Patents

Literature

35results about How to "Fast mold closing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

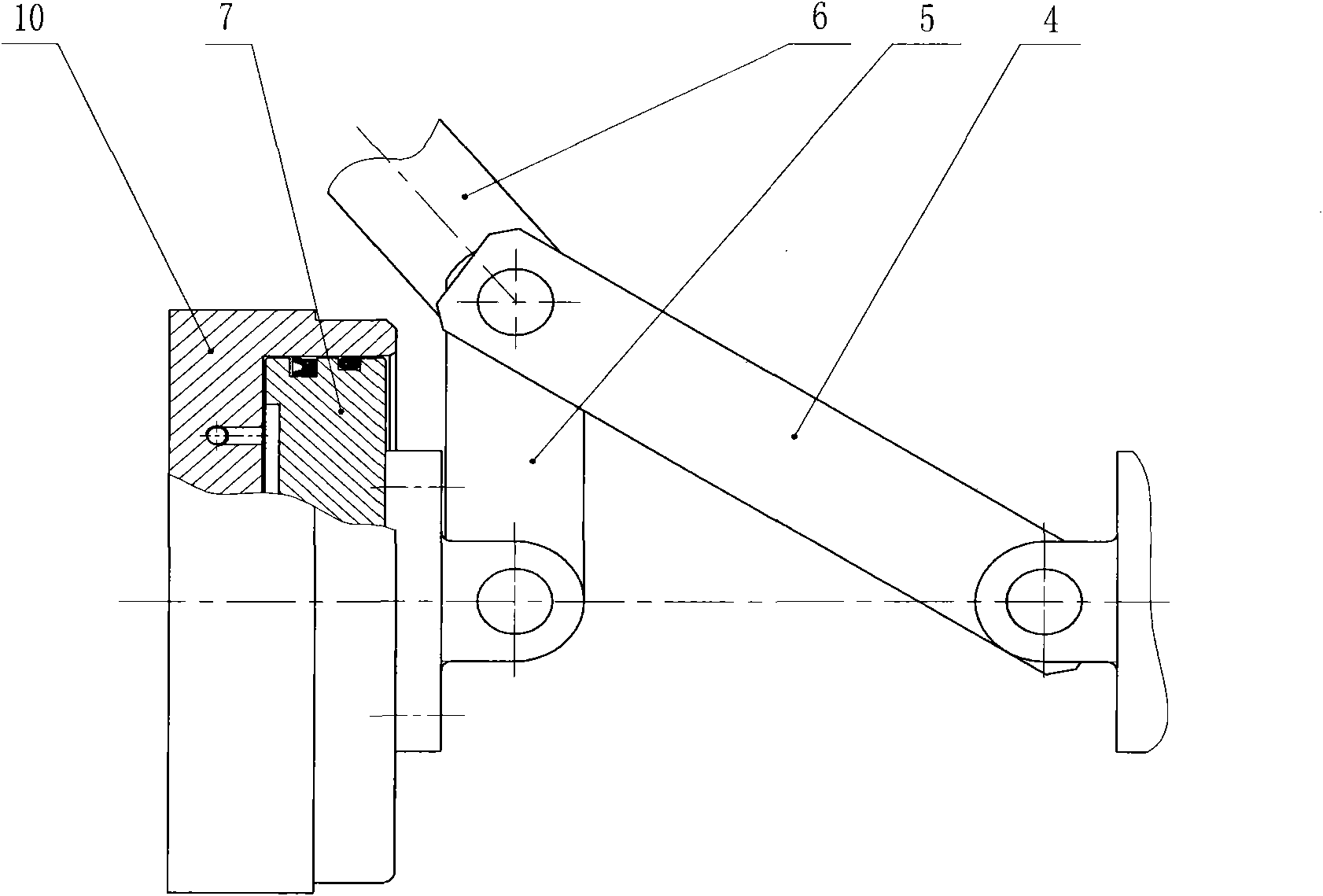

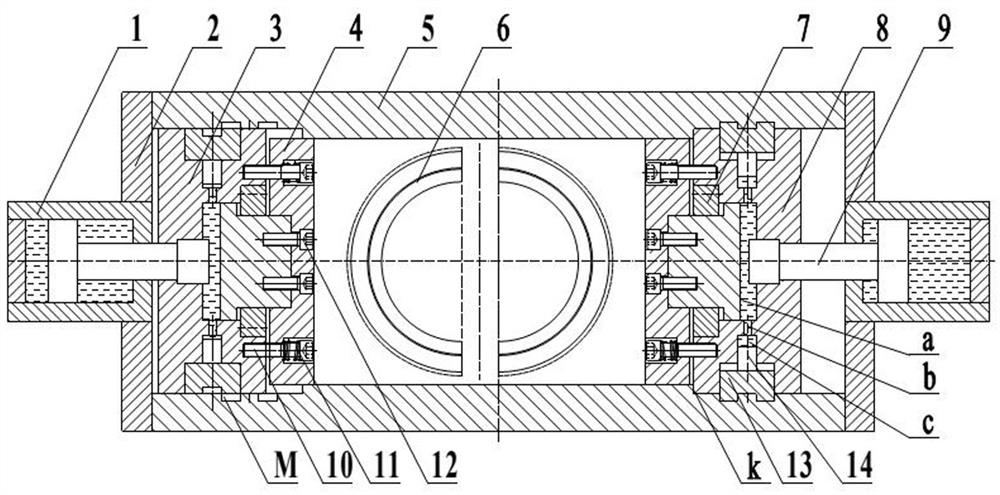

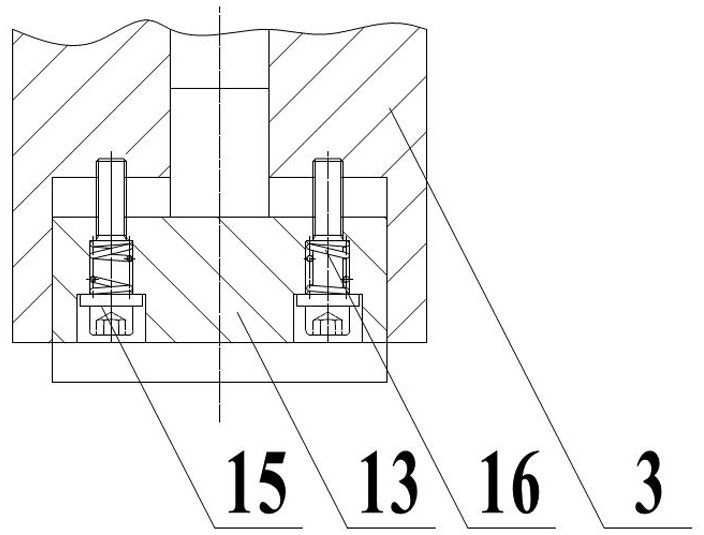

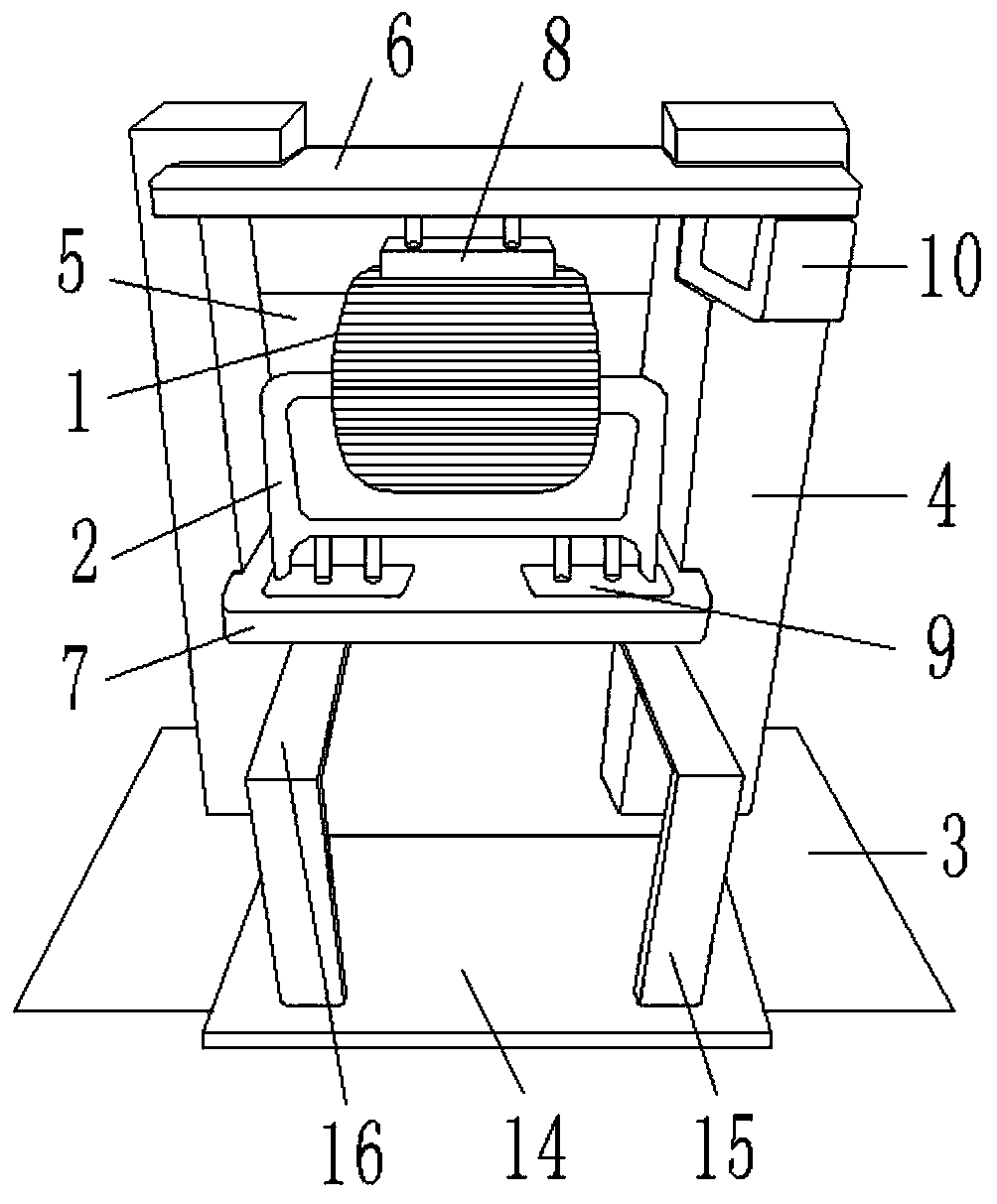

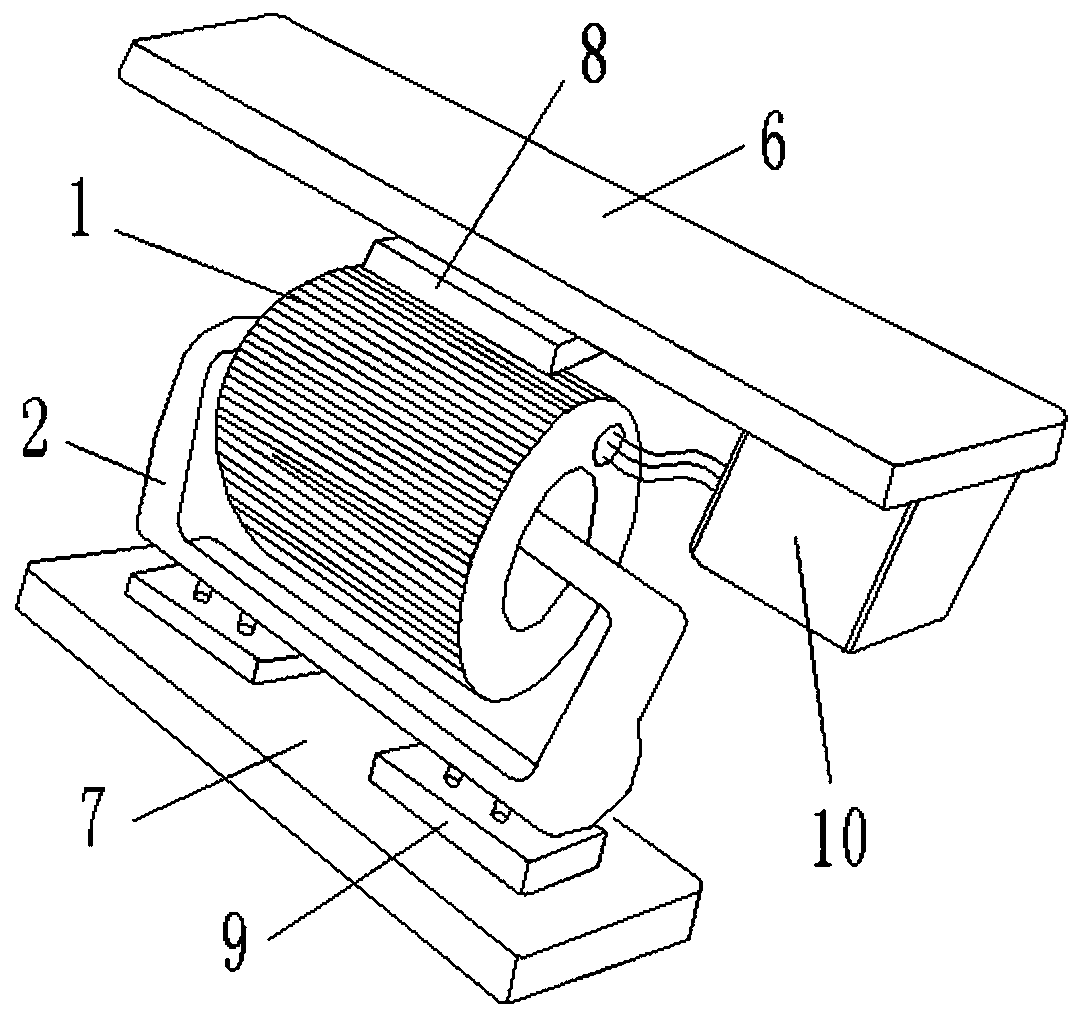

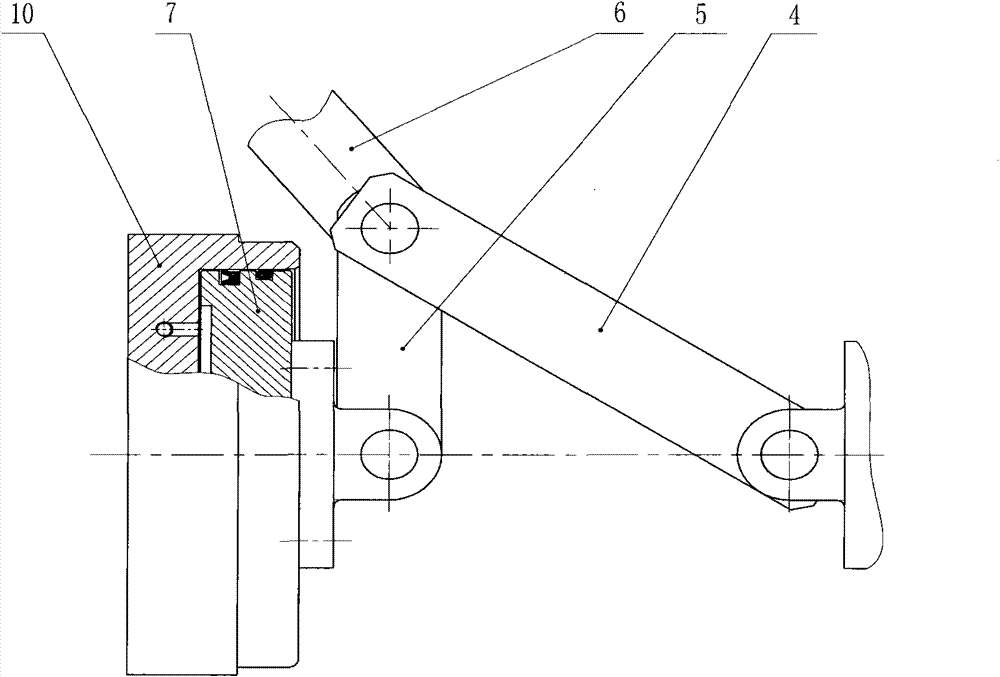

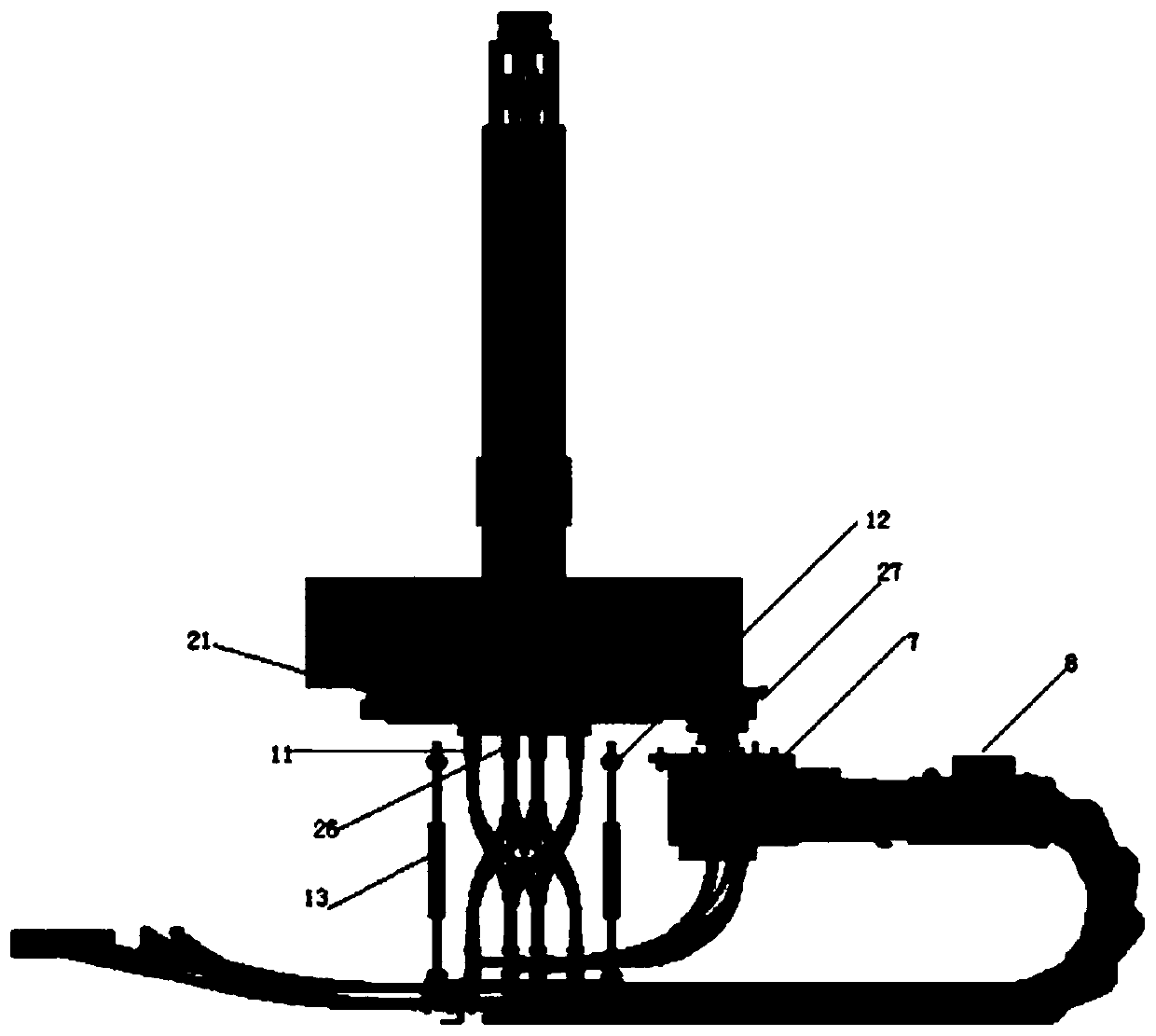

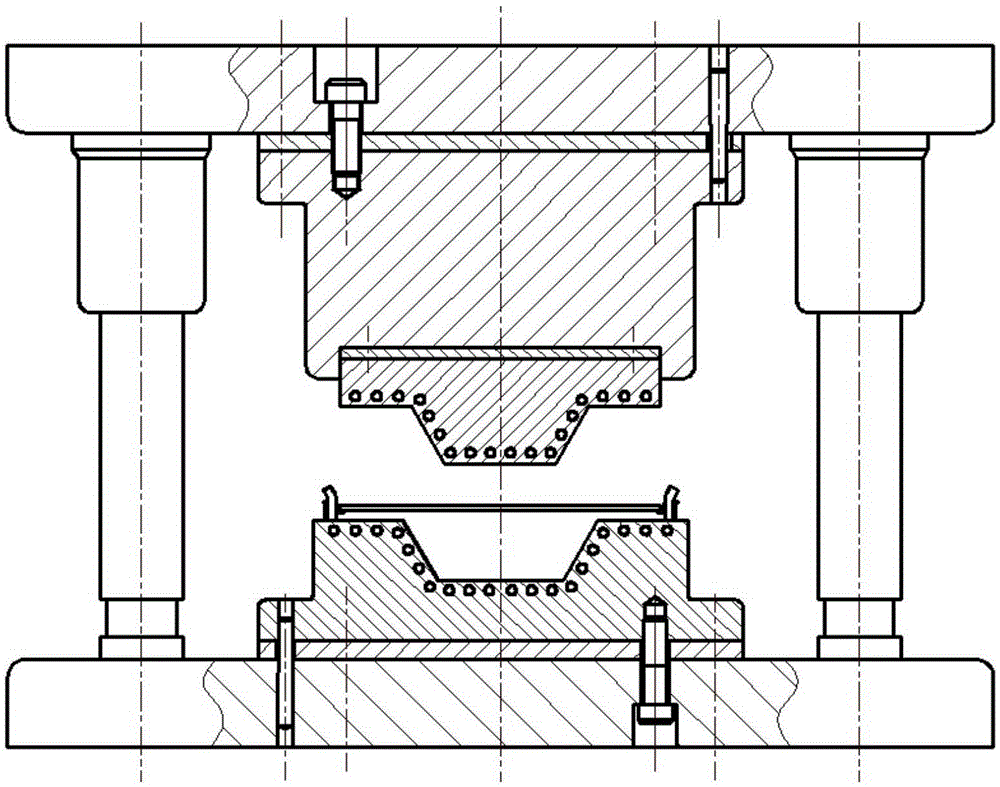

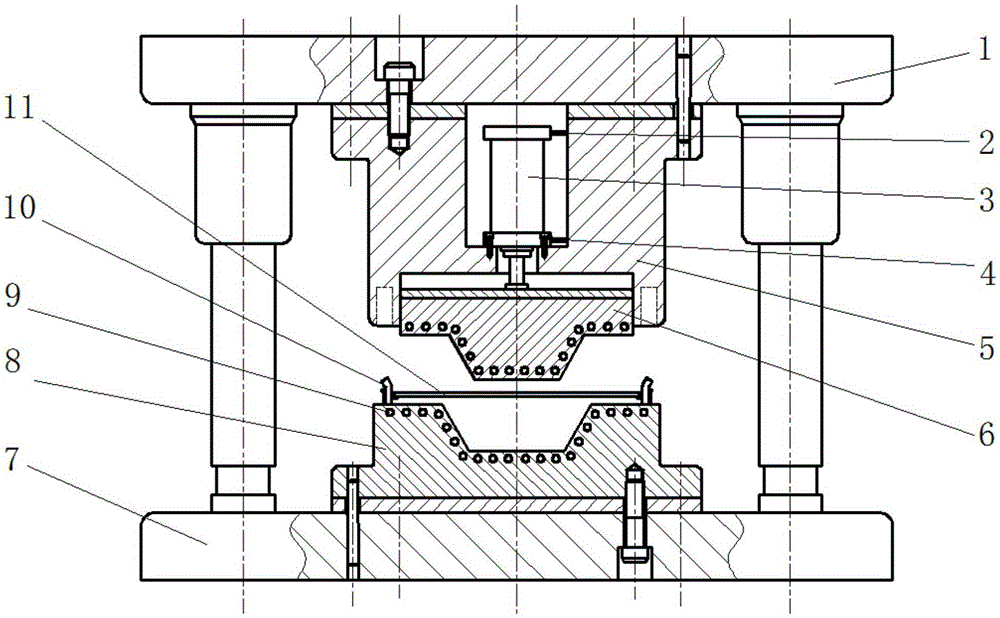

Super-strength steel hot stamping die capable of carrying out rapid spotting through gas assistance

