Straw mixed raw material fermentation charging and discharging blocking resisting method

A technology of mixing raw materials, feeding and discharging materials, applied to biological sludge treatment, gas production bioreactors, etc., to achieve the effects of increasing CODcr concentration, reducing the probability of feed blockage, and good reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

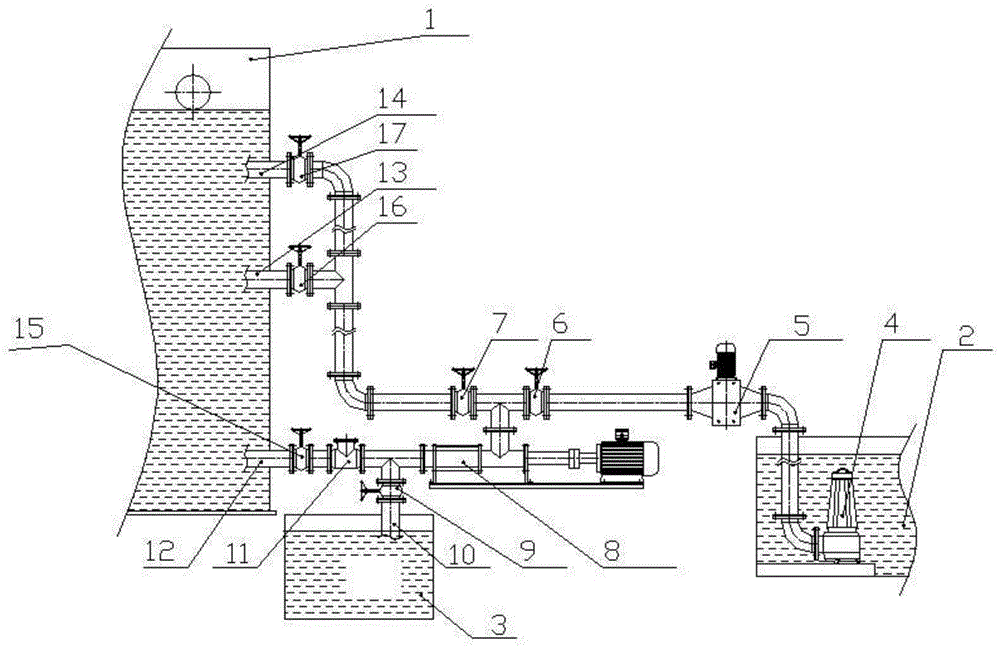

[0026] Such as figure 1 As shown, the forced discharge system of the present invention consists of a fermenter 1, a feed tank 2, a discharge tank 3, a cutting pump 4, a pipe crusher 5, a first gate valve 6, a second gate valve 7, and a screw feed pump 8 , third gate valve 9, slag discharge pipe 10, check valve 11, feed pipe 12, lower discharge pipe 13, upper discharge pipe 14, fourth gate valve 15, fifth gate valve 16, sixth gate valve 17 and pipelines .

[0027] Described fermentation tank 1 is anaerobic fermentation tank, and its upper end is provided with overflow port, and the bottom of fermentation tank 1 is provided with slag discharge pipe (not drawn in the figure), and its lower part is provided with feeding pipe 12, and middle part is provided with bottom pipe. The discharge pipe 13 is provided with an upper discharge pipe 14 on the top.

[0028] The feed pool 2 is equipped with a cutting pump 4, the discharge port of the cutting pump 4 communicates with the feed po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com