Offenend-spinnmaschine

A spinning machine and free-end technology, applied in the field of free-end spinning machines, can solve the problems that the bobbin diameter cannot be taken into account, and the operating parameters cannot be adjusted separately.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

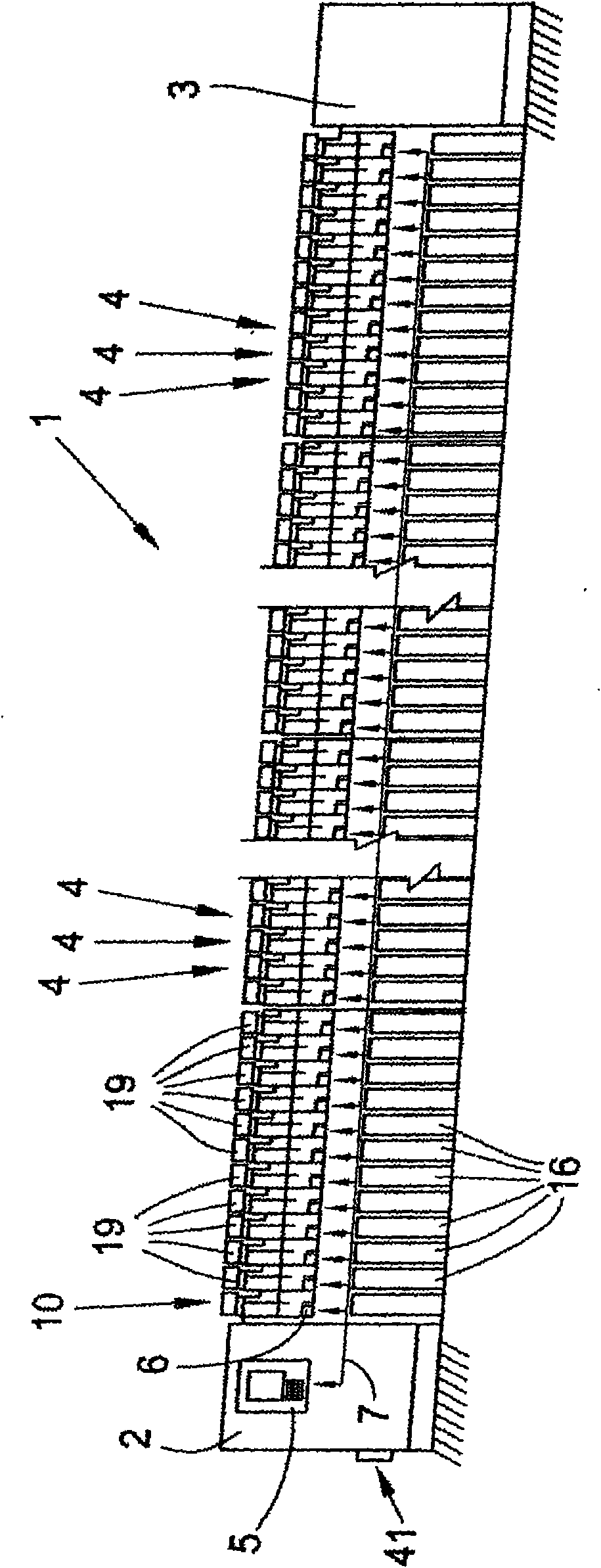

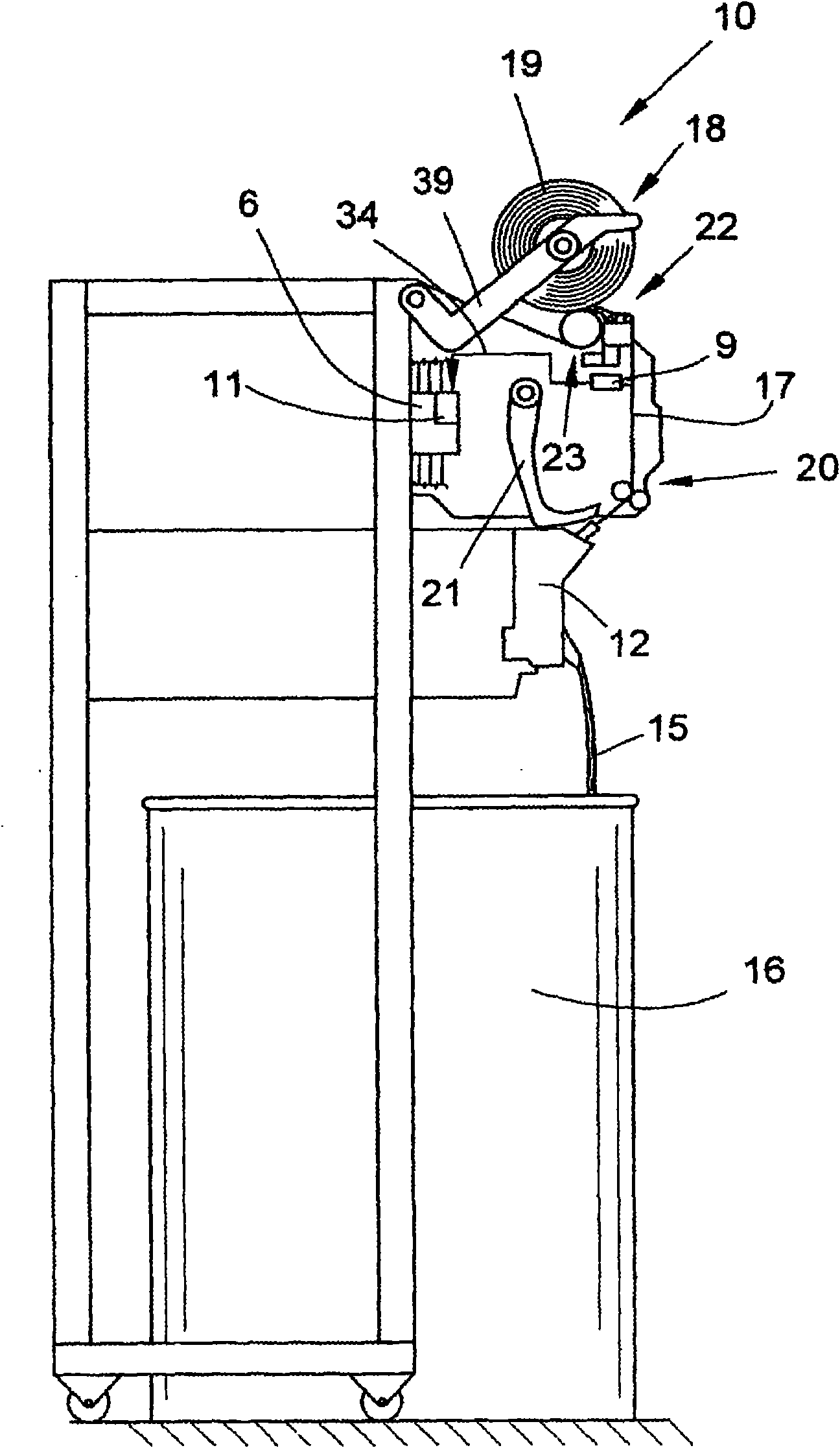

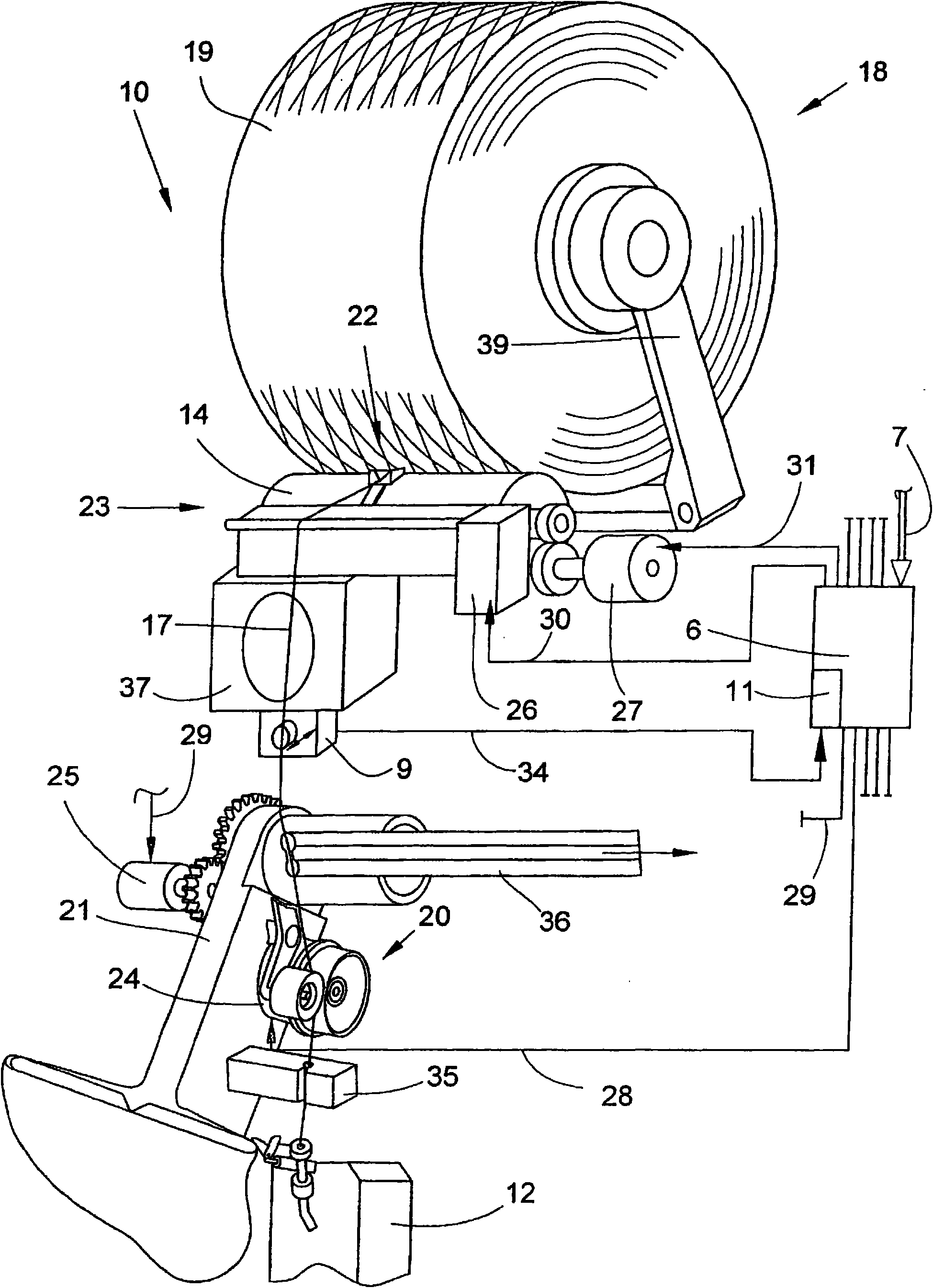

[0022] figure 1 An open-end rotor spinning machine 1 is schematically shown in front view with so-called end frames 2, 3, which are connected by a plurality of continuous access channels as known and therefore not further illustrated , the access channel is, for example, a negative pressure channel for supplying spinning negative pressure to the spinning device, an electrical channel of a yarn monitoring device and / or a bus system, and a cable channel for supplying power to a plurality of workstations 4 . These access channels are to a certain extent the "backbone" of the textile machine, on which the yarn forming devices or cross-winding devices of the textile machine 1 can be placed, said yarn forming devices or cross-winding devices forming multiple Common station 4 and a pilot station 10. For example, the vacuum supply of the textile machine (not shown) itself, the electrical energy supply and the central control unit 5 of the textile machine 1 are arranged on the end fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com