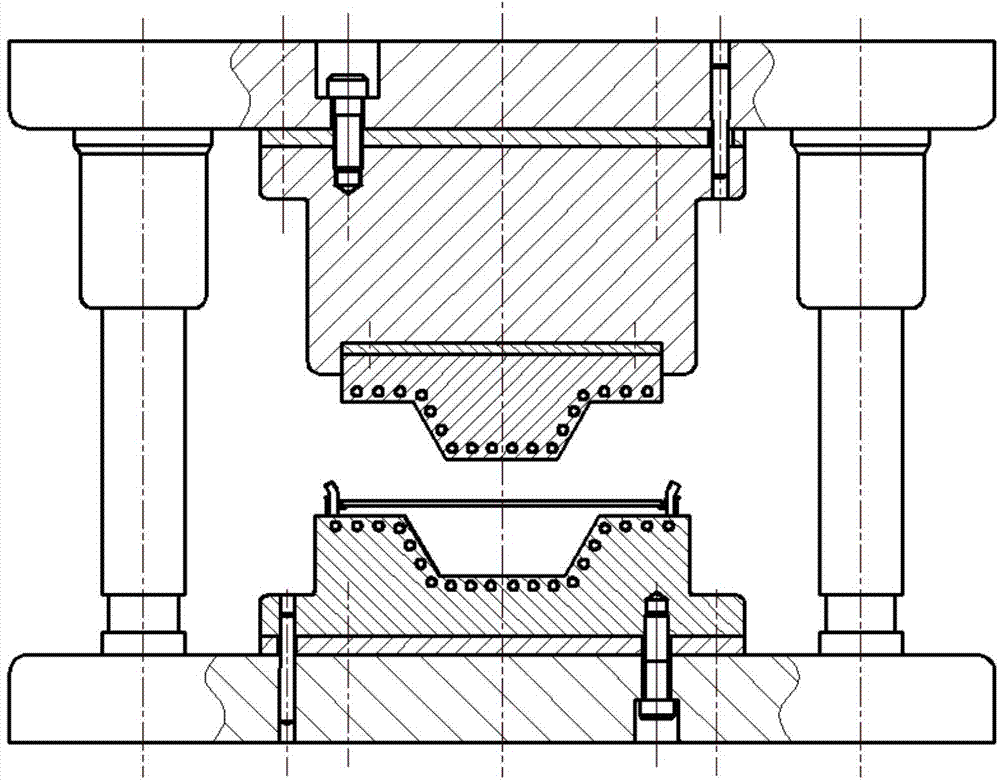

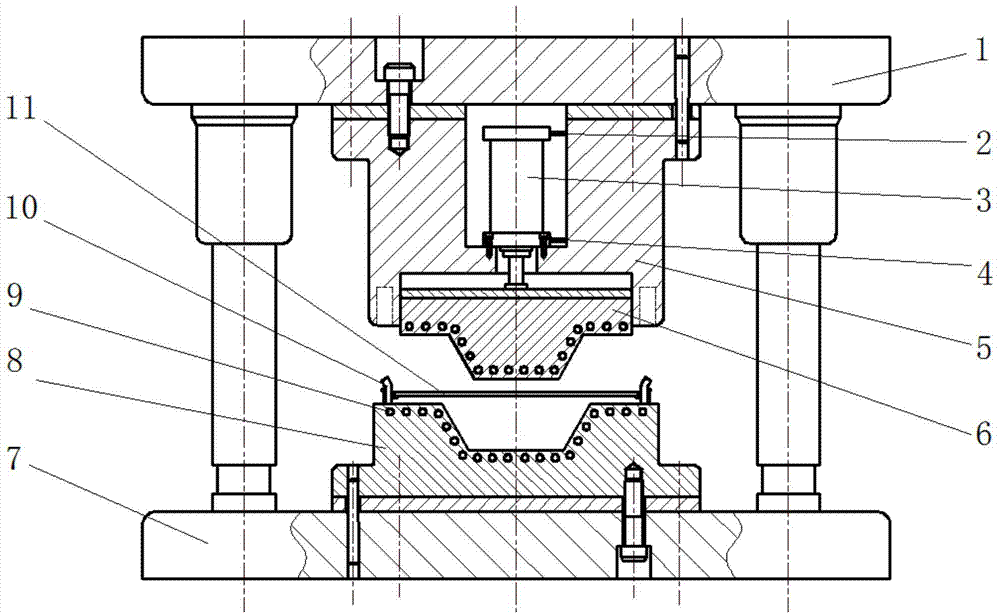

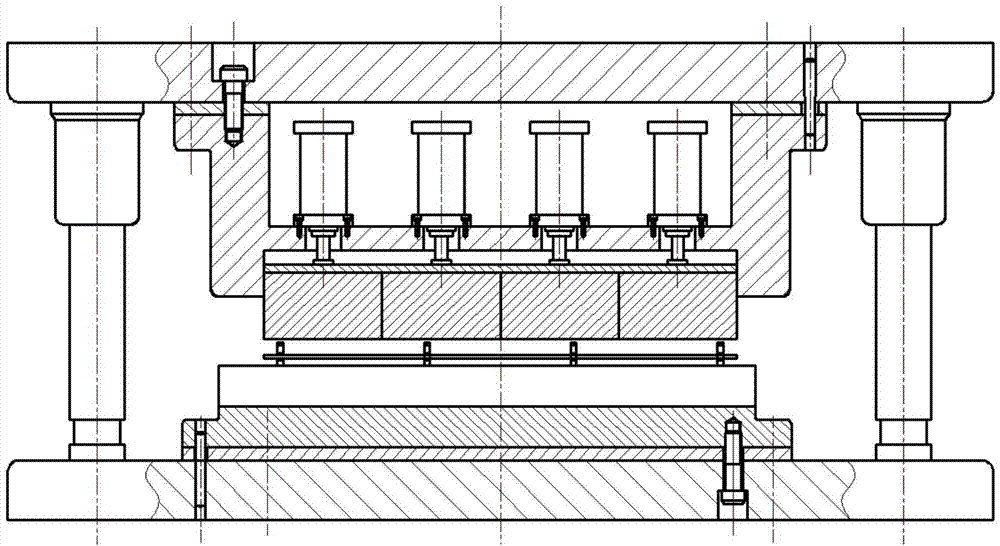

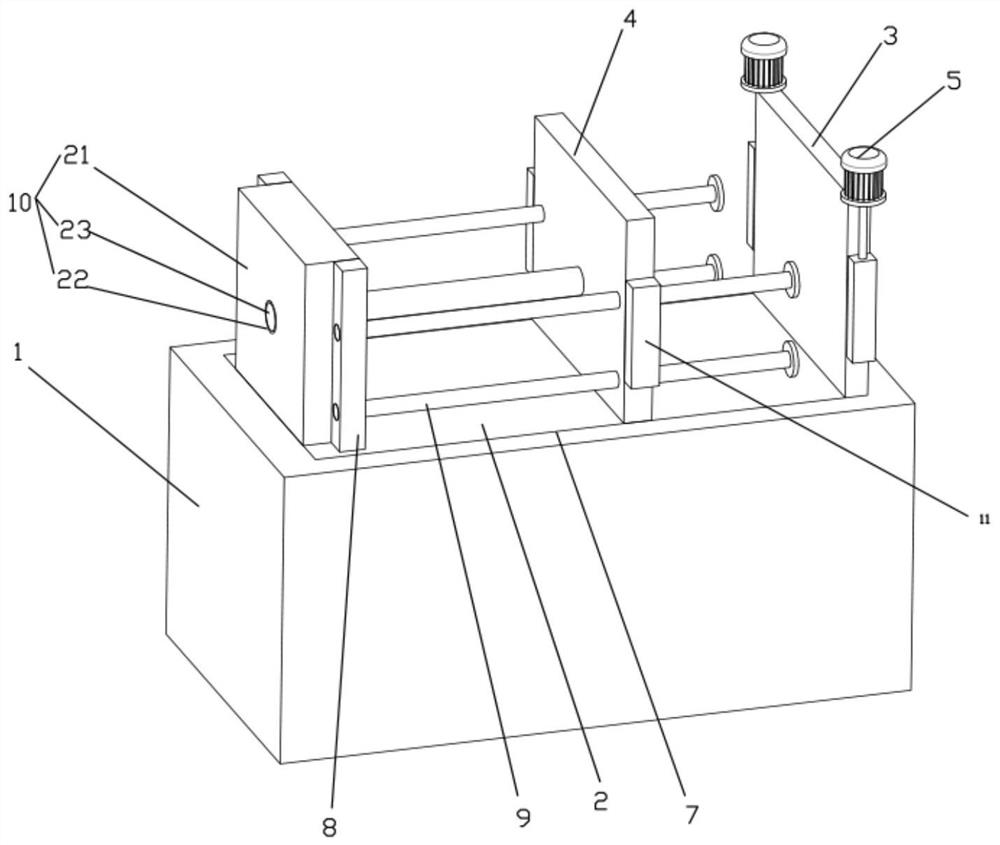

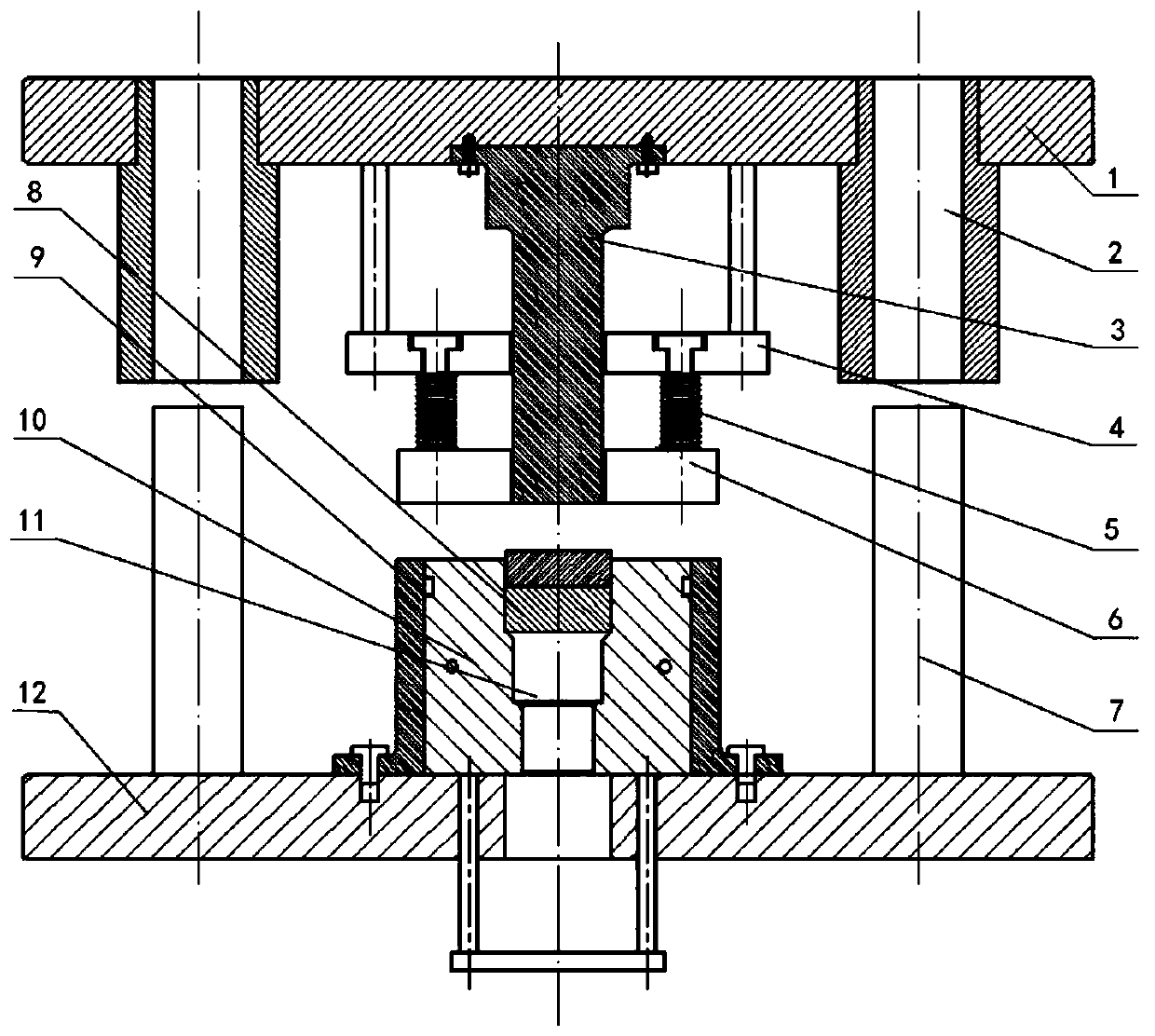

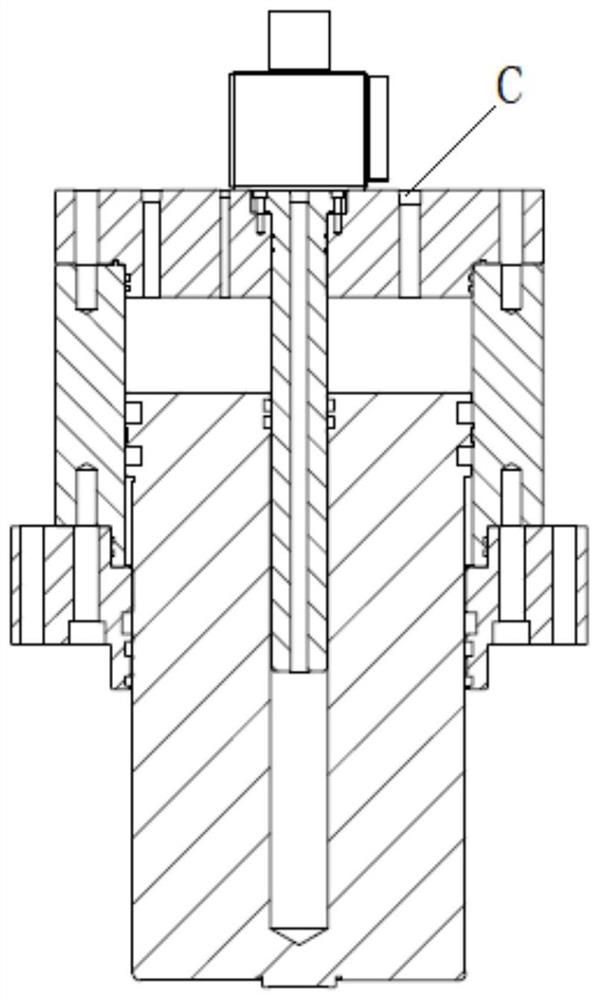

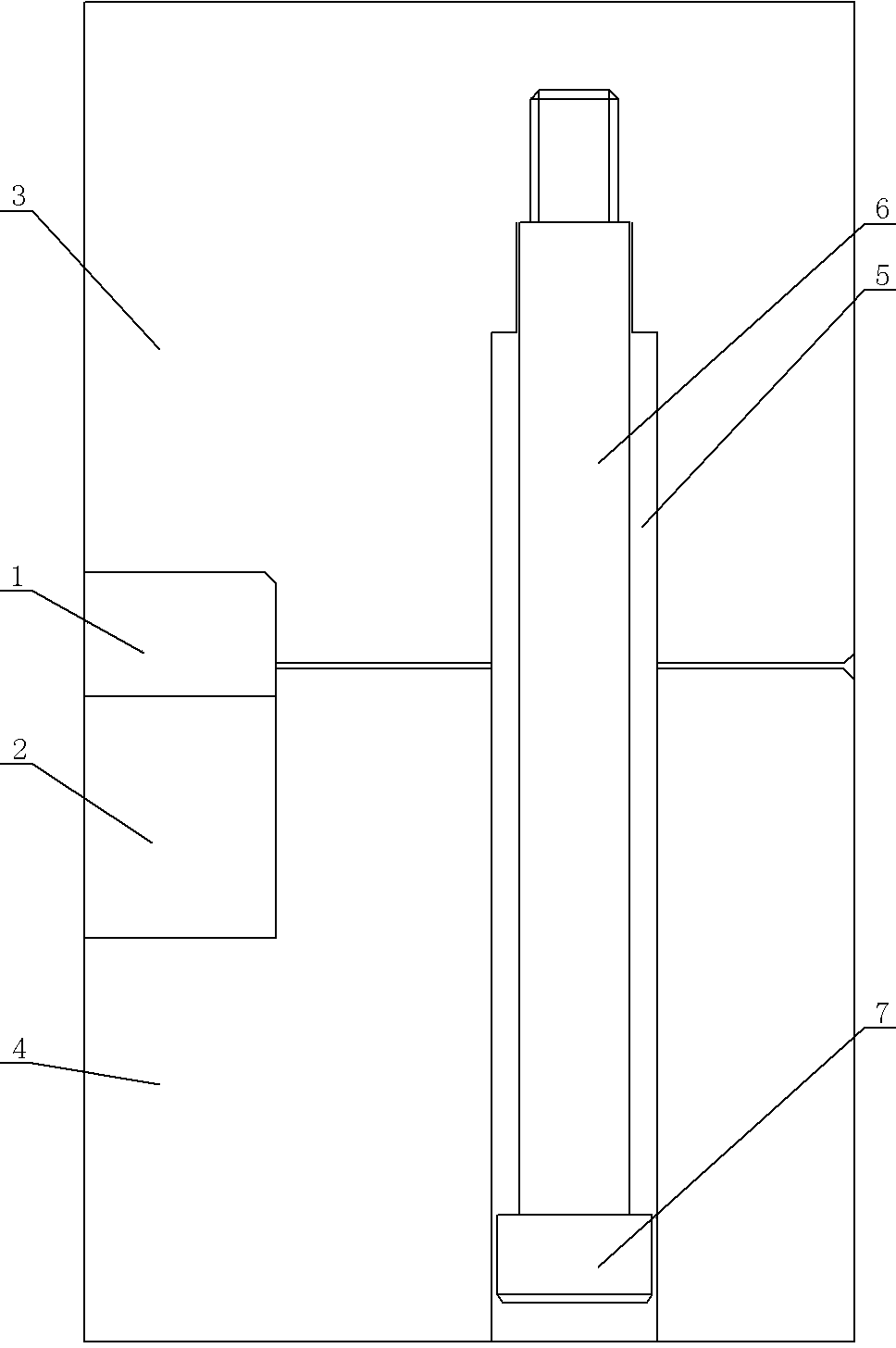

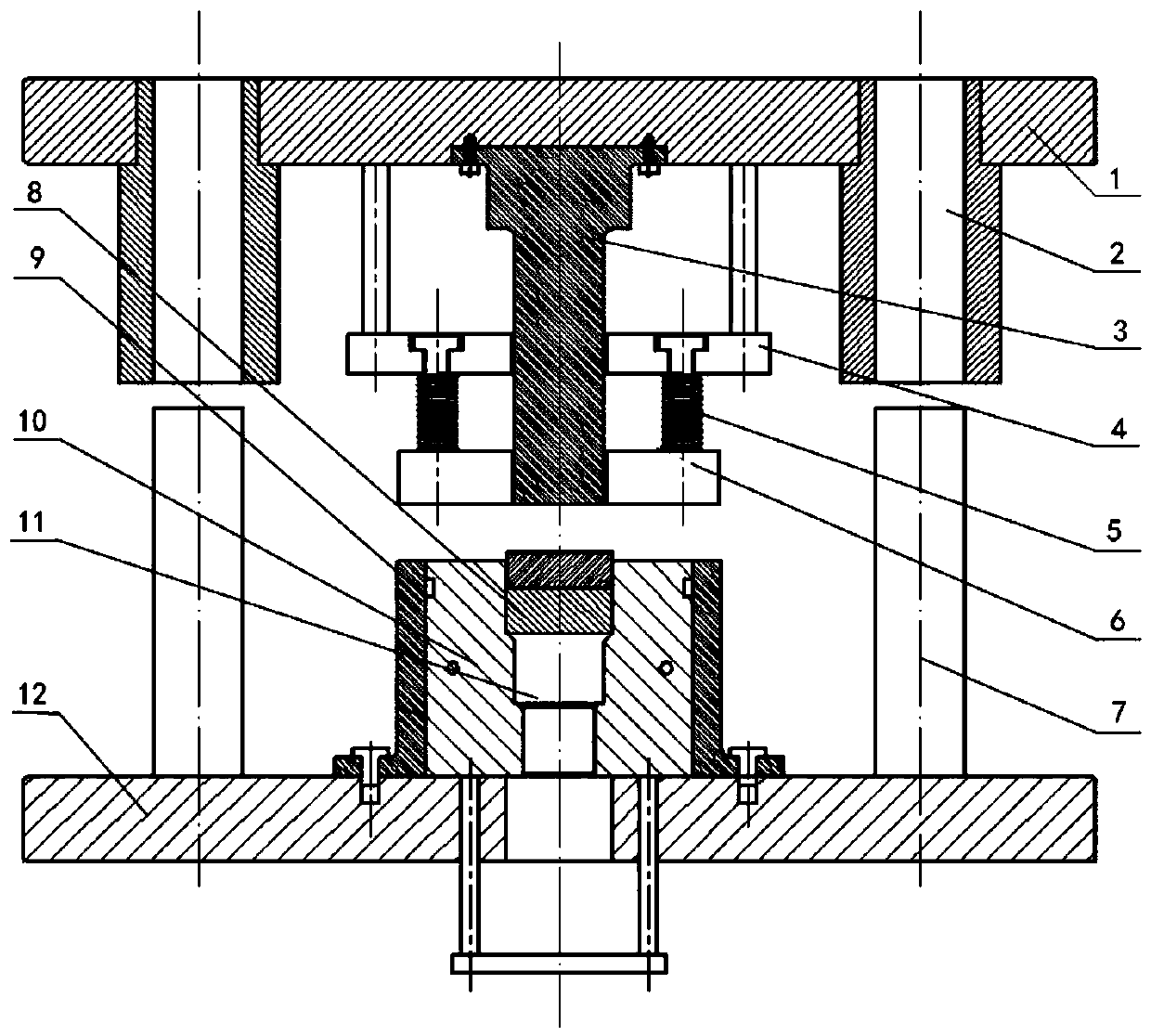

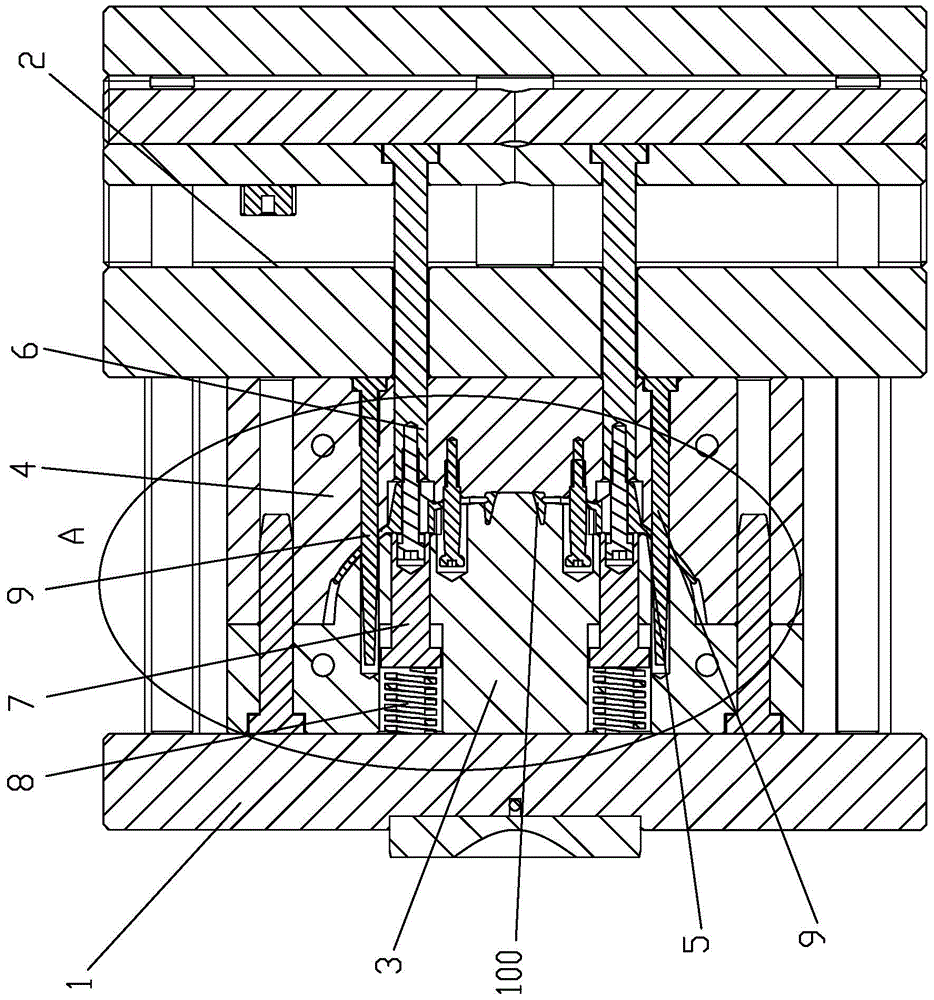

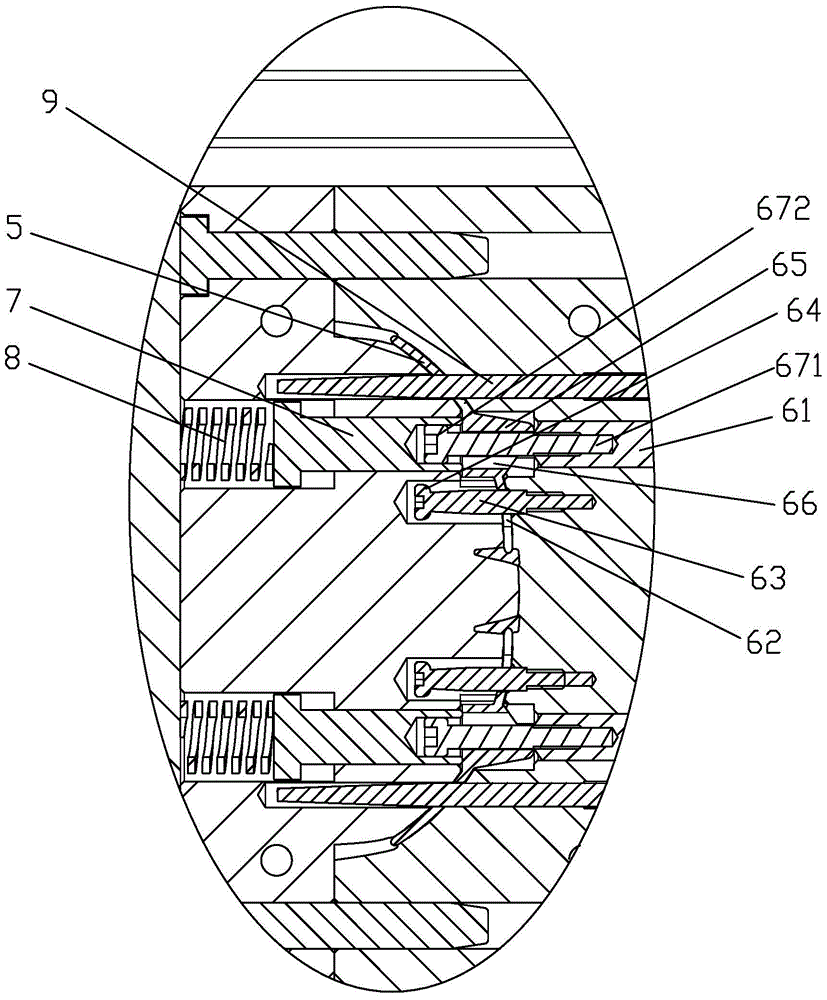

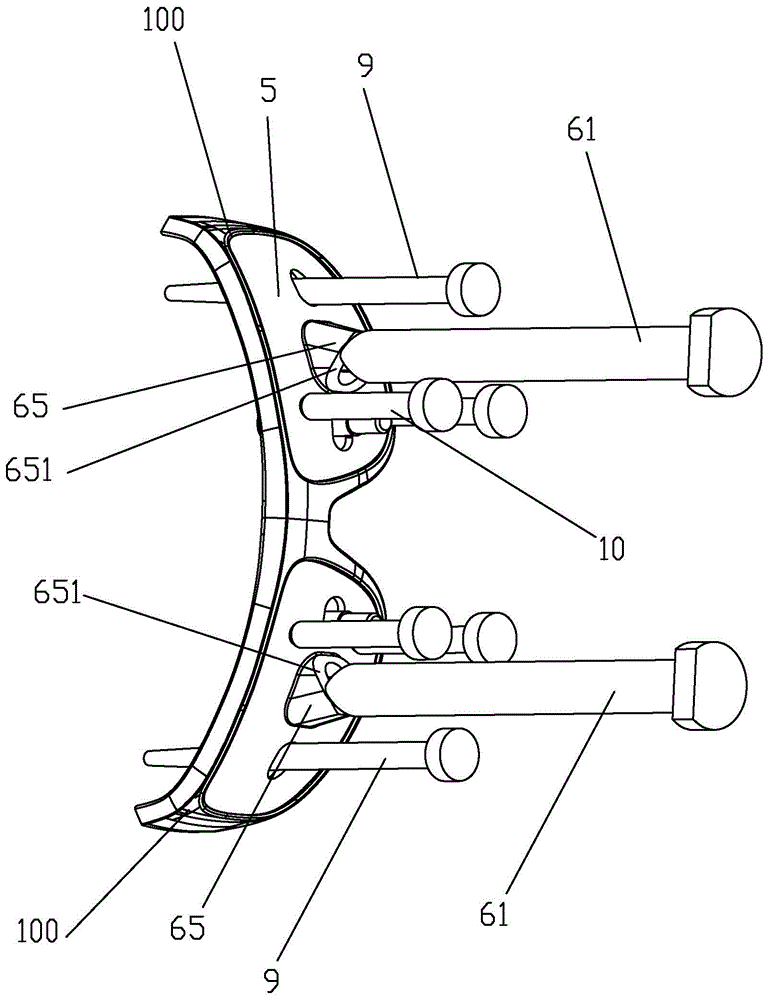

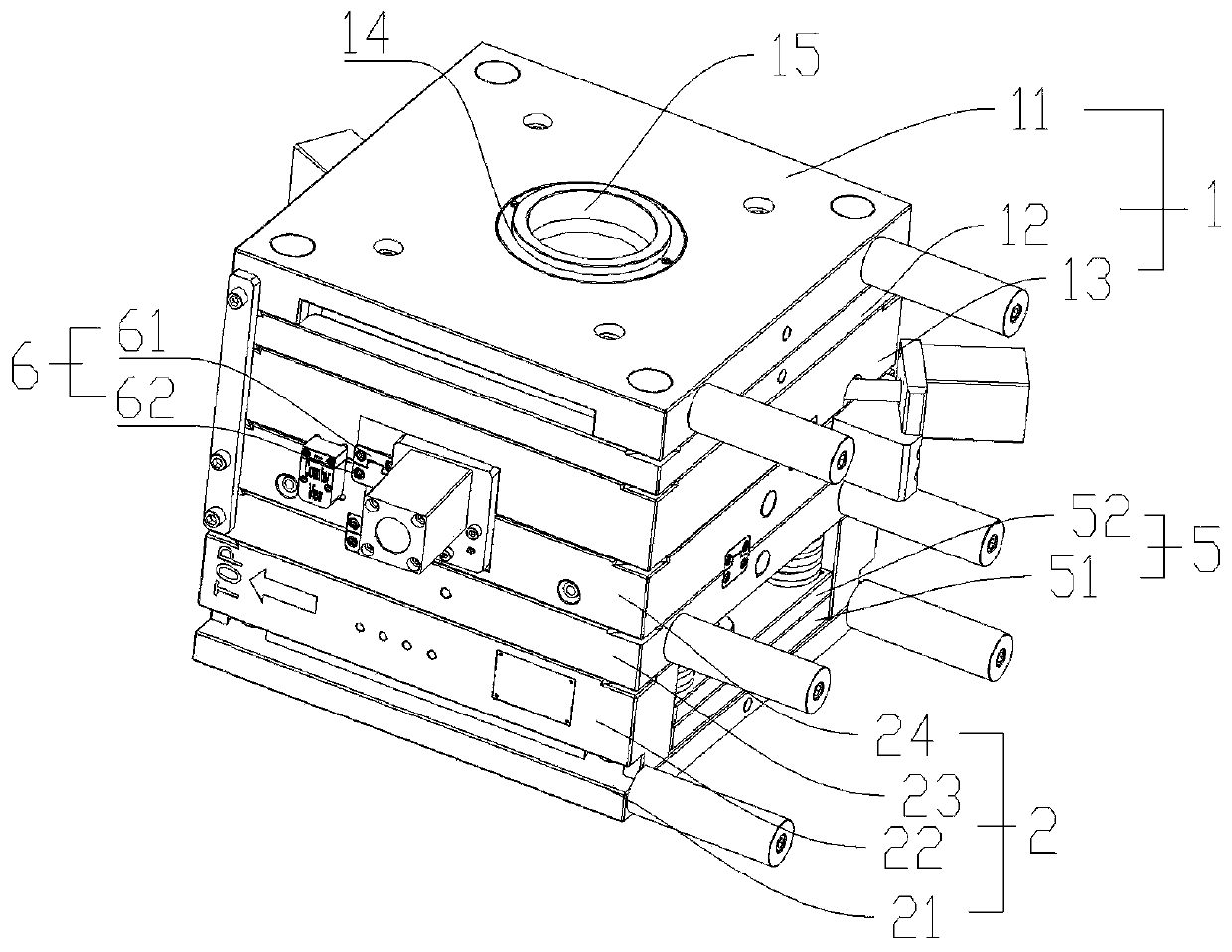

The invention relates to a super-strength steel hot stamping die capable of carrying out rapid spotting through gas assistance and belongs to the field of hot stamping forming. The die is mainly formed by an air cylinder (3), a male die (6), a female die (8), a fixing plate (5), an upper die plate (1), a lower die base (7) and other main parts. The male die (6) is arranged on the upper die plate (1) through the fixing plate (5). The air cylinder (3) is arranged in the fixing plate. A piston rod of the air cylinder is connected with the male die. In the stamping process, air enters to push the male die to rapidly descend through the air cylinder, a sheet metal (11) is rapidly stamped and formed, and the male die and the female die (8) rapidly carry out spotting. The super-strength steel hot stamping die mainly solves the problems that a used common hydraulic machine is too low in spotting speed, thus, the temperature of the sheet metal drops too fast, the cooling effect is uneven, and the mechanical properties of a workpiece is poor in the hot stamping forming process, and has importance guiding significance on utilizing an existing common hydraulic machine to produce super-strength steel hot stamping pieces for manufacturing enterprises.

