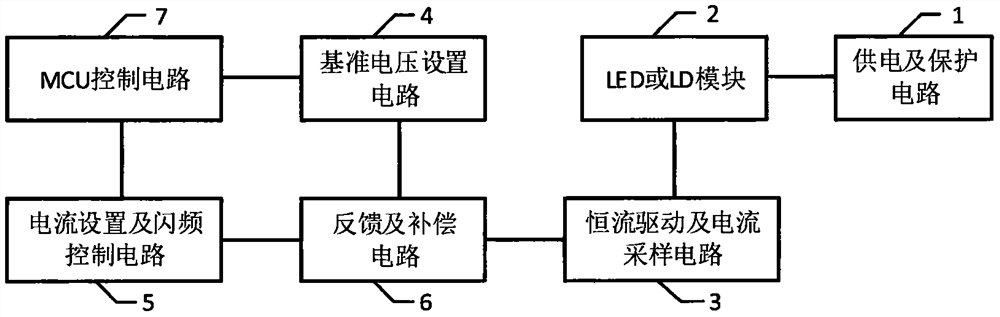

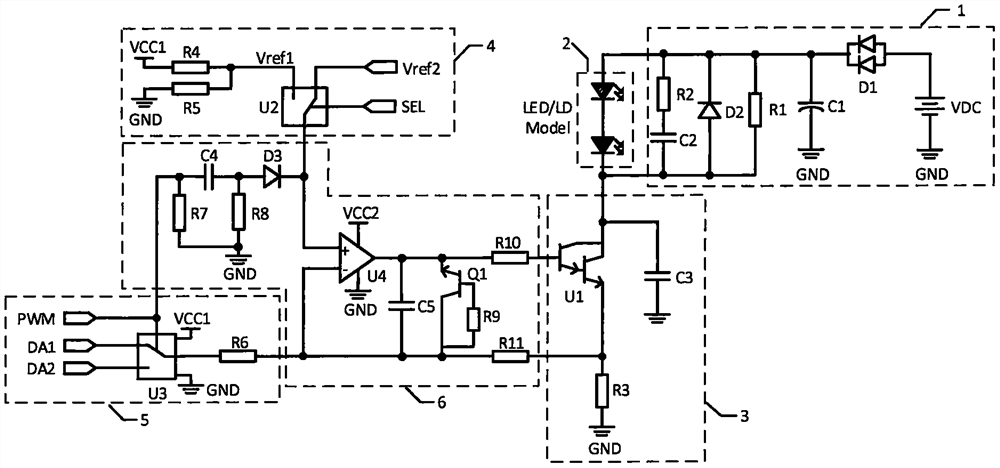

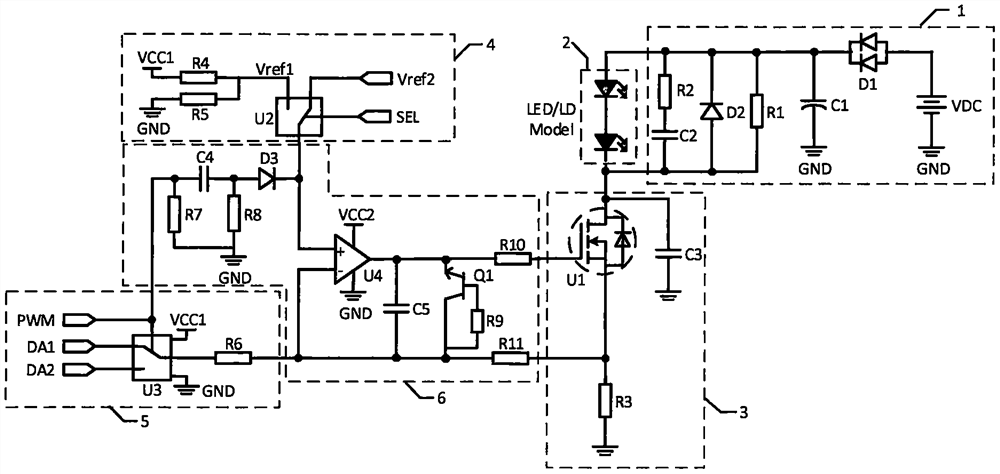

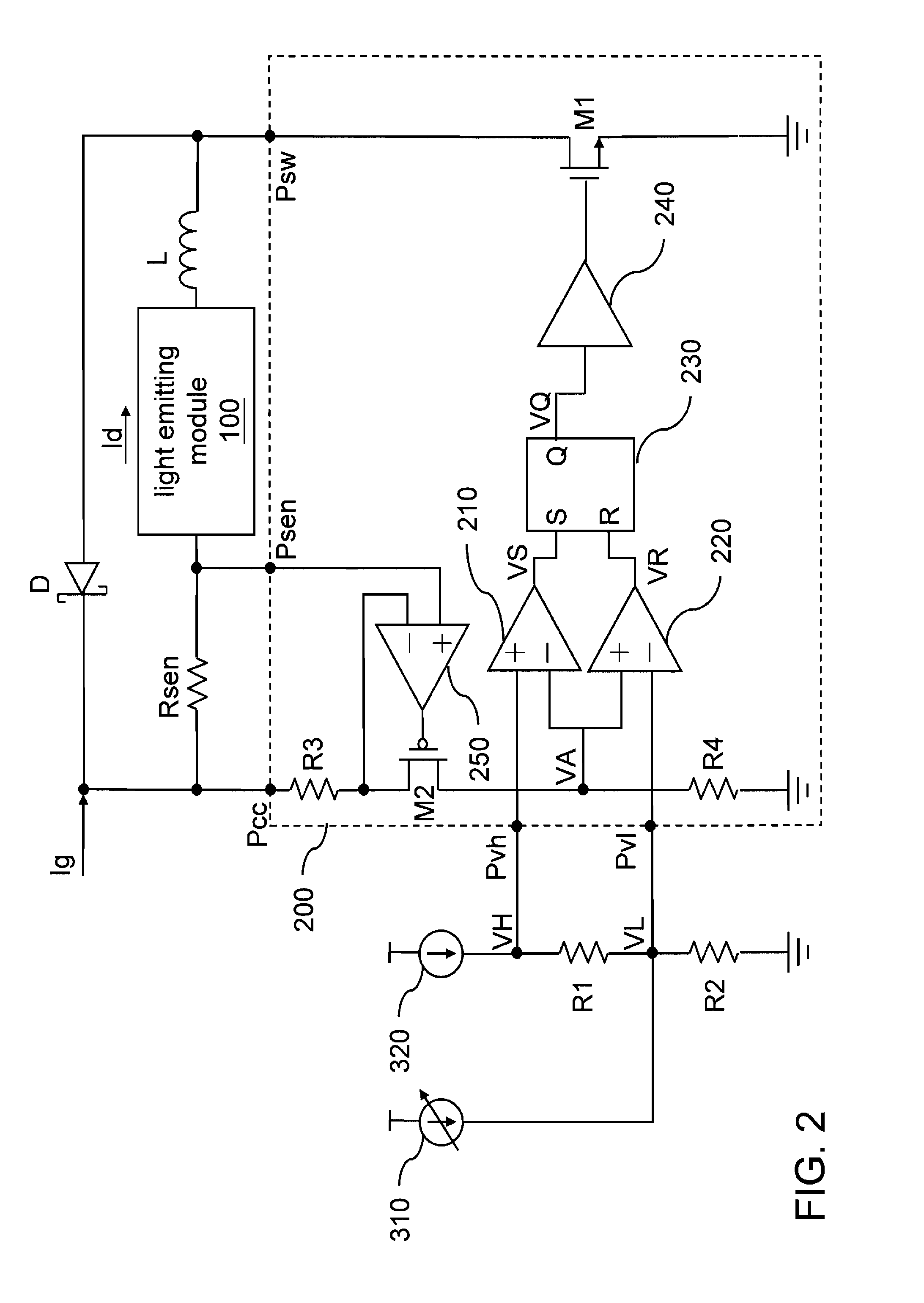

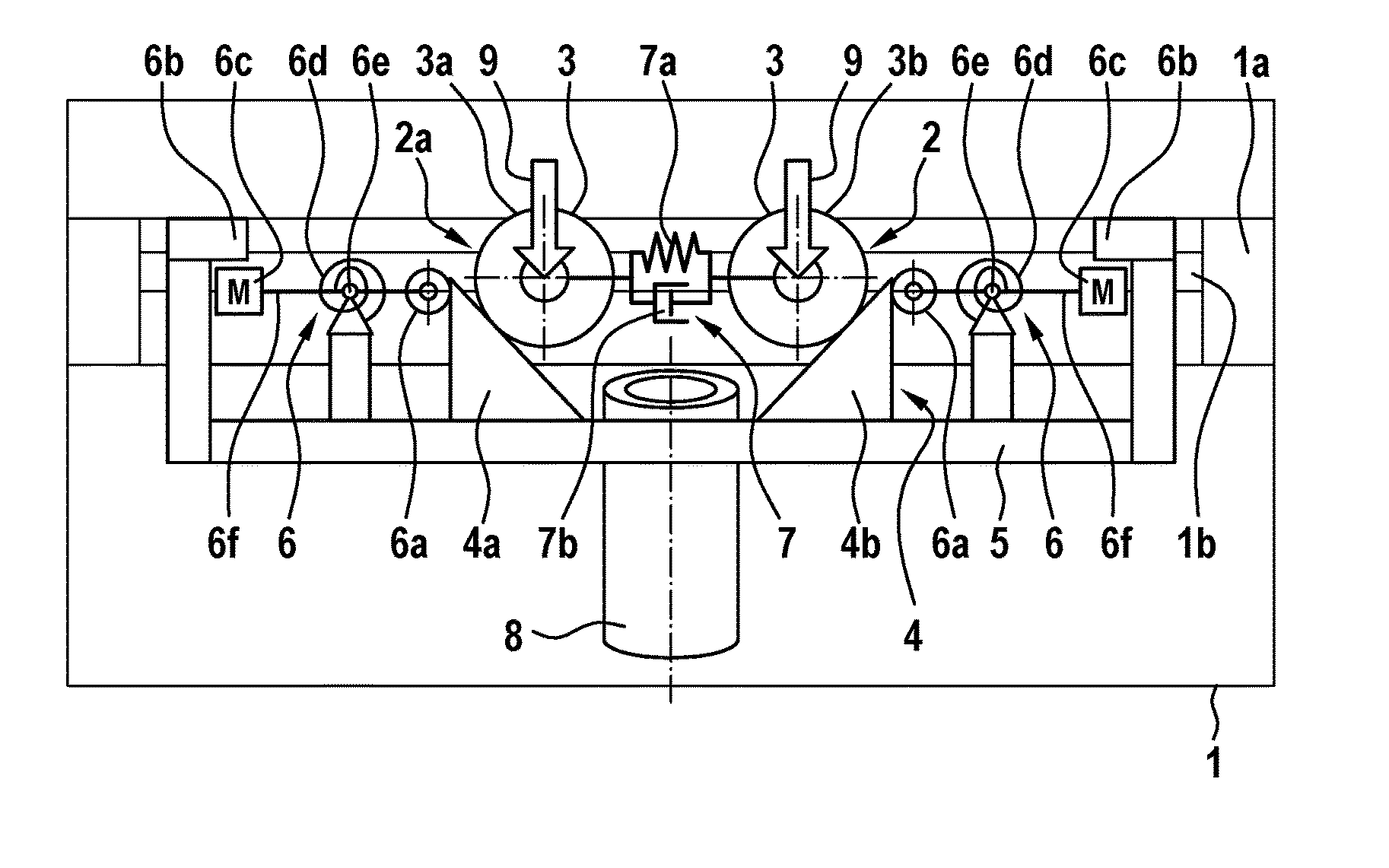

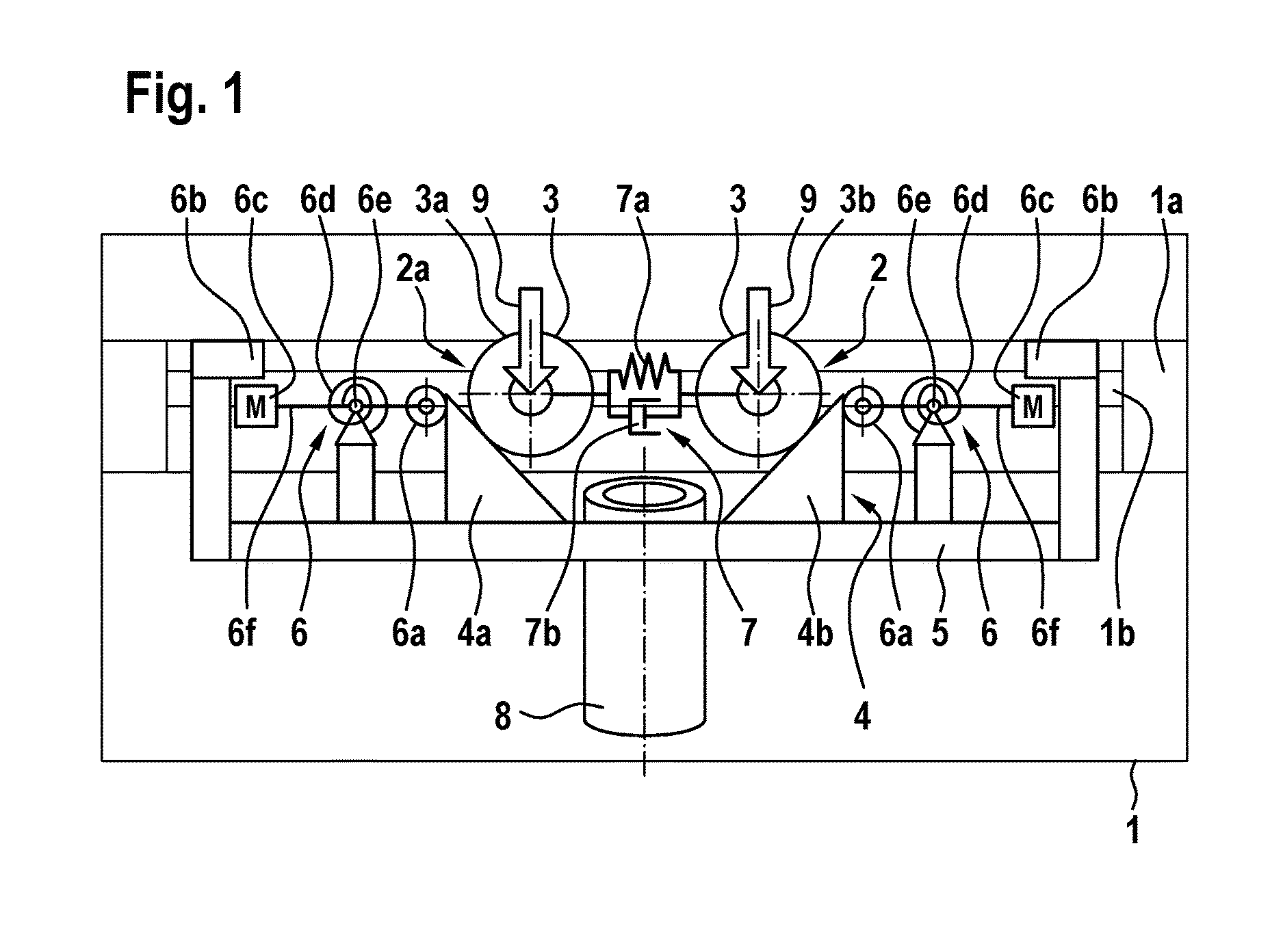

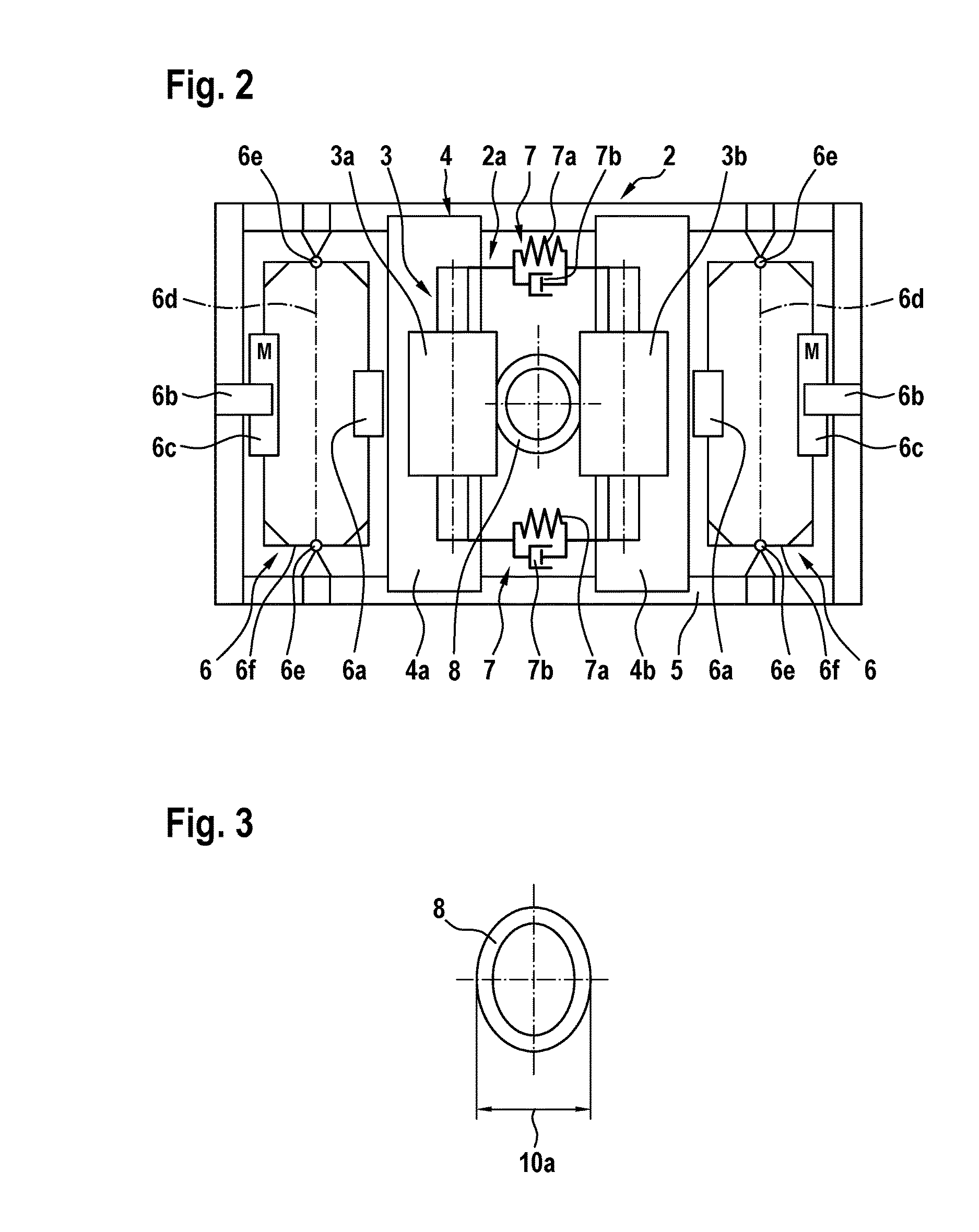

Current-adjustable and PWM flicker controlled constant-current driving circuit and control method

ActiveCN111629490AAccurate outputConstant controlElectrical apparatusSemiconductor lamp usageHemt circuitsControl theory

The invention relates to a current-adjustable and PWM flicker control constant-current driving circuit, which comprises a power supply and protection circuit (1), an LED or LD module (2), an MCU control circuit (7), a constant-current driving and current sampling circuit (3), a reference voltage setting circuit (4), a current setting and flicker control circuit (5) and a feedback and compensationcircuit (6). The constant-current driving and current sampling circuit is used for realizing adjustment of current output. The reference voltage setting circuit is used for setting reference voltageof the output current. The current setting and flicker control circuit is used for setting a pulse or a constant current value and setting frequency and pulse width. The feedback and compensation circuit realizes current feedback and dynamic compensation of the system, achieves the purpose of stabilizing current output, and has the effects of improving the rising speed of output current and widening the width of the output current. According to the invention, the constant current or pulse current of the LED or LD module can be adjusted, PWM adjustment and flicker control of the pulse current can be carried out, and the requirement of constant current driving in an LED light source and an LD laser system in a machine vision system can be met.

