Falling film type evaporator

A falling-film evaporator and heat exchanger technology, which is applied to evaporators/condensers, refrigeration components, refrigerators, etc., can solve the problem that the overall heat transfer performance of falling-film evaporators is reduced, easy to evaporate incompletely, and the lower liquid The problem of uneven spraying can improve the anti-tilt, complete evaporation and improve the utilization of space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

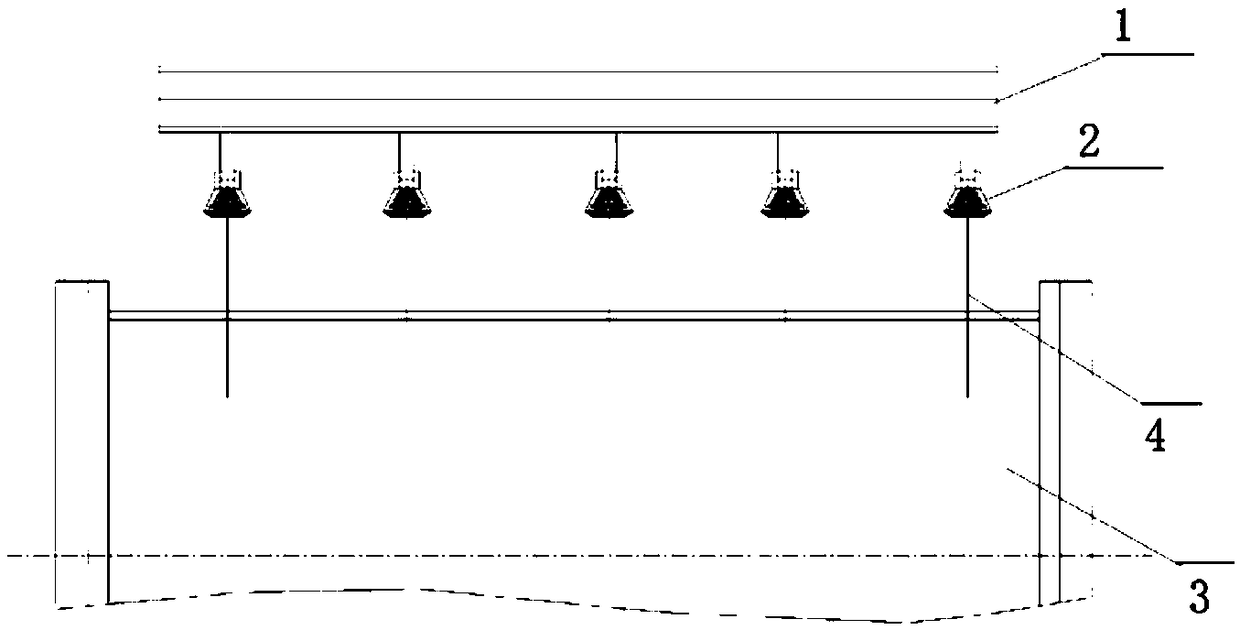

[0024] Embodiment 1: as figure 1 As shown, the falling film evaporator of the present invention includes a liquid separation main pipe 1, a plurality of distributors 2 communicated with the liquid separation main pipe 1, a heat exchanger 3, and a distribution pipe connecting the distributor 2 and the heat exchanger 3. The top of the liquid pipe 4 and the heat exchanger 3 is provided with a support plate 38 for fixing the liquid pipe 4 . In this embodiment, the distance between the liquid distribution pipe 4 and the upper end of the heat exchanger 3 is not greater than 20 mm, and the distance between adjacent distributors 2 is not greater than 256 mm.