Owner:JILIN UNIV

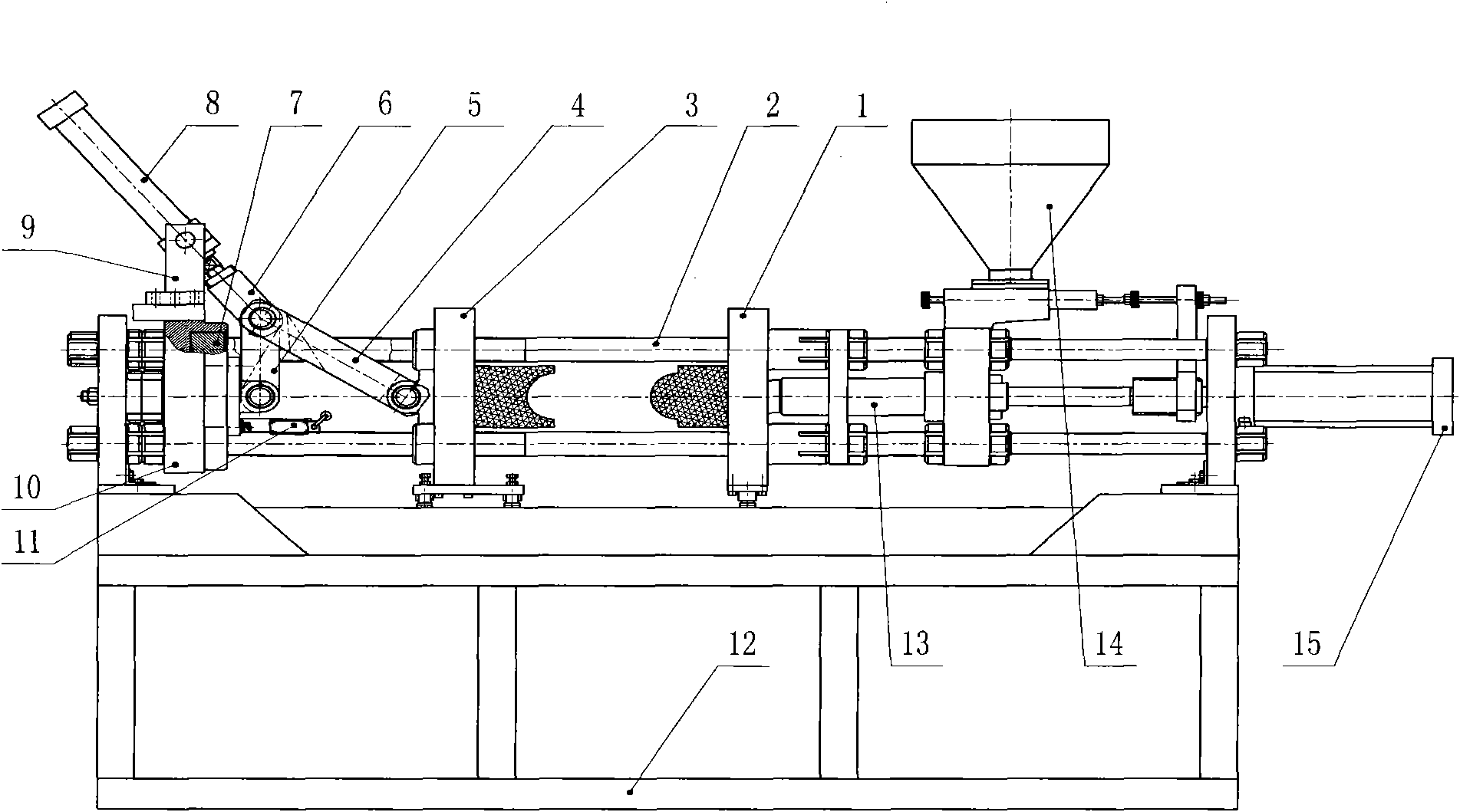

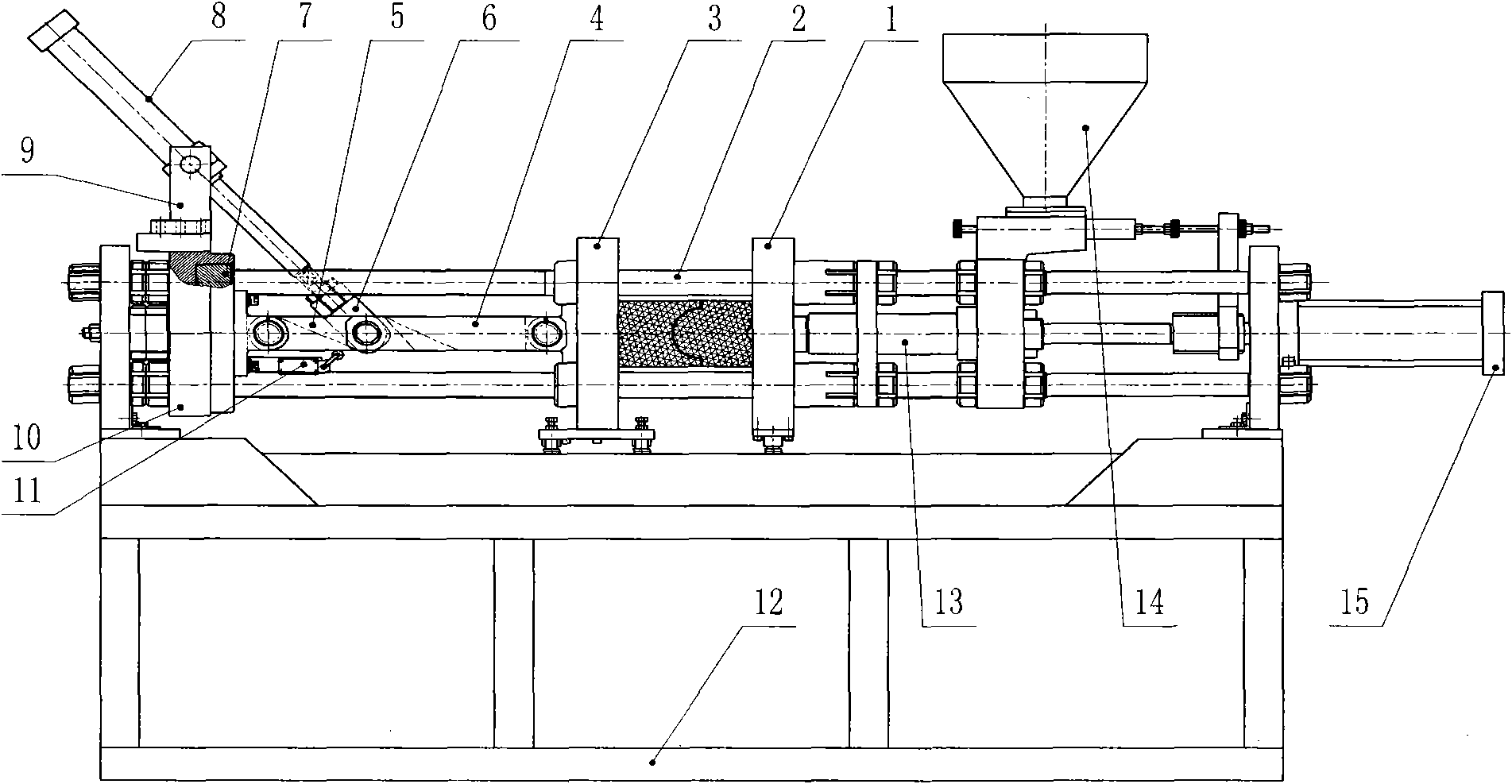

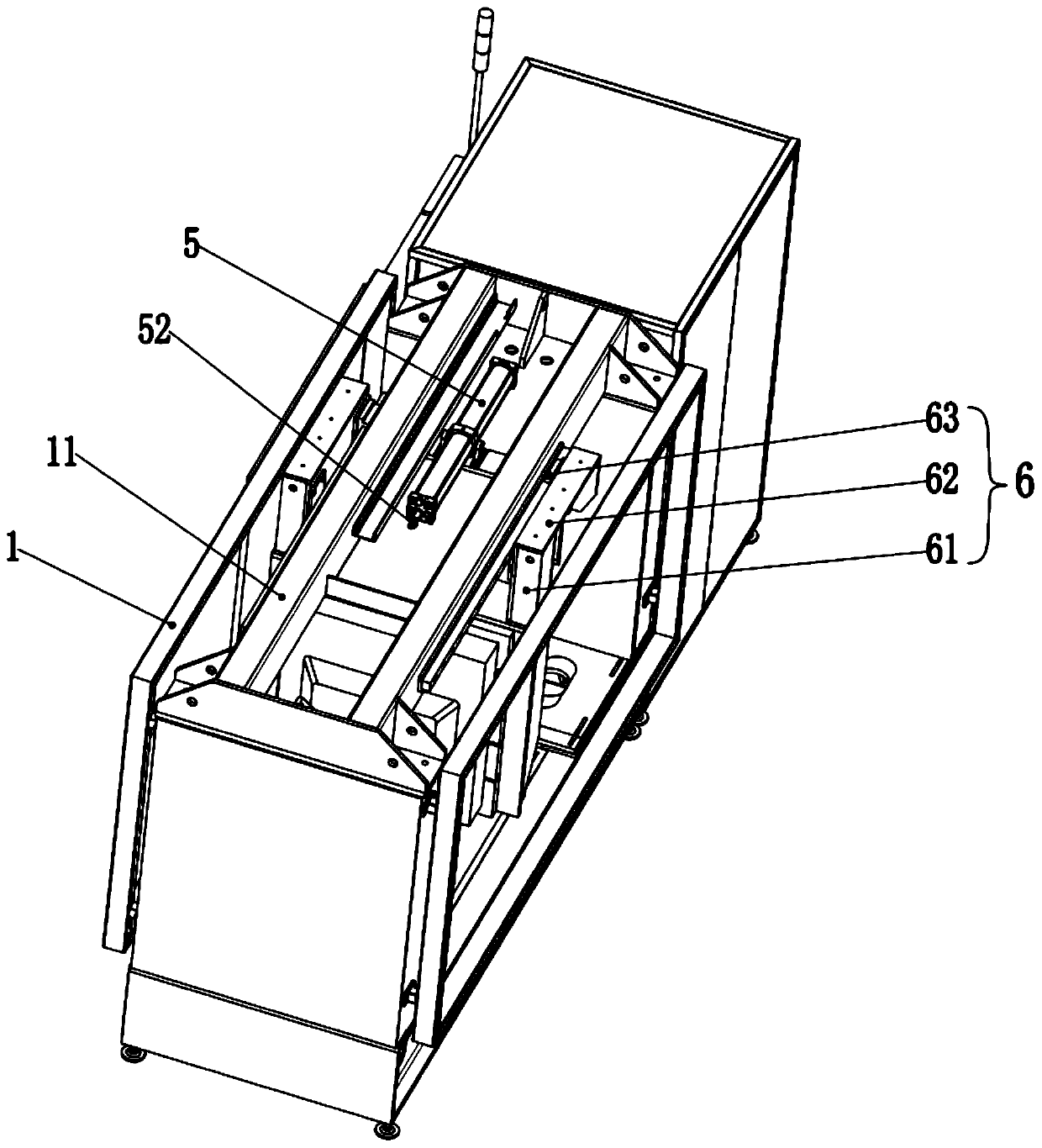

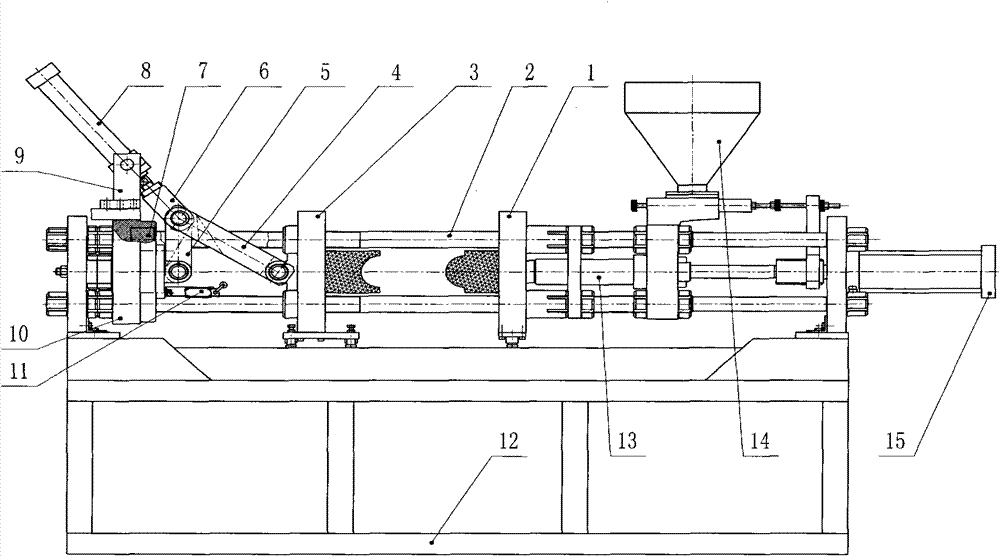

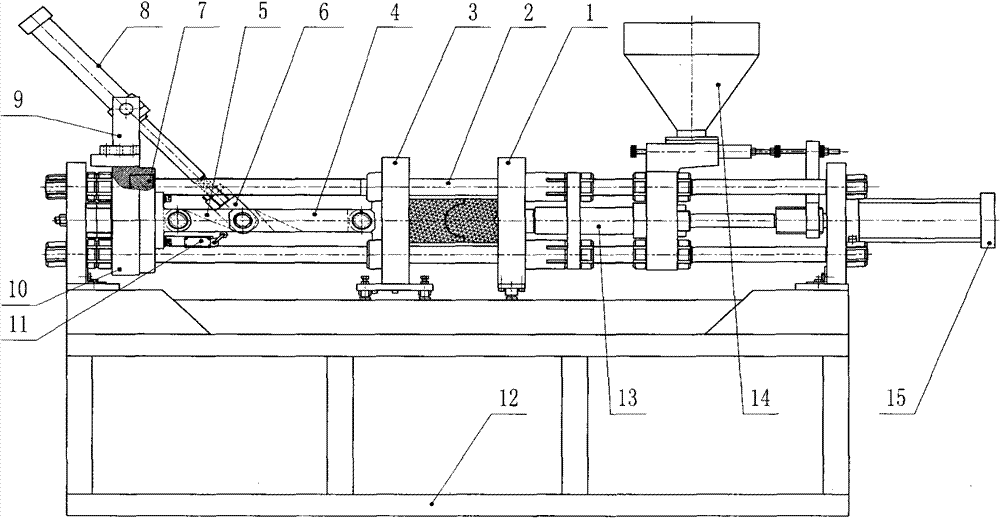

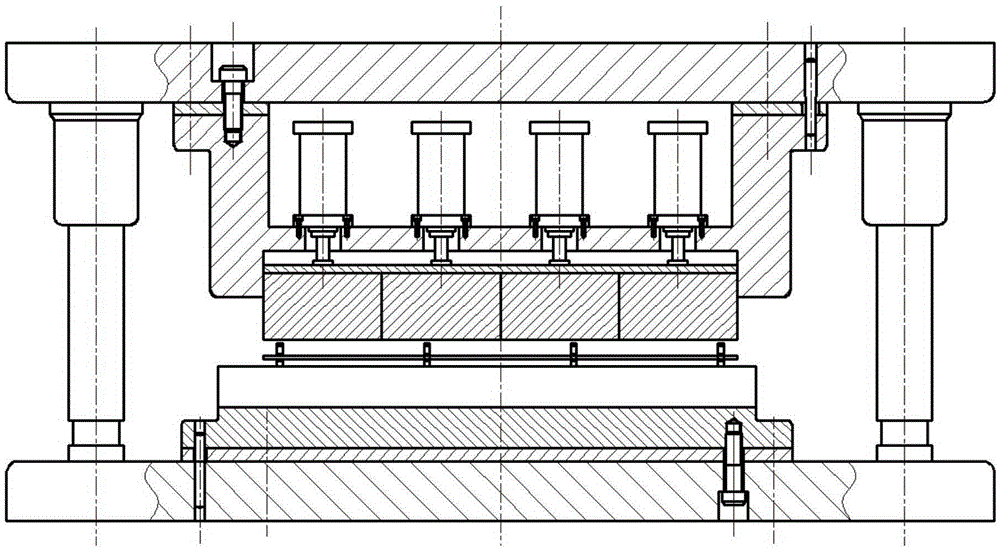

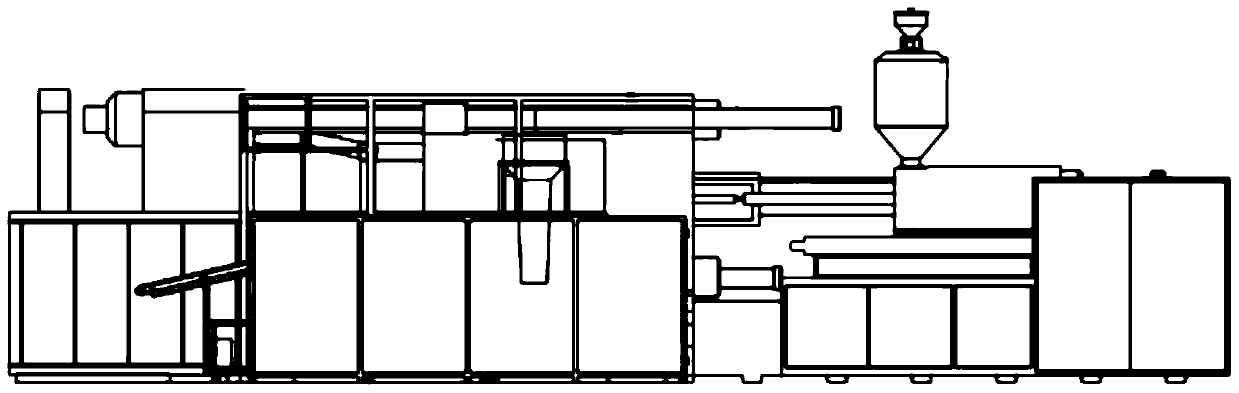

Cable-stayed horizontal injection molding machine

The invention relates to a cable-stayed horizontal injection molding machine comprising a lathe bed, a screw rod, a charging barrel, a hopper, an injection cylinder, a connecting rod mechanism, a die assembly mechanism and a die locking mechanism. The cable-stayed horizontal injection molding machine is characterized in that the connecting rod mechanism is connected with a die assembly cylinder, the die locking mechanism is hinged with a die locking piston disk, the die assembly and the die opening adopt a cable-stayed crank cylinder mechanism, and the die locking adopts a disk type cylinder mechanism. The cable-stayed horizontal injection molding machine has the characteristics of simple structure, low cost, wide adaptability and the like, strengthens die locking capability, improves injection area and is safe and reliable.

Owner:滕武超

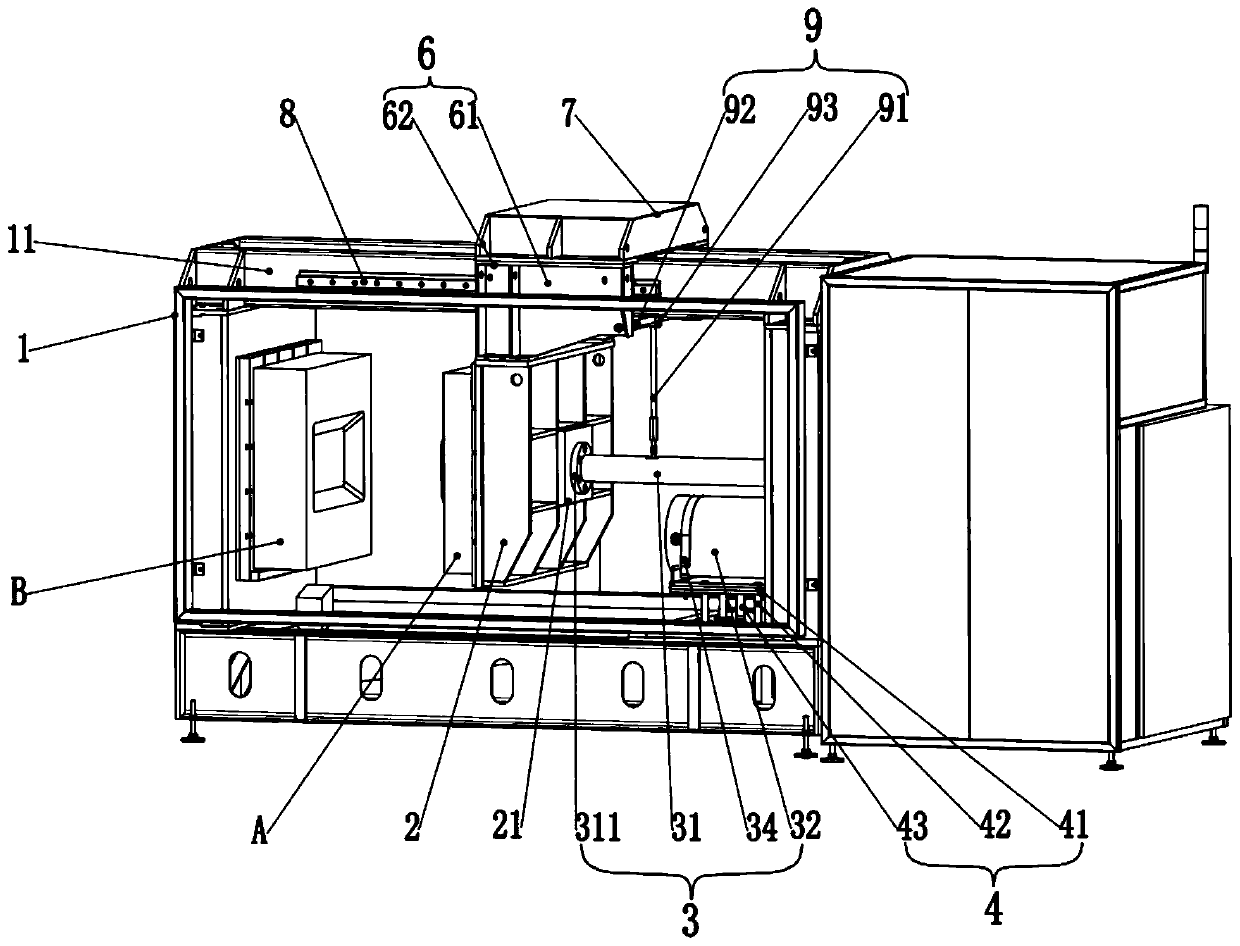

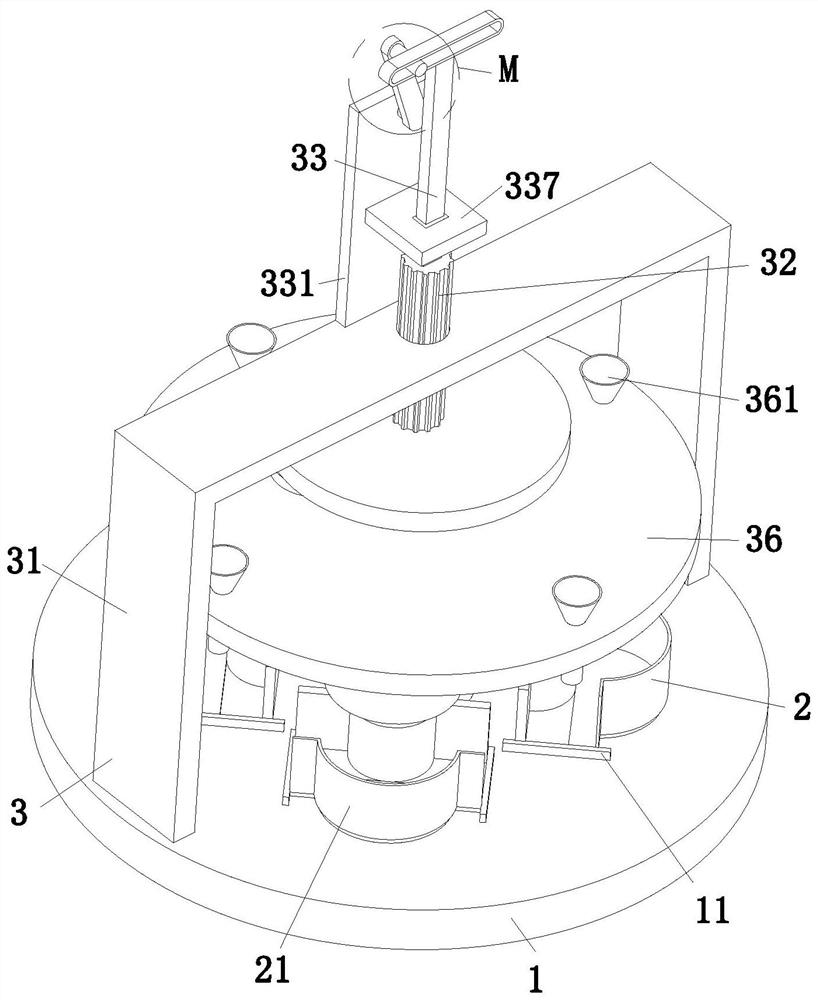

High-pressure grouting machine applied to domestic ceramic

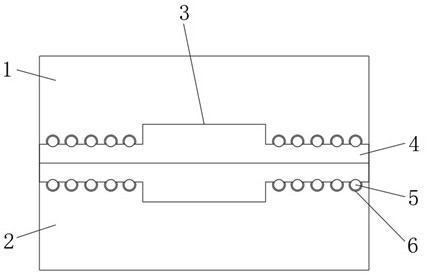

PendingCN110744675AShorten the action cycleAvoid collisionAuxillary shaping apparatusSlip casting mouldsEngineeringMechanical engineering

