Water-pressure separation type methane-generating tank

A separate, biogas digester technology, applied in the field of biogas digesters, can solve the problems of difficulty in discharging solids and low utilization rate of raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

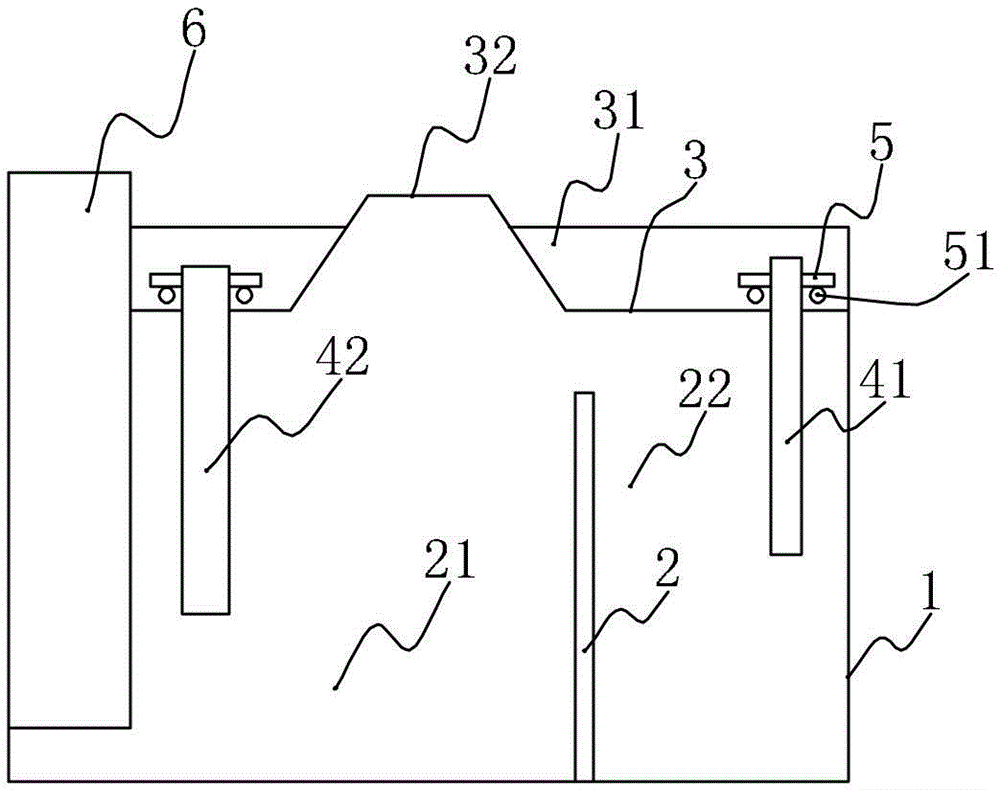

[0015] Such as figure 1 As shown, the hydraulic separation biogas digester of the present invention includes a pond body 1 , and a vertical baffle 2 is arranged at the bottom of the pond body 1 . The baffle 2 divides the bottom area of the cell 1 into two separate parts. Among them, the two independent parts are divided into two areas, one large and one small. The larger area is the solid area 21 and the smaller area is the liquid area 22 . Wherein, a cover plate 3 is provided on the top of the pool body 1, and a hydraulic pool 31 is provided on the cover plate 3, and a biogas port 32 is provided in the middle of the cover plate 3. In addition, a liquid inlet pipe 41 is inserted in the liquid area 22 , and the upper end of the liquid inlet pipe 41 is located in the water pressure pool 31 . A slag feeding pipe 42 is inserted in the solid area 21 , and the upper end of the slag feeding pipe 42 is also located in the hydraulic pool 31 . Moreover, the diameter of the slag fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com