Owner:CASI VISION TECH (LUOYANG) CO LTD

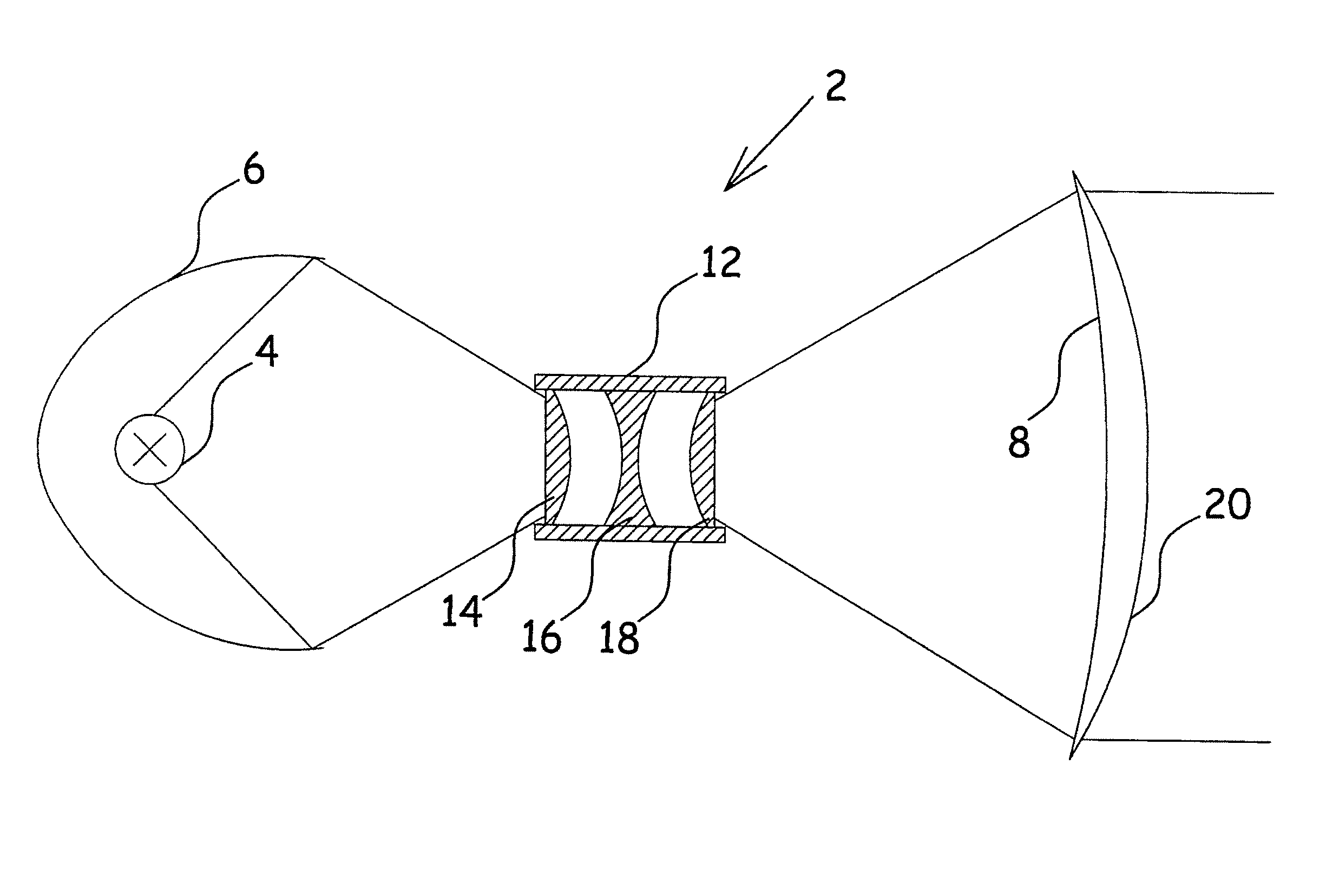

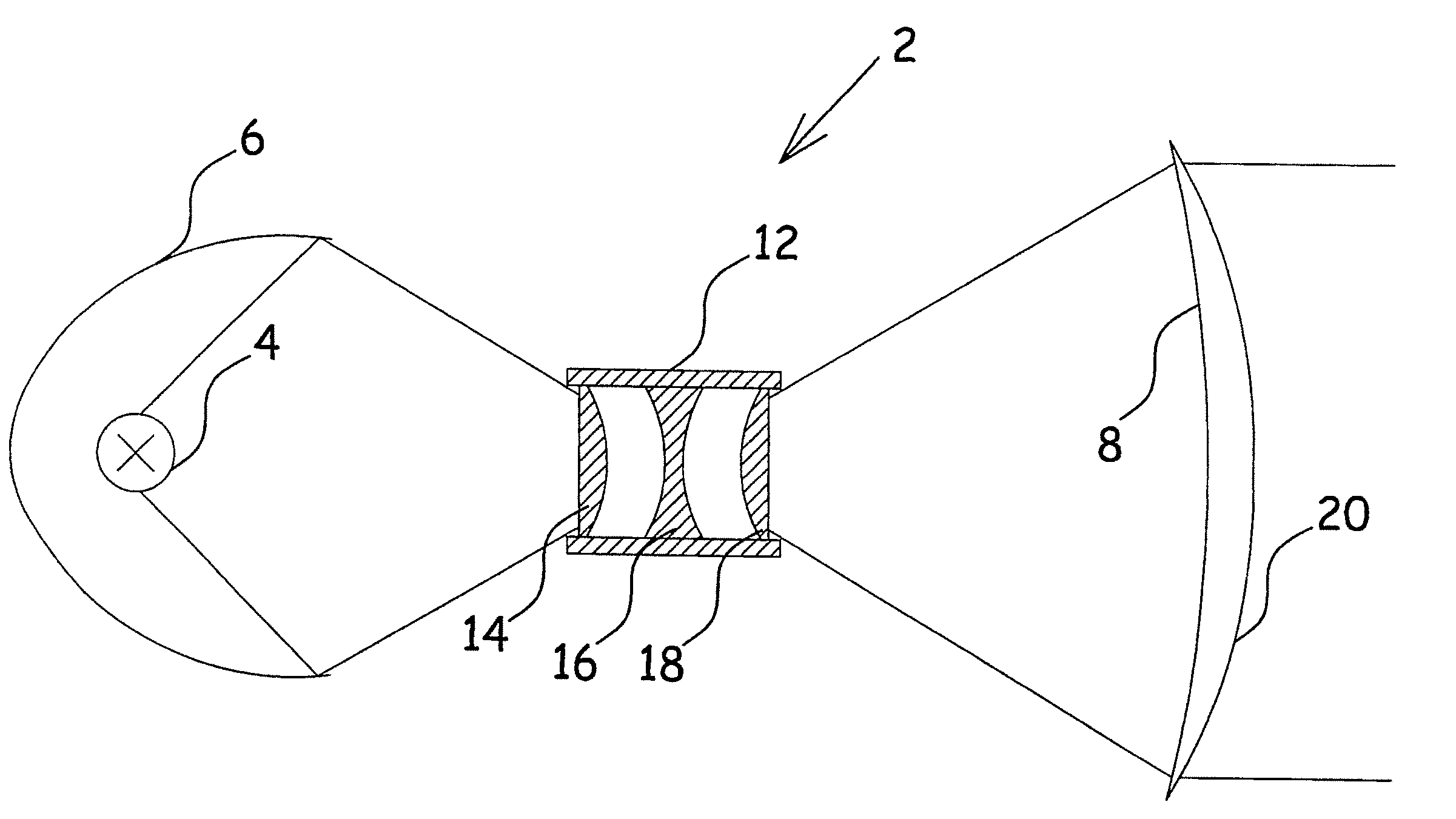

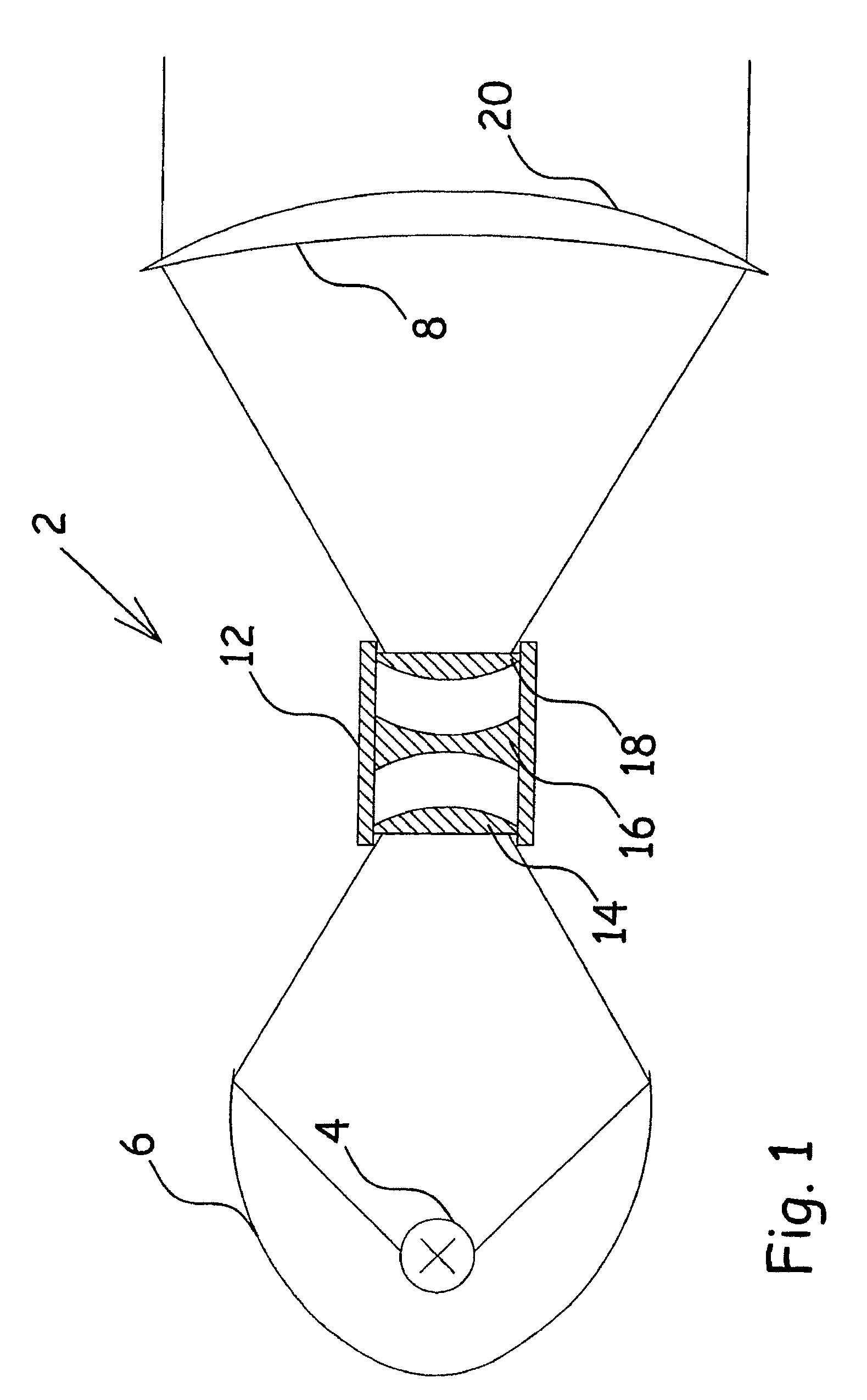

Light Assemblies

ActiveUS20080158884A1Economical to useReduce weightLighting applicationsMechanical apparatusLight beamOptoelectronics

The present invention relates to a method for forming a light beam, and to a light assembly comprising at least one light source placed in conjunction with a fixed reflector, which reflector forms a beam of light into light forming means, which light assembly comprises a front lens, where the light forming means at least comprise a light deflecting means for changing the light angle of the light beam after passing through the front lens. The object of the invention is to achieve a light assembly, where major optical components are mechanically fixed in relation to a housing for achieving a light assembly, the mass centre of which changes only slightly during operation. A further object is to achieve a closed light assembly having openings in the case only for cooling. This can be achieved, if the front lens has a central part that differs from the surrounding parts of the front lens, and where the light deflecting means in a first position concentrates the light beam into the central part of the front lens to generate a wide-angle light beam, and where the light deflecting means in a second position distributes the light beam over the entire front lens to generate a narrow-angle light beam, and where the light deflecting means is connected with a first actuator, and where the light deflecting means is movable between the first and the second position. A very efficient wash light zoom system can hereby be achieved, where the front lens has different characteristics between its centre portions and the rest of the surrounding part of the front lens. Because of the internal light deflecting means, the front lens does not have to be movable with respect to the housing. Furthermore, the reflector and the lamp are held in a fixed position. This may result in constant control of the air flowing around the optical components.

Owner:MARTIN PROFESSIONAL

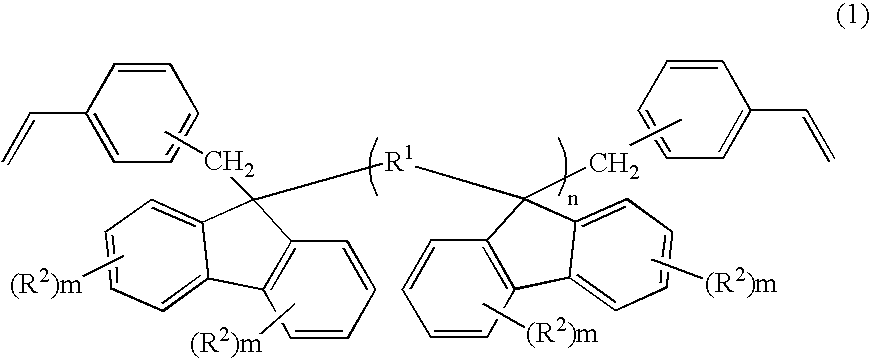

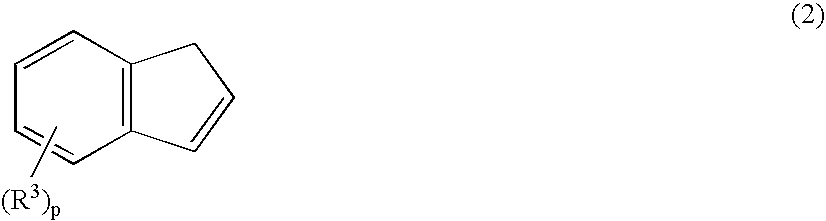

Curable resin composition

InactiveUS20080004367A1Easily disperse dielectric powderConstant controlSynthetic resin layered productsSolid-state devicesElastomerDielectric

The problem of the present invention is to provide a curable resin composition having a low dielectric tangent and affording a cured product superior in the adhesion strength to a conductor. According to the present invention, a curable resin composition comprising curable polyvinylbenzyl compound (A), and modified styrene elastomer (B) having one or more kinds of not less than one functional group selected from the group consisting of a hydroxyl group, a carboxyl group, an amino group and an acid anhydride group is provided. In this composition, dielectric powder (C) is easily dispersed, and a composition containing powder (C) can afford a cured product having a high dielectric constant. By curing the composition of the present invention, an insulating layer preferable for electrical circuits can be provided.

Owner:AJINOMOTO CO INC

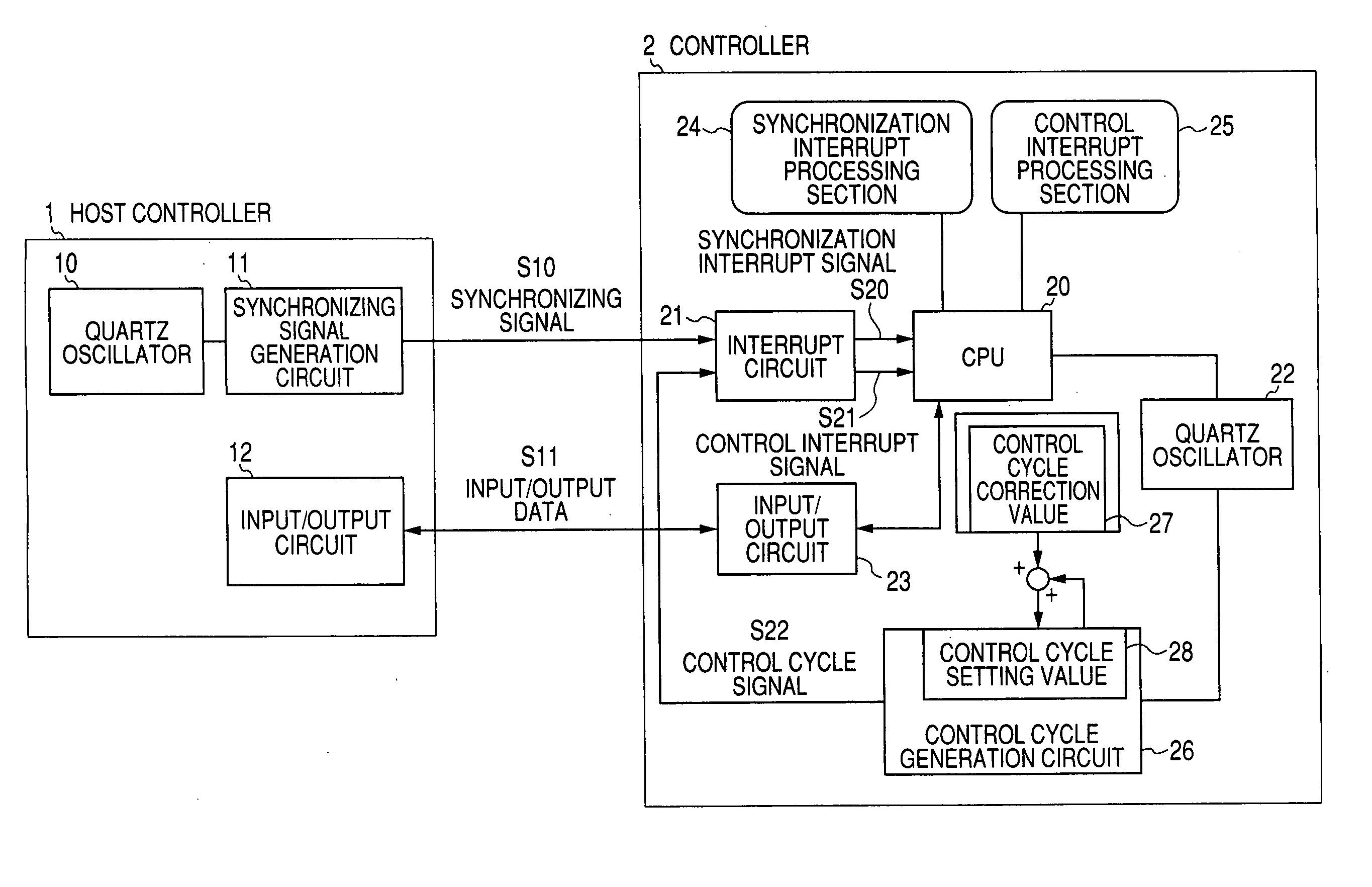

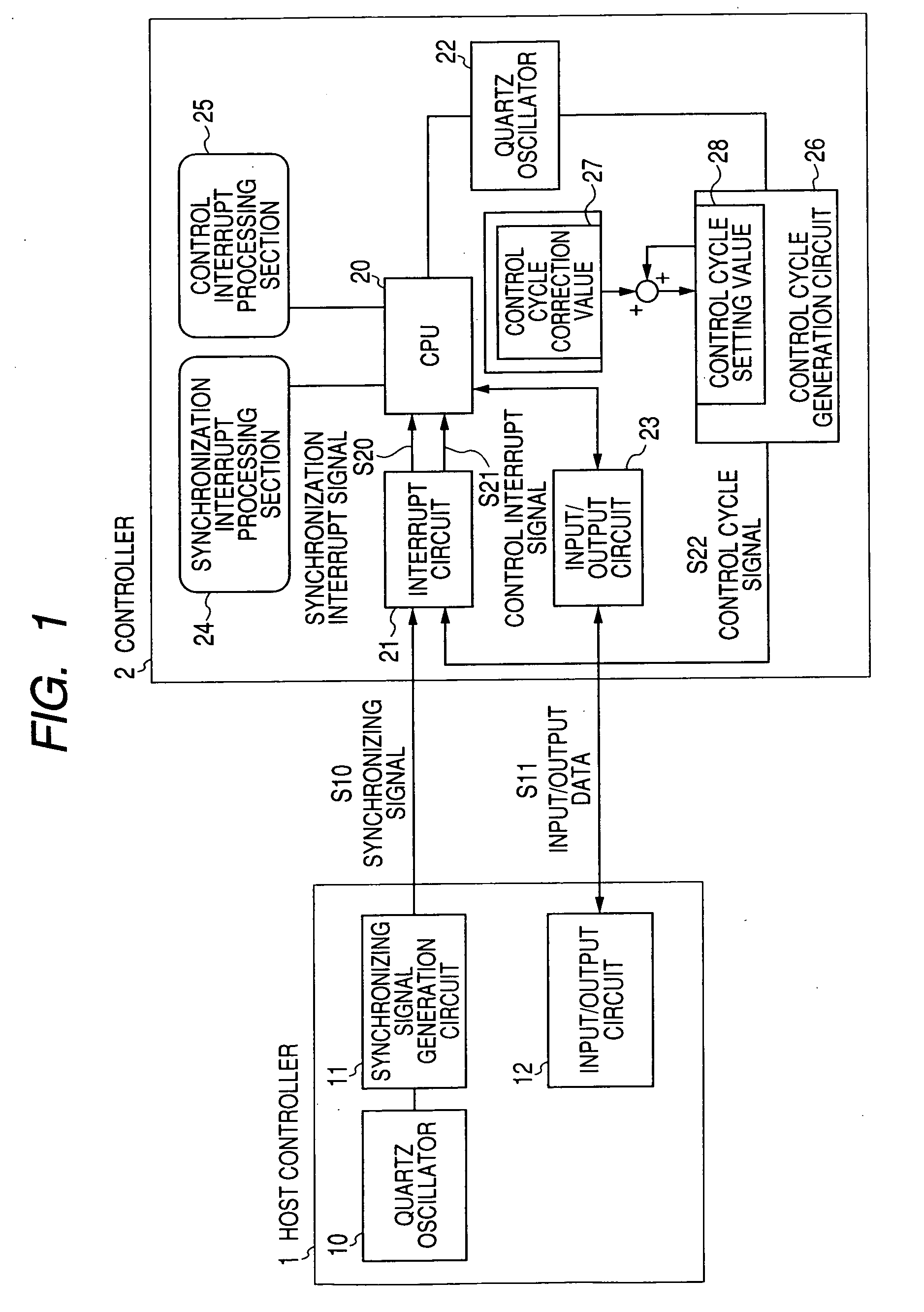

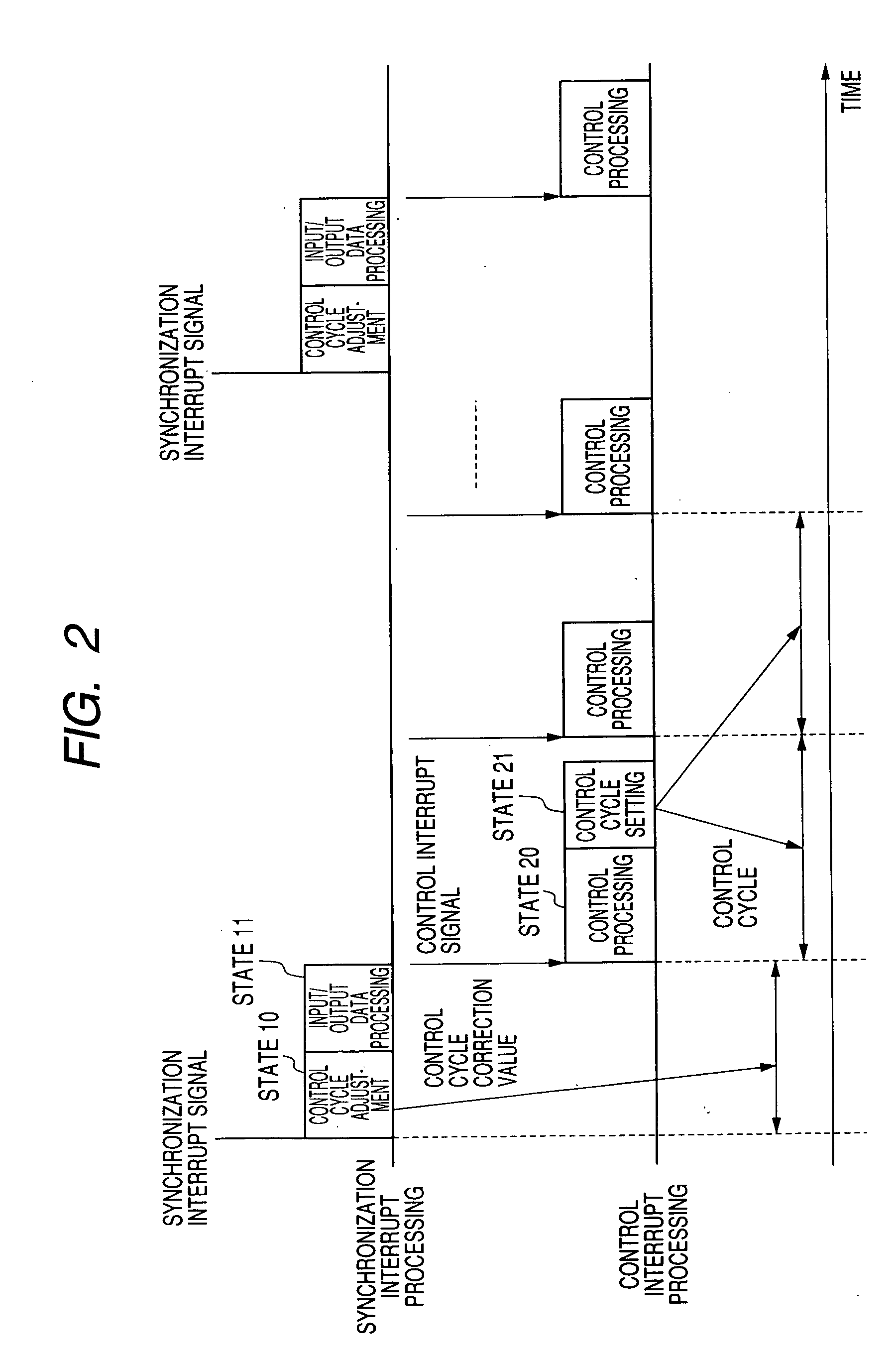

Control device and control method capable of external synchronization

InactiveUS20060153008A1Maintain control processing cycle constantSignificant processing timeSynchronous motors for clocksProgramme control in sequence/logic controllersData synchronizationControl break

The problem to be met by the present invention is to provide a controller which can execute control processing in synchronism with a synchronizing signal output from a host controller without taking into consideration a difference between a clock signal used for generating a synchronizing signal of the host controller and a clock signal used for generating a control cycle signal of a controller; and can enhance accuracy performance of control. According to the present invention, in a controller having a control interrupt processing section, a synchronization interrupt processing section adjusts means for generating a control cycle signal to thus generate a control interrupt signal such that the control cycle signal is generated while being delayed by an amount equal to or greater than the duration of an accuracy error between a quartz oscillator used for generating a synchronization interrupt signal and a quartz oscillator used for generating the control cycle signal, thereby executing control interrupt processing in synchronism with the synchronizing signal from the outside.