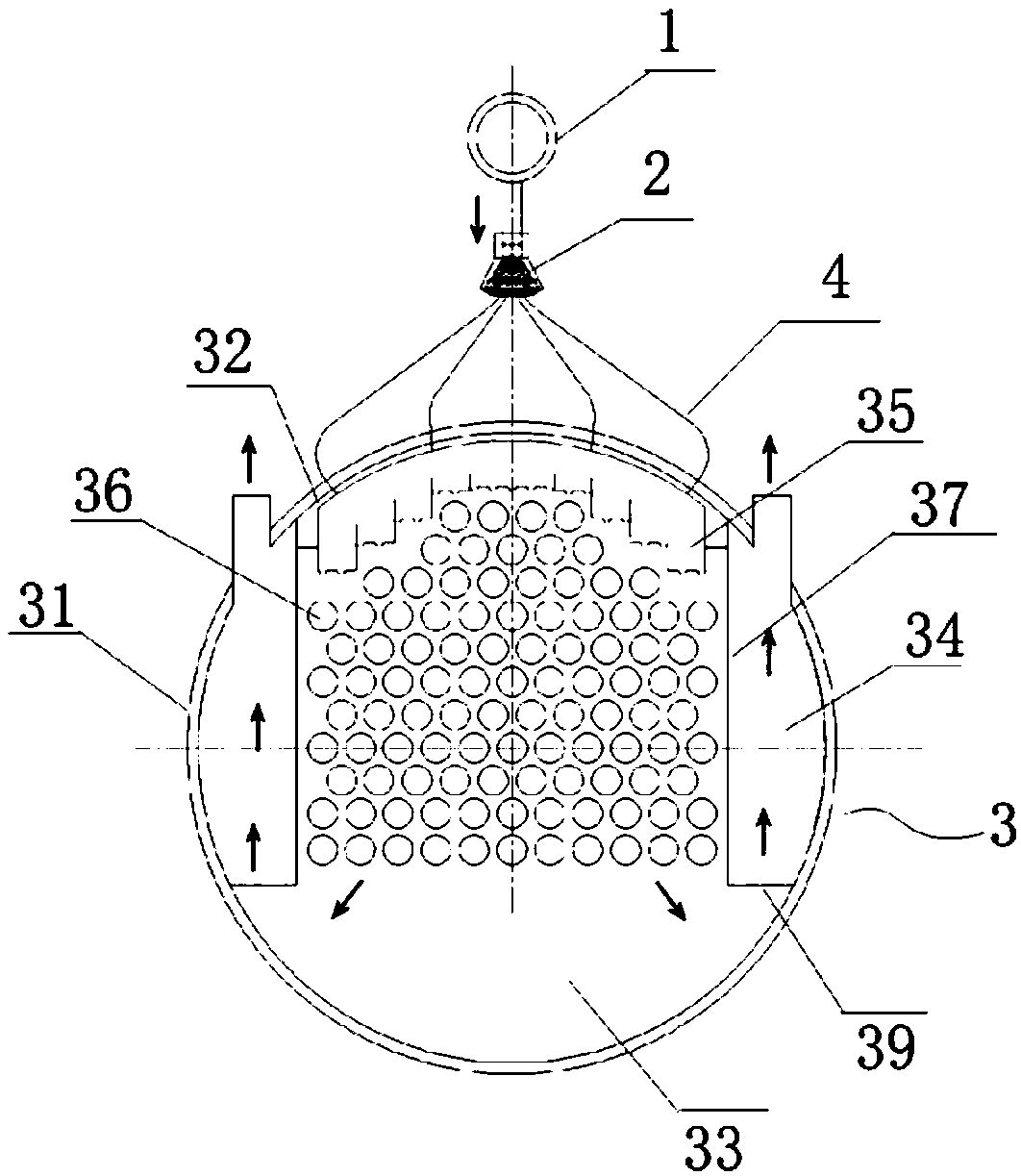

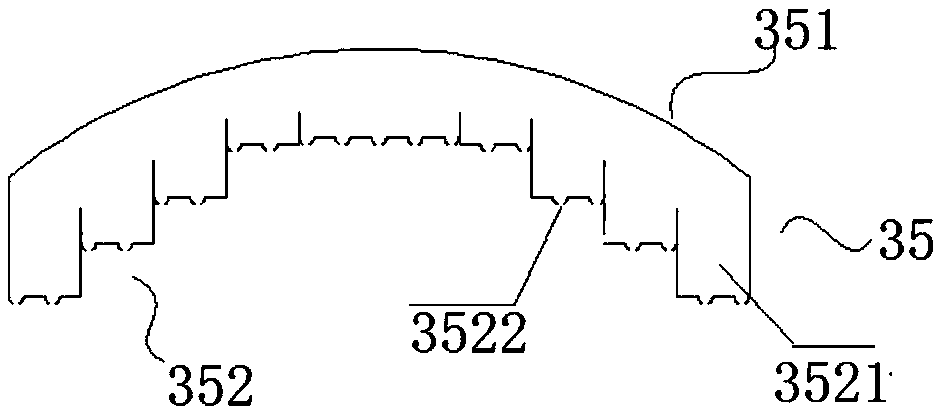

[0025] Such as figure 2 As shown, the heat exchanger 3 includes a housing 31, a liquid inlet chamber 32 located inside the housing 31, a heat exchange chamber 33 communicated with the liquid inlet chamber 32, and an air outlet chamber 34 communicated with the heat exchange chamber 33; the heat exchange chamber 33 Located at t...

Embodiment 2

[0029] Embodiment 2: as Figure 5 As shown, the cylinder of the heat exchanger 3 is square. Compared with the cylindrical cylinder of the heat exchanger 3 in Embodiment 1, the cylinder of the heat exchanger is square, which can increase the available area of the cylinder and make it modular. Splicing, small footprint, the cylinder size of the evaporator can be designed according to the site, strong applicability.

[0030] In the present invention, the distribution of the original falling film evaporator liquid equalizing plate is changed to the form of a liquid separator, which can reduce the diameter of the cylinder and reduce the cost of the unit. The cooling capacity of the unit is high, and the control precision is high. The arc-shaped equalizing plate in the evaporator makes the contact between the heat exchange tube and the liquid more uniform, provides the evaporation capacity of the liquid, and increases the heat exchange efficiency of the container.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com