Straw anaerobic fermentation system and method

An anaerobic fermentation and straw technology, applied in fermentation, biochemical equipment and methods, bioreactor/fermenter combination, etc., can solve the problems of acidification, unrealistic large-scale biogas projects, etc., to increase contact and improve raw material processing. amount of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

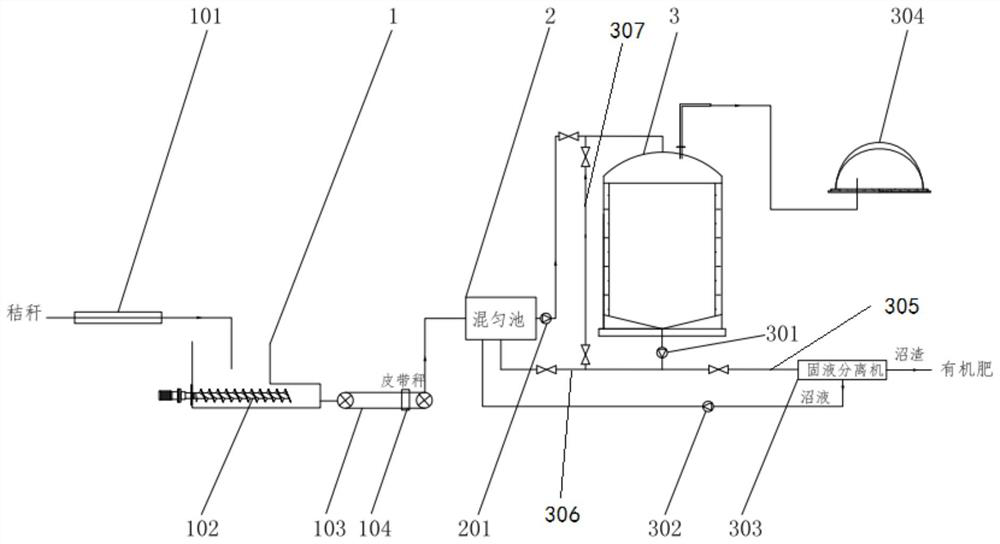

[0042] Embodiment 1 of the present invention is a straw anaerobic fermentation system, comprising a straw feeding mechanism 1, a mixed feeding mechanism, a fermentation tank 3, a circulation mechanism, a gas storage membrane 304 and a reflux mechanism;

[0043]The straw feeding mechanism is used to transfer the crushed straw to the mixing feeding mechanism, and the downstream of the straw feeding mechanism is connected to the mixing feeding mechanism;

[0044] The mixing and feeding mechanism includes a mixing tank 2 and a lifting pump 201. The mixing tank 2 is used to mix the straw with the recirculated biogas slurry; the downstream of the mixing tank 2 is connected to the fermentation tank 3 through the lifting pump 201;

[0045] The fermenter 3 is connected with a circulation mechanism so that the material at the bottom of the fermenter 3 circulates and enters the fermenter 3 from the top of the fermenter 3. The fermenter 3 communicates with the gas storage membrane 304, the...

Embodiment 2

[0056] A straw anaerobic fermentation process adopts a straw anaerobic fermentation system disclosed in Example 1, specifically comprising the following steps:

[0057] (1) Pretreatment: The straw is first crushed in a pulverizer to a length of 2cm to 10cm. After crushing, it is placed in a ventilated and dry place for drying treatment, and then transported to the mixing tank through the straw feeding mechanism at a uniform speed, and processed with the biogas slurry produced after fermentation. Mixing ingredients, controlling the feeding speed of the straw feeding mechanism and the discharging speed of the mixing tank so that the dry matter content of the obtained mixed material is 8-10%;

[0058] (2) Feeding: The mixed material in the mixing tank is fed to the feeding port on the top of the fermentation tank through the lifting pump, and the feeding port is switched according to the feeding situation to achieve the purpose of uniform distribution;

[0059] (3) Anaerobic ferm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com