Owner:YASKAWA DENKI KK

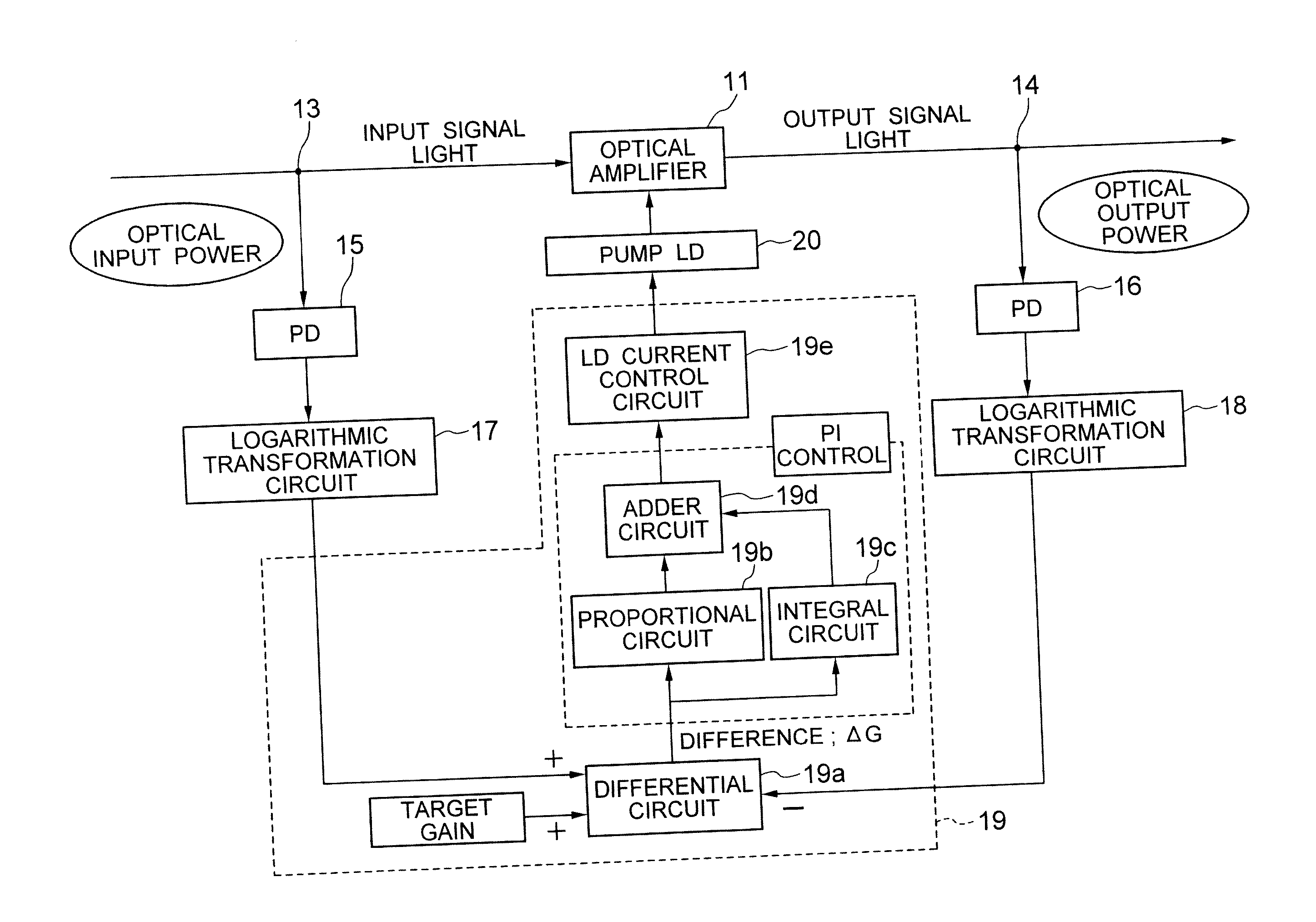

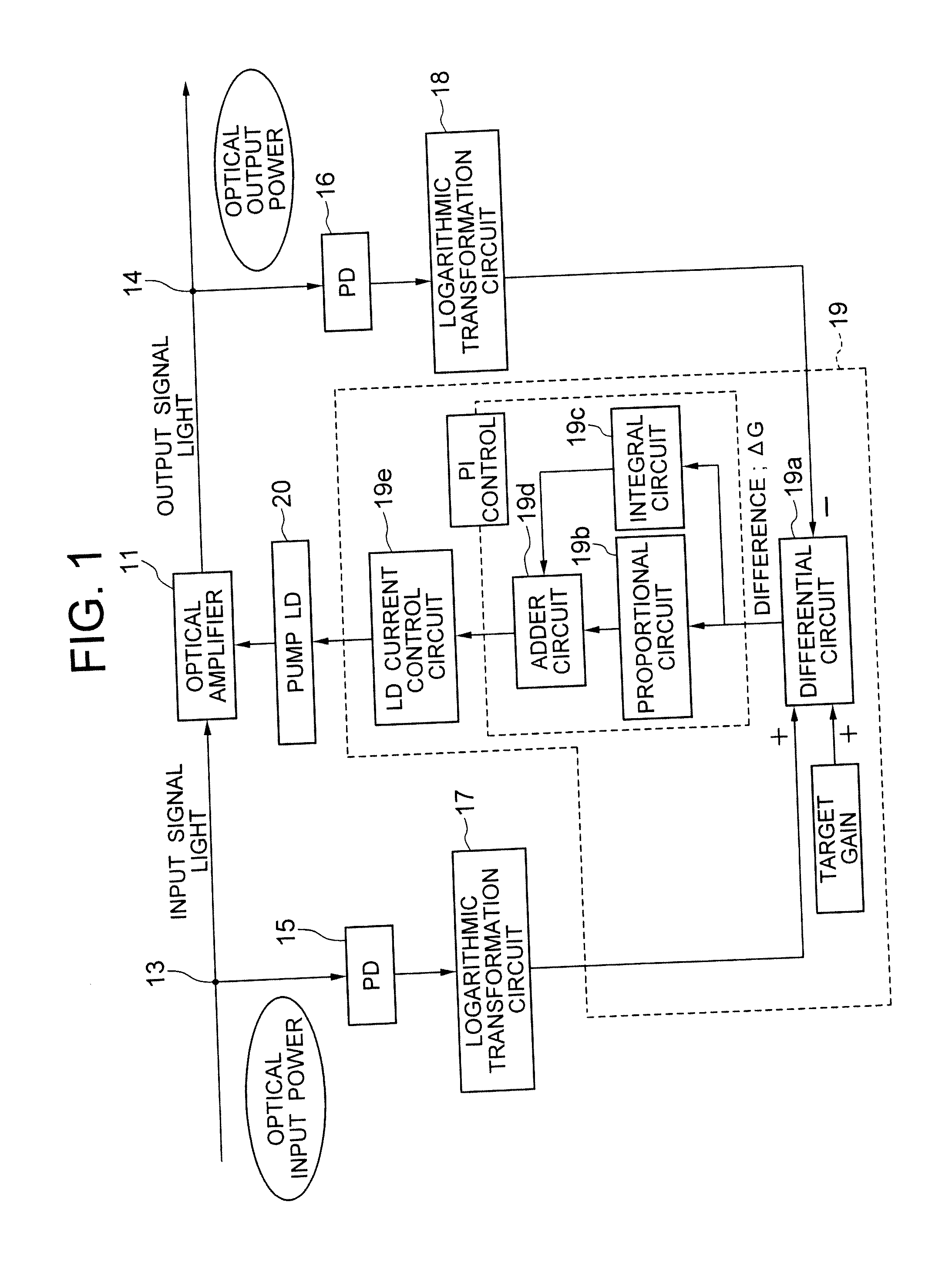

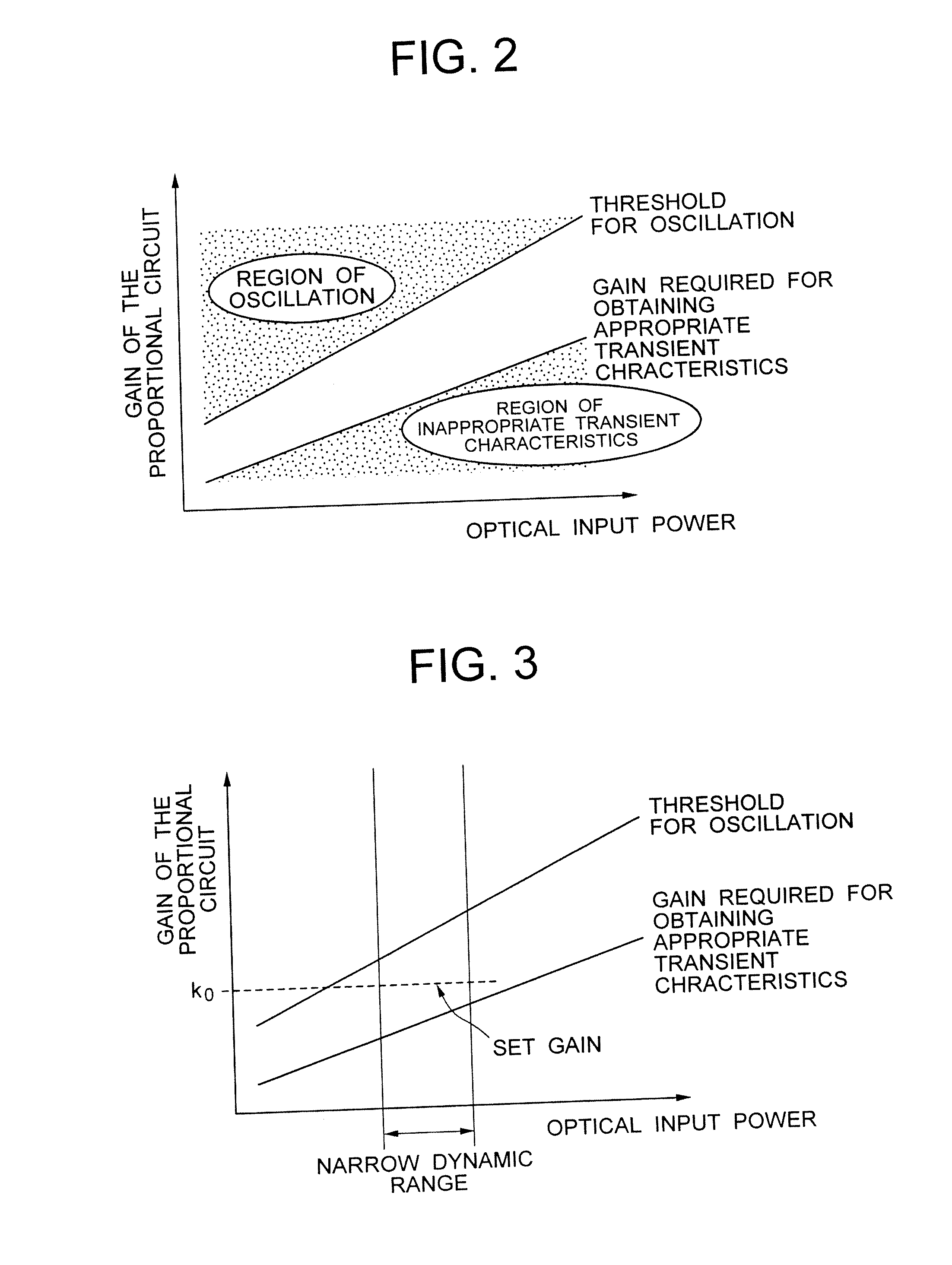

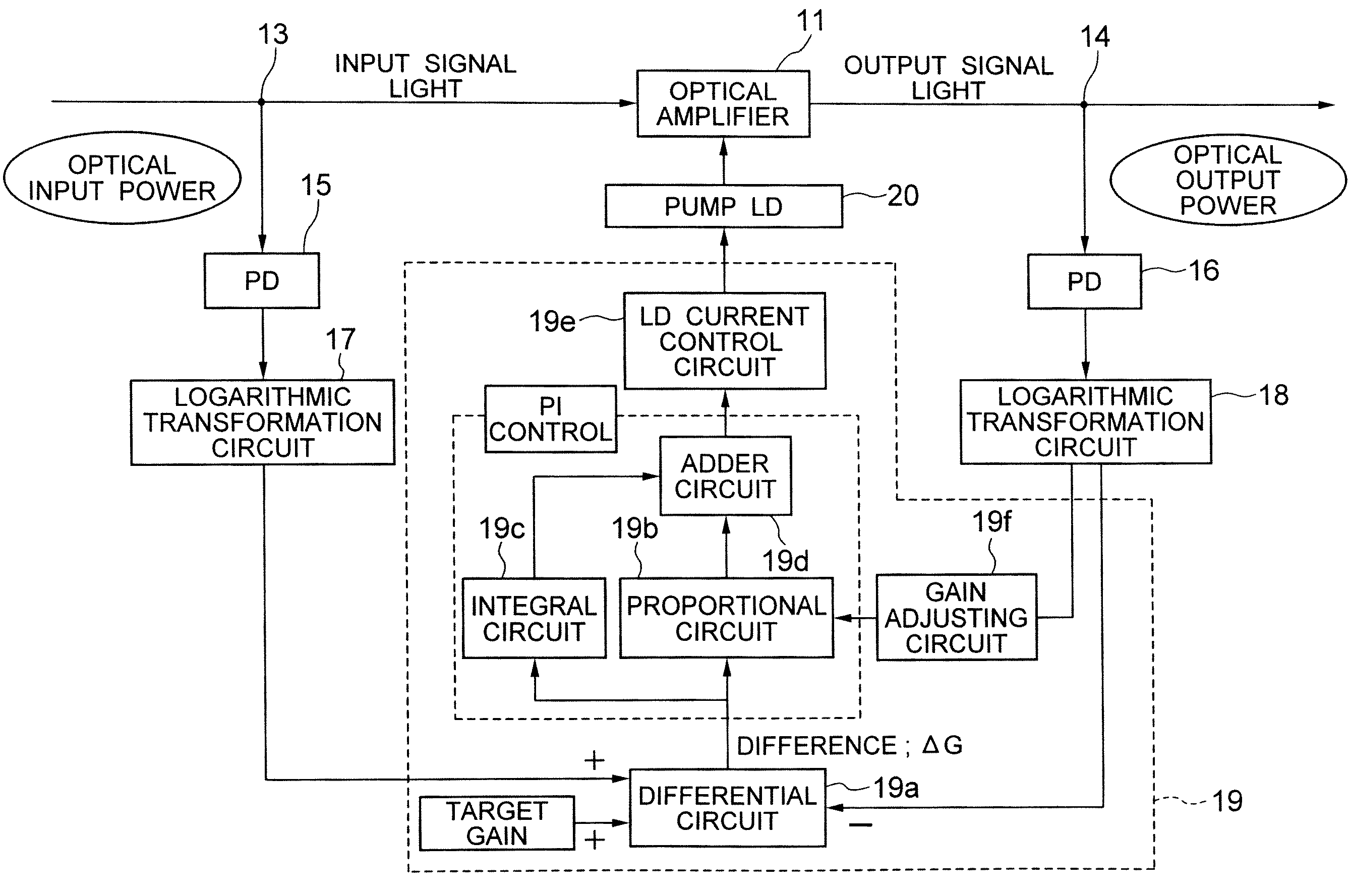

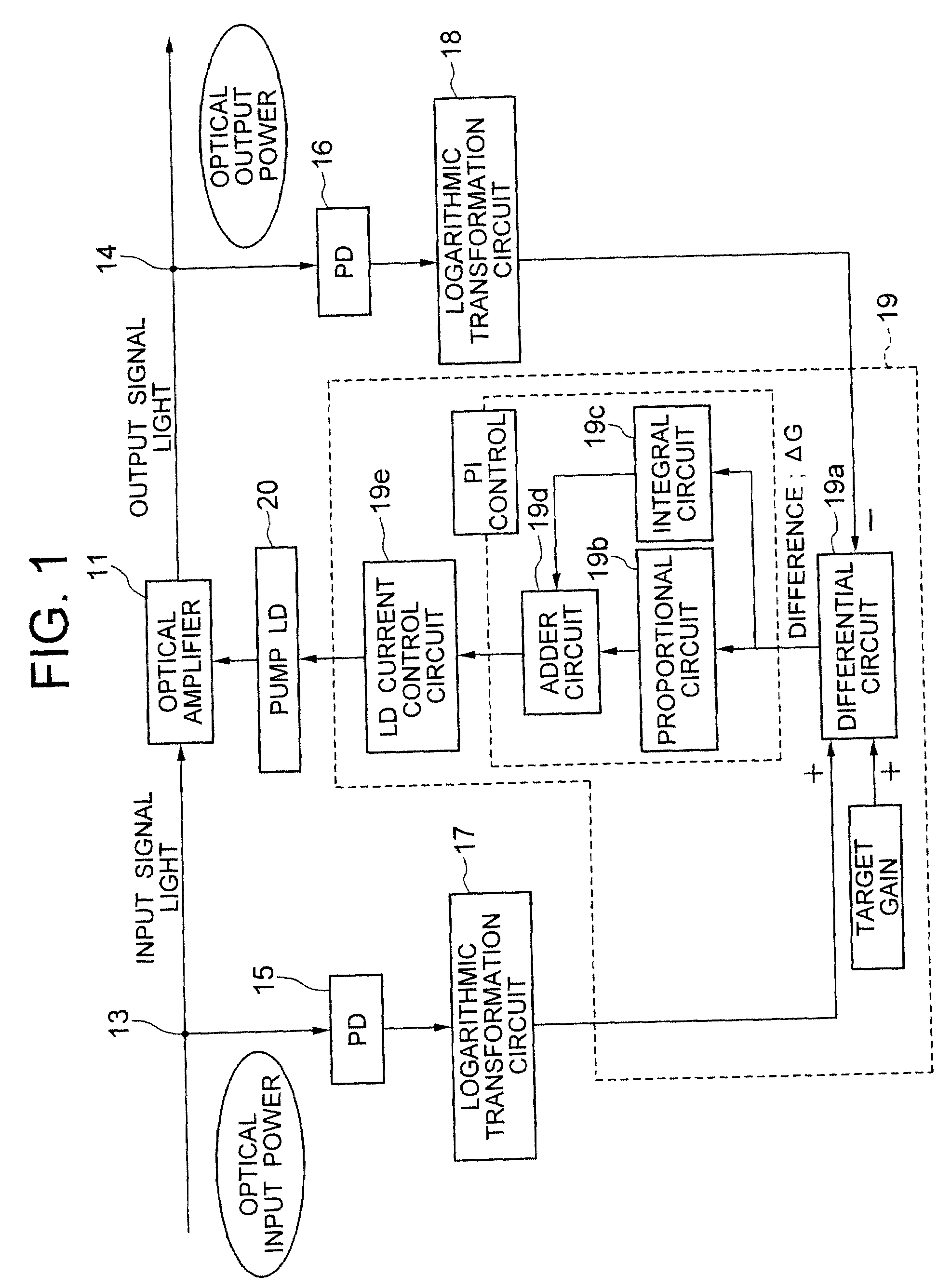

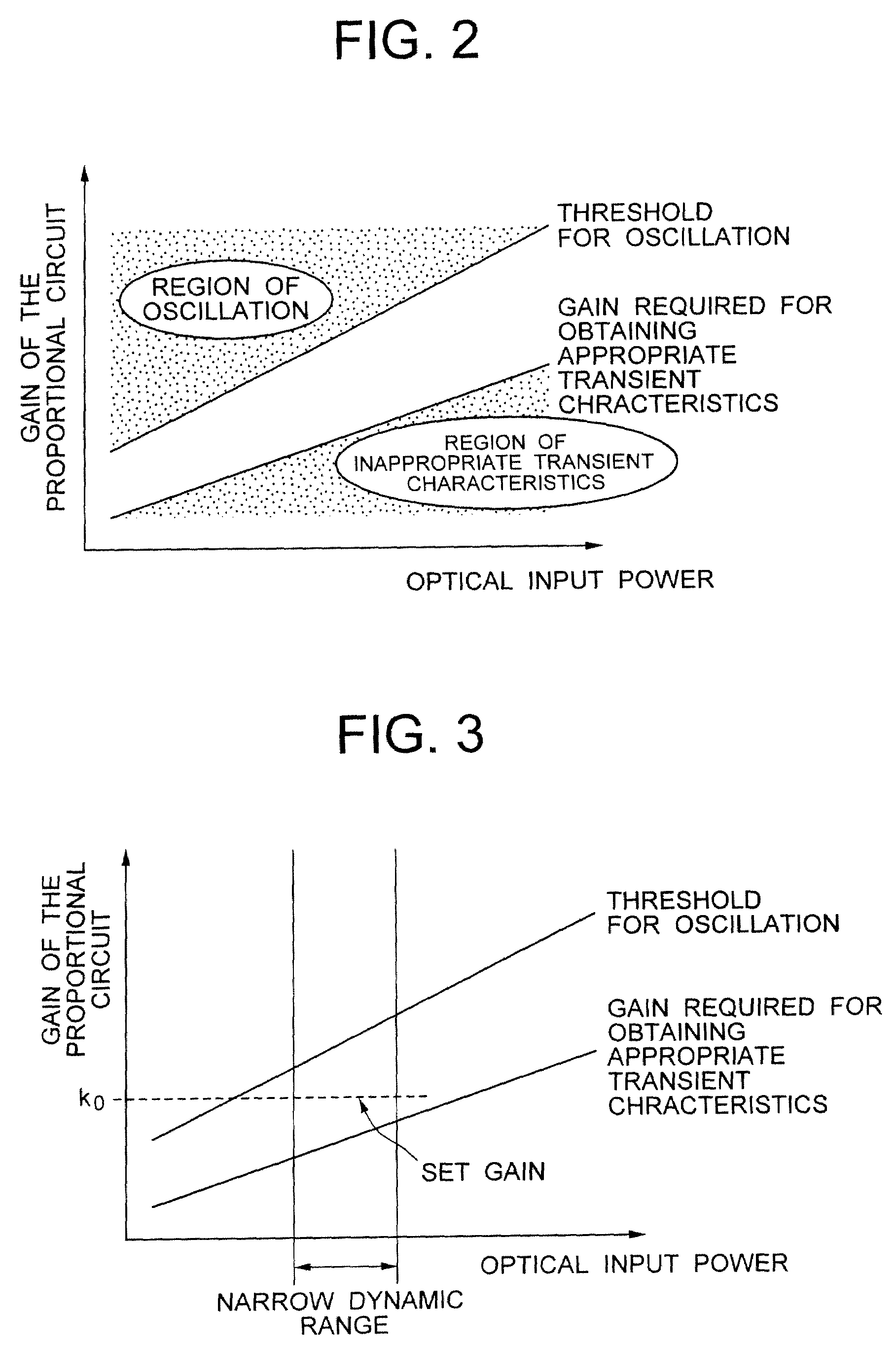

Optical amplifying method, optical amplifying apparatus, and optical amplified transmission system using the apparatus

ActiveUS20080068700A1High speed optical signal transmissionStable controlOptical transmission with multiple stagesFibre transmissionEngineeringOptical amplifier

A proportional constant adjusting circuit is arranged in the AGC circuit of the optical amplifying apparatus, and the proportional constant of the proportional circuit is continuously adjusted in correspondence to the optical input power monitored by the PD and the logarithmic transformation circuit. The AGC circuit controls the pump LD based on the monitored optical input / output power so as to control the gain of the optical amplifier to be a requested value.