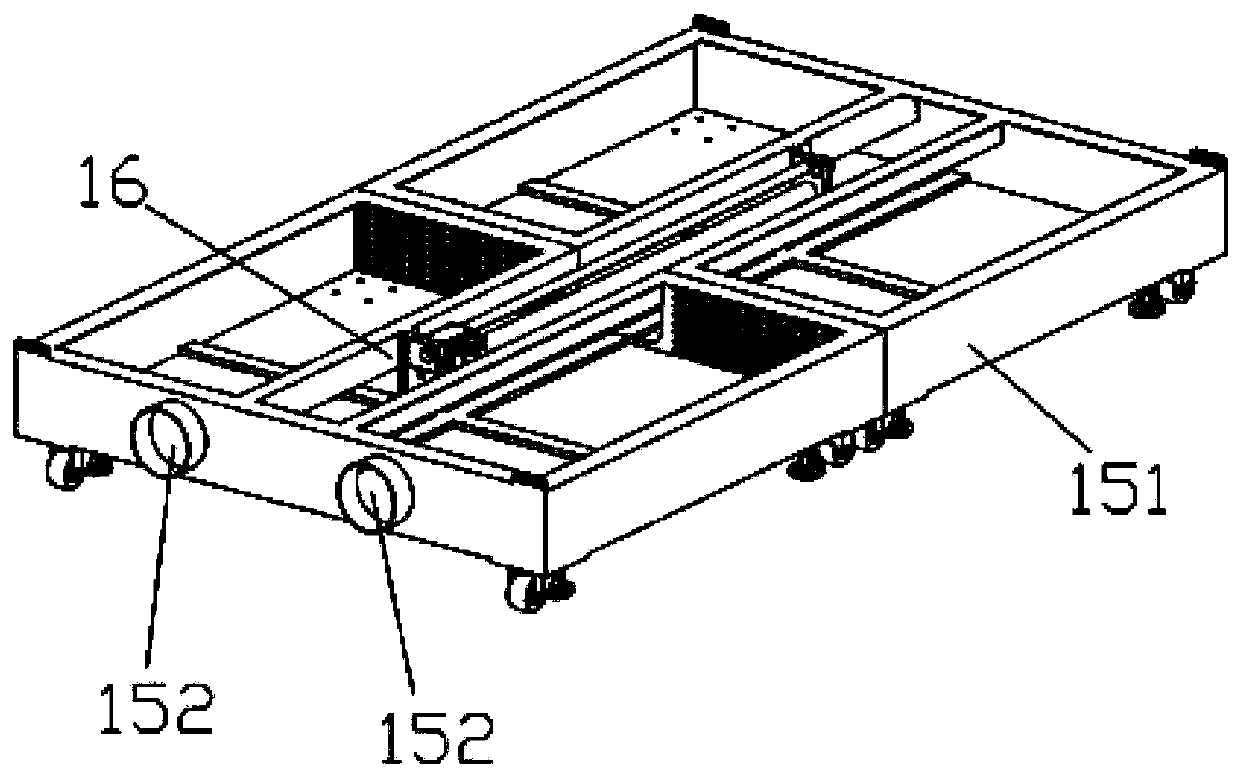

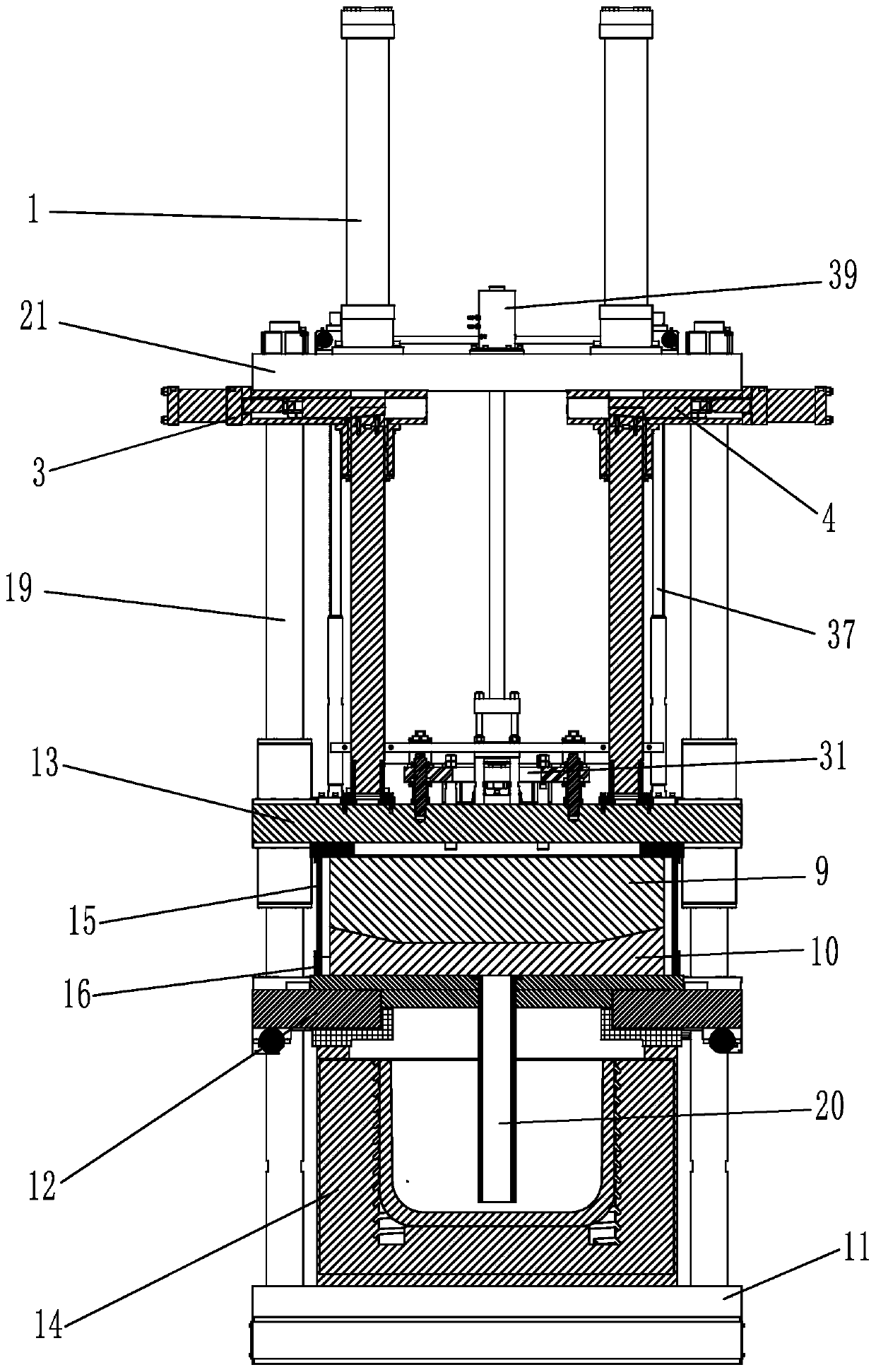

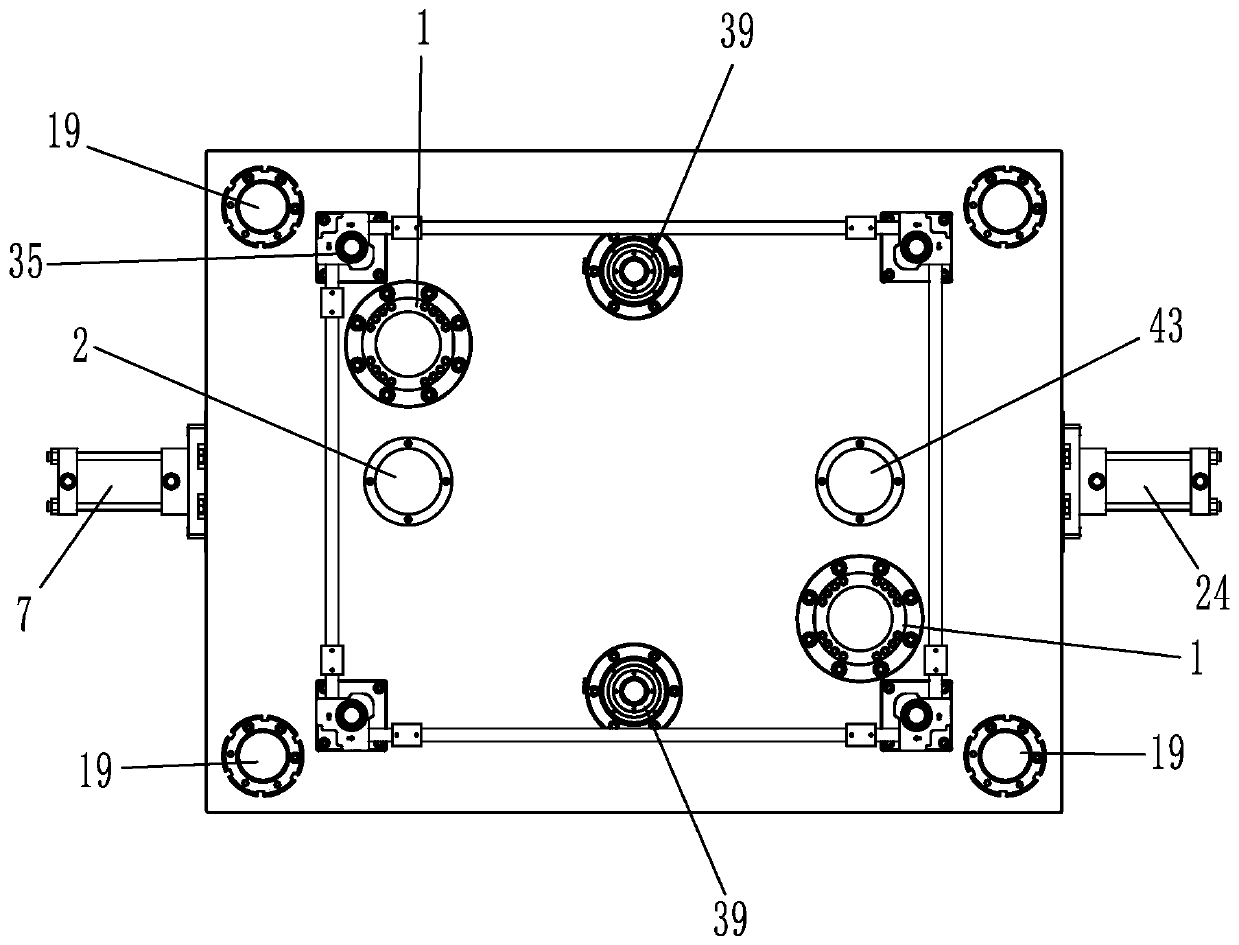

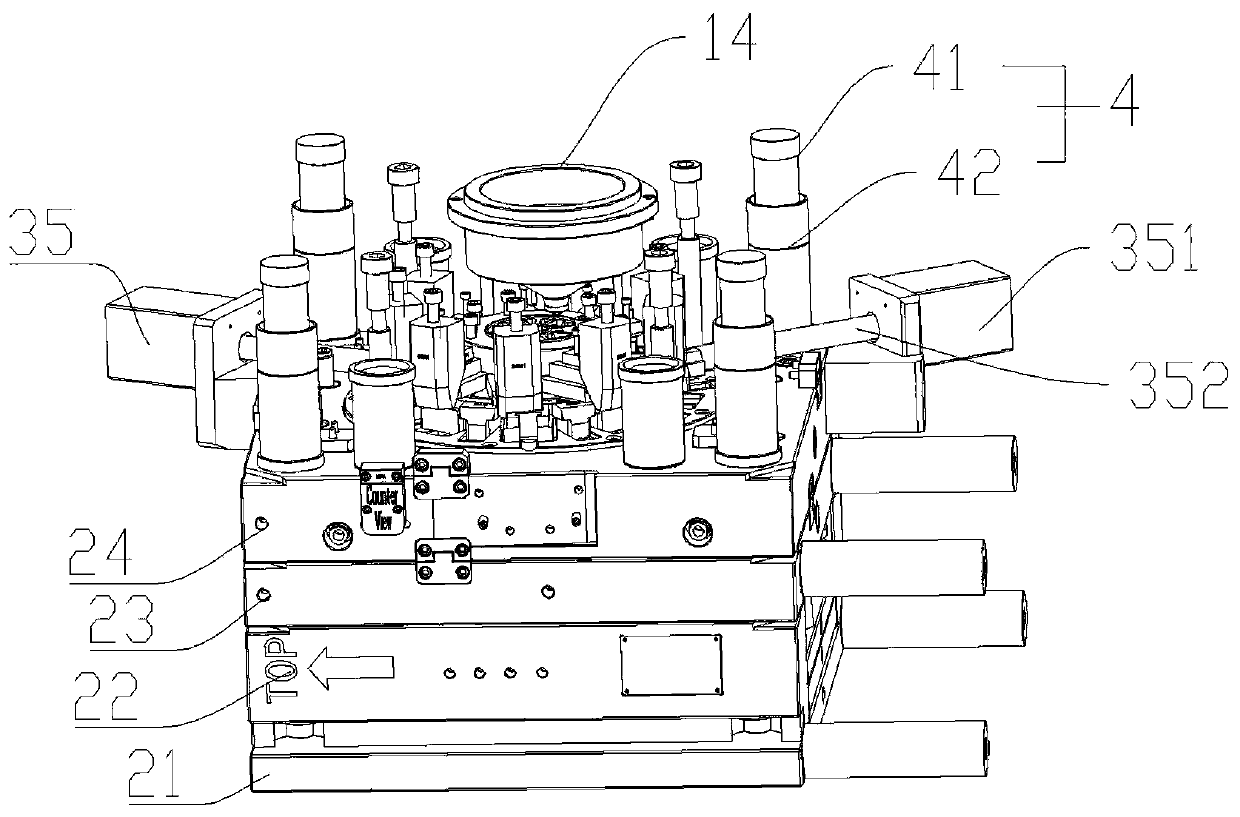

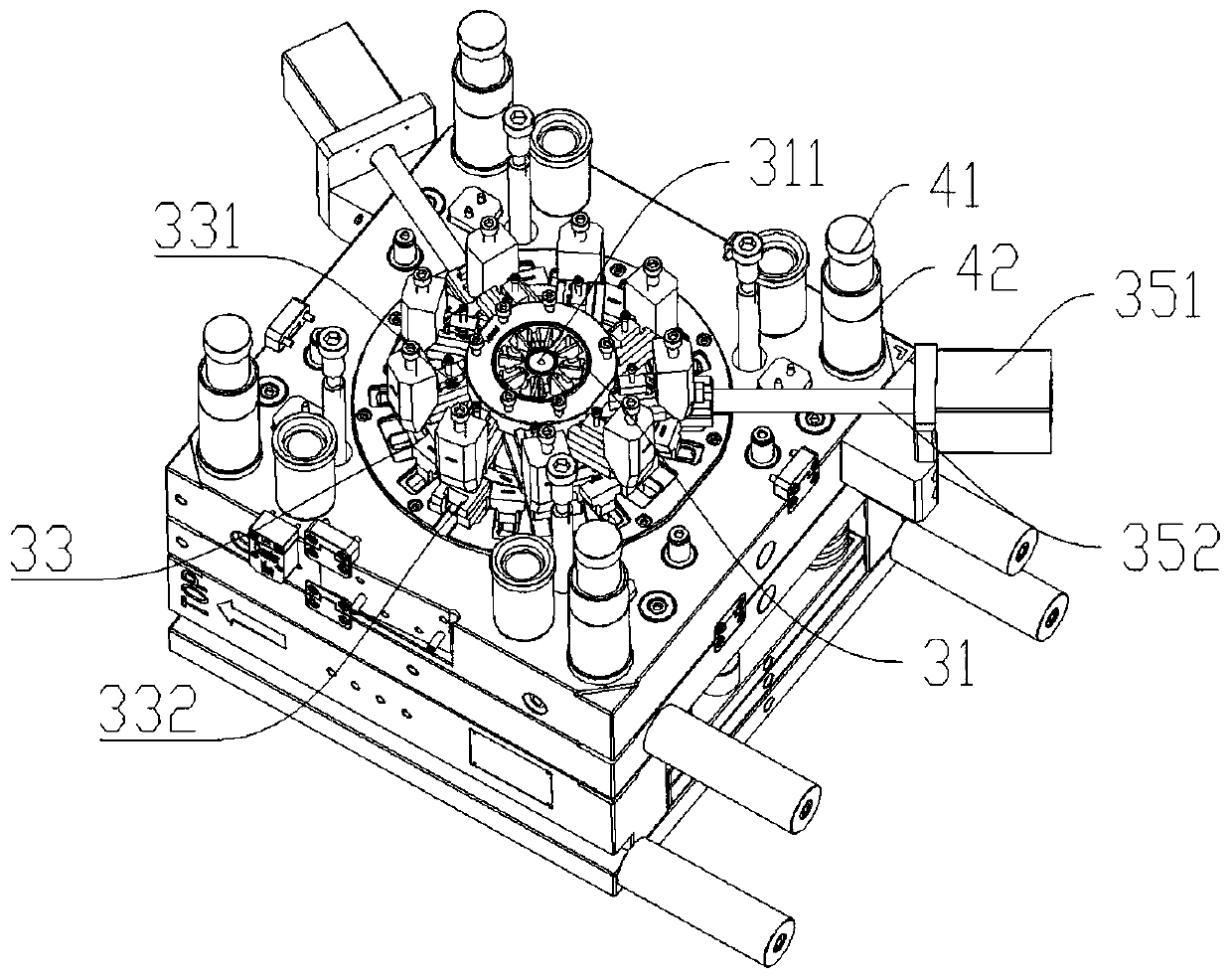

The invention provides a high-pressure grouting machine applied to domestic ceramic, wherein a movable mold installation frame is fixed at the center of a rack, a push rod is disposed on the rear endof the movable mold installation frame, and a push device used for pushing the push rod is fixed on the rear part of the rack; a lifting device is installed on the bottom end of the rear part of the rack, the push device is installed on the lifting device, and the push device is driven by the lifting device to ascend and descend; and the push device is located behind the push rod after descending,and the push device is connected to the push rod after ascending and used for pushing the push rod. The invention provides the high-pressure grouting machine applied to domestic ceramic. The machinehas the beneficial effects that a movable mold can be quickly or slowly moved at the right time, so low-pressure, middle-pressure and high-pressure die assembly of the movable mold can be realized atthe right time; grouting into a die can be realized by a grouting system at the right time under low, middle and high pressures; fast die assembly, grouting and mold opening can be realized; die assembly is quick and alignment is precise; an action cycle of the ceramic high-pressure grouting machine can be effectively shortened; quality of a grouted ceramic body can be effectively improved; and production efficiency of equipment can be increased.

Owner:佛山市谊恒机械配件有限公司

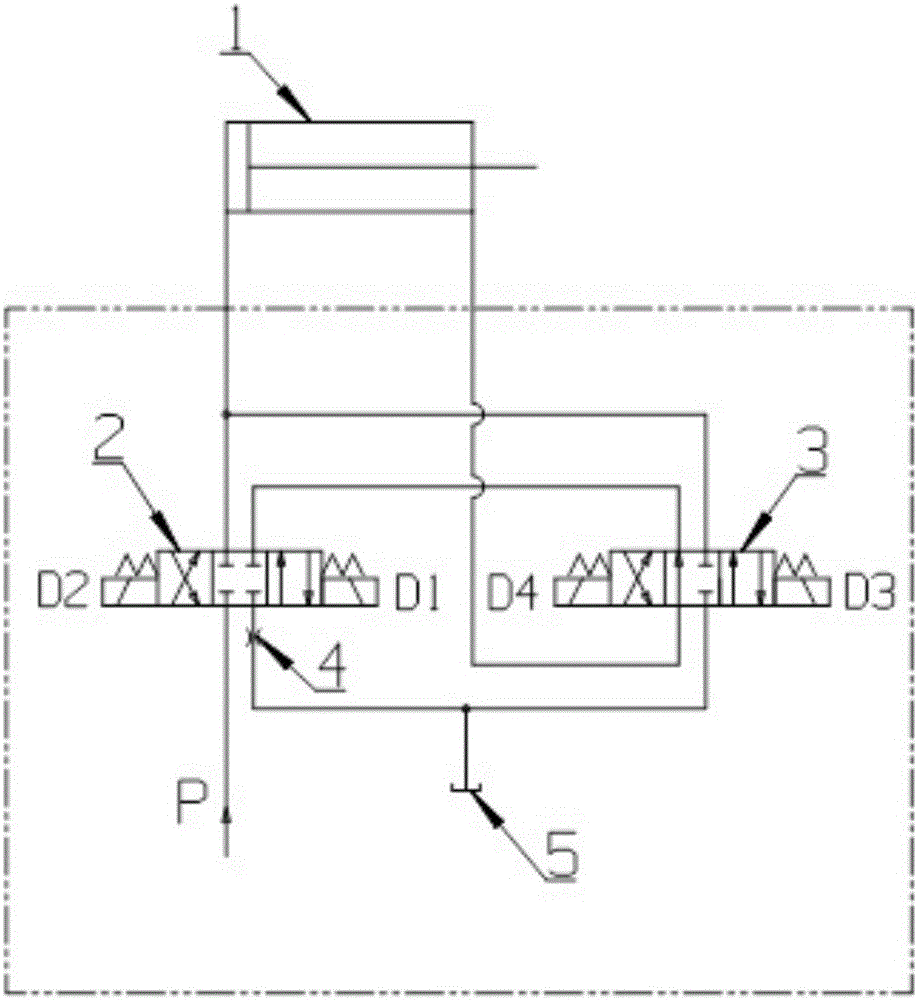

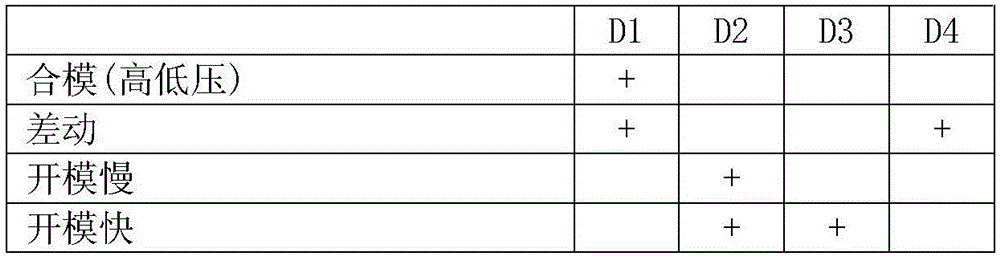

Mold opening and closing oil circuit of injection molding machine

The invention provides a mold opening and closing oil circuit of an injection molding machine. The mold opening and closing oil circuit comprises an oil circuit body, wherein the oil circuit body comprises a mold opening and closing oil cylinder, a first reversing valve, a second reversing valve, a damper and an oil tank; the mold opening and closing oil cylinder is arranged at the top end of the oil circuit body, and connected with the first reversing valve and the second reversing valve; the first reversing valve is connected with the damper; and the oil tank is arranged at the bottom of the oil circuit body. According to the mold opening and closing oil circuit provided by the invention, various functions of rapid mold closing (differential motion), mold closing, low pressure mold closing, high-pressure mold locking, slow mold opening, rapid mold opening and the like can be realized by only two two-station three-way reversing valves, so that operation procedures are reduced, the working efficiency is improved, and the production cost is reduced.

Owner:WUXI HAITIAN MACHINERY

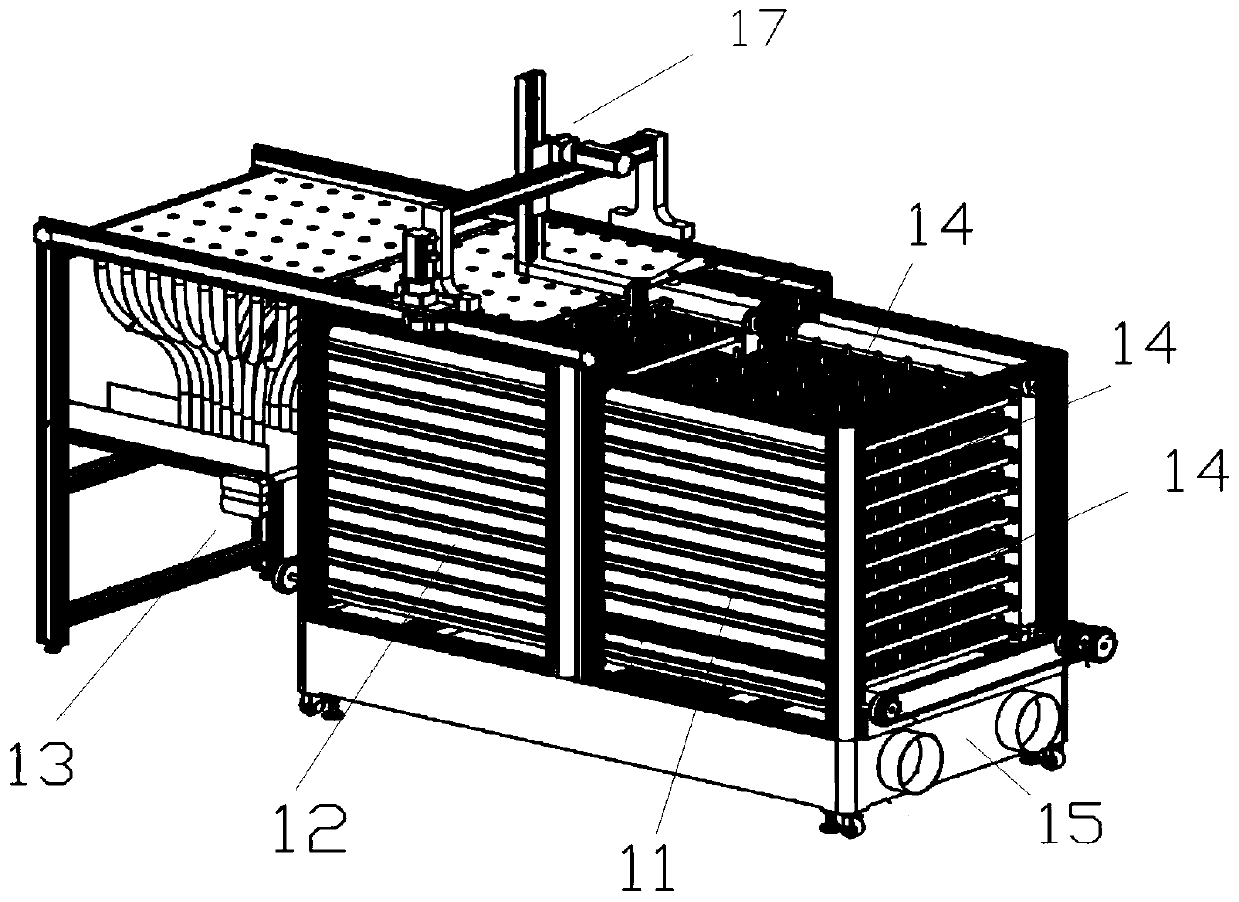

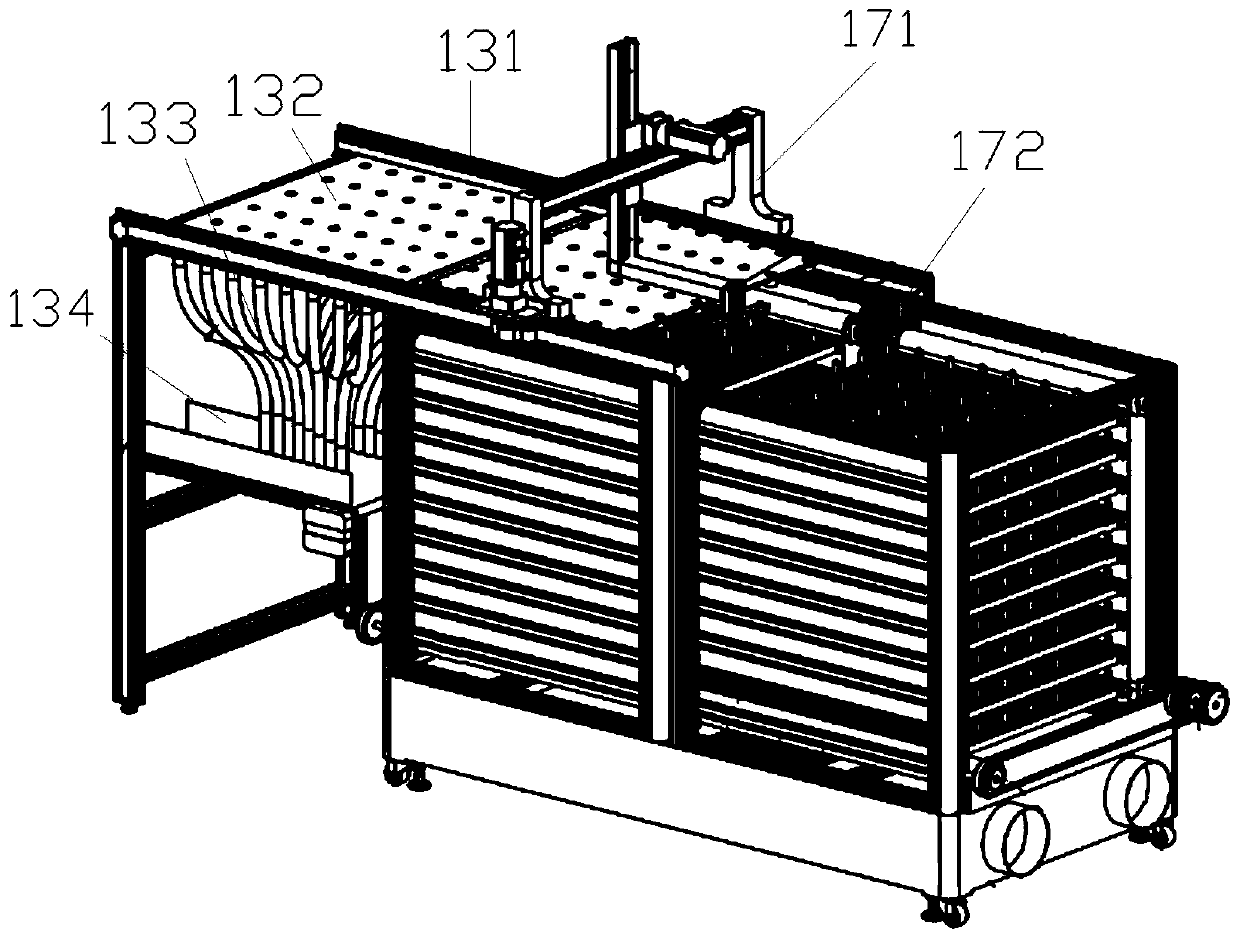

Outside mold storage cooling device and outside mold storage cooling method

InactiveCN111168956AImprove utilization efficiencyImprove cooling effectThermodynamicsProcess engineering

The invention provides an outside mold storage cooling device. The outside mold storage cooling device comprises a descending device, an ascending device, a cooling device, a lower tray moving deviceand an upper tray moving device. The outside mold storage cooling device is used for outside mold cooling of products, the trays are driven by a descending synchronous belt and an ascending synchronous belt to be cooled in the descending device and the ascending device, the cooling path is lengthened through the circuitous layout, the longer cooling time is achieved, cooling is more sufficient, the space is saved, and the space utilization efficiency is improved. However, due to the fact that cooling is conducted outside the mold, the cooling time inside the mold of an injection molding machine is shortened, the injection molding machine can conduct rapid mold closing and next injection molding, and therefore the production capacity of injection molding of the injection molding machine isgreatly improved, and flexible cooperative production of rapid molding and cooling outside the mold is achieved.

