A kind of preparation method of 3',6'-dimethoxyfluoran yellow thermosensitive dye

A technology of dimethoxyfluoran and heat-sensitive dyes, which is applied in the field of preparation of 3',6'-dimethoxyfluoran yellow heat-sensitive dyes, and can solve the problems of inability to discharge, high energy consumption and product yield. Low problems, to achieve the effect of improving yield, low reaction temperature, and improving reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

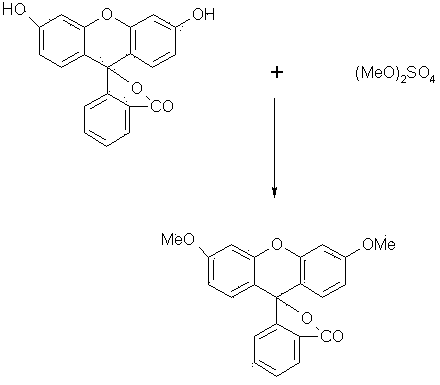

Image

Examples

Embodiment 1

[0020] In a 500 ml three-necked flask, add 16.64 grams of fluorescein with a content of 90%, 2 grams of polyethylene glycol-400 and 150 ml of toluene, start stirring, and stir at room temperature for 0.5 hours; add 8 g of sodium hydroxide under stirring, Stir and disperse at room temperature for 1 hour; then heat up to 60°C, add 19.9g of dimethyl sulfate dropwise in 0.5 hours, and keep warm for 4.0 hours; add 70ml of water and continue to react at 60°C for 0.5 hours; stand still, Separate the solvent layer, concentrate under reduced pressure and reclaim toluene to dryness, add 50 milliliters of methanol to disperse, filter and dry 14 grams of crude product; the crude product is subjected to column separation, the column packing is chromatographic neutral alumina, and the mobile phase is acetone and The mixed solution of chloroform (1:5), the first color band material was collected as the product, concentrated, filtered, and dried to obtain 12.5 grams of white product, the total...

Embodiment 2

[0022] In a 500 ml three-necked flask, add 16.64 g of fluorescein with a content of 90%, 1 g of tetrabutylammonium bromide and 150 ml of ethylbenzene, start stirring, and stir at room temperature for 0.75 hours; add 11.2 g of potassium hydroxide under stirring, and Stir and disperse for 0.5 hours; then heat up to 85°C, add 22.7g of dimethyl sulfate dropwise in 1.0 hour, and keep warm for 3.0 hours; add 60 ml of water and react at 85°C for 0.5 hours, separate the solvent layer, reduce Concentrate under pressure and recover ethylbenzene to dryness, add 50 milliliters of methanol to disperse, filter and dry 13.9 grams of crude product; the crude product is subjected to column separation, the column packing is chromatographic neutral alumina, and the mobile phase is a mixture of acetone and chloroform ( 1:7), the first color band material was collected as the product, concentrated, filtered, and dried to obtain 12.6 grams of white product, the total yield was 77.6%, and the liquid ...

Embodiment 3

[0024] In a 500ml three-necked flask, add 16.64g of fluorescein with a content of 90%, 1g of tetrabutylammonium bromide and 150ml of methyl ethyl benzene, start stirring, and stir at room temperature for 1 hour; add 13.8 potassium carbonate while stirring, stir and disperse at room temperature 0.85 hours; then heat up to 90°C, add 20g of dimethyl sulfate dropwise in 0.75 hours, and keep warm for 3.5 hours; add 85ml of water and react at 90°C for 1 hour; separate the solvent layer, concentrate and recover under reduced pressure Ethylbenzene to dryness, add 50 milliliters of methanol to disperse, filter, dry thick product 14.1 grams; Thick product carries out column separation, and column packing is chromatographic neutral alumina, and mobile phase is the mixed solution of acetone and chloroform (1:9 ), collect the first color band material as the product, concentrate, filter and dry to obtain 12.9 grams of white product, the total yield is 79.4%, and the product liquid color con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com