Owner:MOLEX INC

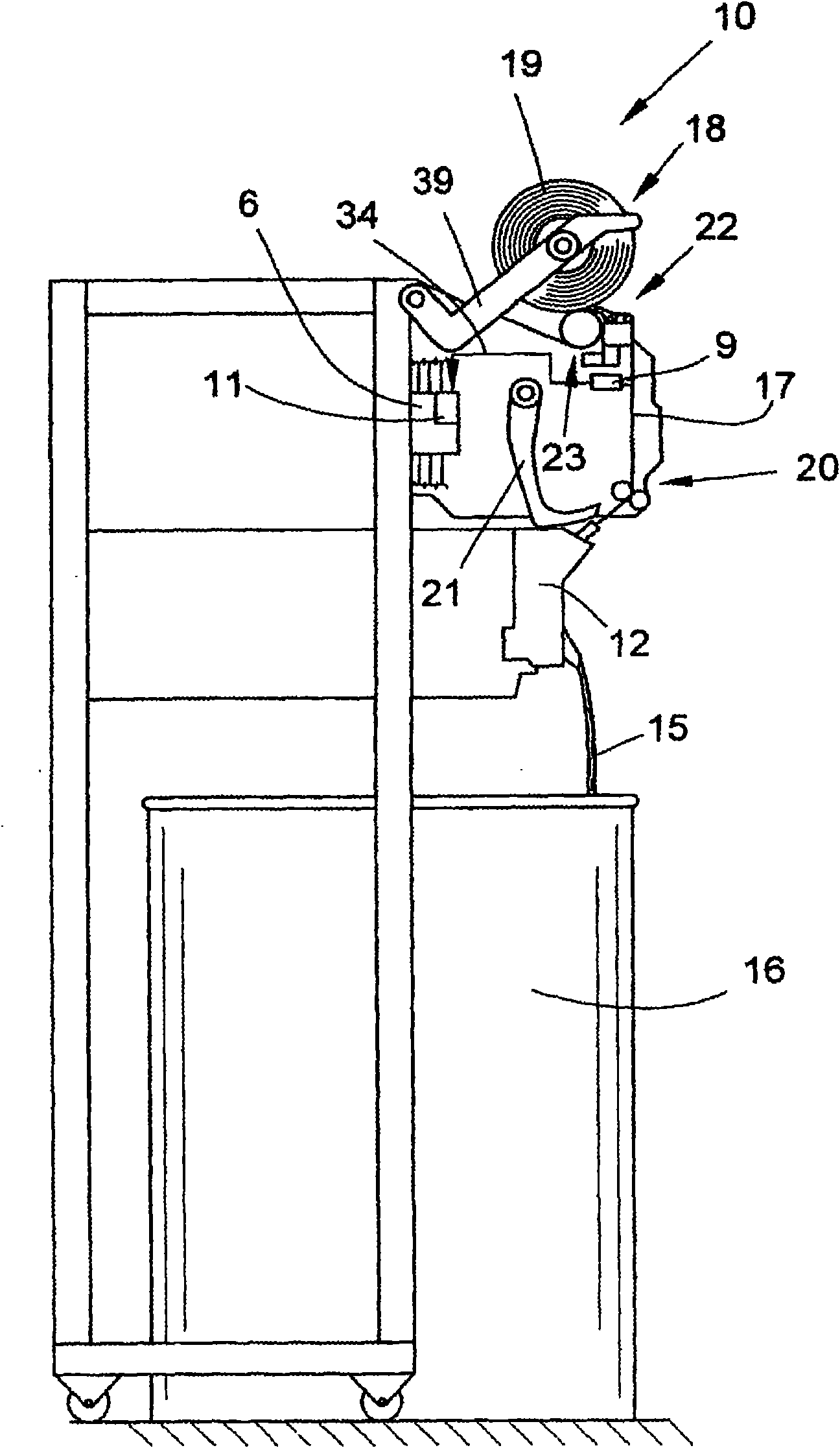

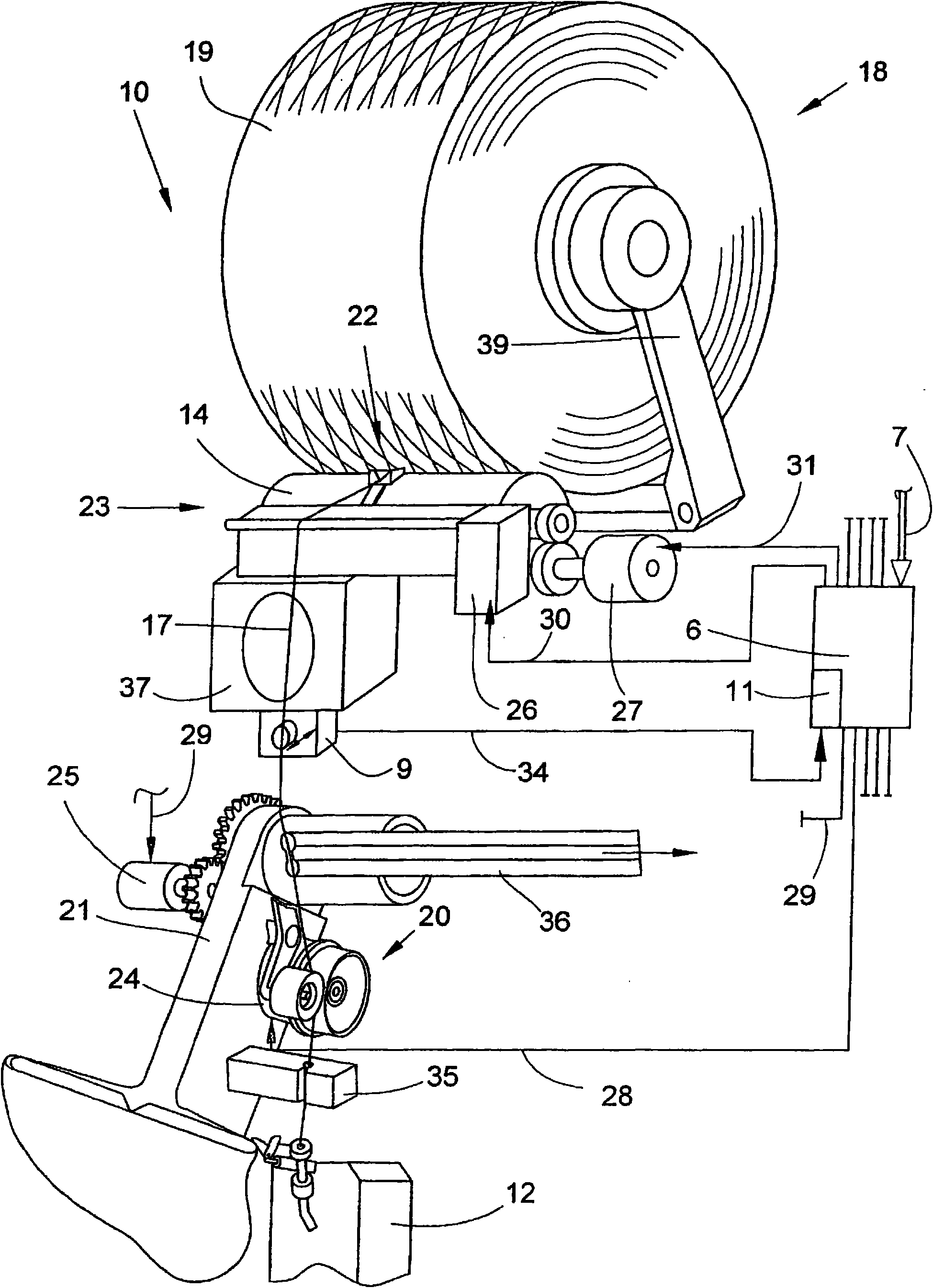

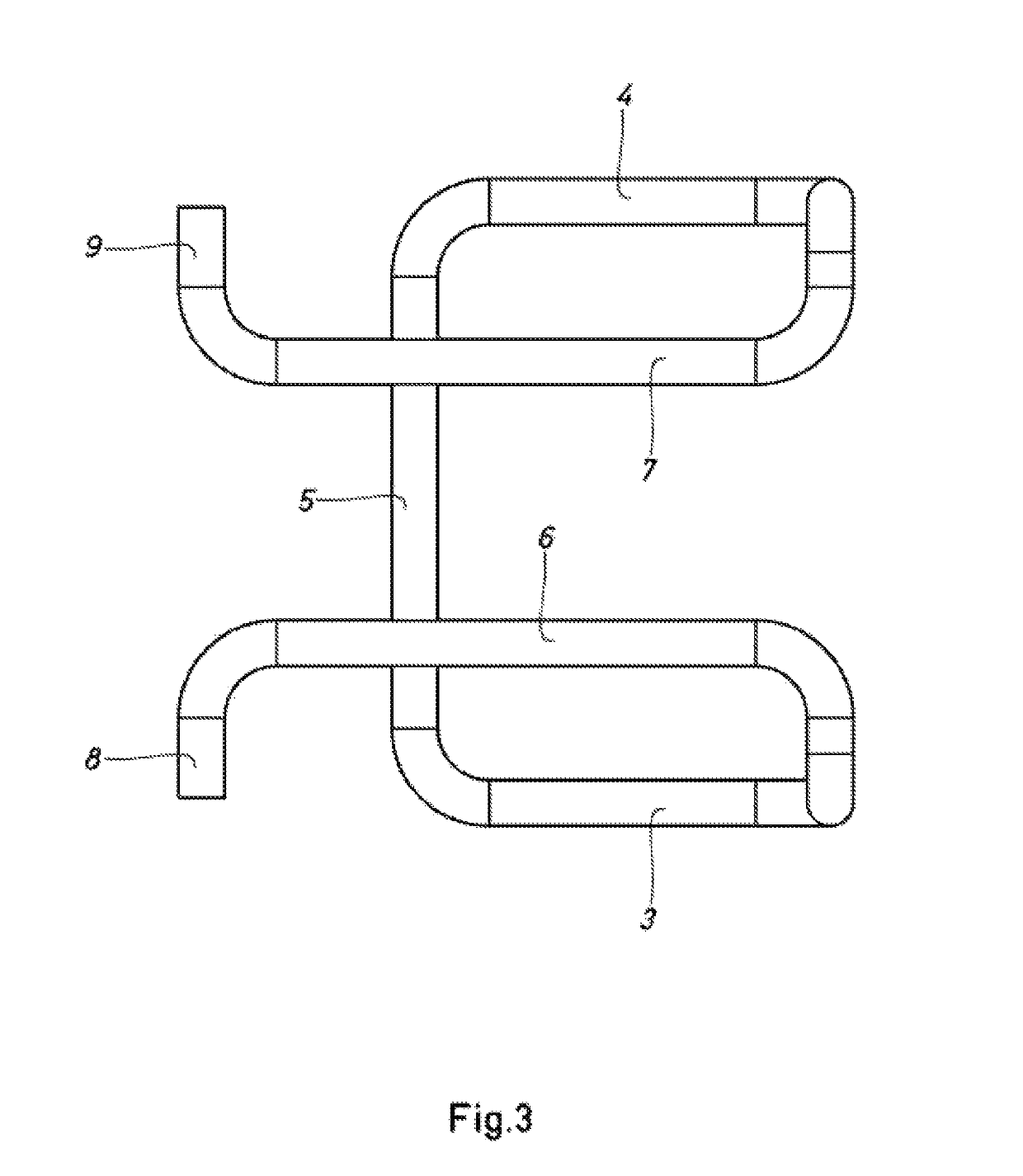

Offenend-spinnmaschine

ActiveCN101657574AEasy to controlConstant controlContinuous wound-up machinesOpen-end spinning machinesYarnBobbin

The invention relates to an open-end spinning machine (1) having a plurality of workstations (4), each comprising a spinning device (12) for producing a thread (17) and a bobbin device (18) for producing a cross-wound bobbin (19), wherein the bobbin device (18) has a bobbin frame (39) for rotatably holding a cross-wound bobbin (19), a thread changing device (22), and a defined controllable bobbindrive device (23). According to the invention, at least one pilot workstation (10) is provided, comprising a thread tension sensor (9) located between a thread drawing-off device (20) and the thread changing device (22), and an associated control and evaluation device (11), which is functionally connected to the bobbin drive device (23) of the pilot workstation (10) and is designed so that, depending on signals from the thread tension sensor (9), the bobbin drive device (23) can be regulated such that during a bobbin travel on the cross-wound bobbin (19), a nearly constant winding tension is ensured. Additionally, control values and / or control curves are created over the bobbin travel by the control and evaluation device (11) based on the controlled variables for the bobbin drive device (23), a defined control of the bobbin drive devices (23) of the plurality of workstations (4) not designed as pilot workstations of the open-end spinning machine taking place during each winding processby means of said control values and / or control curves.

Owner:SAURER GERMANY GMBH & CO KG

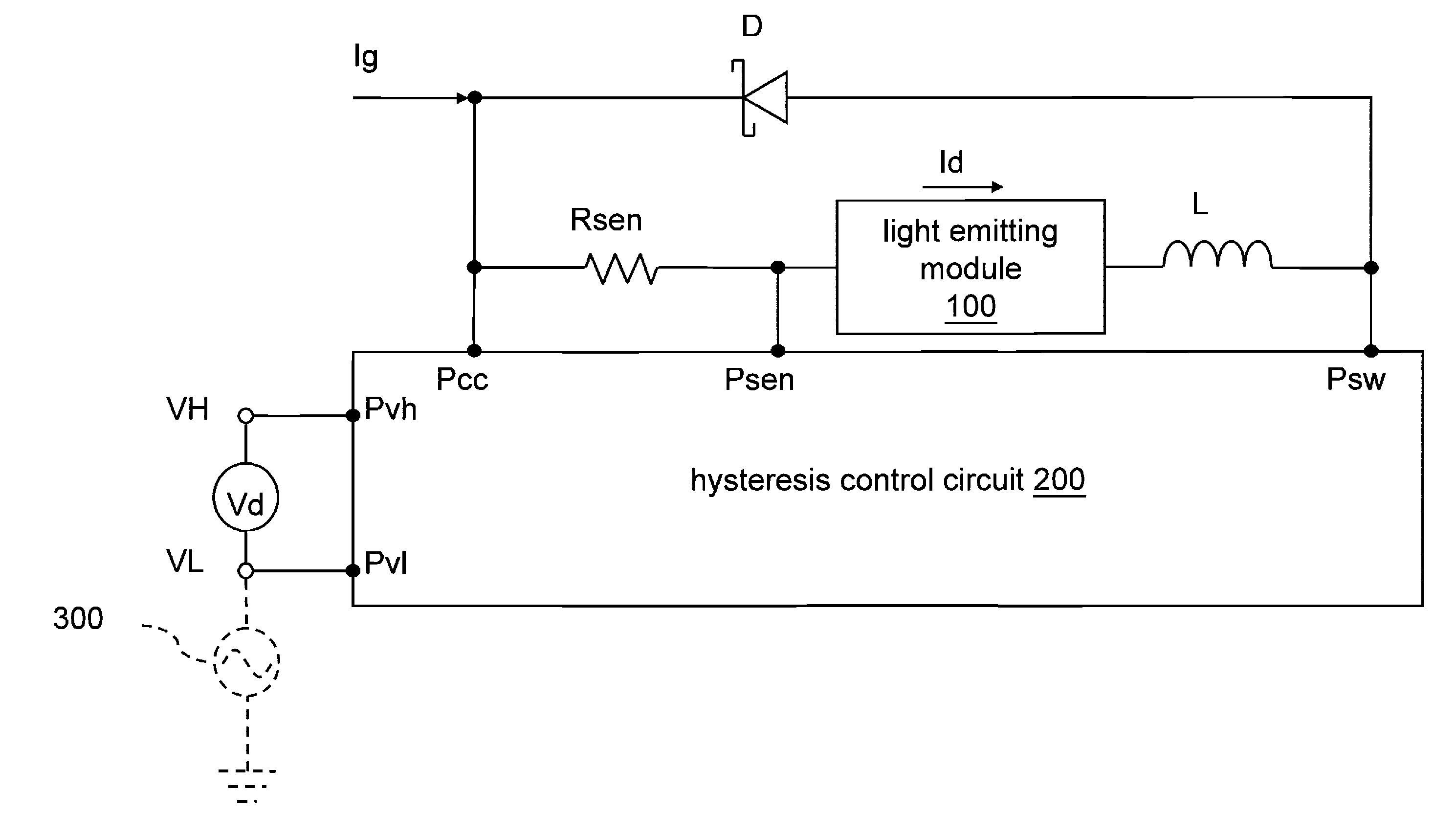

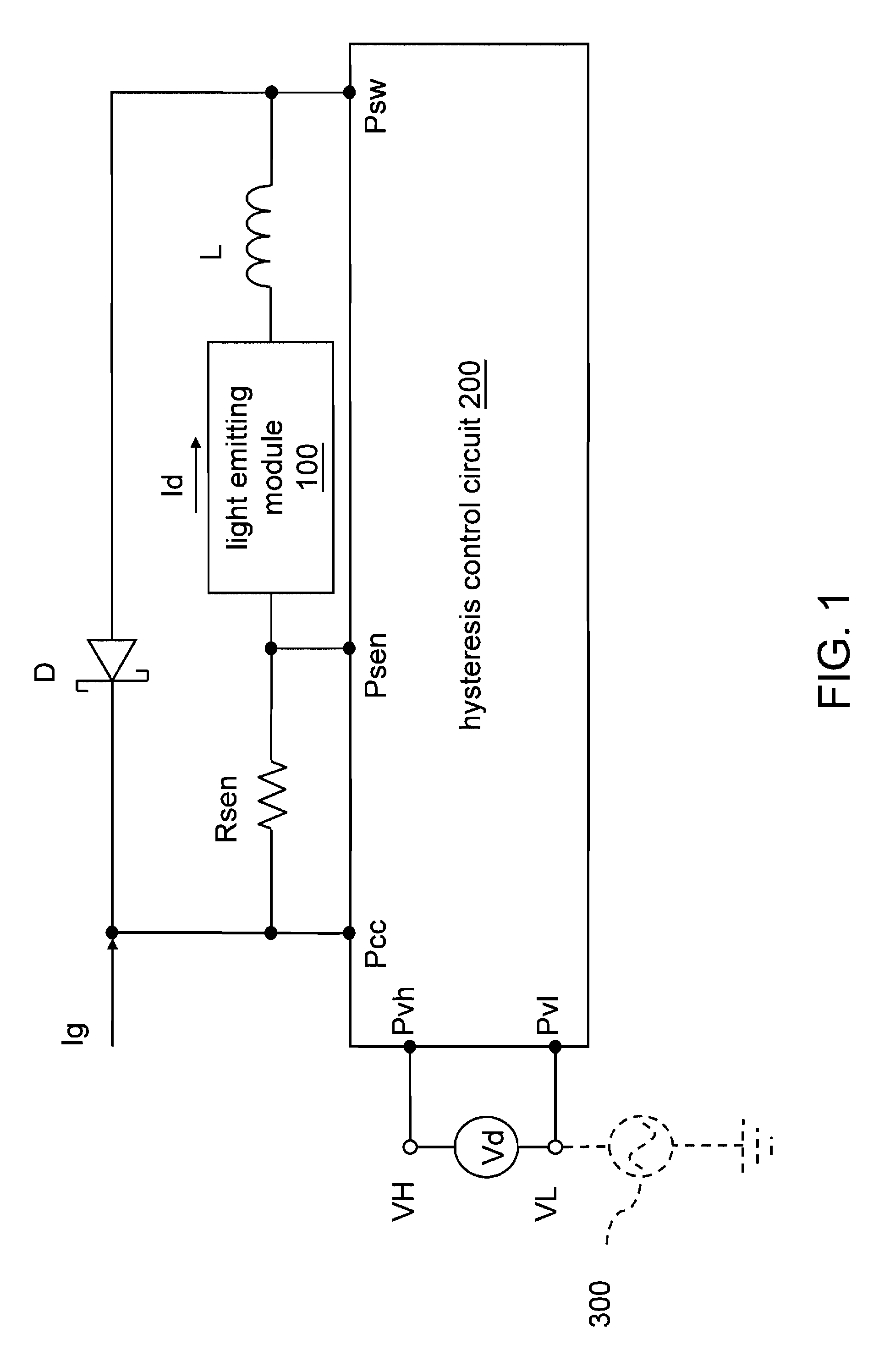

Fixed frequency dimming method and fixed frequency dimming circuit for light emitting module

ActiveUS20110012522A1Efficient conversionMaintain conversion efficiencyElectrical apparatusElectroluminescent light sourcesHysteresisLower limit

A fixed frequency dimming method and fixed frequency dimming circuit for a light emitting module can control light emitting brightness of the light emitting module through a hysteresis control circuit. A voltage difference between an upper limit voltage and a lower limit voltage of a hysteresis width of the hysteresis control circuit is maintained at a fixed value, and a driving current flowing through the light emitting module is changed by changing the upper limit voltage or the lower limit voltage.

Owner:MACROBLOCK INC

Optical amplifying method, optical amplifying apparatus, and optical amplified transmission system using the apparatus

InactiveUS7511883B2High speed optical signal transmissionStable controlOptical transmission with multiple stagesFibre transmissionOptical amplifierTransmission system

A proportional constant adjusting circuit is arranged in the AGC circuit of the optical amplifying apparatus, and the proportional constant of the proportional circuit is continuously adjusted in correspondence to the optical input power monitored by the PD and the logarithmic transformation circuit. The AGC circuit controls the pump LD based on the monitored optical input / output power so as to control the gain of the optical amplifier to be a requested value.