Owner:彭道兴

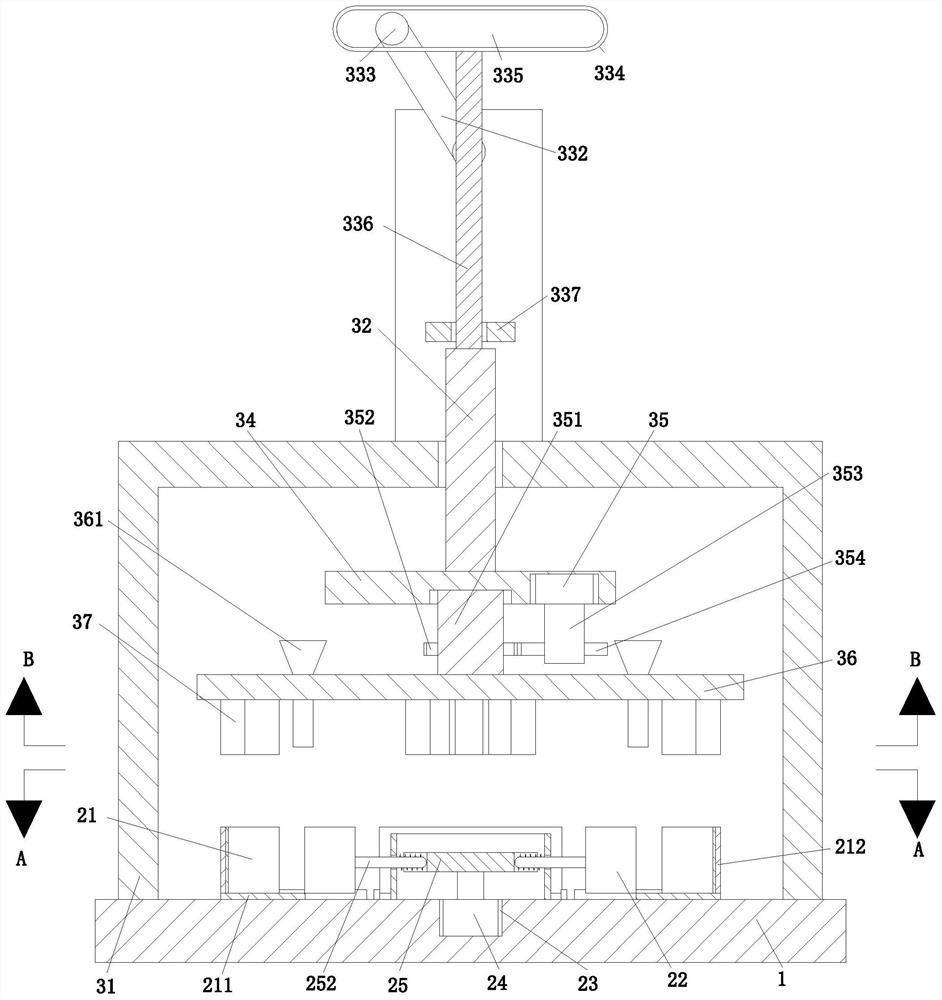

Hydraulic pressurizing mold locking device for split mold

ActiveCN113305168AMove quicklySupercharged locking achievedExtrusion diesExtrusion control devicesEngineeringMechanical engineering

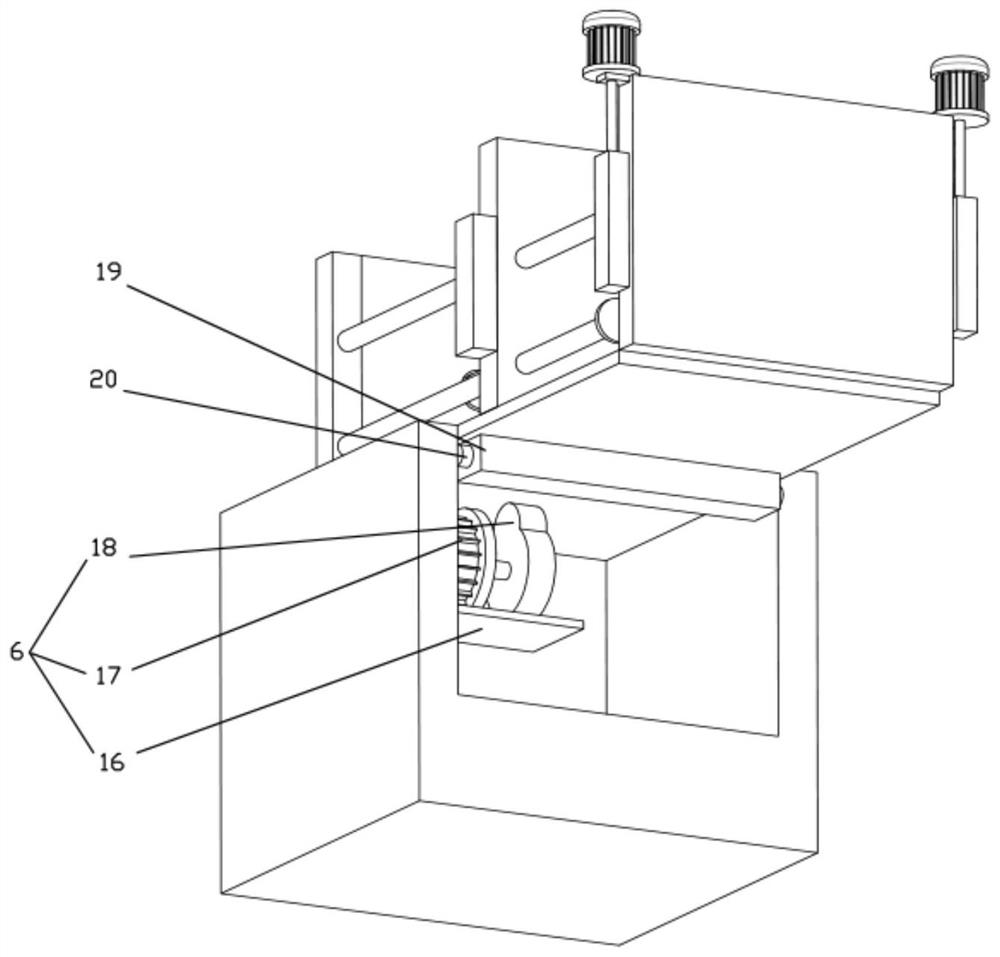

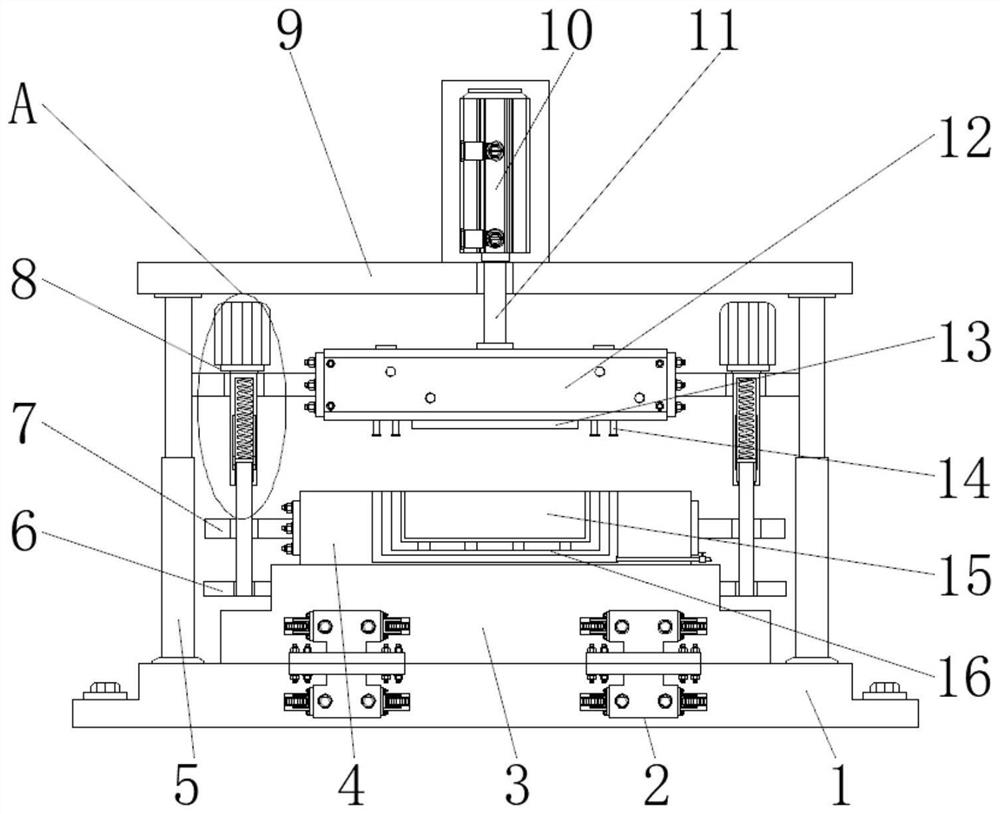

The invention discloses a hydraulic pressurizing mold locking device for a split mold. The device comprises a frame, a mold closing mechanism and a pressurizing and locking mechanism, the pressurizing and locking mechanism comprises a pressurizing mechanism and a restraining mechanism used for restraining movement of the pressurizing mechanism, the pressurizing mechanism comprises a pressurizing sliding block with a pressurizing cavity inside, a small-diameter pressure cylinder and a large-diameter pressurizing cylinder are sequentially arranged in the pressurizing cavity in the mold closing direction, a pressure piston is arranged in the pressure cylinder in a sliding fit mode, a pressurizing piston is arranged in the pressurizing cylinder in a sliding fit mode, the mold closing mechanism drives the pressurizing sliding block to move to a preset position, the position of the pressurizing sliding block is locked through the restraining mechanism, the power output end of the mold closing mechanism drives the pressure piston to move in the pressurizing cavity, pressure is transmitted through a pressure transmitting medium to enable the pressurizing piston to act, and large mold closing force is applied to the split mold. According to the scheme, the pressurizing mechanism is driven by the mold closing mechanism, the mold opening and closing stroke is large, the mold opening space of the mold is increased, and technological operation is facilitated.

Owner:HENAN UNIV OF SCI & TECH

High-speed-driven injection molding machine mold closing structure

The invention discloses a high-speed-driven injection molding machine mold closing structure, and belongs to the technical field of injection molding machine. The high-speed-driven injection molding machine mold closing structure comprises a base, a bottom plate, a fixed mold plate, a movable mold plate, an acceleration assembly and an auxiliary separation assembly, a groove is formed in the base, the position, close to the surface of the base, of the groove is hinged to the bottom plate, a vertical rod is fixed to the upper end of the bottom plate, a guide rod penetrates through the vertical rod, the movable mold plate is slidably connected to the outside of the guide rod, the fixed mold plate is fixed to the upper end of the base, and a driving mechanism is fixed to the end, away from the fixed mold plate, of the movable mold plate. According to the structure, auxiliary acceleration of the injection molding machine mold closing structure is carried out through the magnetic attraction effect and mechanical rotation, mold closing can be rapidly carried out, losses of pressure, temperature and the like are reduced in the whole process of injecting melt into a cavity, then the balance is improved when the whole cavity is filled with the melt, and the product quality is improved.