Owner:MOLEX INC

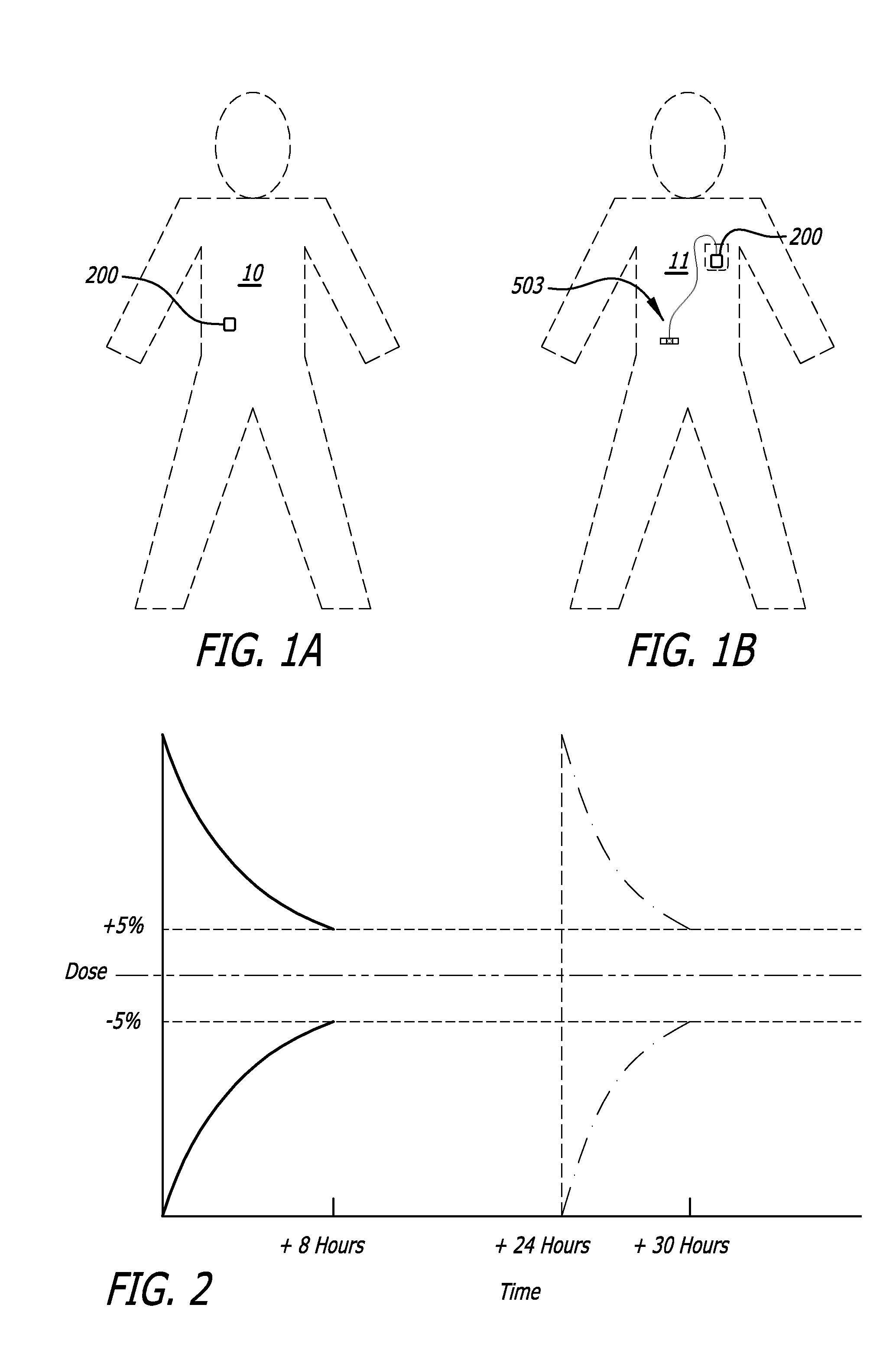

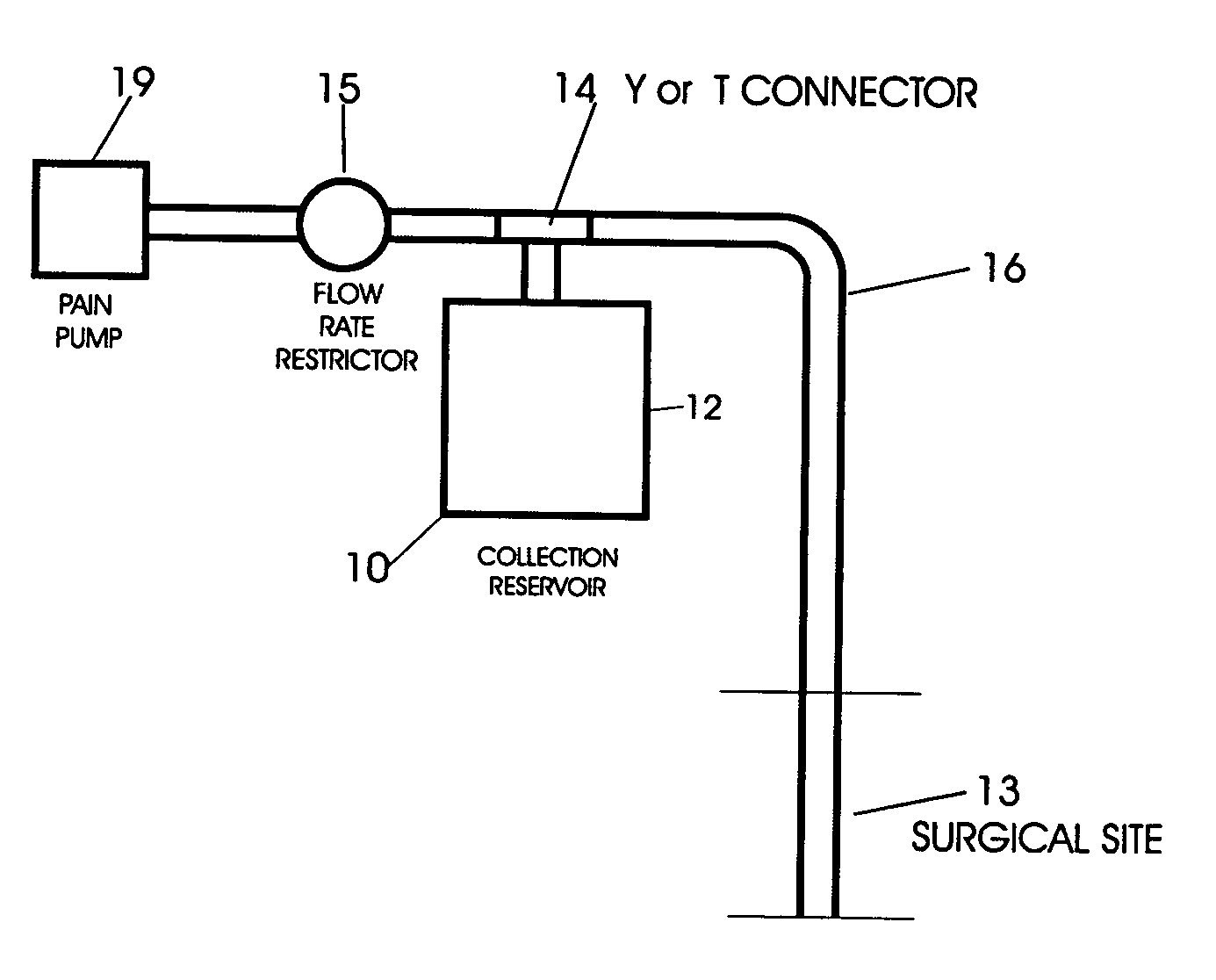

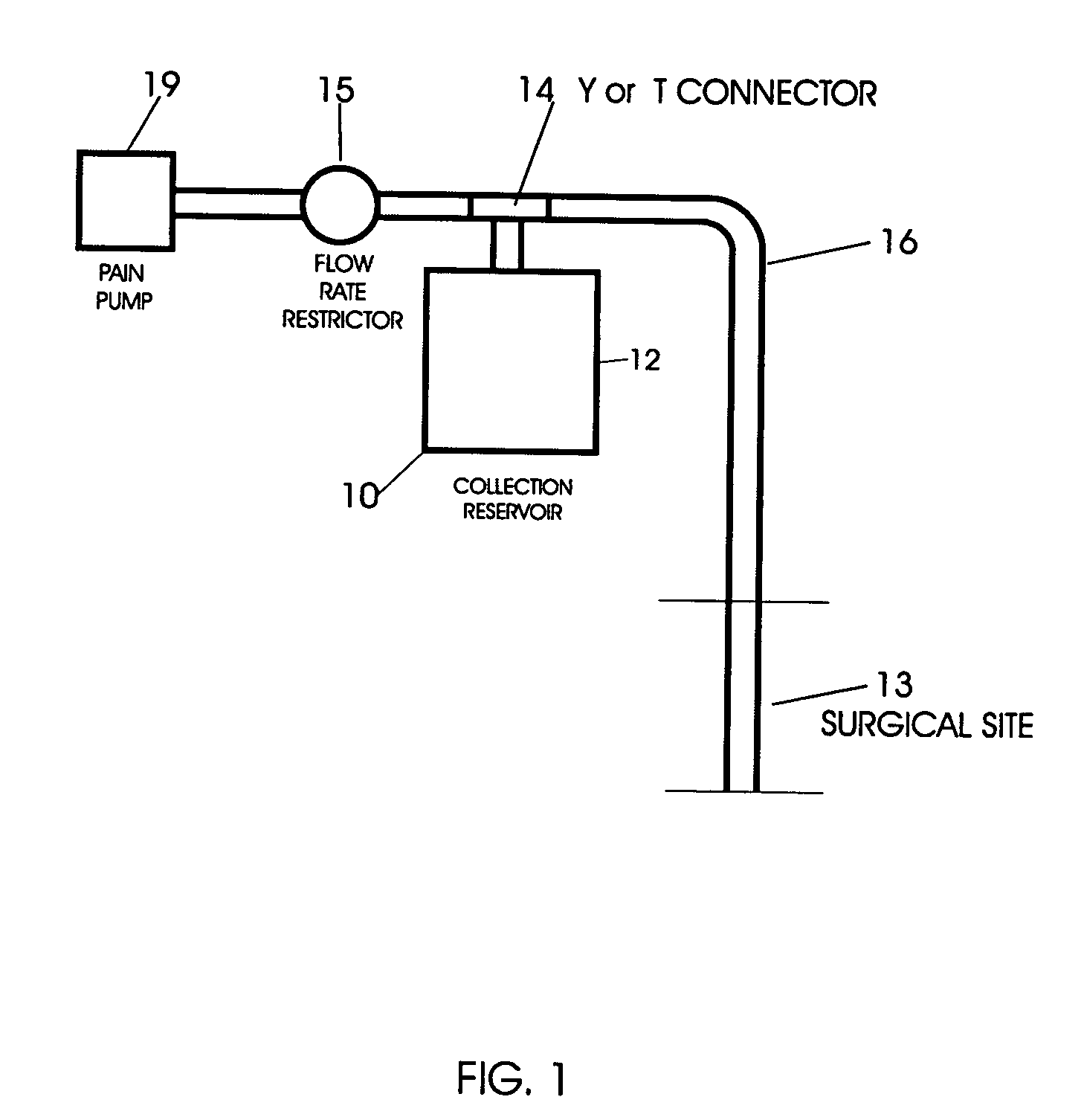

Collection reservoir for an ambulatory pain pump system

InactiveUS20050065470A1Prevent suckingConstant controlAnaesthesiaCatheterClosed systemTopical anesthetic

An apparatus for the collection of excess delivered local anesthetic from a ambulatory pain pump system into a bulb collection reservoir having a flexible compressible container. A cap is located at one end of the bulb having two ports, an inlet port for accepting excess local anesthetic and an outlet port with a removable closure allowing air to escape as the collection reservoir fills forming a closed system. The apparatus for the collection of excess local anesthetic delivered at a relatively constant controlled rate of flow into an intra-operative site is universal to fit a pain pump system with a fluid storage means, a catheter for deliver of the fluid, and a flow rate restrictor. The collection apparatus may also be attached to the catheter of a pain pump system at the distal end or more proximal by means of a Y or T collector located within the catheter. This safety feature can be universally applied to any pain pump system.

Owner:REED PAMELA S +1

Materials, method, and apparatus for detecting neutrons and ionizing radiation

InactiveUS8993968B2Significant rateConstant controlMeasurement with scintillation detectorsMaterial analysis by optical meansCalorescenceDiffusion

Owner:NANOPTICS

Light assemblies

ActiveUS8042972B2Constant controlDirt collected on the surfaces of the optical components is reducedLighting applicationsMechanical apparatusLight beamOptoelectronics

A method for forming a light beam, and a light assembly having at least one light source with a fixed reflector which directs a beam of light light assembly having a front lens, and a light deflecting mechanism for changing the light angle of the light beam after passing through the front lens. The front lens has a central part that differs from the surrounding parts of the front lens, and the light deflecting mechanism, in a first position, concentrates the light beam into the central part of the front lens to generate a wide-angle light beam, and in a second position, distributes the light beam over the entire front lens to generate a narrow angle light beam. The light deflecting mechanism is connected with a first actuator, and is movable between the first and the second position.

Owner:MARTIN PROFESSIONAL

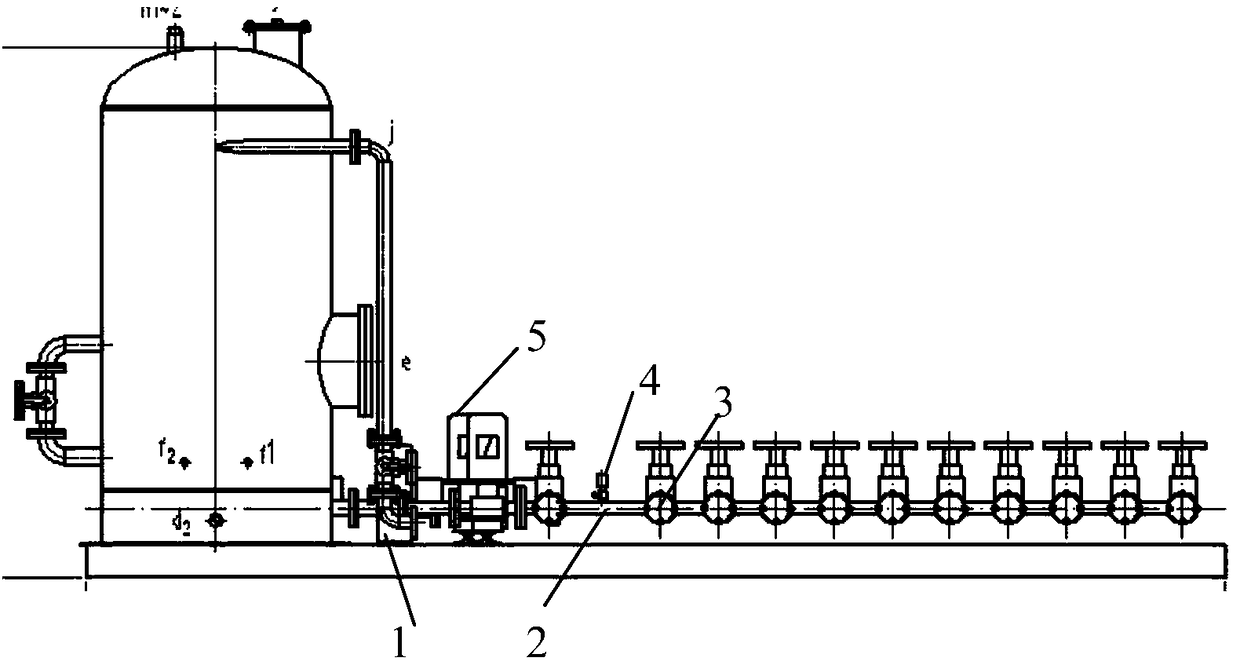

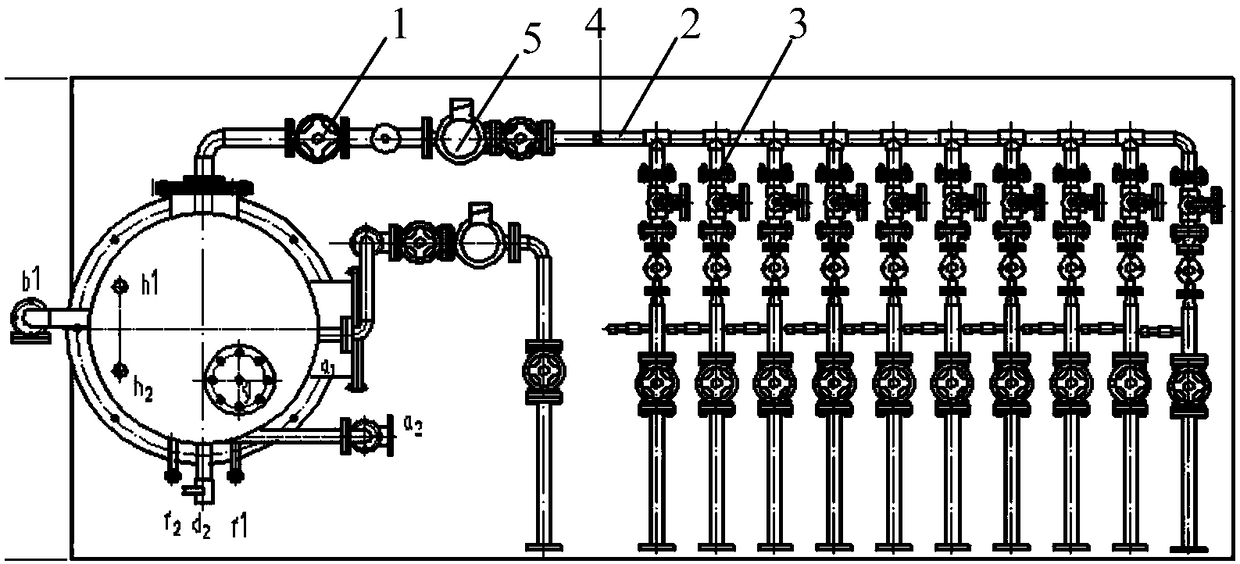

Intelligent skid-mounted chemical dosing device used for oil field producing well sets

InactiveCN109113664AConstant pressureEasy maintenance and repairCleaning apparatusAutomatic controlClosed loop

The invention discloses an intelligent skid-mounted chemical dosing device used for oil field producing well sets. The device includes a chemical dosing pump arranged on an oil well, a chemical dosingmain pipe connected to the chemical dosing pump, and chemical dispensing pipes communicating with the chemical dosing main pipe; a pressure transducer and an automatic flow controller are installed on the chemical dosing main pipe; and a closed loop can be formed by the pressure transducer and the automatic flow controller. The device adopts an advanced automatic control technology, and forms theclosed loop with a pressure transmitter, so that automatic adjusting can be achieved, the constant pressure of the inlets and outlets of pumps and pipelines can be guaranteed, and quantitative functions can be accomplished; the compact structure and small land occupation area of the whole device can be realized through a reasonable and optimized pipeline process; through the utilization of computer technologies, control technologies and communication technologies, remote monitoring, sub-metering and data processing can be accomplished, and therefore, the device is suitable for current industrial modernization models, the enhancement of production management levels can be promoted, and refined management can be realized; and the device has an automatic remote-control function and a manualcontrol mode, so that the device is the best solution for paraffin and scale control and chemical dosing in oil fields.