Owner:宁波瑞宝智能装备有限公司

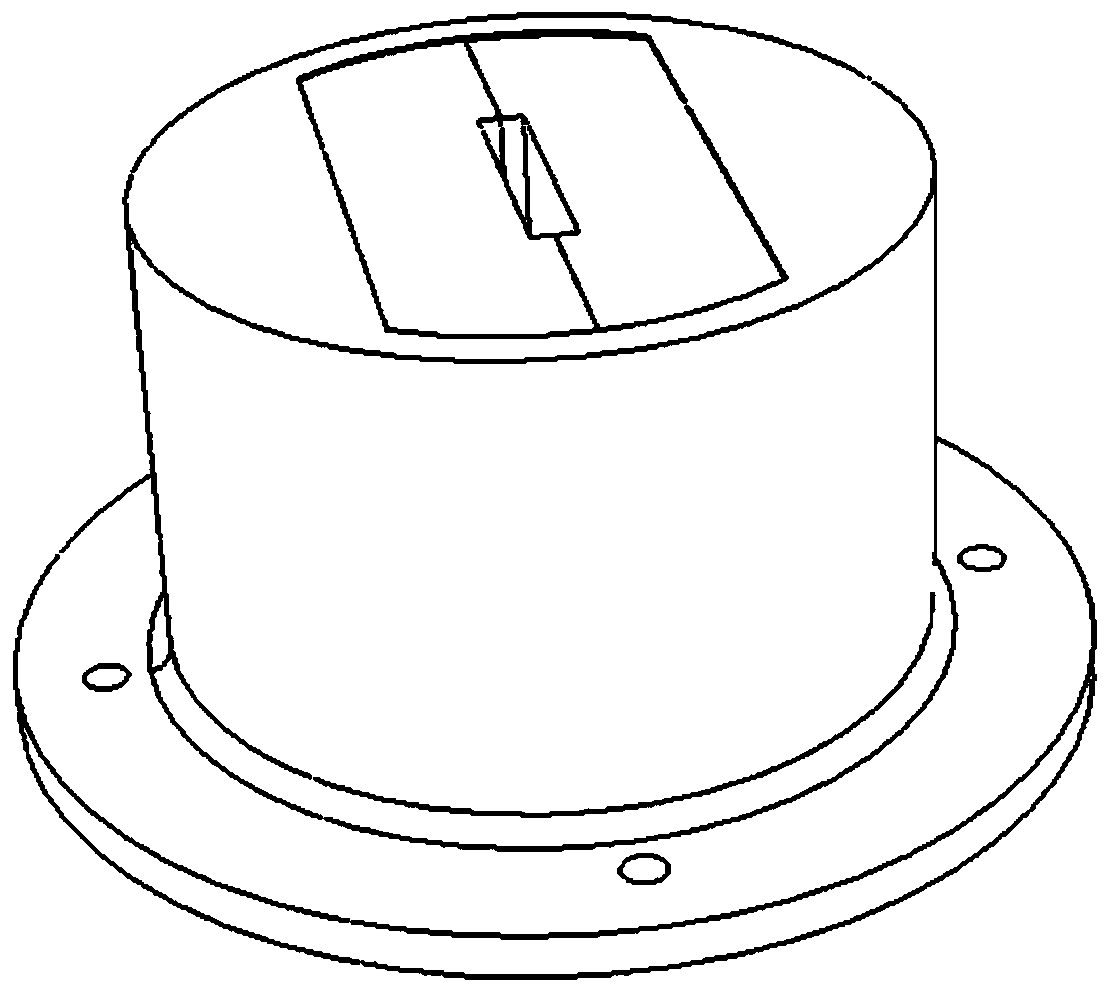

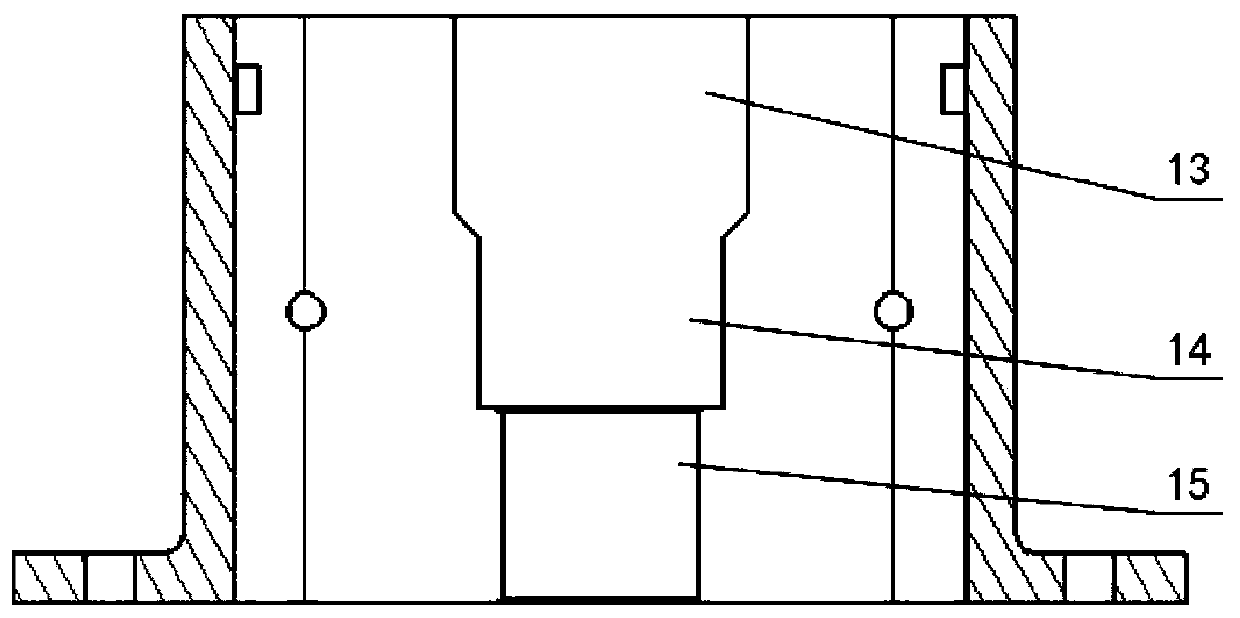

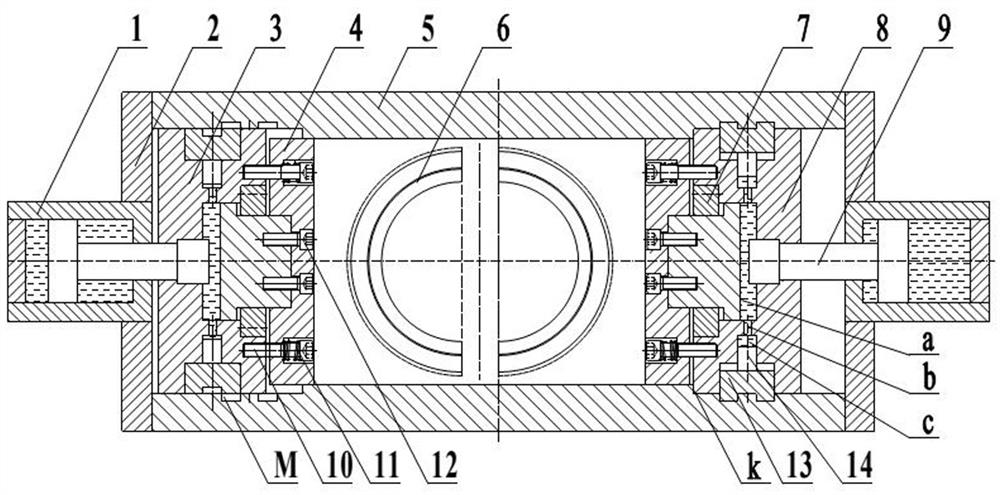

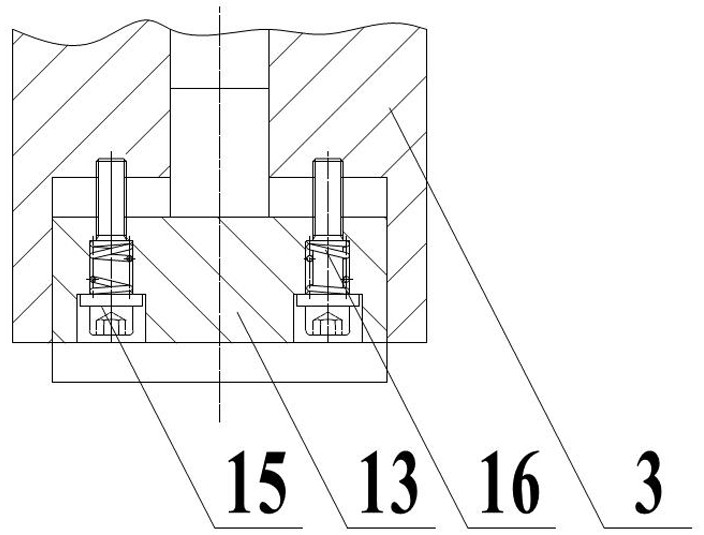

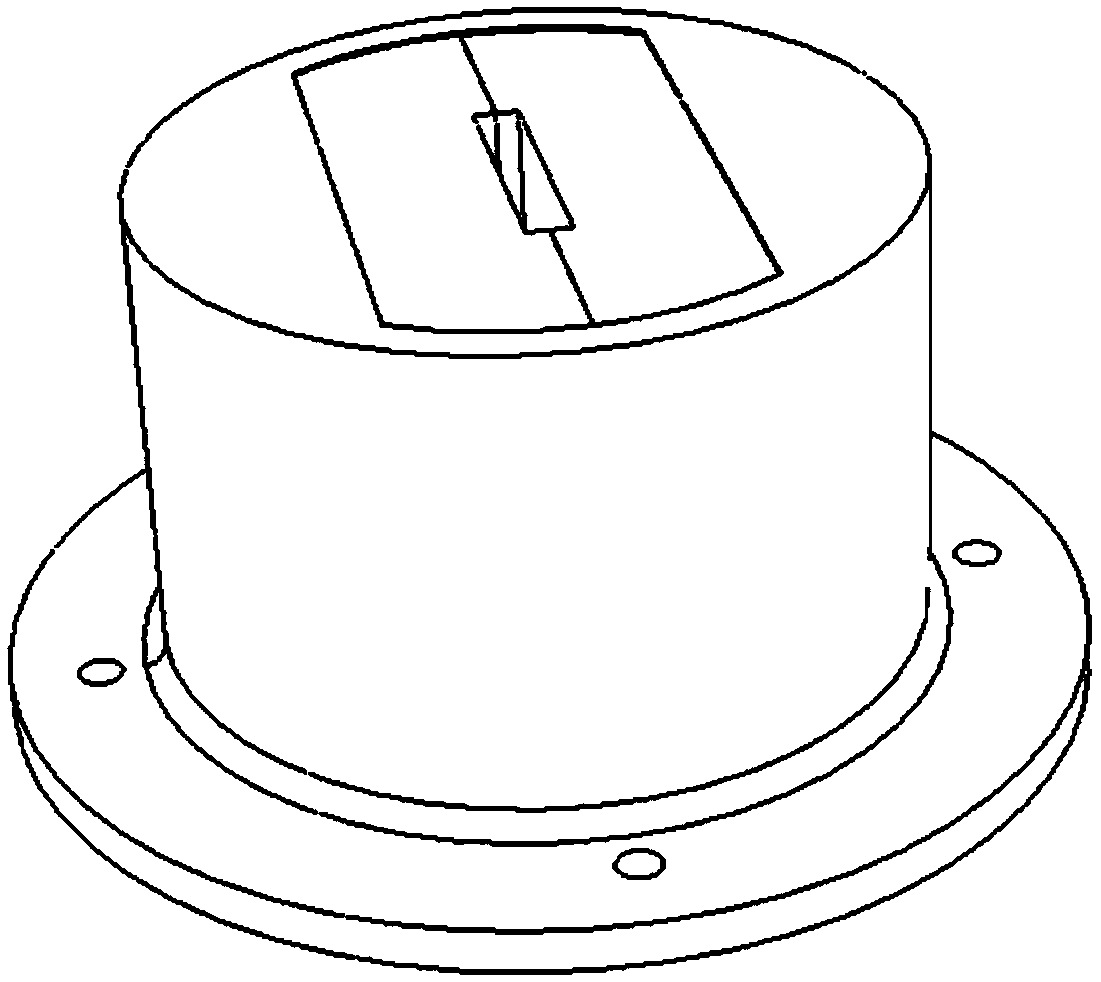

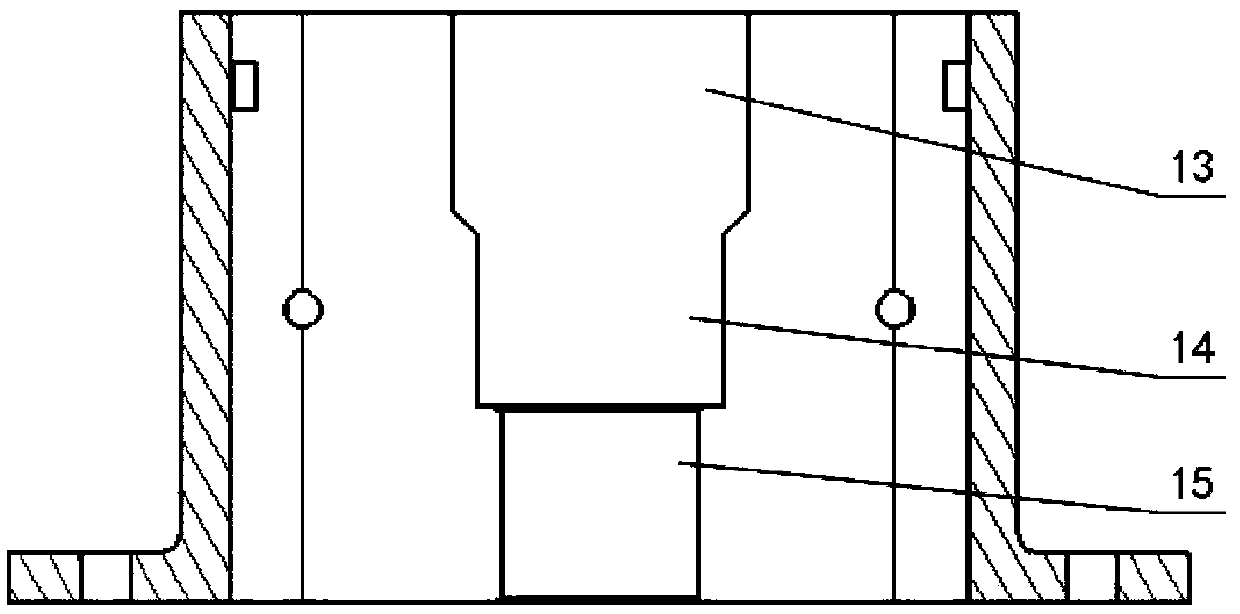

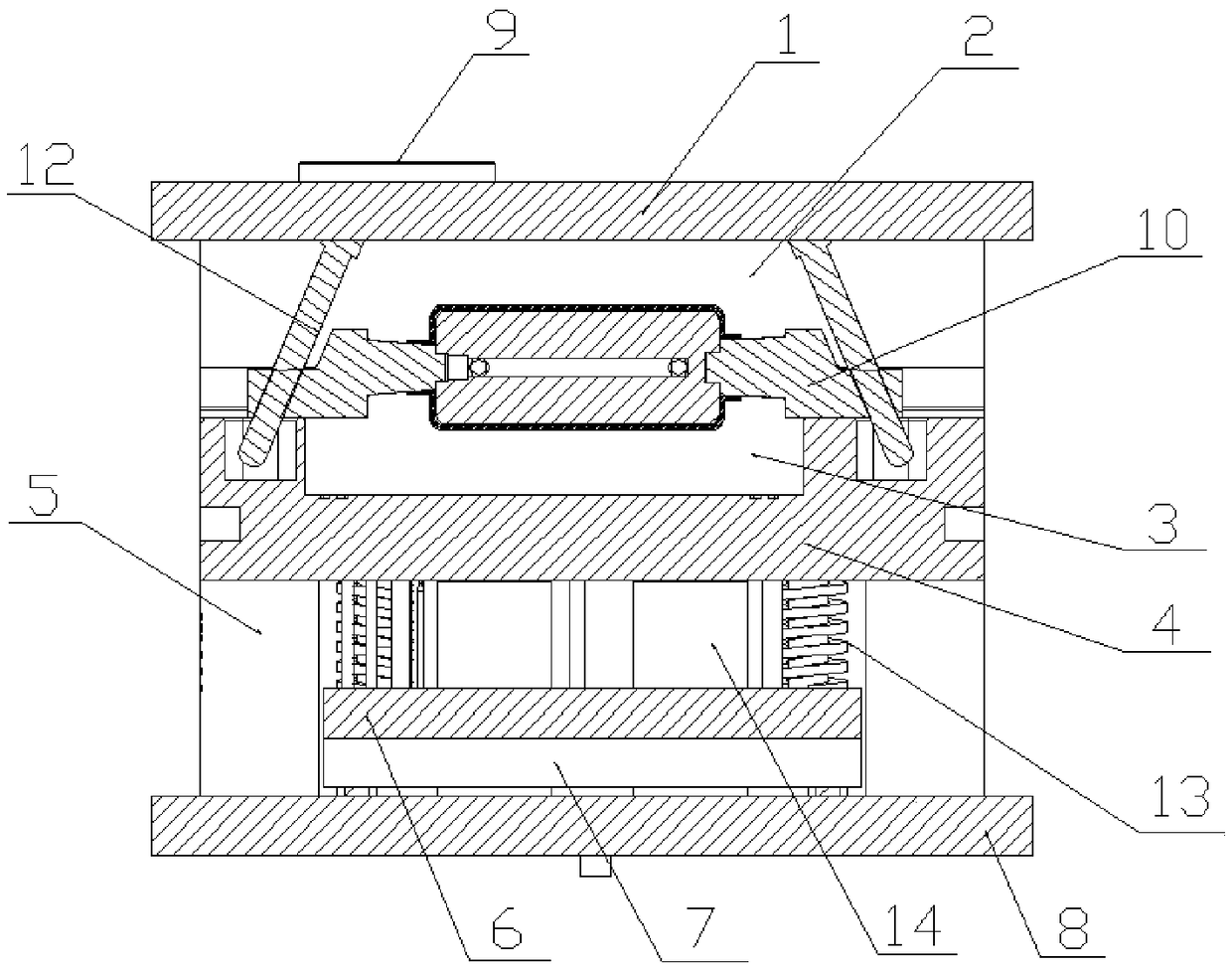

Asymmetric continuous large-deformation extrusion die for magnesium alloy

The invention discloses a magnesium alloy asymmetric continuous large-deformation extrusion processing die, and belongs to the field of non-ferrous metal plastic forming. The asymmetric continuous large-deformation extrusion processing die comprises an upset-extruding cavity at the upper part and an extruding cavity at the lower part, and a forming channel hole can be designed to be in an asymmetric type. The extrusion deformation of one side of a casting material is large while the extrusion deformation at the other side is small, so that the deformation is intensified. Die cores are detachable, and various types of die cores which can be suitable for different sizes are designed, so that different production requirements can be met. After one casting material is deformed, the casting material can be quickly replaced with the next casting material, so that continuous production is realized. The die is mainly used for realizing continuous extrusion forming of a sheet of a magnesium alloy sheet-shaped casting material, and the magnesium alloy sheet-shaped part which is uniform in structure and optimized in performance can be obtained through the processing technology.

Owner:JILIN UNIV

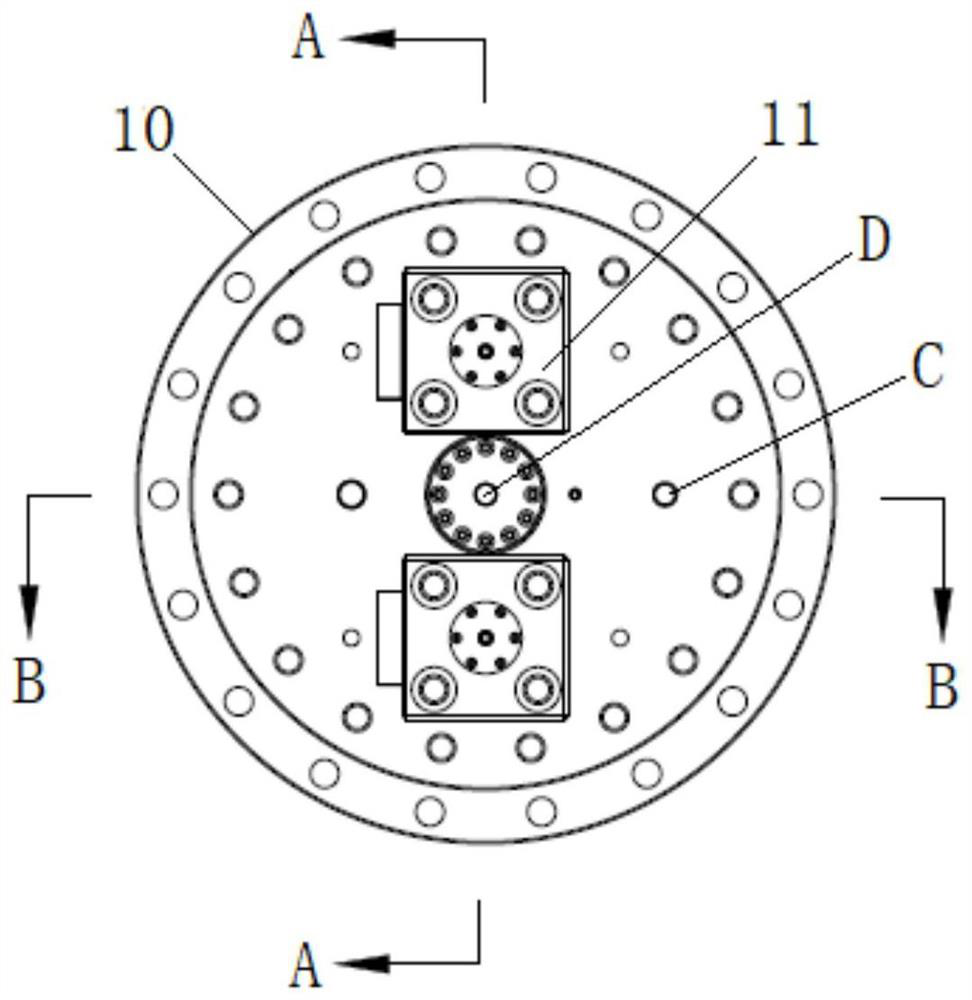

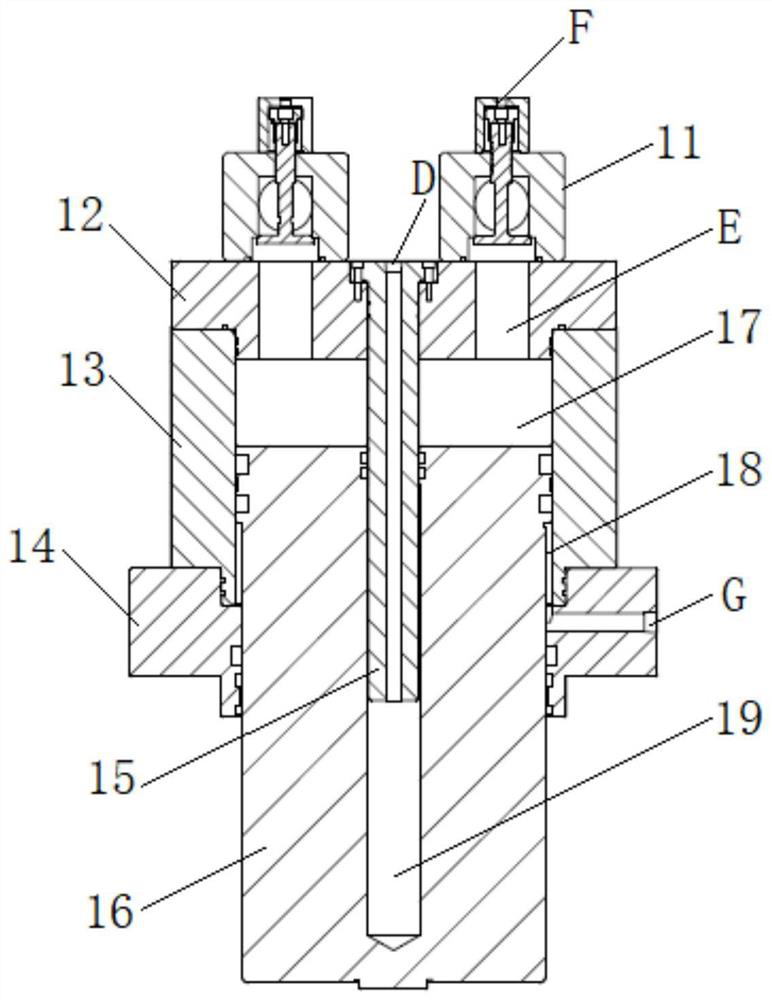

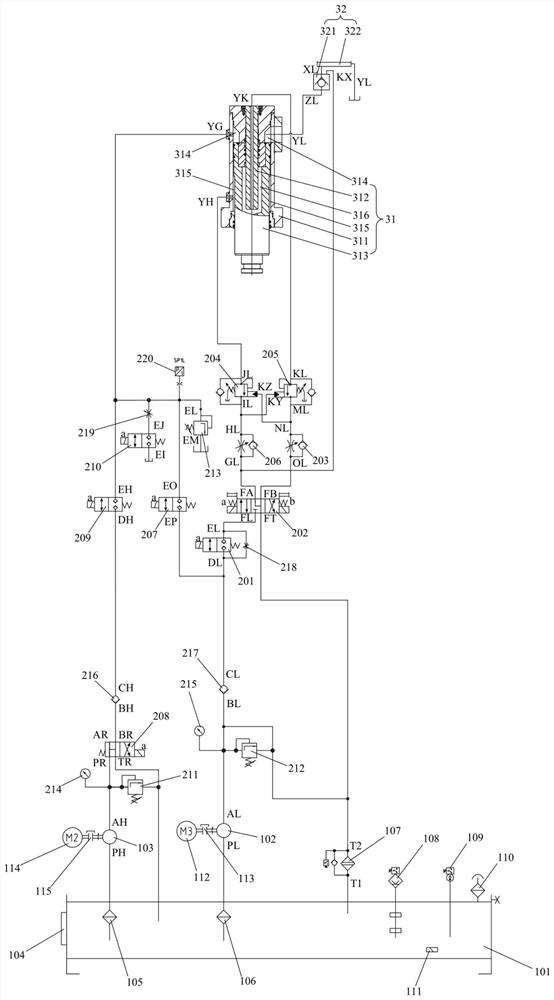

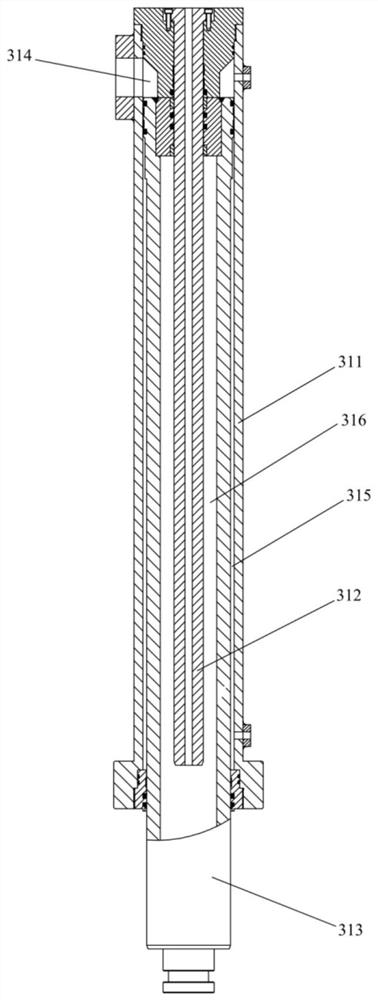

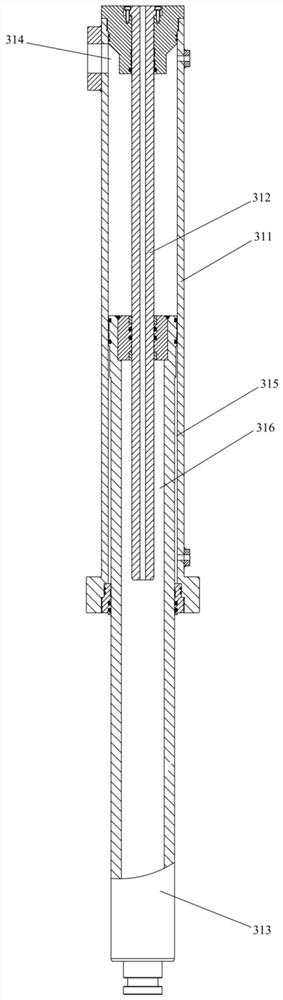

Efficient child-mother cylinder and hydraulic control system thereof

PendingCN113290797AHigh speedLarge outputFluid-pressure actuator testingServomotor componentsOil canCylinder mold

The invention relates to an efficient child-mother cylinder and a hydraulic control system thereof. The efficient child-mother cylinder comprises a mother cylinder body, a child cylinder body and a piston rod. At least one mother cylinder mold closing oil inlet and at least one differential oil inlet are formed in the top of the mother cylinder body, and a mold opening oil inlet is formed in the bottom of the mother cylinder body. The child cylinder body is slidably arranged in the mother cylinder body, and the lower end of the child cylinder body extends out of the cylinder body, so that a mold closing cavity and a mold opening cavity are formed in the mother cylinder body. A mold closing channel extending into the child cylinder body is arranged at the upper end of the child cylinder body. The upper end of the piston rod is fixed to the mother cylinder body, and the lower end extends into the mold closing channel. The piston rod is of a hollow structure, and a child cylinder mold closing oil inlet is formed in the upper end of the piston rod. According to the efficient child-mother cylinder and the hydraulic control system thereof, the mother cylinder mold closing oil inlets are formed in the mother cylinder body so that a large amount of oil can be conveniently fed into the mold closing cavity, and meanwhile, hydraulic oil in the mold opening cavity can be guided into the mold closing cavity through the differential oil inlets, so that the mold closing speed is high, the working efficiency is improved, the output force is large, and the requirement of a large-load occasion can be met.

Owner:SUZHOU LIZHU MACHINERY

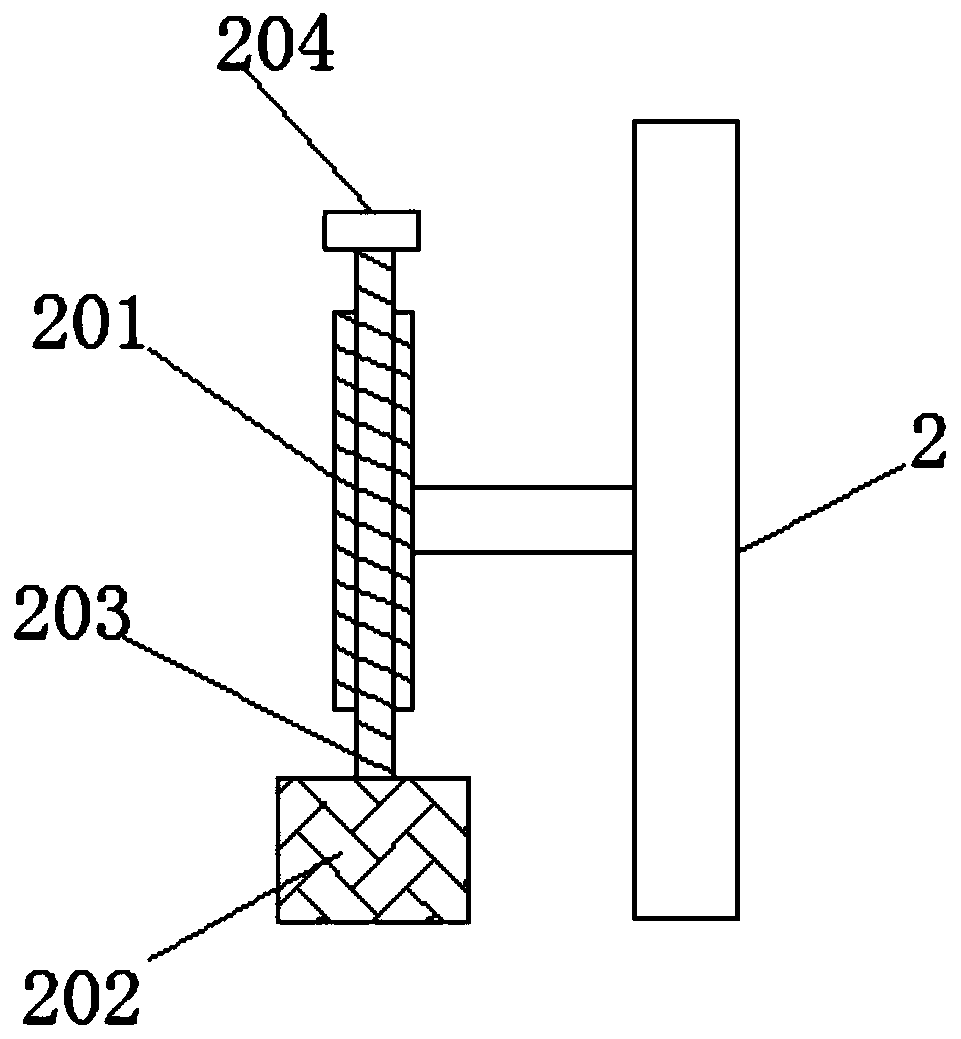

Demolding limiting structure

The invention provides a demolding limiting structure. Through the demolding limiting structure, in demolding, a front mold does not shift in the plane so that the next mold closing process can be carried out fast and accurately, and the distance of travel is less so that energy is saved. The demolding limiting structure comprises a front mold, a rear mold, an A plate and a B plate. A cavity is formed between the front mold and the rear mold. The front mold is fixedly connected to the A plate. The demolding limiting structure is characterized in that the opposite parts of the A plate and the B plate are provided with a guide groove; the guide groove is arranged vertically; a limiting bolt is arranged in the guide groove; the guide groove passes through the B plate and extends to the middle of the A plate from bottom to top; a screw thread part of the limiting bolt passes through the guide groove from bottom to top and is fixedly connected to the A plate; and the a lower part of the limiting bolt is a screw part.

Owner:WUXI CITY NEW DISTRICT WEICHUANGLI MOLD FACTORY

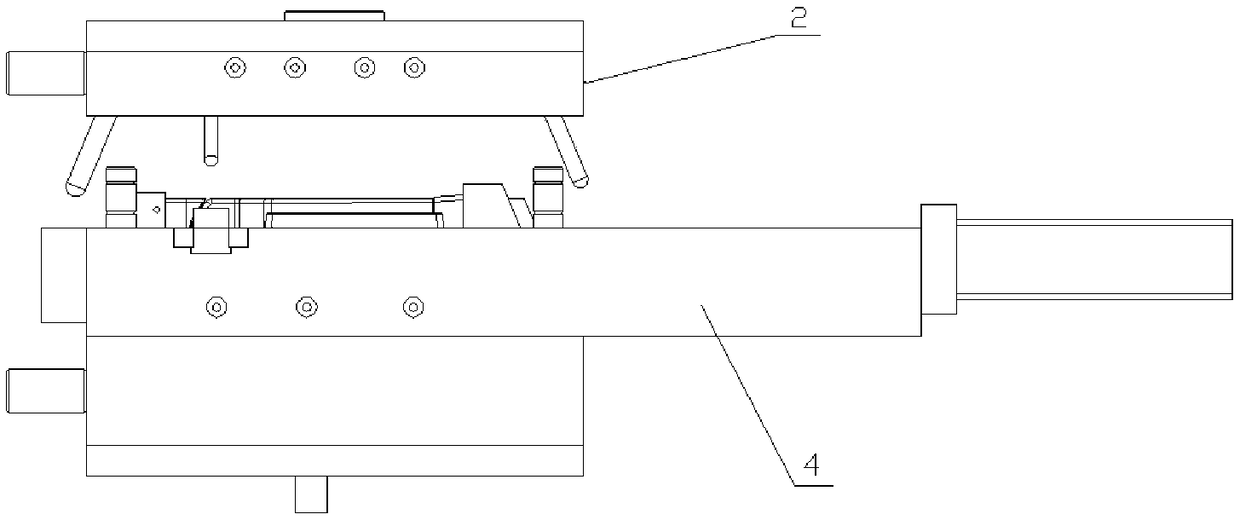

Casting machine capable of quickly locking mold

The invention relates to a casting machine capable of quickly locking a mold. The casting machine is characterized by comprising a main oil cylinder, a middle partition plate, a movable plate, an upper top plate, a first locking guide pillar, a second locking guide pillar, a heat preservation furnace, a pressure kettle, a mold, a split wedge-shaped locking mechanism and a material returning mechanism; the split wedge-shaped locking mechanism consists of a first wedge-shaped locking mechanism and a second wedge-shaped locking mechanism, and the first wedge-shaped locking mechanism and the second wedge-shaped locking mechanism are arranged in a left-right mirror symmetry mode; the material returning mechanism comprises a material returning driving mechanism, a guide column, a material returning guide sleeve, a material returning plate, a material returning rod and a limiting column; and the material returning plate is positioned above the movable plate, the driving end of the material returning driving mechanism is fixedly connected with the material returning plate, the material returning guide sleeve is fixed on the material returning plate, the guide column is arranged in the material returning guide sleeve in a penetrating mode and is in sliding connection with the material returning guide sleeve, and the lower end of the guide column is fixedly connected with the movable plate. The casting machine realizes fast mold locking and mold closing of the casting machine, improves the production efficiency, ensures the operation safety, and has good locking effect during mold locking.

Owner:北京航大新材科技有限公司 +1

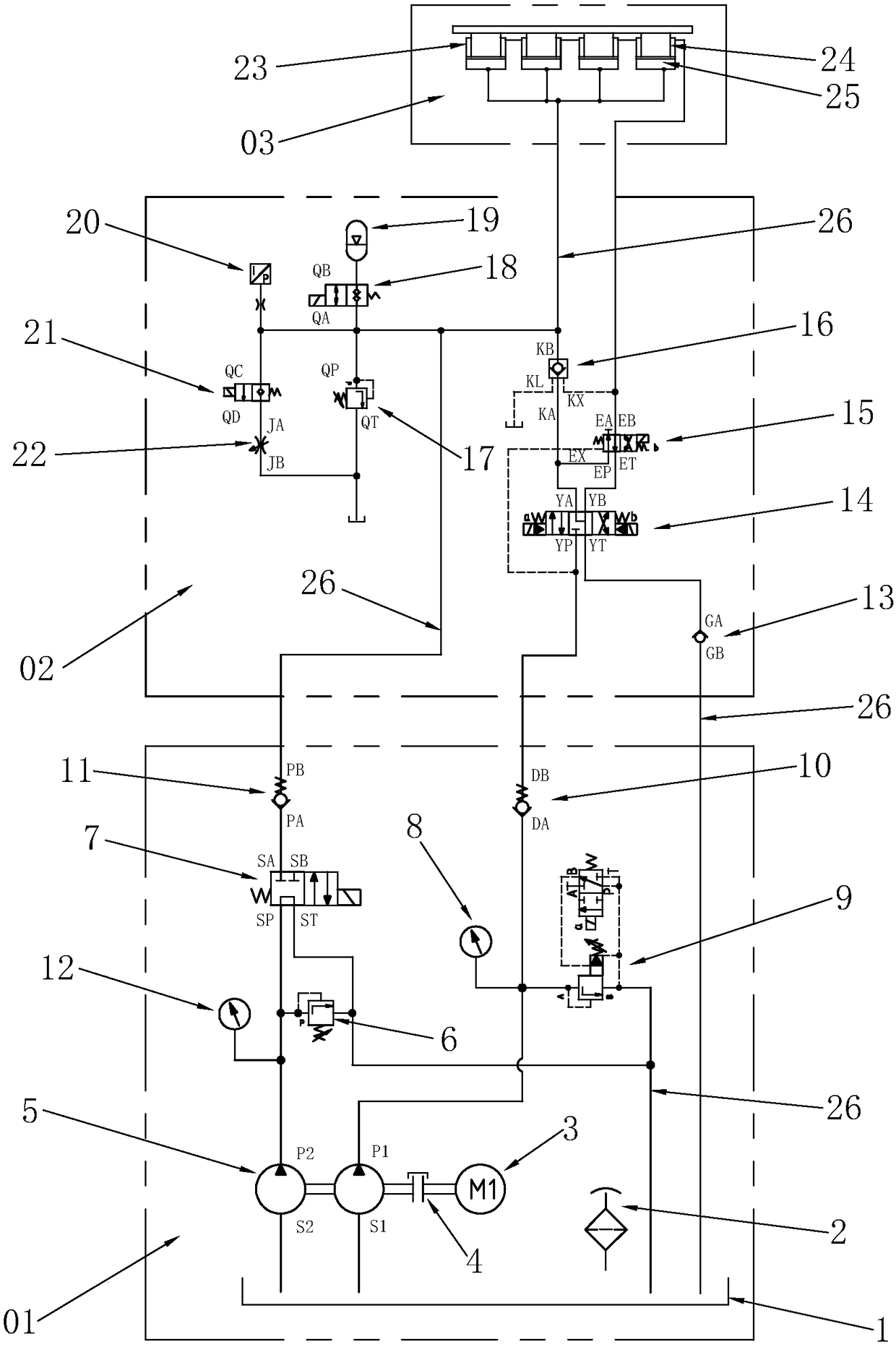

Integrated hydraulic system and tire vulcanizing machine

PendingCN113175463ACompact structureSimple structureServomotor componentsServomotorsHydraulic pumpEngineering

The invention relates to the field of tire forming, and discloses an integrated hydraulic system and a tire vulcanizing machine. The integrated hydraulic system comprises a hydraulic pump source, a control valve block and an executing mechanism, the executing mechanism comprises an integrated oil cylinder and a liquid filling unit, the integrated oil cylinder comprises a cylinder body, a static piston rod and a movable piston rod, the static piston rod is fixedly arranged in the cylinder body, the movable piston rod is arranged in the cylinder body in a sliding mode and matched with the static piston rod in a sliding mode, a rodless cavity and a rod cavity are formed between the movable piston rod and the cylinder body, a fast forward cavity is formed between the movable piston rod and the static piston rod, the liquid filling unit is used for supplying hydraulic oil to the rodless cavity, and the hydraulic pump source supplies the hydraulic oil to the rod cavity, the rodless cavity and the fast forward cavity through a control valve block. The system is compact in structure, reduces the occupied space, is simple and convenient to install, improves the working efficiency, provided with few pipeline connecting points, is low in leakage probability of the hydraulic oil, realizes quick die assembly without additionally outputting flow by an oil pump, reduces the cost and energy consumption, and reduces noise.

Owner:SAFE RUN & HISCENT MACHINERY SUZHOU

Casting mold convenient to position

The invention discloses a casting mold convenient to position. The casting mold comprises a fixing seat, a mounting seat, a fixed mold seat, a mounting frame and a positioning frame, a fixing mechanism is arranged on one side of the surface of the fixing seat and comprises a fixing block, a mounting block, a mounting wheel, a positioning pin and a fixing groove, the fixing block is arranged on oneside of the surface of the fixing seat, and the mounting block is mounted on one side of the bottom end of the fixing block. The fixing block is pushed, the fixing block drives the mounting block tomove, so that the mounting wheel is driven to slide into the fixing groove, the fixing seat and the mounting seat are fixed through the fixing mechanism, then the positioning pin is screwed into the mounting block, the further reinforcing effect is achieved, then operations opposite to the processes are conducted, and the fixing mechanism on one side of the surface of the mounting seat is mounted,so that the functions of stably mounting a lower mold seat of the casting mold and stably forging the casting mold are realized.

Owner:CHENZHOU XIONGJIAN MACHINE TOOL CASTING

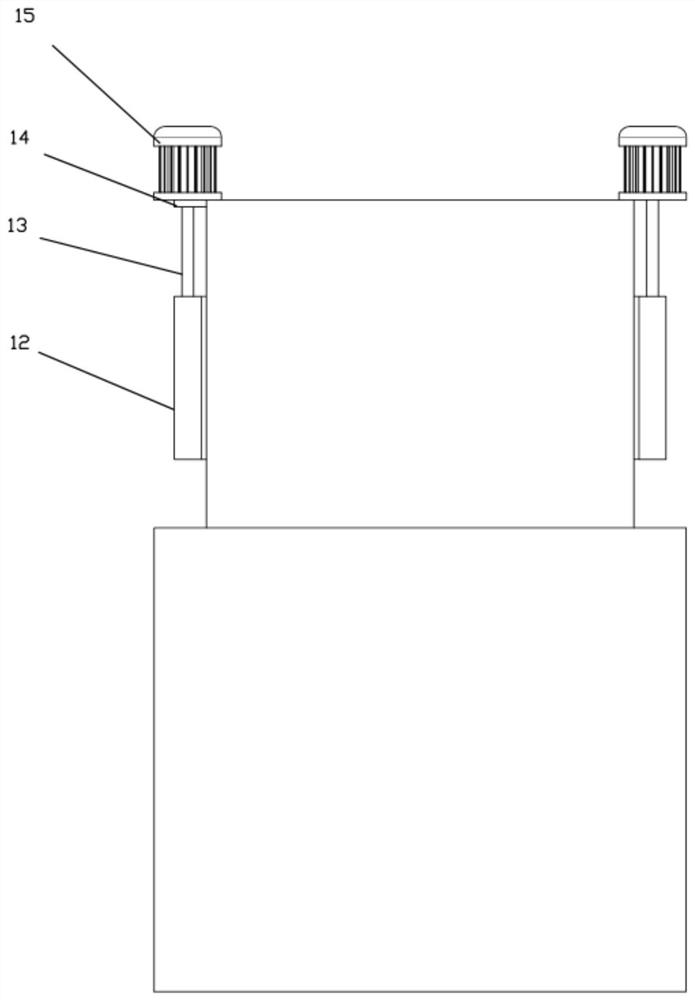

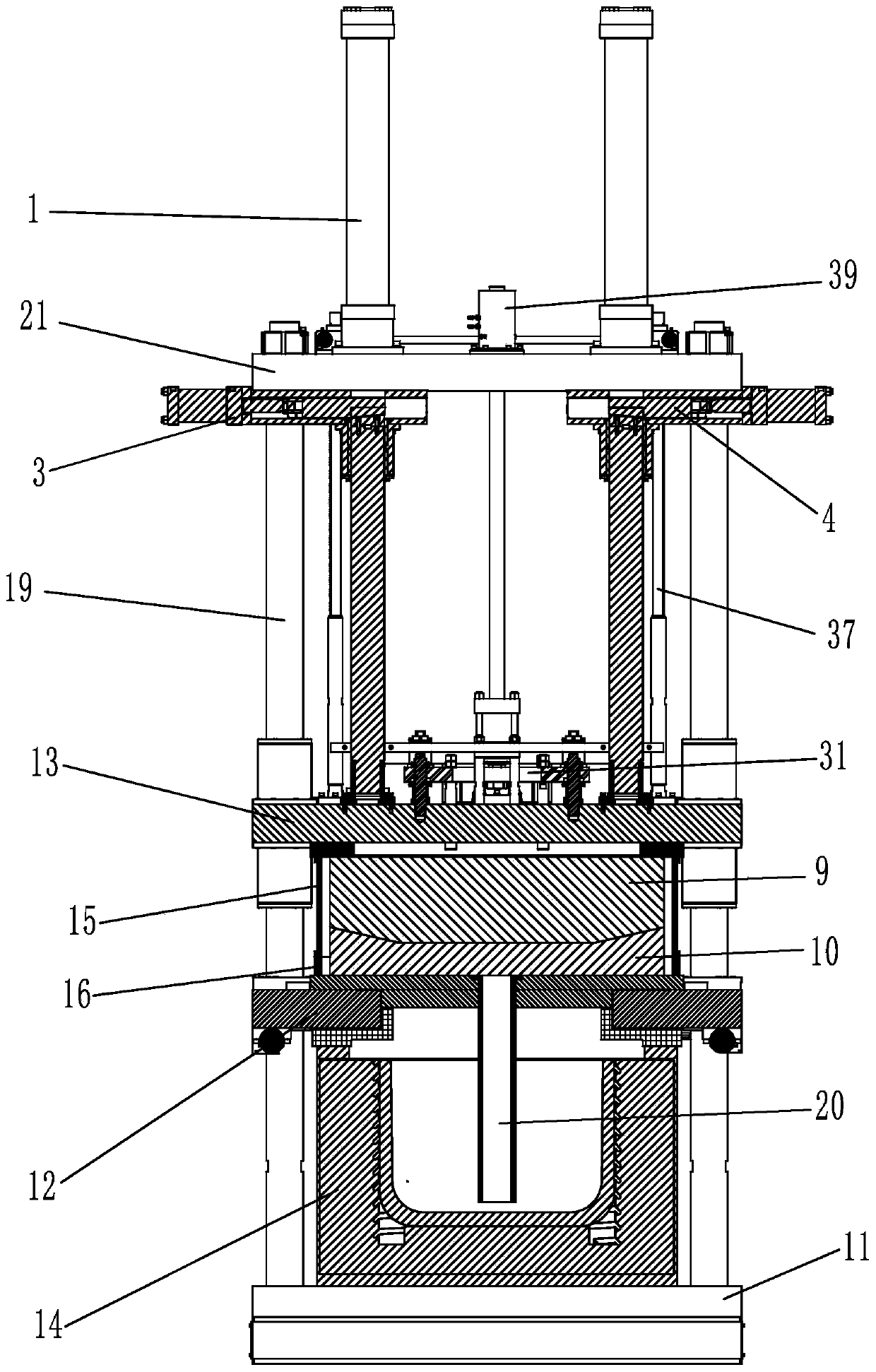

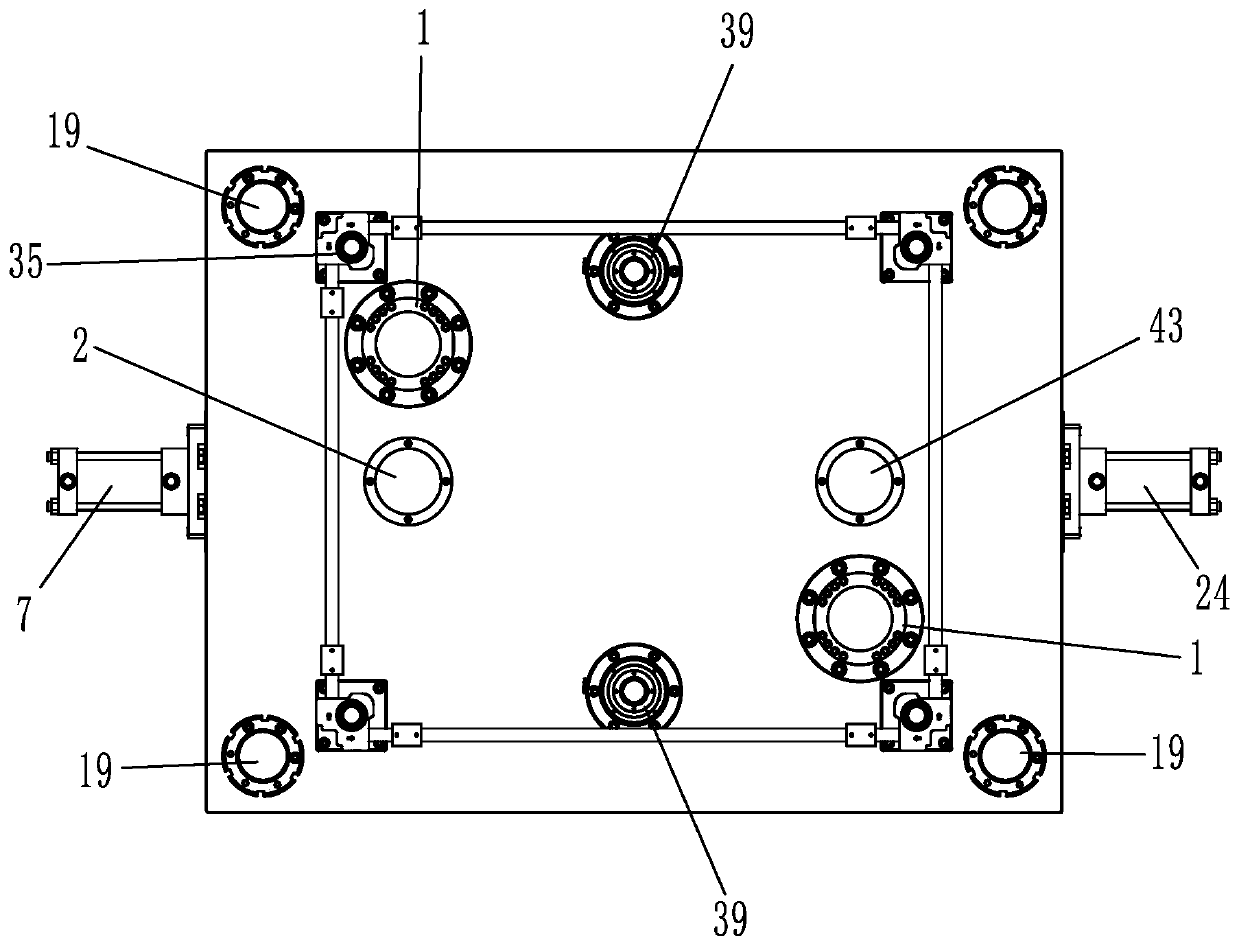

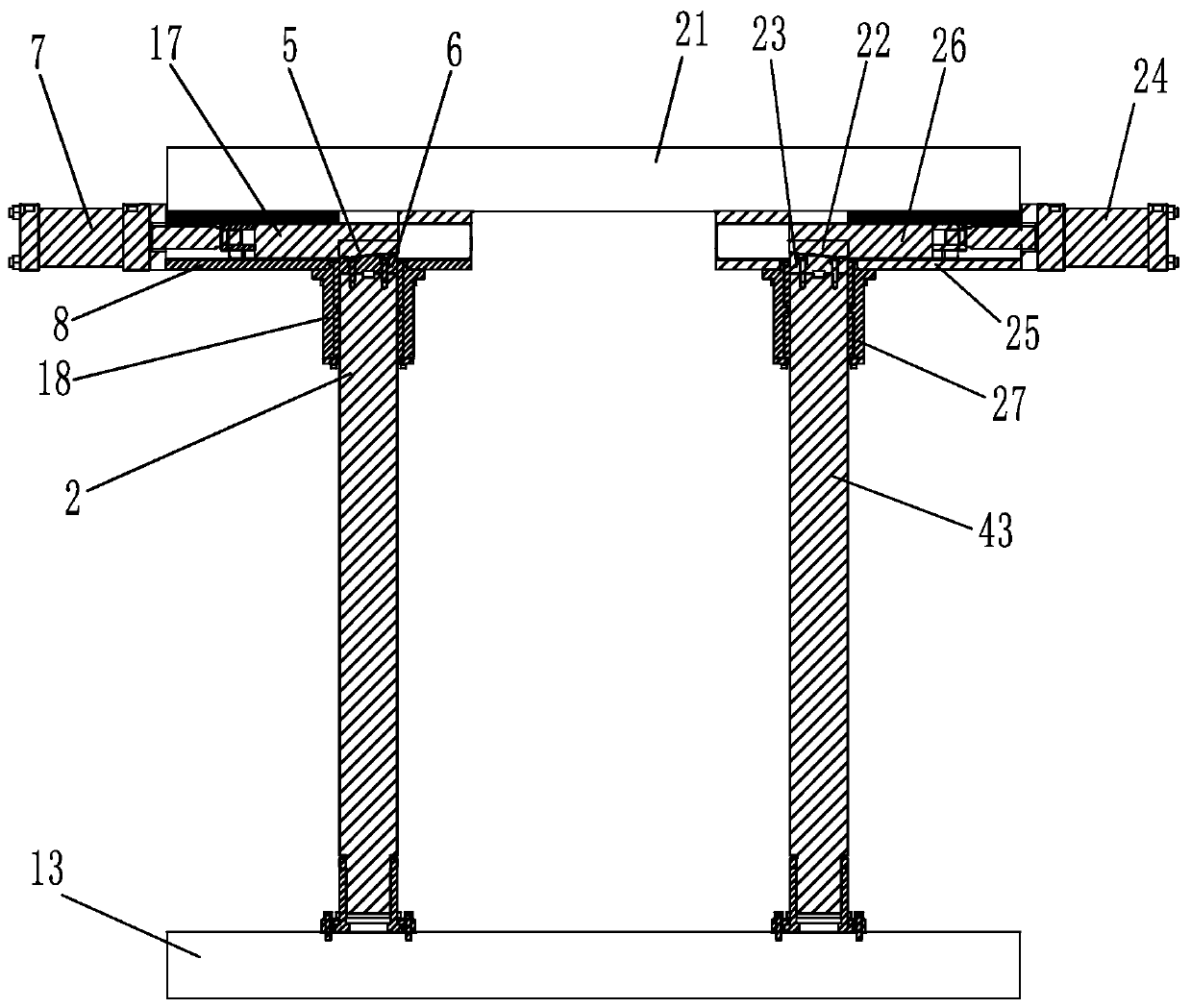

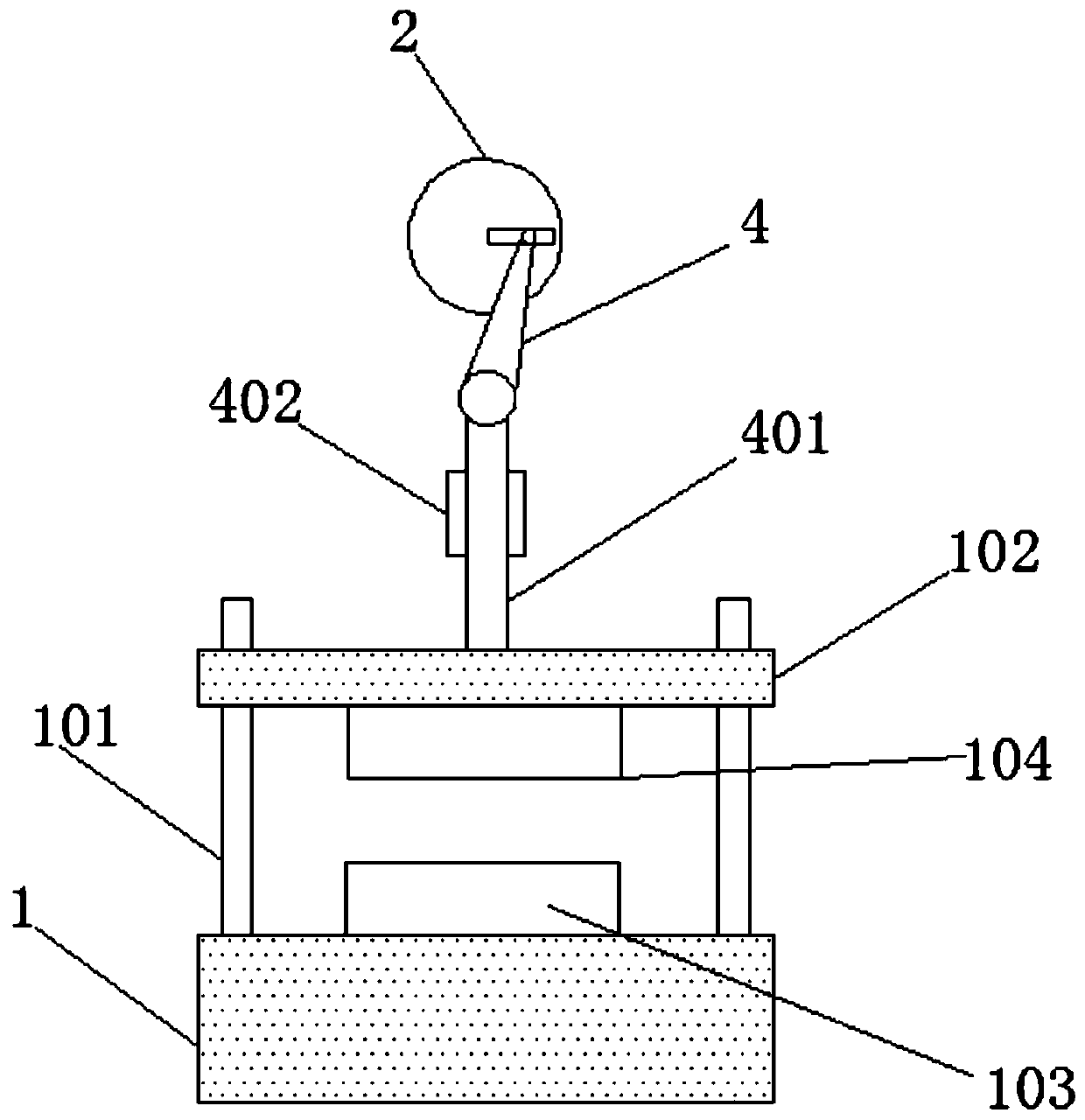

A device and method for installing and pre-adjusting molds of transformer coils based on APG

ActiveCN108987097BReduce temperature dropIncreased process safetyCoils manufactureTransformerInstrument transformer

The invention provides an APG-based transformer coil mold mounting pre-adjusting device and a method thereof. The pre-adjusting device comprises a limiting device and an adjusting device. The limitingdevice comprises a base, two vertical plates and a back plate. The adjusting device comprises a first mounting plate, a second mounting plate, a first fixing block, a second fixing block and a winding fixing block. The connecting wires of the first transformer coil, the second transformer coil and the first transformer coil can be fixed on the two mounting plates respectively through the three fixing blocks. The two vertical plates are provided with grooves, wherein a first limit groove, a second limit groove and a third limit groove are formed between the two vertical plates, the first limitgroove and the first mounting plate are matched, the second limit groove and the second mounting plate are matched, and the third limit groove and the winding fixing block are matched. As that devicedoes not need to adjust the coil unde the high temperature, the mold can be quickly closed to reduce the temperature drop, and the device has the advantages of high processing safety, high product quality and high production efficiency.

Owner:CHONGQING HUAHONG INSTR

A hydraulic pressurized mold clamping device for flap closing molds

ActiveCN113305168BMove quicklySupercharged locking achievedExtrusion diesExtrusion control devicesPressure transmissionEngineering

A hydraulic pressurized mold clamping device for flap-closing molds, comprising a frame, a mold clamping mechanism and a pressurized locking mechanism; the pressurized locking mechanism includes a pressurized mechanism and a pressurized and locked mechanism for the movement of the pressurized mechanism. Constrained restraint mechanism, the pressurizing mechanism includes a pressurizing slider with a pressurizing cavity inside, and a small-diameter pressurizing cylinder and a large-diameter pressurizing cylinder are sequentially arranged in the pressurizing chamber along the mold clamping direction. A pressurizing piston is slidably fitted in the pressurizing cylinder, and a pressurizing piston is slidably fitted in the pressurizing cylinder. The clamping mechanism drives the pressurizing slider to move to a preset position, and pressurizes the pressurization through the restraining mechanism. The position of the slider is locked, the power output end of the clamping mechanism drives the pressing piston to move in the pressurizing cavity, and the pressurizing piston moves through the pressure transmission medium, which exerts a large clamping force on the flap-closing mold. The pressurizing mechanism of this scheme is driven by the mold clamping mechanism, and has a larger mold opening and closing stroke, which increases the mold opening space of the mold and facilitates the process operation.

Owner:HENAN UNIV OF SCI & TECH

Magnesium alloy asymmetric continuous large-deformation extrusion machining mold

ActiveCN109604365AImprove extrusion performanceImprove performanceExtrusion diesNonferrous metalLarge deformation

The invention discloses a magnesium alloy asymmetric continuous large-deformation extrusion processing die, and belongs to the field of non-ferrous metal plastic forming. The asymmetric continuous large-deformation extrusion processing die comprises an upset-extruding cavity at the upper part and an extruding cavity at the lower part, and a forming channel hole can be designed to be in an asymmetric type. The extrusion deformation of one side of a casting material is large while the extrusion deformation at the other side is small, so that the deformation is intensified. Die cores are detachable, and various types of die cores which can be suitable for different sizes are designed, so that different production requirements can be met. After one casting material is deformed, the casting material can be quickly replaced with the next casting material, so that continuous production is realized. The die is mainly used for realizing continuous extrusion forming of a sheet of a magnesium alloy sheet-shaped casting material, and the magnesium alloy sheet-shaped part which is uniform in structure and optimized in performance can be obtained through the processing technology.

Owner:JILIN UNIV

Cable-stayed horizontal injection molding machine

The invention relates to a cable-stayed horizontal injection molding machine comprising a lathe bed, a screw rod, a charging barrel, a hopper, an injection cylinder, a connecting rod mechanism, a die assembly mechanism and a die locking mechanism. The cable-stayed horizontal injection molding machine is characterized in that the connecting rod mechanism is connected with a die assembly cylinder, the die locking mechanism is hinged with a die locking piston disk, the die assembly and the die opening adopt a cable-stayed crank cylinder mechanism, and the die locking adopts a disk type cylinder mechanism. The cable-stayed horizontal injection molding machine has the characteristics of simple structure, low cost, wide adaptability and the like, strengthens die locking capability, improves injection area and is safe and reliable.

Owner:滕武超

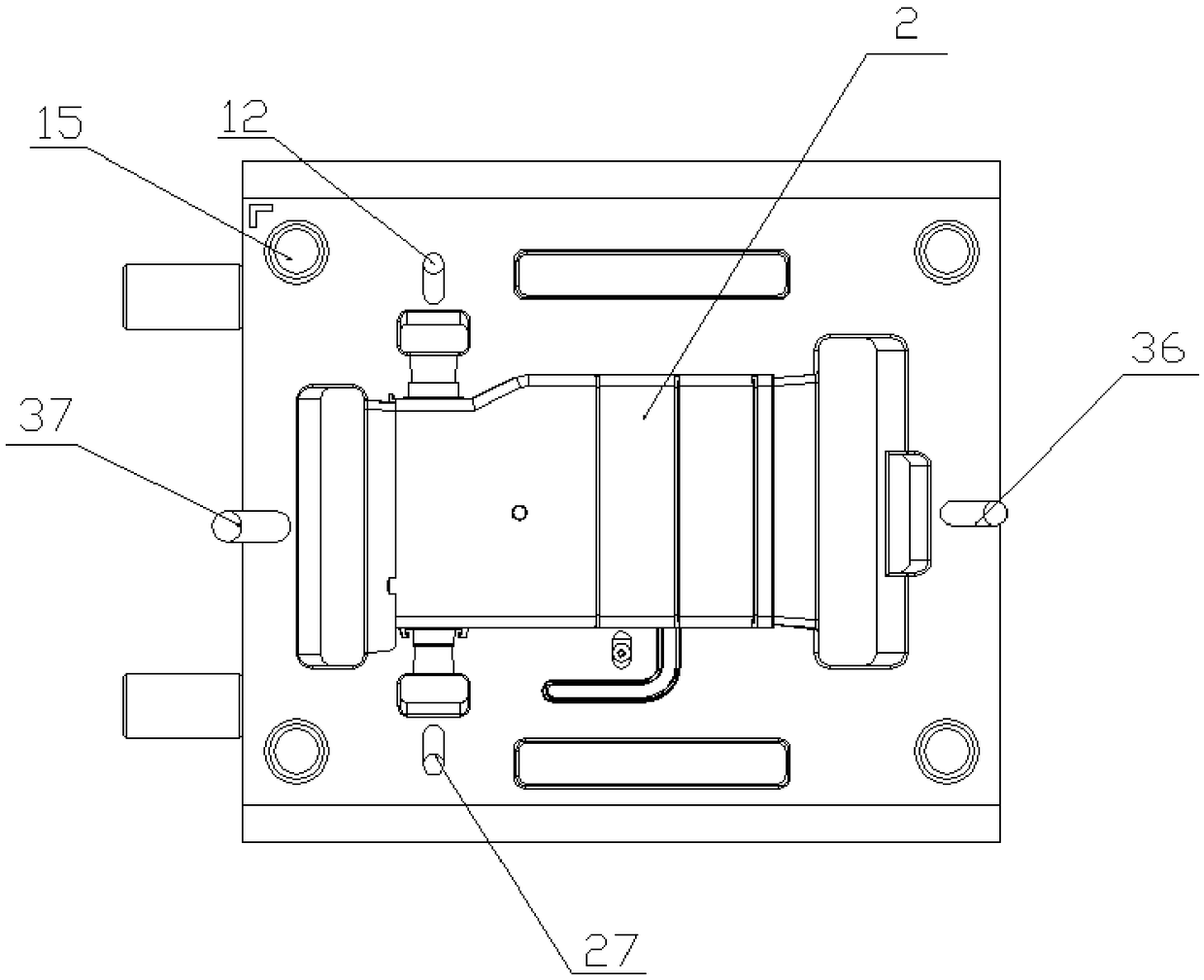

Injection mold of coffee maker material box

InactiveCN109049533AFast mold closingQuick partingDomestic articlesHollow articlesEngineeringMechanical engineering