Owner:SHAANXI XINGCHEN PETROLEUM TECH

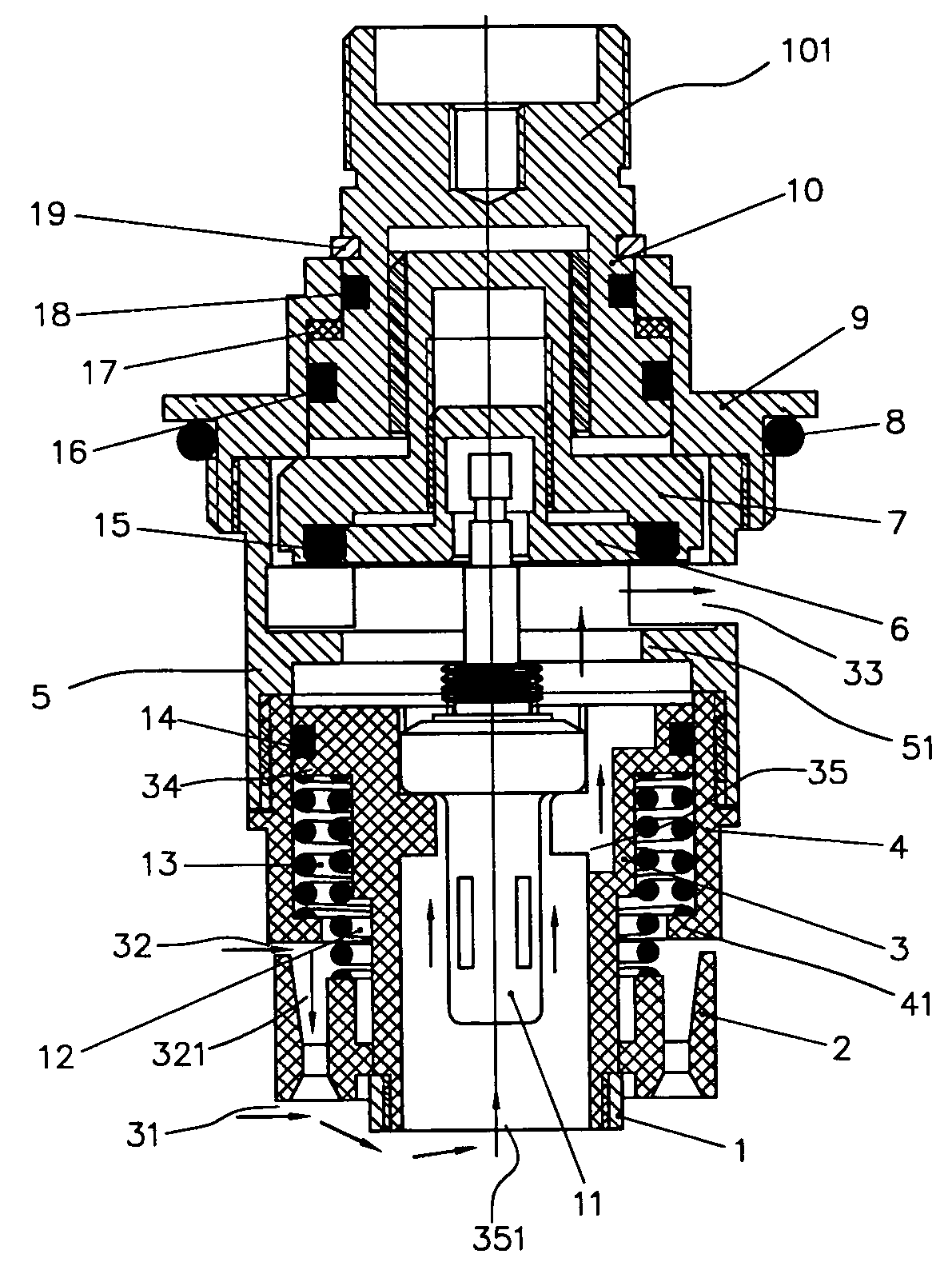

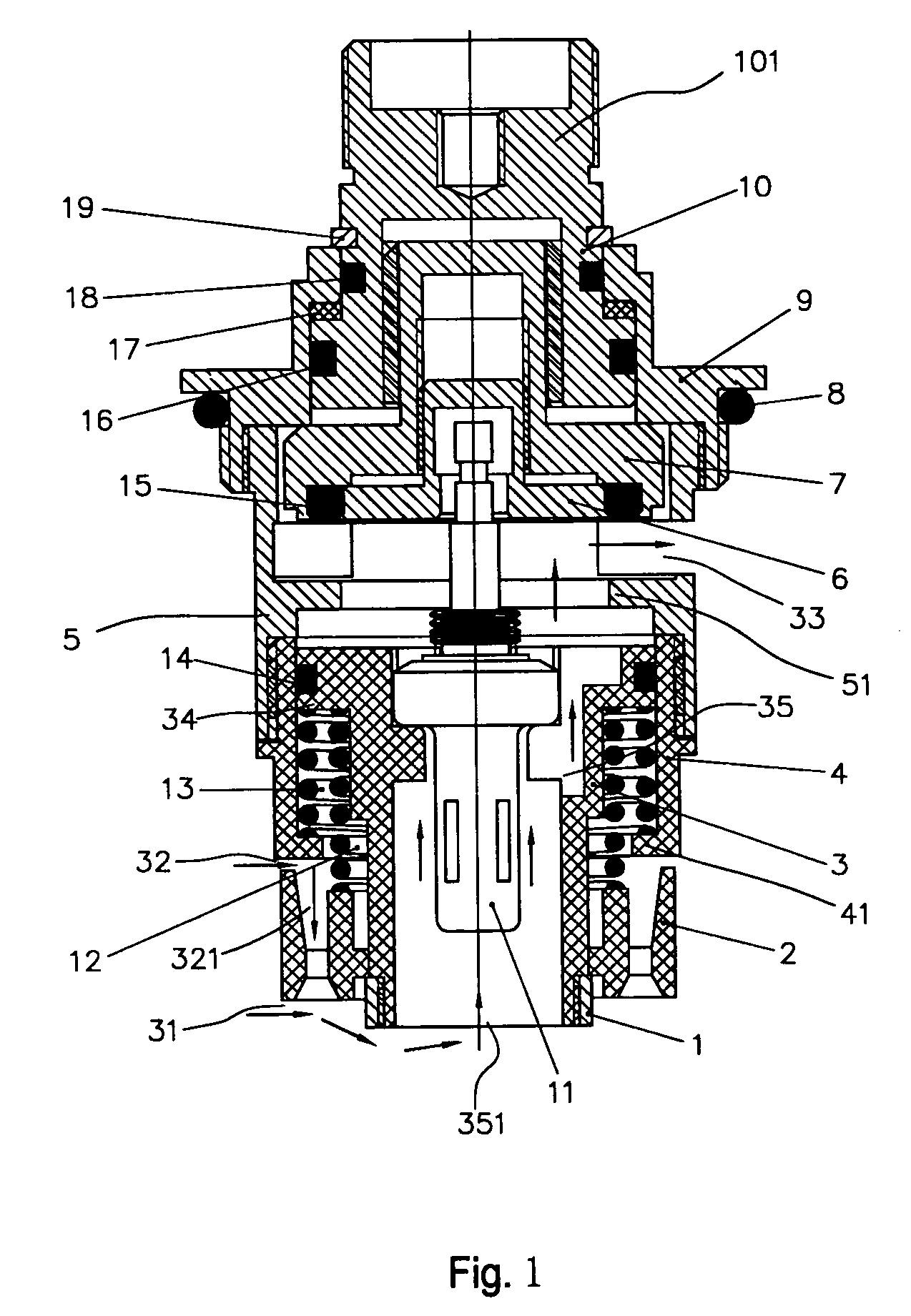

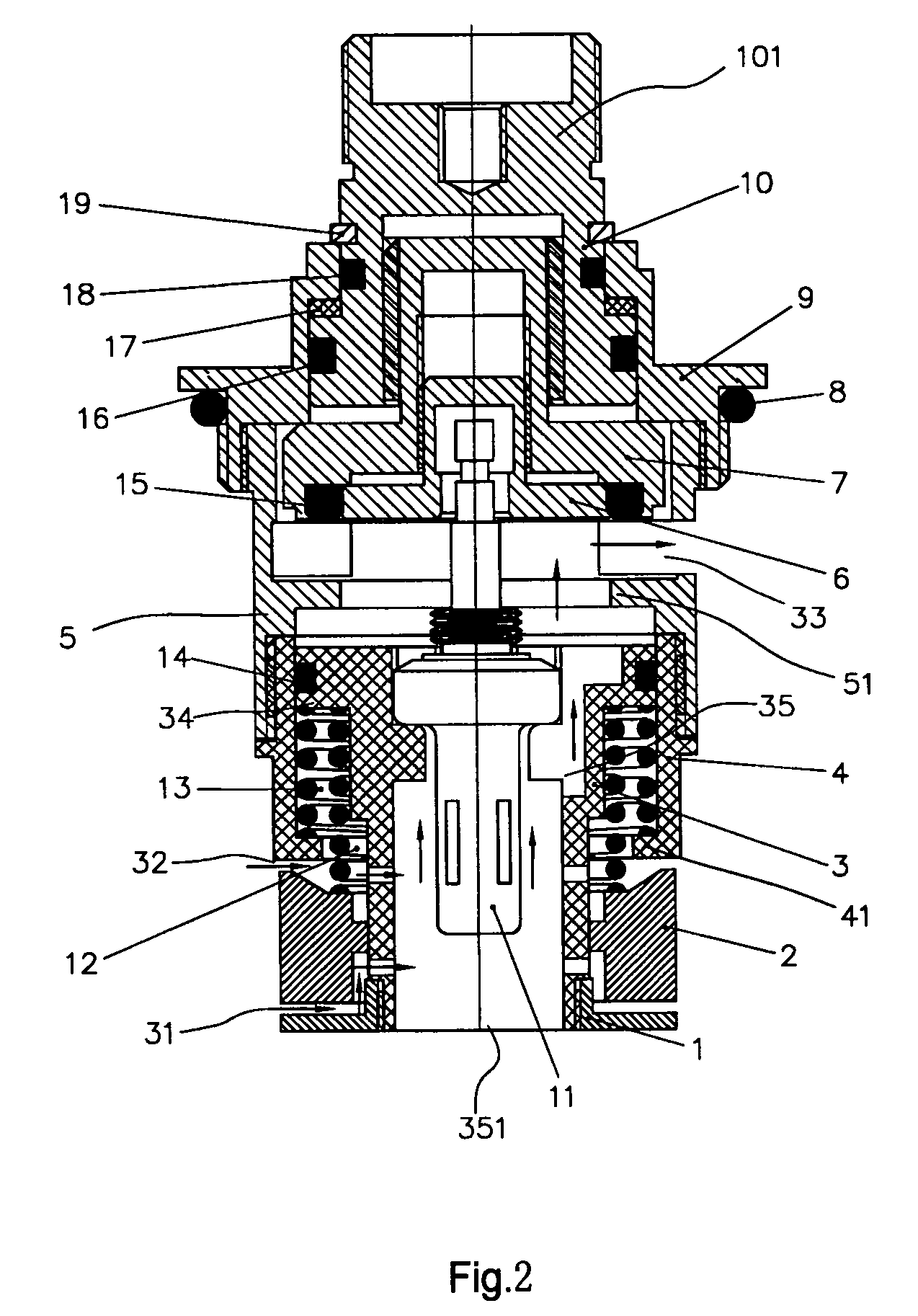

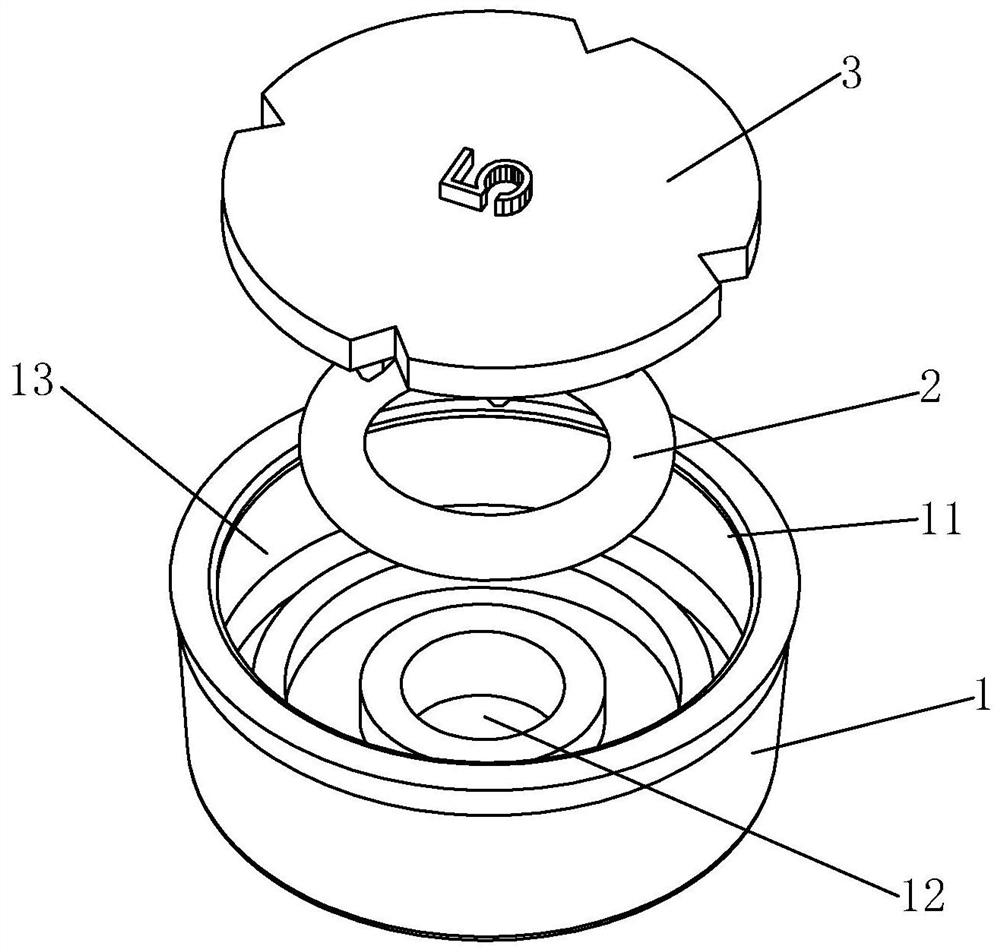

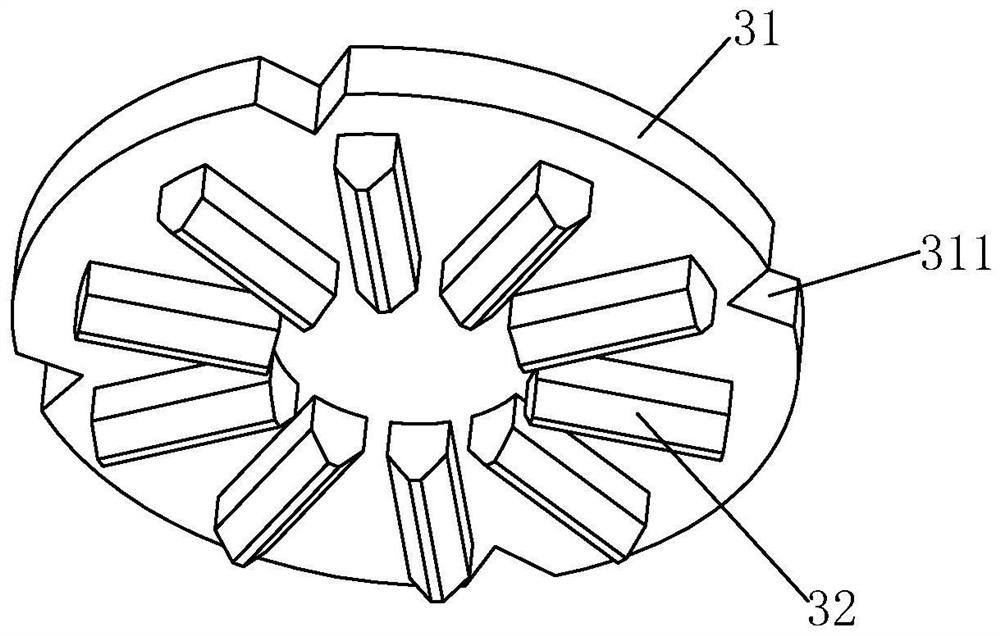

Successive type constant-temperature valve core with single handle

ActiveUS20100163636A1Small sizeSimple structureTemperature control without auxillary powerOperating means/releasing devices for valvesEngineeringMechanical engineering

A successive type constant temperature valve core with single handle comprises a valve cover, a temperature adjusting assembly, a thermo sensitive element and a control assembly for hot and cold inlet water, combining in the chamber of the valve cover from top to bottom, wherein, the control assembly for hot and cold water inlet comprises a holder of the thermo sensitive element, an adjuster, a put-off spring, a buffer spring and a holding piece. The upper part of the holder of the thermo sensitive element props the thermo sensitive element, and the lower part extends from the lower end of the valve cover; the buffer spring is arranged outside the holder of the thermo sensitive element, and the two ends respectively prop the holder of the thermo sensitive element and the adjuster; the adjuster is axial adjustably restricted to the periphery of the lower part of the holder of the thermo sensitive element by matching the buffer spring with the holding piece; the put-off spring is arranged outside the buffer spring, and the two ends are respectively prop the holder of the thermo sensitive element and the valve cover; the top and foot of the adjuster respectively forms cold water inlet and hot water inlet; water outlet is arranged on the wall of the valve cover; the holder of the thermo sensitive element is provided with a mixed water passage that communicates with the cold water inlet, the hot water inlet and the water outlet.

Owner:SUPREMA (ZHUHAI J V) THERMOSTATIC SANITARYWARE CO LTD

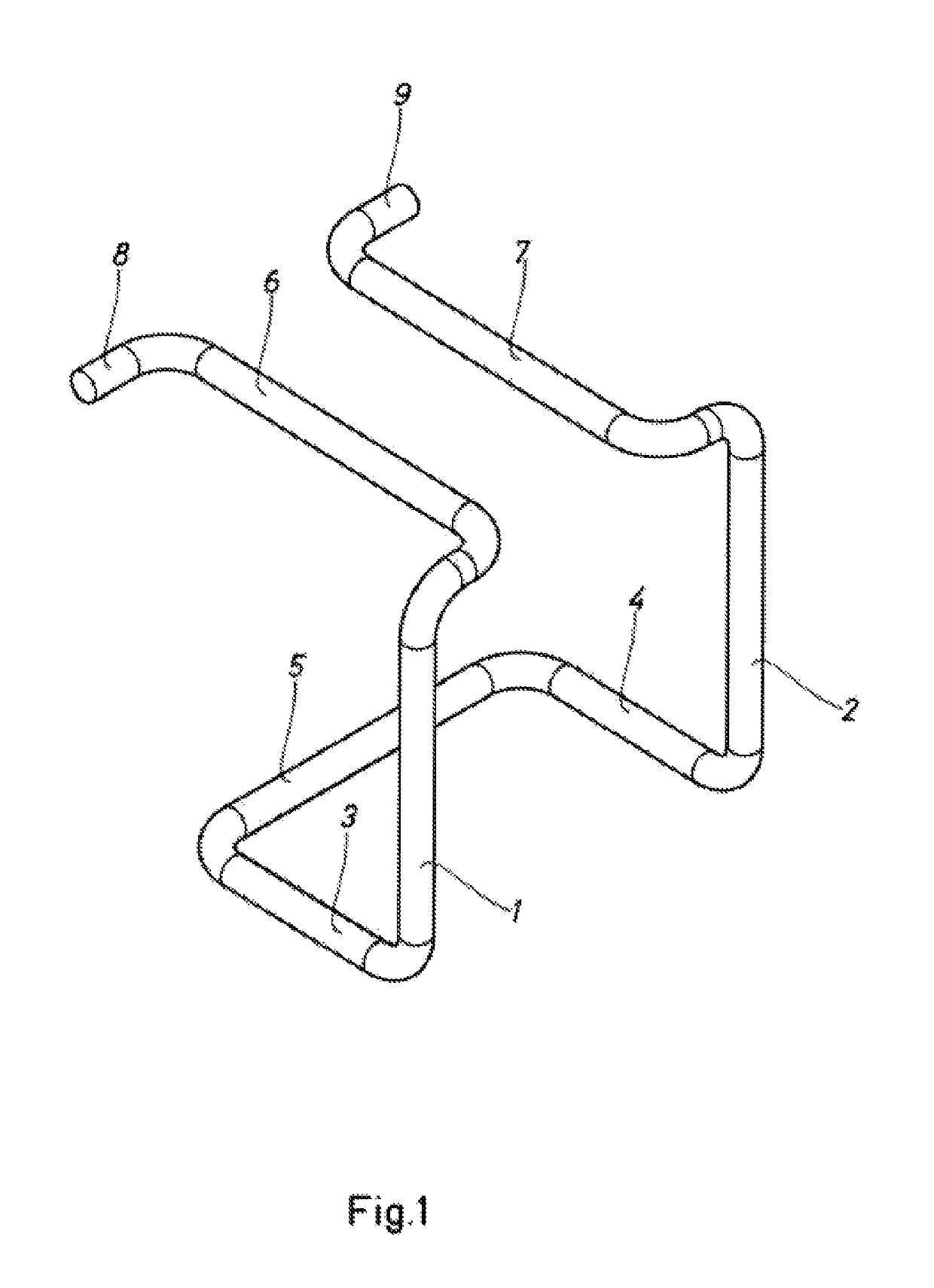

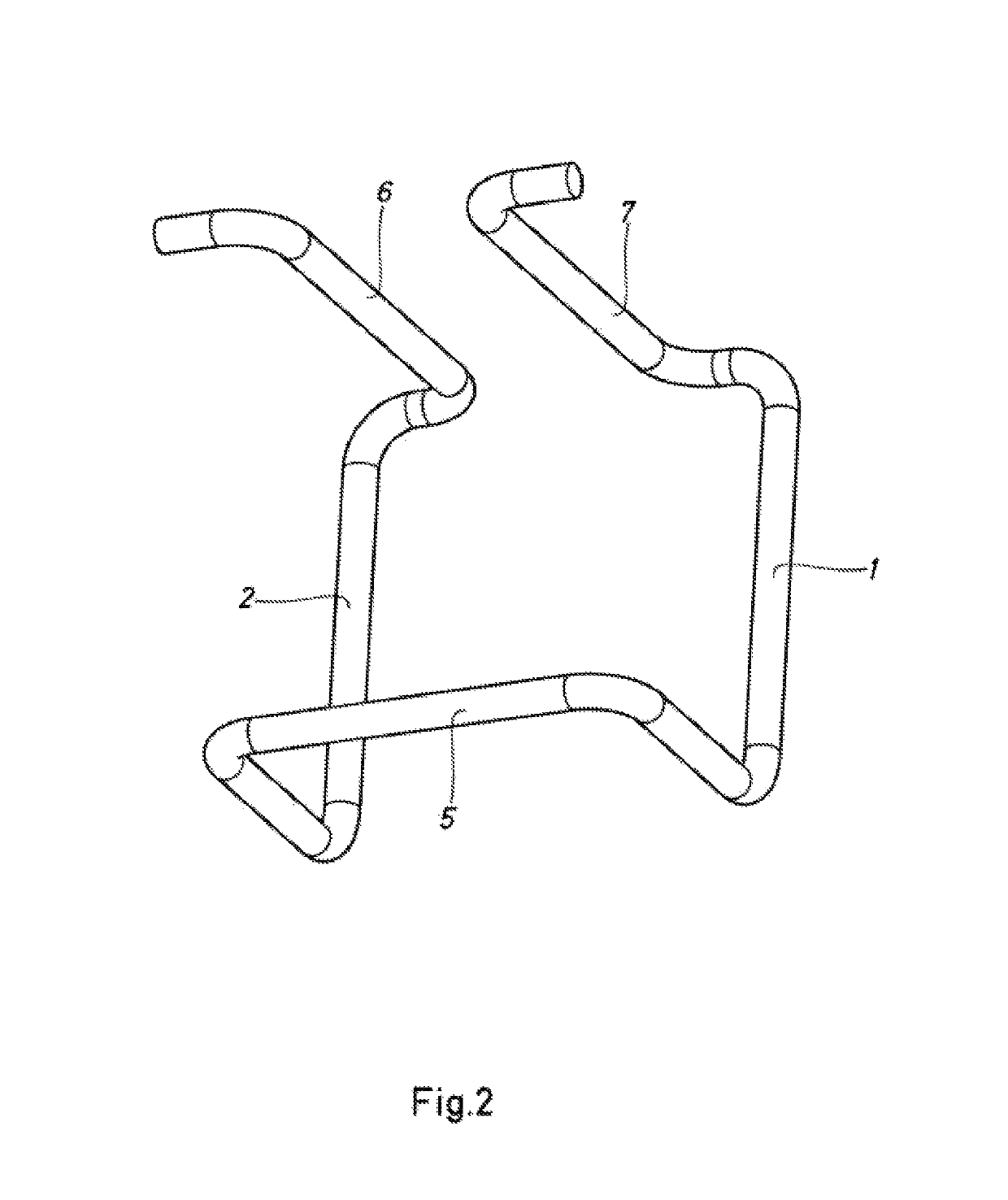

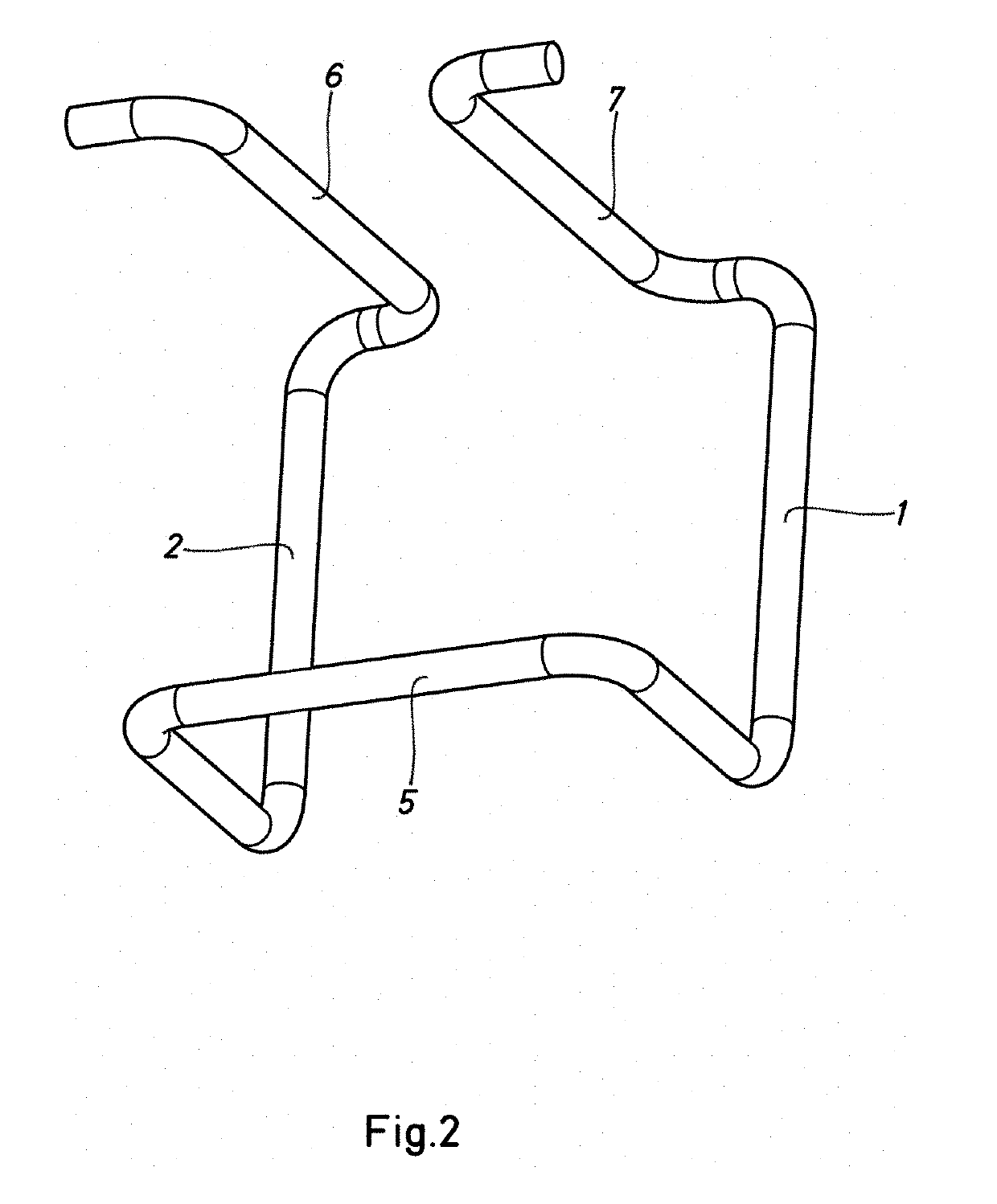

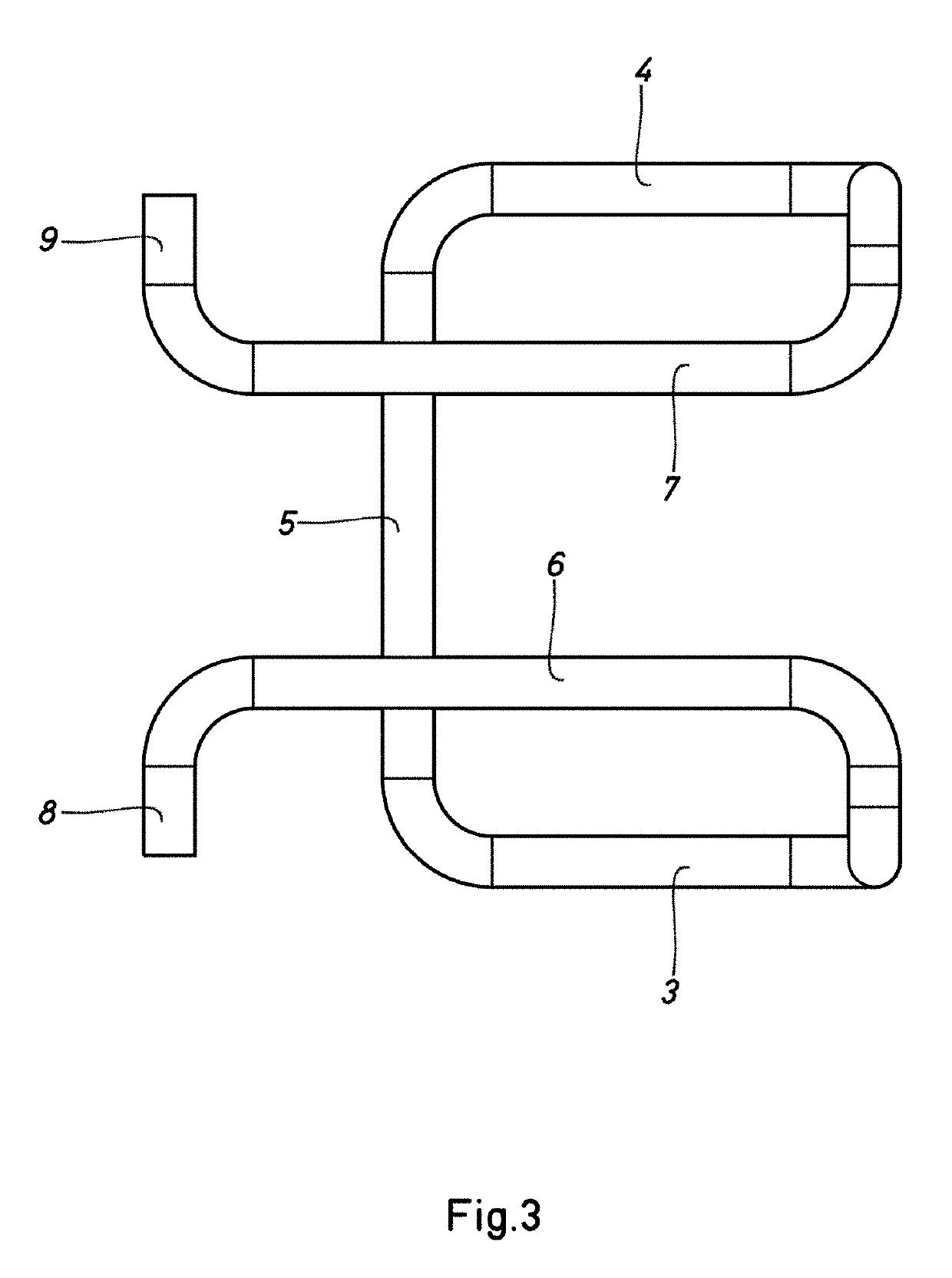

Device for dismountably connecting two intersecting formwork beams

ActiveUS10385577B2Efficient use ofConstant and readily controlled clamping pressureRod connectionsForms/shuttering/falseworksEngineeringMechanical engineering

The invention relates to a device for dismountably connecting two intersecting formwork beams, which comprises a single-component elastic structure with two intermediate arms joining together respective areas for pressing the two beams together in support areas, and which can longitudinally slide over one of the beams until it reaches the other beam, the device being elastically deformed by means of pressure or impact thereon, so as to clamp or hold both beams and press them together.

Owner:SISTEMAS TCNICOS DE ENCOFRADOS

Energy absorbing system for absorbing energy of an object in a vehicle in a crash situation

ActiveUS20170021791A1High strengthDecrease acceleration and forceVehicle seatsSupports/holding devicesEngineeringAcceleration Unit

An energy absorbing system that is adapted for absorbing energy of an object in a vehicle in a crash situation by decreasing acceleration and force acting on the object in the crash situation, the energy absorbing system comprising at least one plastically deformable energy absorber that is plastically deformable in the crash situation. A mass-dependent self-adjusting mechanism is provided, the mass-dependent self-adjusting mechanism being adapted for adjusting, on the basis of an underlying mass of the object, a required compensation force that is to be provided by the energy absorbing system in the crash situation for plastically deforming the at least one plastically deformable energy absorber in order to decrease the acceleration and force acting on the object.

Owner:AIRBUS HELICOPTERS DEUT GMBH

Plasma processing apparatus

ActiveUS9805915B2Improve accuracyConstant controlElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceMotor control

In the present invention, there is provided a plasma processing apparatus including a vacuum processing chamber for applying a plasma processing to a sample, a sample stage deployed inside the vacuum processing chamber for mounting the sample thereon, induction antennas provided outside the vacuum processing chamber, a radio-frequency power supply for supplying a radio-frequency power to the induction antennas, and a Faraday shield which is capacitively coupled with the plasma, a radio-frequency voltage being applied to the Faraday shield from the radio-frequency power supply via a matching box, wherein the matching box includes a series LC circuit including a variable capacitor and an inductor, a motor control unit for controlling a motor for the variable capacitor, and a radio-frequency voltage detection unit for detecting the radio-frequency voltage applied to the Faraday shield, the matching box executing a feedback control over the radio-frequency voltage applied to the Faraday shield.

Owner:HITACHI HIGH-TECH CORP

Device for dismountably connecting two intersecting formwork beams

ActiveUS20190284823A1Efficient use ofLittle dependencyRod connectionsForms/shuttering/falseworksEngineeringMechanical engineering

Owner:SISTEMAS TCNICOS DE ENCOFRADOS

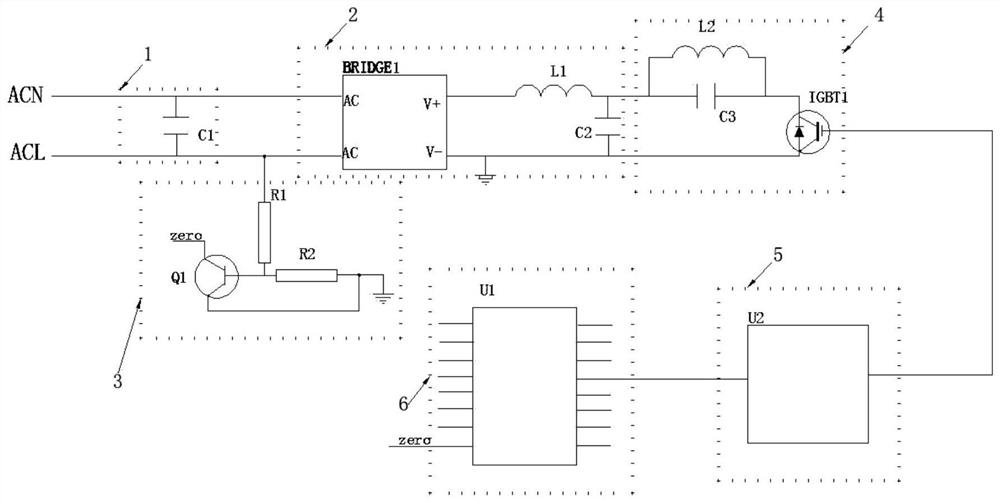

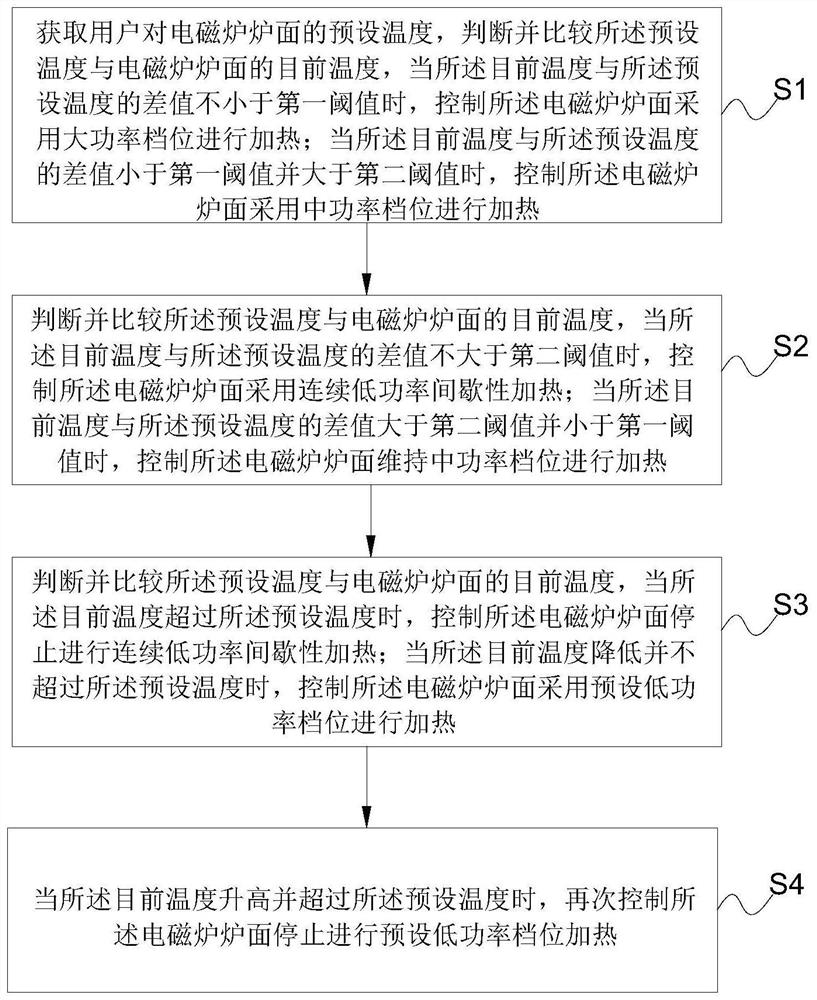

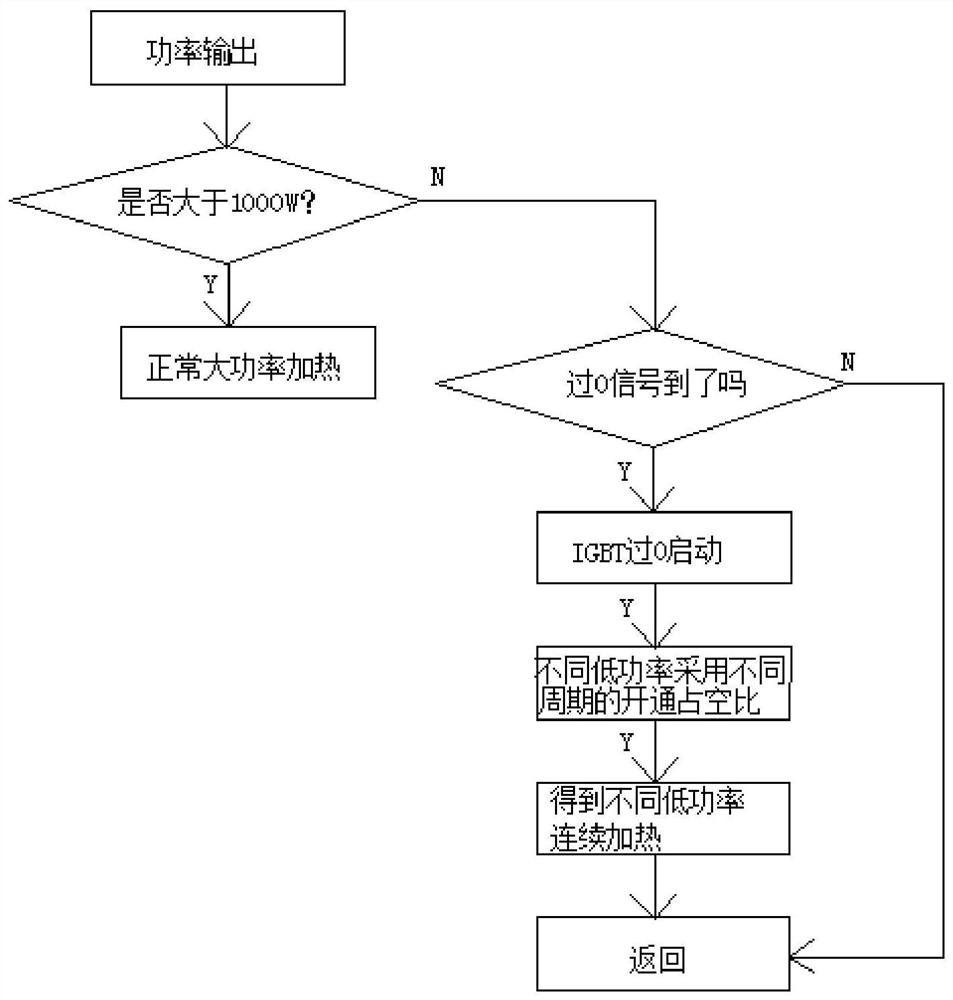

Induction cooker surface temperature control circuit and method

PendingCN112859958AReduce the temperatureReduce lossTemperatue controlTemperature controlHemt circuits

According to the induction cooker surface temperature control circuit and method, a first pin of a triode Q1 in a zero-cross detection circuit is connected with a zero-cross signal receiving pin of a main control chip circuit, a second pin of the triode Q1 is connected with one end of a resistor R2, and a third pin of the triode Q1 is connected with the other end of the resistor R2; one end of the resistor R1 is connected between the third pin of the triode Q1 and the resistor R2, and the zero cross detection circuit is connected between the EMC protection circuit and the rectification filter circuit through the other end of the resistor R1; the preset temperature of the surface of the induction cooker by a user is obtained, the preset temperature and the current temperature of the surface of the induction cooker are judged and compared, and heating control is performed on the temperature in the induction cooker by adopting various power combinations, so that more accurate and more stable temperature is achieved. According to the invention, when power of the induction cooker is relatively low, heating can still be carried out without stopping, so that the temperature of food in a pot can be controlled more accurately and more constantly by utilizing different high and low powers.

Owner:广东顺德锐椒电器有限公司

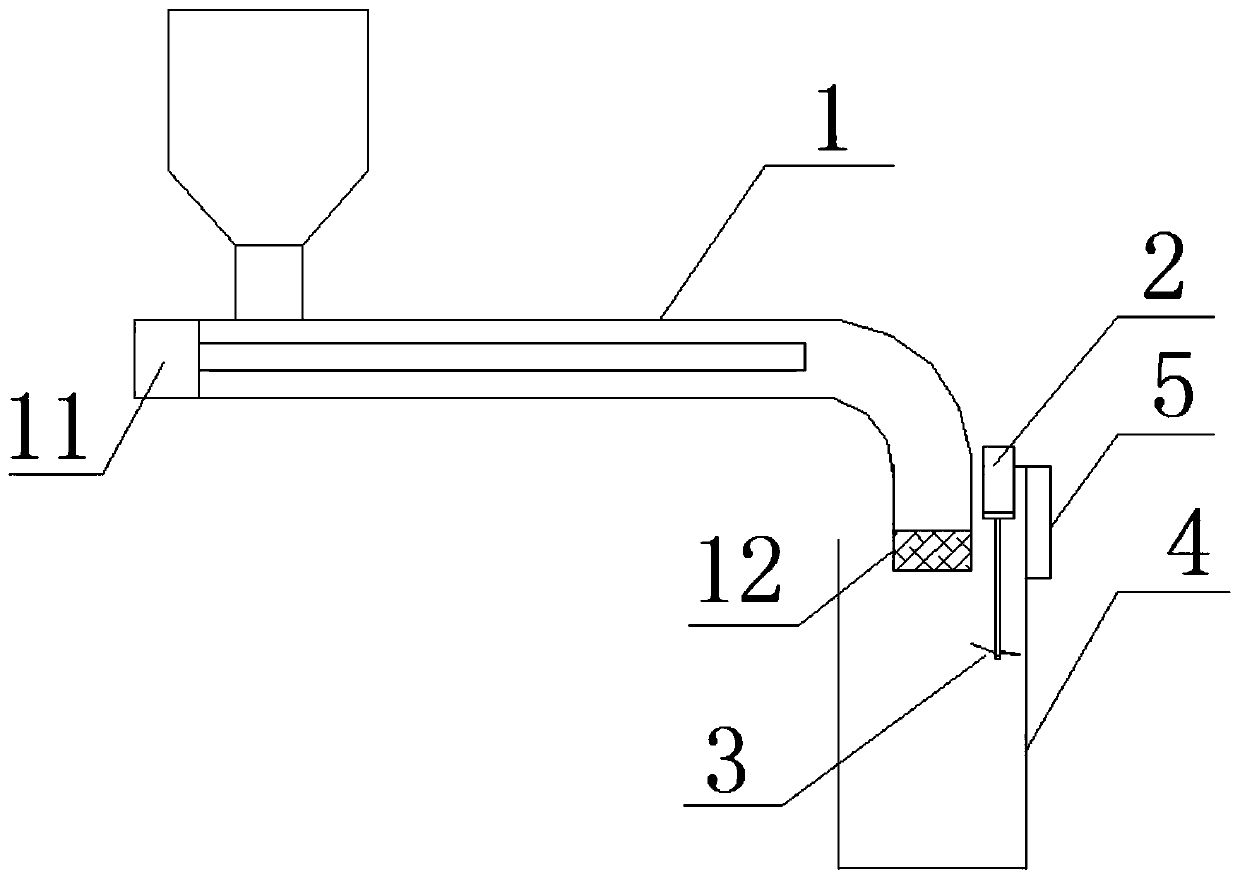

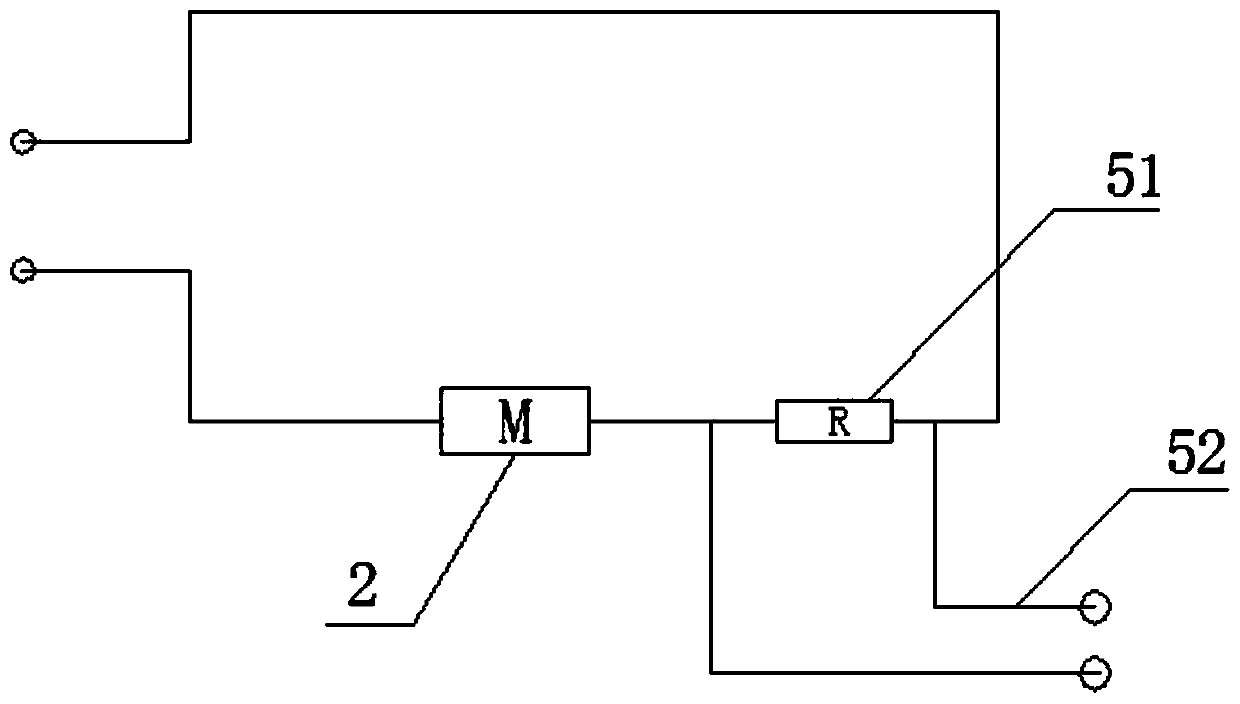

A melt level control device

The invention discloses a melt liquid level control device comprising a small direct-current motor, a material cylinder and an electrical cabinet. Stirring blades are arranged on the lower portion ofthe small direct-current motor and located in the material cylinder, and an adjusting resistor and a frequency converter control signal connector are arranged in the electrical cabinet. The adjustingresistor is electrically connected with the small direct-current motor in series, the frequency converter control signal connector is electrically connected with the adjusting resistor in parallel, and the electrical cabinet is located at the side edge of the small direct-current motor. The melt liquid level control device has the advantages that the small direct-current motor is arranged in the material cylinder, the stirring blades are arranged at the lower end of the material cylinder, a melt in the material cylinder is stirred, the adjusting resistor is electrically connected in series, afrequency converter for controlling an extruding motor of a screw extruder is connected with the adjusting resistor in parallel, the rotating speed of the screw extruder can be adjusted to be matchedwith the liquid level in the material cylinder, namely, the rotating speed is large when the liquid level is low, and the rotating speed is small when the liquid level is high, and thus the liquid level in the material cylinder can be well controlled to be constant for transferring.

Owner:江苏惠沣环保科技有限公司

Dry powder inhaler

ActiveUS10112019B2Improve discharge characteristicImprove discharge characteristicsRespiratorsLiquid surface applicatorsAirflowPharmaceutical formulation

An inhaler for use with a dry powder pharmaceutical formulation, including: a chamber containing the dry powder formulation, a valve disposed in series with the chamber for regulating air flow through the chamber, and a bypass coupled around the combination of the chamber and the valve, where the valve and bypass cooperate for ensuring that the air flow is at least essentially fixed or kept constant or at a minimum accepted or desired or required flow rate through the chamber, and for varying air flow restriction through the inhaler with flow rate, or for keeping the air flow restriction generally constant.

Owner:BOEHRINGER INGELHEIM PHARM KG

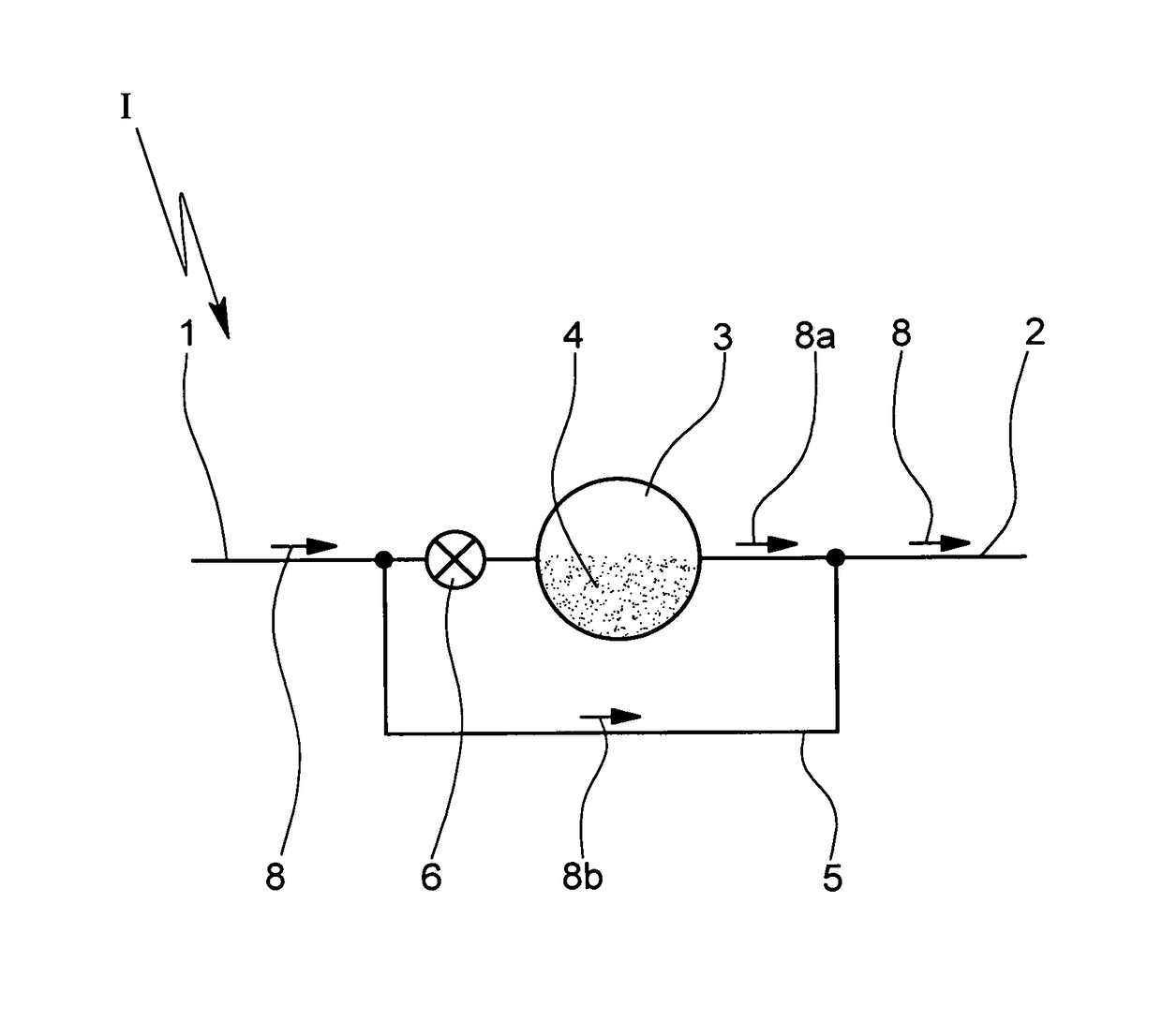

Constant flow device, water outlet terminal, bubbler and adapter

PendingCN114233908AHigh sensitivityConstant flow controlDomestic plumbingSpray nozzlesStream flowWater flow

The invention discloses a galvanostat, a water outlet terminal, a bubbler and an adapter, the galvanostat comprises a shell and an elastic ring, a water flow cavity, a water inlet and a water outlet are formed in the shell, the water inlet and the water outlet are communicated with the water flow cavity, and the elastic ring is arranged at the end, where the water outlet is located, of the water flow cavity; the elastic ring is located on the periphery of the water outlet. The device further comprises a movable part which is movably arranged in the water flow cavity, the movable part is provided with a plurality of extrusion parts which face the elastic ring and are distributed in the circumferential direction of the elastic ring at intervals, and when water enters the water inlet, the movable part is driven by water pressure to move towards the side where the elastic ring is located. Each extrusion part is close to or in contact with or extrudes the elastic ring, and a water passing gap communicated with the water flow cavity and the water outlet is formed between every two adjacent extrusion parts. The movable part is arranged, the area of the pressed face of the movable part is easily larger than that of the pressed face of the elastic ring, and therefore the high-sensitivity flow control valve is high in sensitivity and constant in flow control.

Owner:厦门市点水科技有限公司

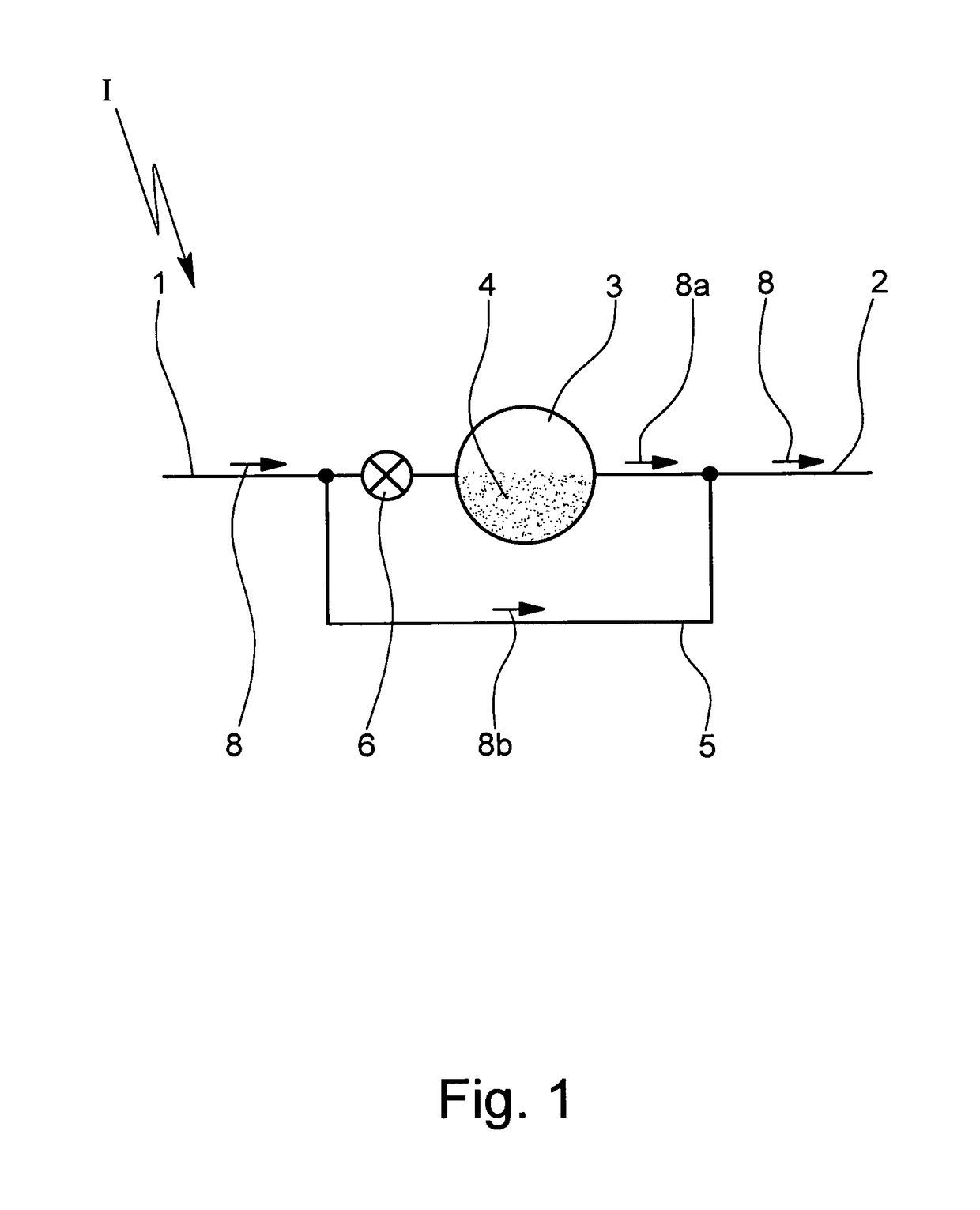

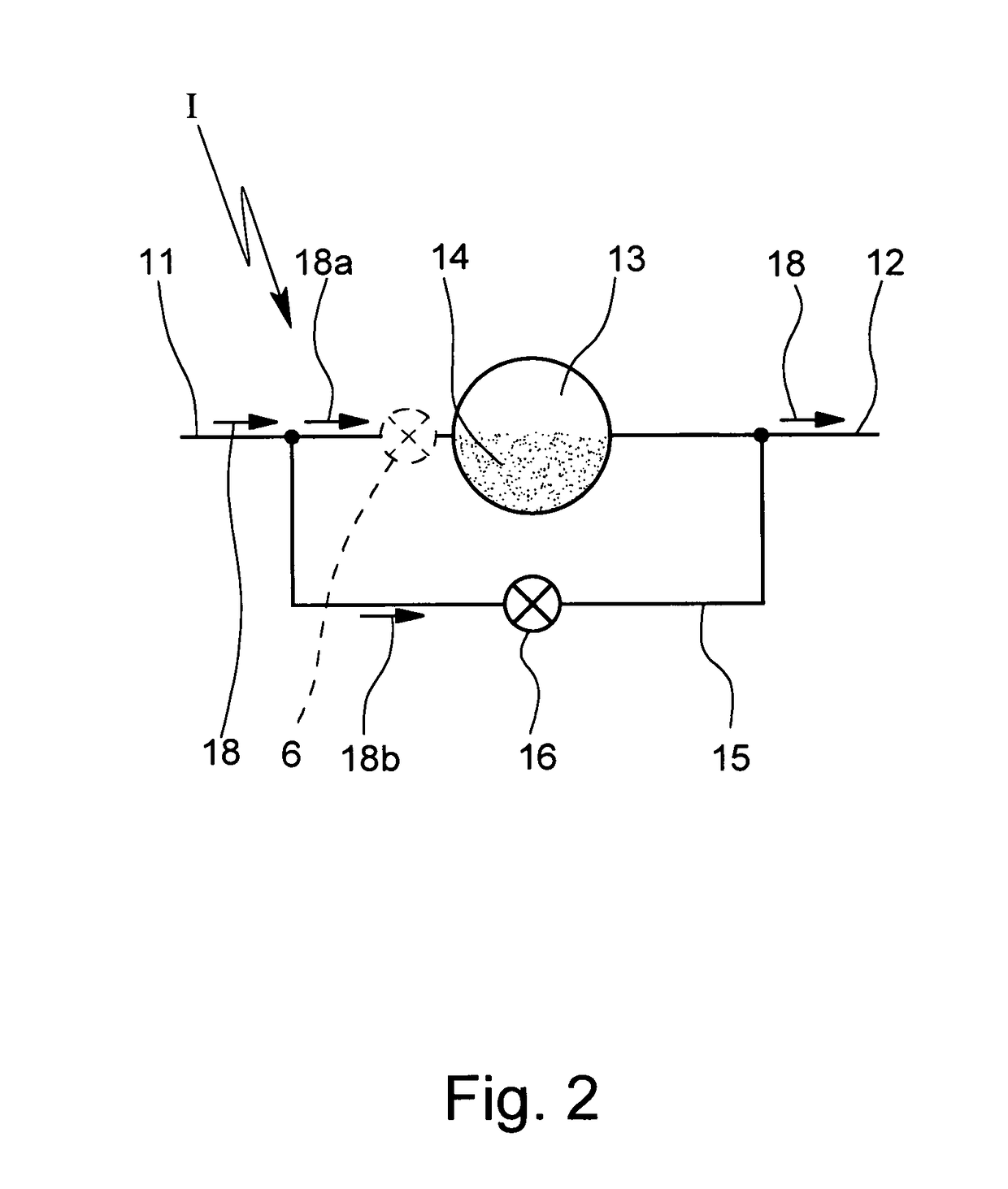

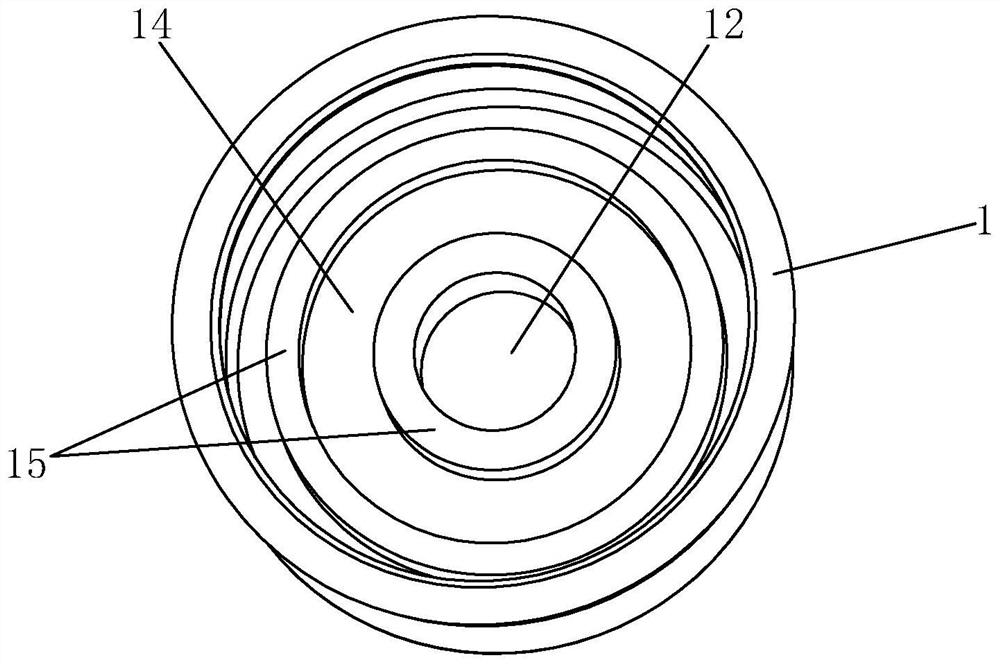

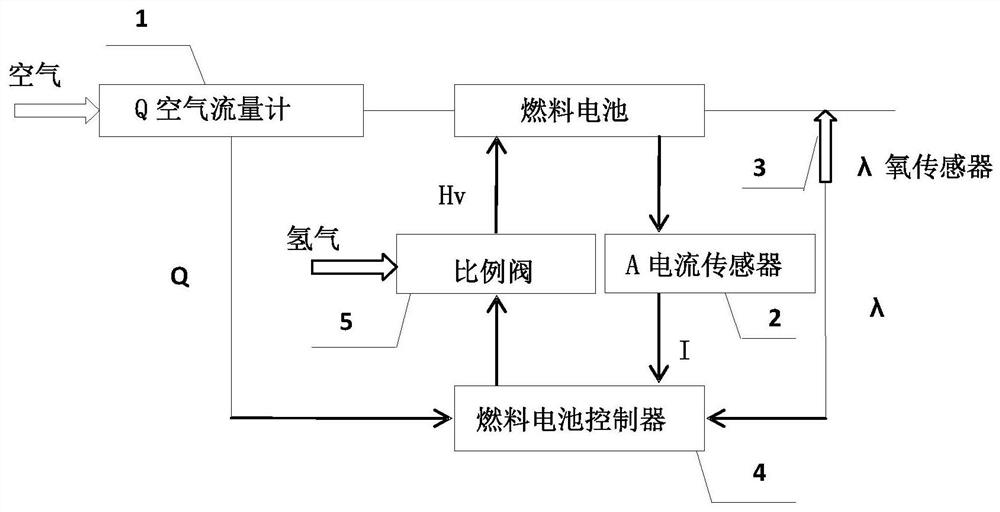

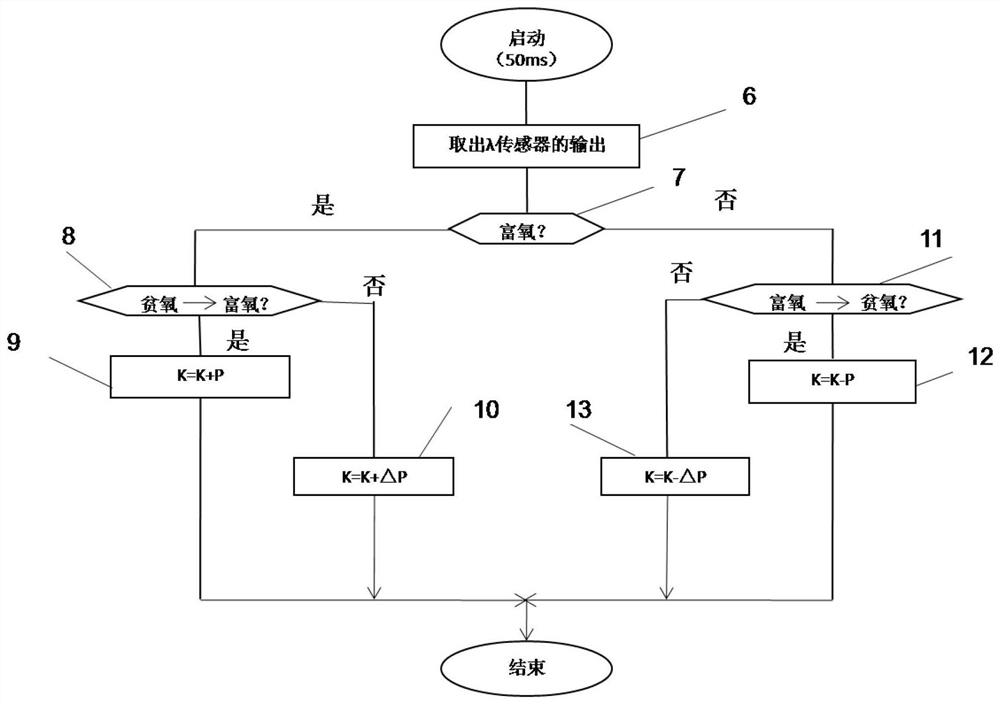

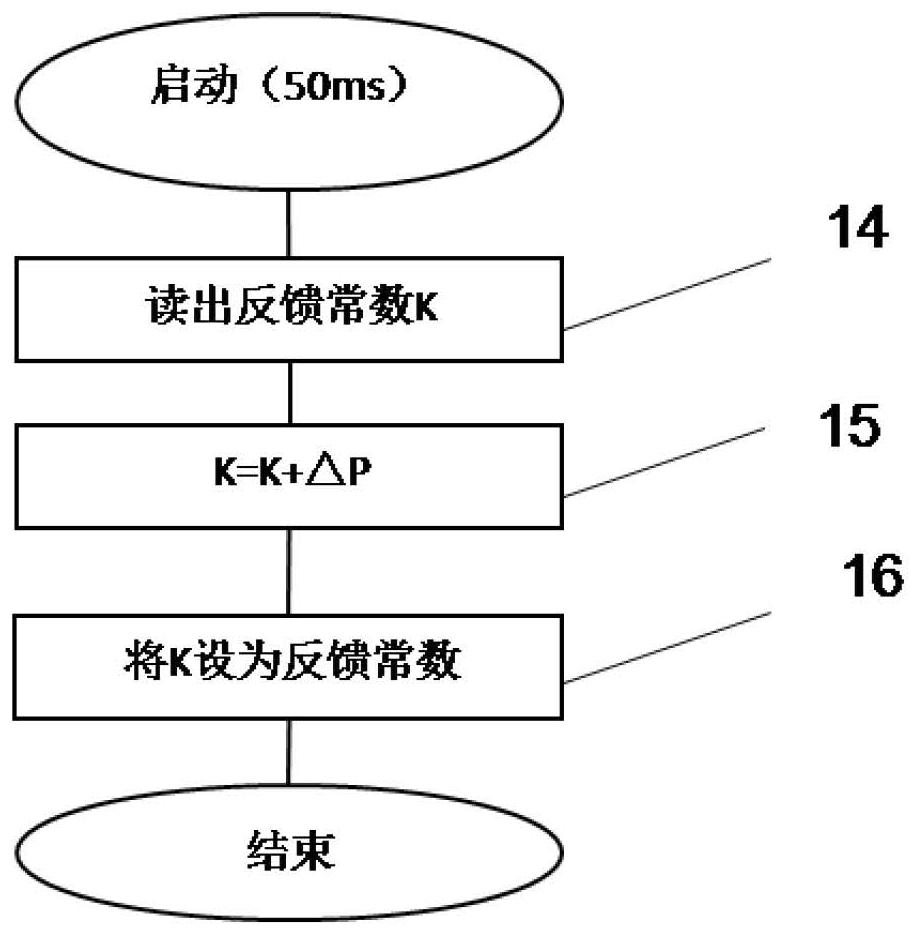

A fuel cell air excess ratio control method and system

ActiveCN110021767BHigh sensitivityEasy to transfer toFuel cell controlCurrent transducerThermodynamics

The invention relates to a fuel cell air excess ratio control method and system. The method comprises the steps of measuring the oxygen concentration of tail gas of an air system in real time; calculating a feedback constant K when a hydrogen intake amount is subjected to PID control according to a difference value between an oxygen concentration measurement value and an oxygen concentration reference value; and judging an oxygen-containing state of the tail gas of the current air system, and according to the change of the oxygen-containing state at the current moment and the previous moment,adding or subtracting different ratio values to or from the feedback constant K to obtain a new feedback constant for calculating the hydrogen intake amount. The system comprises a fuel cell controller, and an air flowmeter, an oxygen concentration sensor, a current sensor and a hydrogen regulating valve connected with the fuel cell controller. The method and the system can effectively improve thecontrol sensitivity, and an air excess ratio is smoothly changed through feedback control of the feedback constant, so that the air excess ratio and a fuel cell current can be conveniently adjusted to be in a matched state, and constant control can be achieved.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com