Owner:杭州天普模具有限公司

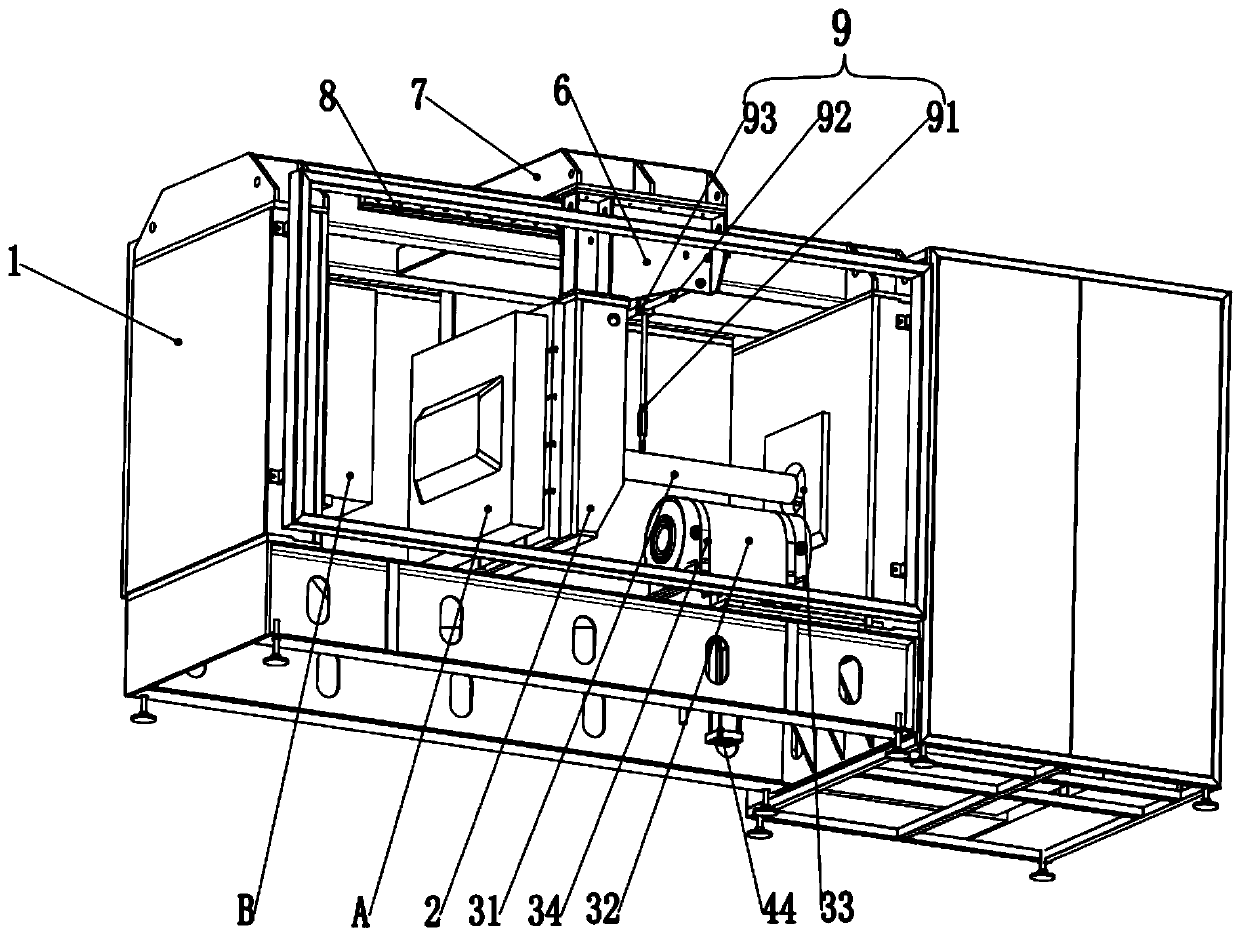

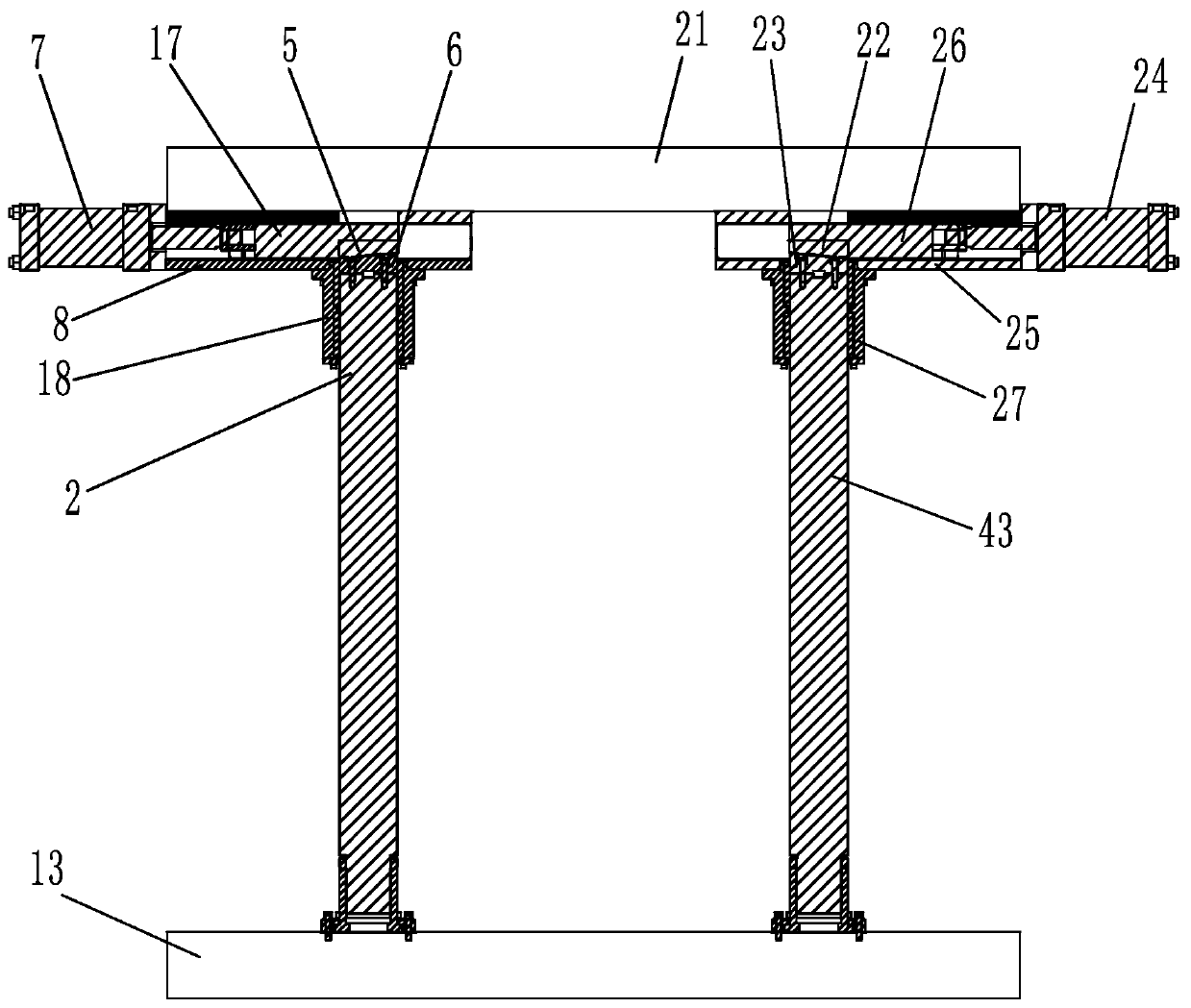

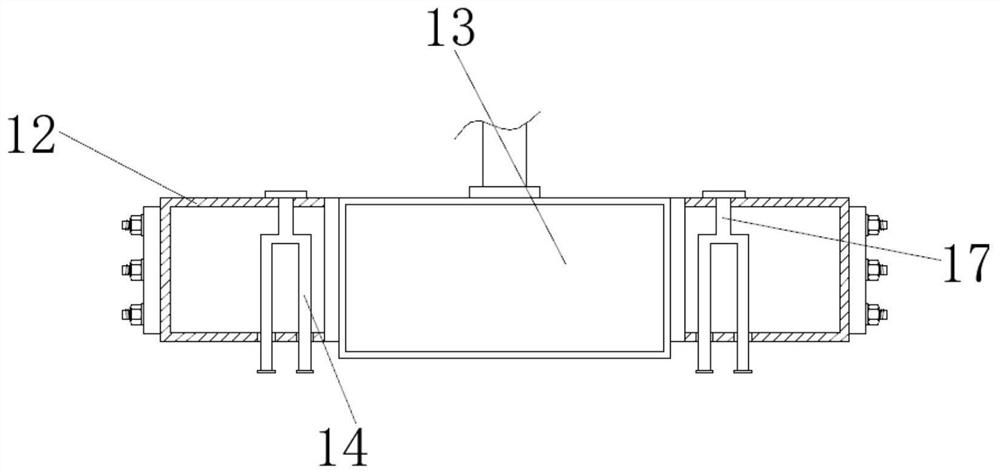

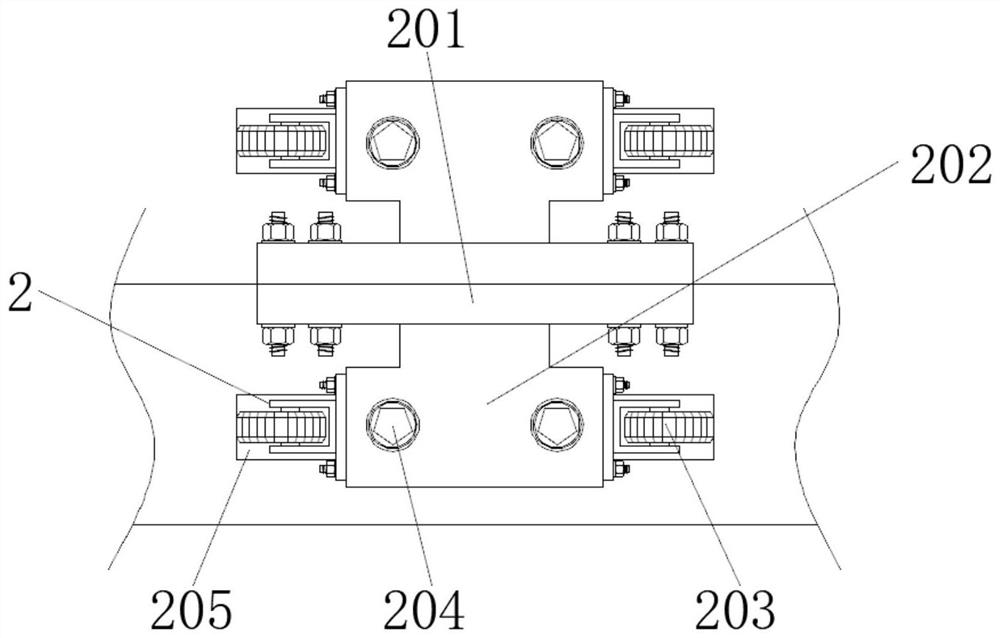

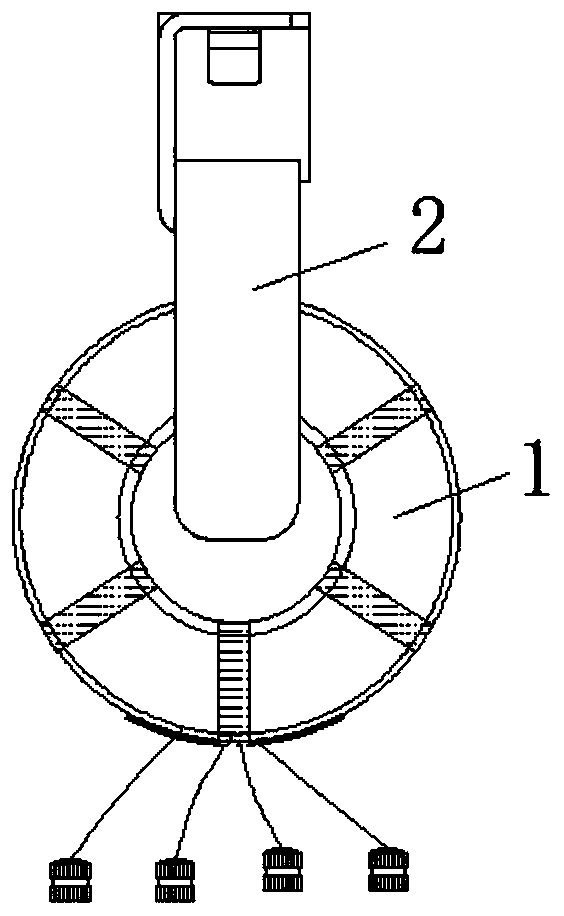

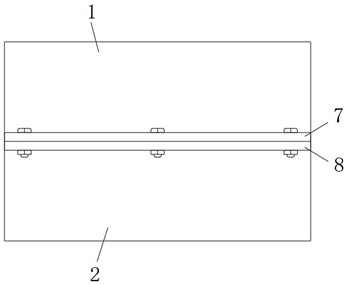

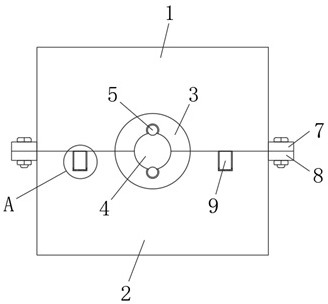

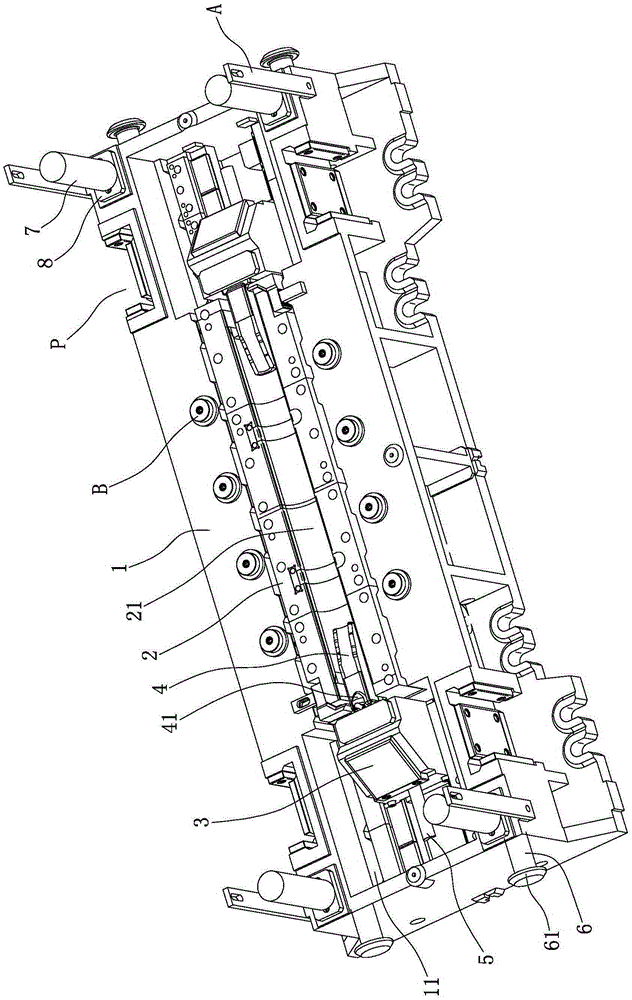

Middle plate structure of horizontal rotary disc opposite-injection machine

The invention relates to a middle plate structure of a horizontal rotary disc opposite-injection machine. The middle plate structure is mainly composed of a middle plate device, a middle plate movingdevice, a transitional connection device, a rotary disc core-pulling device, a rotary disc rotating control device and the like, wherein the middle plate device is mainly composed of a middle plate, amiddle plate fixing seat, a middle plate rotating seat and a middle plate moving plate; the transitional connection device is mainly composed of a transitional connection plate and double-headed bolts; the rotary disc core-pulling device is mainly composed of a rubber hose, a ferrule-type connector, a water divider connecting plate and a steel towing chain; the middle plate moving device is mainly composed of a linear guide rail, a linear guide rail sliding block, a mold-moving piston rod, a connector and hitching legs; and the middle plate rotating control device is mainly composed of a gearreducer and a motor. Moving power is provided for a plate structure by the middle plate moving device, the rotary disc rotating control device controls the rotating direction and the rotating speed of the middle plate, and when the middle plate rotates to the appropriate position, mold-closing is conducted again for injection. Rapid mold-closing of the middle plate structure is achieved through the middle plate moving device, after injection pressure-maintaining is completed, the rotating direction and the rotating speed of the middle plate structure are controlled by the rotary disc rotatingcontrol device, and thus the stable rotating process is achieved.

Owner:TEDERIC MACHINERY

Fast mould clamping device for casting machine

The invention discloses a fast mould clamping device for a casting machine. The casting machine includes a main oil cylinder, a middle partition plate, a moving plate, an upper top plate, a first mould clamping guide pillar and a second mould clamping guide pillar. The fast mould clamping device is characterized in that: the fast mould clamping device includes a split type wedged locking mechanismand a rejecting mechanism; the split type wedged locking mechanism is composed of a first wedged locking mechanism and a second wedged locking mechanism; the first wedged locking mechanism and the second wedged locking mechanism are arranged in a left and right mirror-symmetry manner; the rejecting mechanism includes a rejecting driving mechanism, a guide pillar, a rejecting guide sleeve, a rejecting plate, a rejecting rod, and a limited pillar; and the rejecting plate is arranged on the moving plate, the driving end of the rejecting driving mechanism is fixedly connected with the rejecting plate, the rejecting guide sleeve is fixed on the rejecting plate, the guide pillar penetrates into the rejecting guide sleeve and is connected with the rejecting guide sleeve in a sliding mode, and the lower end of the guide pillar is fixedly connected with the moving plate. According to the fast mould clamping device for the casting machine, fast mould clamping and mould closing of the casting machine are achieved, production efficiency is improved, the operation safety is ensured, and the effect of mould clamping is outstanding.

Owner:北京航大新材科技有限公司 +1

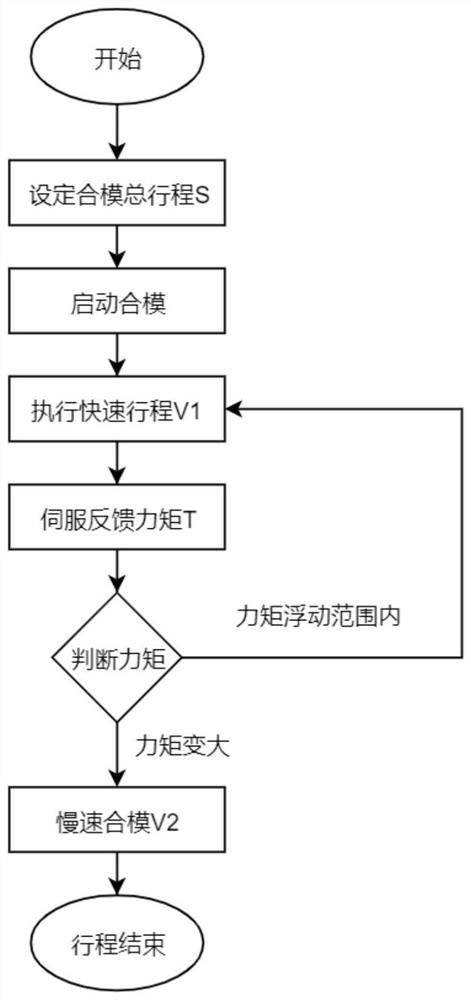

Molding mold blocking method and molding apparatus

PendingCN114318954AReduce shockEffective protectionTextiles and paperProcess engineeringMechanical engineering

The invention provides a mold closing method of a forming mold and a forming device. The mold closing method of the forming mold comprises the steps that the preset moment T0 of mold closing is obtained; a mold closing starting signal is obtained, mold closing is conducted, the real-time torque T1 in the mold closing process is obtained, and the real-time torque T1 is compared with the preset torque T0; and the mold closing speed in the mold closing process is adjusted according to the comparison result of the real-time torque T1 and the preset torque T0. By means of the technical scheme, the technical problem that in the prior art, the mold closing efficiency of a forming mold is low can be solved.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

Expanding die for expanding head of longitudinal welded pipe and manufacturing process of expanding die

InactiveCN113042625AQuality improvementImprove efficiencyShaping toolsFurnace typesEngineeringMechanical engineering

The invention discloses an expanding die for an expanding head of a longitudinal welded pipe and a manufacturing process of the expanding die, and relates to the technical field of dies. The expanding die for the expanding head of the longitudinal welded pipe comprises an upper die and a lower die. The upper die is arranged above the lower die in a covering manner, semicircular grooves are formed in the middles in the upper die and in the lower die, meanwhile, the two semicircular grooves are combined to form a cavity, channels are symmetrically formed in the positions, located on the two sides of the cavity, in the upper die and the lower die, the two channels are connected to the two ends of the cavity correspondingly, so that the cavity communicates with the two channels, ball grooves distributed in the horizontal direction in the equidistant direction are formed in the tops and the bottoms of the inner walls of the two channels, and balls are movably installed in the ball grooves. According to the expanding die, point contact between the balls and the longitudinal welded pipe replaces surface contact between the longitudinal welded pipe and the die, wear of the surface wall of the longitudinal welded pipe is effectively reduced, and the expanding die is beneficial to improving the expanding quality and efficiency of the longitudinal welded pipe.

Owner:扬州杰润机械有限公司

Pneumatic type positioning device used for torsion beam punch forming

InactiveCN105251905APrevent reverseRapid positioningShaping toolsMetal-working feeding devicesEngineeringCushion

The invention discloses a pneumatic type positioning device used for torsion beam punch forming. A tapered wedge block is arranged in each mould cavity of a mould base; opposite ends of two tapered wedge blocks are provided with mandrels; the top surface of the left mandrel is integrally formed with a convex hull which is close to the right end surface of the corresponding tapered wedge block; stand columns are arranged on four corners of the top surface of the mould base, and the lower end of each stand column is fixed with a cushion block; a group of connecting plates is arranged at each of left and right ends of the mould base; the connecting plates are in the shapes of long-strip rectangles; front and rear rows of limiting blocks are arranged on the middle part of the top surface of the mould base; the limiting blocks are two-section type hollow short columns which are small in upper parts and large in lower parts; guide slots are symmetrically formed in front and rear sides of the left end of the mould base; guide slots are also symmetrically formed in front and rear sides of the right end of the mould base; and the four guide slots are distributed in the shape of a rectangle. The pneumatic type positioning device is delicate in conception, reasonable in design, easy to implement, simple in structure and high in production efficiency; and the formed torsion beam is easy to identify in a left-right direction.

Owner:CHONGQING SKYMAN AUTOMOBILE BODY MFG

Double-layer tire vulcanizer pressurization oil cylinder hydraulic control system

ActiveCN109501339AFast mold closingGuarantee vulcanization qualityServomotor componentsServomotorsControl systemFuel tank

The invention provides a double-layer tire vulcanizer pressurization oil cylinder hydraulic control system comprising a hydraulic pump source, a control valve block and a pressurization oil cylinder which are connected through pipelines. The hydraulic pump source comprises an oil tank, a double oil pump, a first check valve, a second check valve and a third reversing valve. The control valve blockcomprises a third check valve and a first reversing valve. S1 and S2 openings of the double oil pump are both connected with the oil tank. A P1 opening of the double oil pump is connected with a DA opening of the first check valve. A DB opening of the first check valve is connected with a YP opening of the first reversing valve. A YA opening of the first reversing valve is connected with a rodless cavity of the pressurization oil cylinder. A P2 opening of the double oil pump is connected with an SP opening of the third reversing valve, and an SA opening of the third reversing valve is connected with a PA opening of the second check valve. A PB opening of the second check valve is connected with the rodless cavity of the pressurization oil cylinder. A rod cavity of the pressurization oil cylinder is connected with a YB opening of the first reversing valve. A YT opening of the first reversing valve is connected with a GA opening of the third check valve. A GB opening of the third checkvalve is connected with the oil tank.

Owner:油威力液压科技股份有限公司

Powder metallurgy bearing bush production forming die

InactiveCN113290241AImprove work efficiencyEasy to unloadTurbinesOther manufacturing equipments/toolsMachineWorkbench

The invention relates to a powder metallurgy bearing bush production forming die which comprises a workbench, a fixing device and a forming device. The fixing device is arranged at the top of the workbench, and the forming device is arranged at the position, located on the outer side of the fixing device, of the top of the workbench. Through cooperation of the workbench, the fixing device and the forming device, firstly, a bearing bush die needing to be produced and formed is subjected to rapid die assembly and die disassembly through the arranged fixing device, so that the working efficiency of a machine during die assembly and die disassembly is greatly improved, the machine can produce a plurality of bearing bushes in batches at the same time through cooperation of the arranged fixing device and the forming device, and therefore, the working efficiency of the machine during production is improved.

Owner:魏海涛

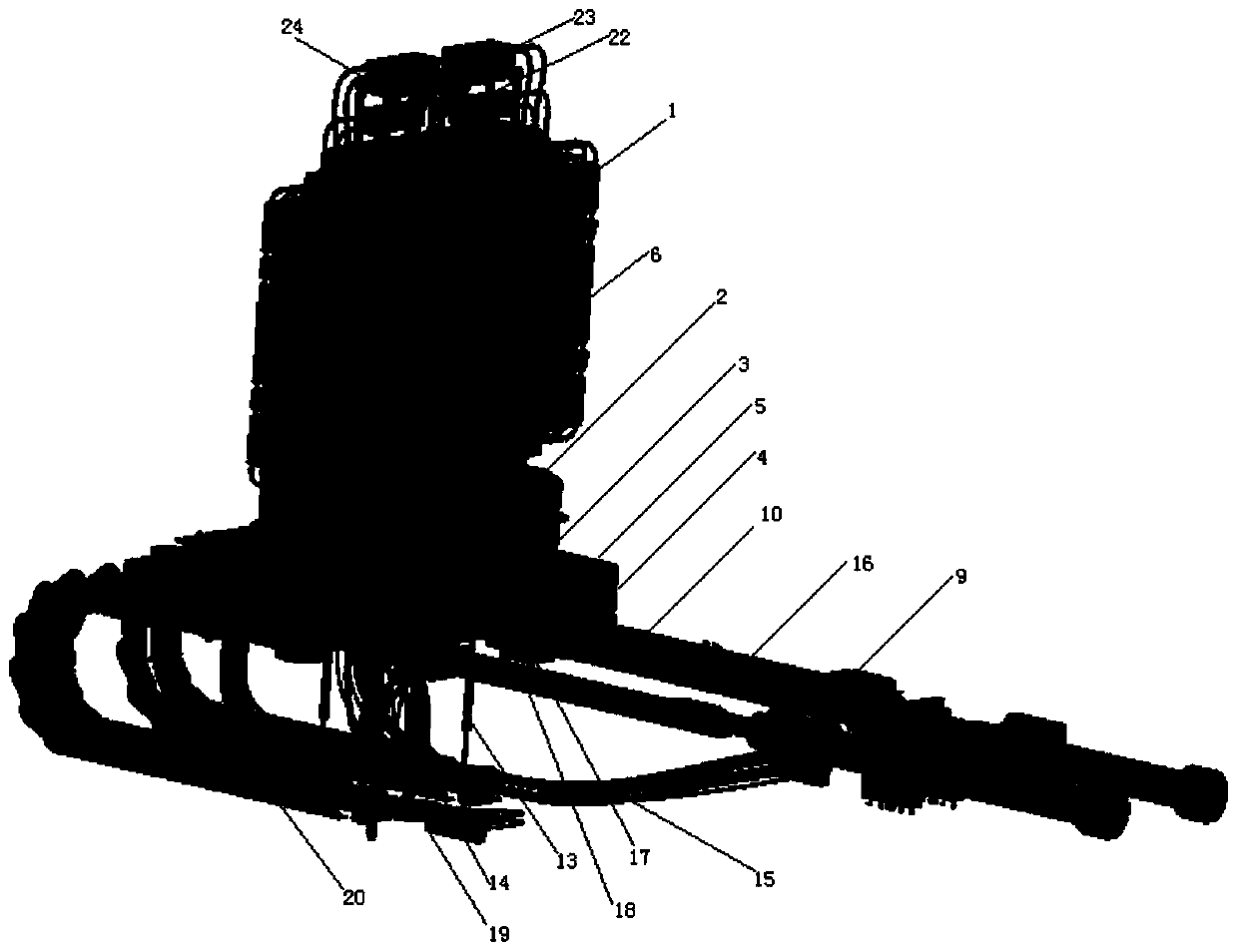

A gas-assisted rapid clamping ultra-high-strength steel hot stamping die

The invention relates to a super-strength steel hot stamping die capable of carrying out rapid spotting through gas assistance and belongs to the field of hot stamping forming. The die is mainly formed by an air cylinder (3), a male die (6), a female die (8), a fixing plate (5), an upper die plate (1), a lower die base (7) and other main parts. The male die (6) is arranged on the upper die plate (1) through the fixing plate (5). The air cylinder (3) is arranged in the fixing plate. A piston rod of the air cylinder is connected with the male die. In the stamping process, air enters to push the male die to rapidly descend through the air cylinder, a sheet metal (11) is rapidly stamped and formed, and the male die and the female die (8) rapidly carry out spotting. The super-strength steel hot stamping die mainly solves the problems that a used common hydraulic machine is too low in spotting speed, thus, the temperature of the sheet metal drops too fast, the cooling effect is uneven, and the mechanical properties of a workpiece is poor in the hot stamping forming process, and has importance guiding significance on utilizing an existing common hydraulic machine to produce super-strength steel hot stamping pieces for manufacturing enterprises.

Owner:JILIN UNIV

Forming device for PVC pipe

InactiveCN111086154AImprove injection qualityWith self-locking functionTubular articlesElectric machineInjection molding machine

The invention discloses a forming device for a PVC pipe. Very one circle a rotary plate rotates, an upper die holder can be driven to conduct die assembling operation one time, and the die assemblingspeed is higher; by adjusting the rotating speed of a motor, the die assembling speed can be adjusted, and manipulation is more facilitated; a worm gear and a worm cooperate with each other, so that the forming device has a self-locking function, die expansion can be effectively prevented during injection molding, and the injection molding quality of an injection molding piece can be effectively improved. The rotating diameter of the rotary plate can be adjusted, the lifting distance of the upper die holder can be flexibly adjusted, and the forming device is more flexible and convenient to use. A buffer device is arranged in a feeding hopper of an injection molding machine, a material is prevented from falling into the injection molding machine at high speed, the injection molding machineis prevented from being damaged, and the service life of the injection molding machine is prolonged. The feeding hopper introduces hot air discharged from an exhaust duct into a blower through a hot air recovery device, the hot air is recycled by the blower, the temperature in a plant is prevented from being raised, and the air in the plant keeps clean.

Owner:江阴市德伯仁管件有限公司

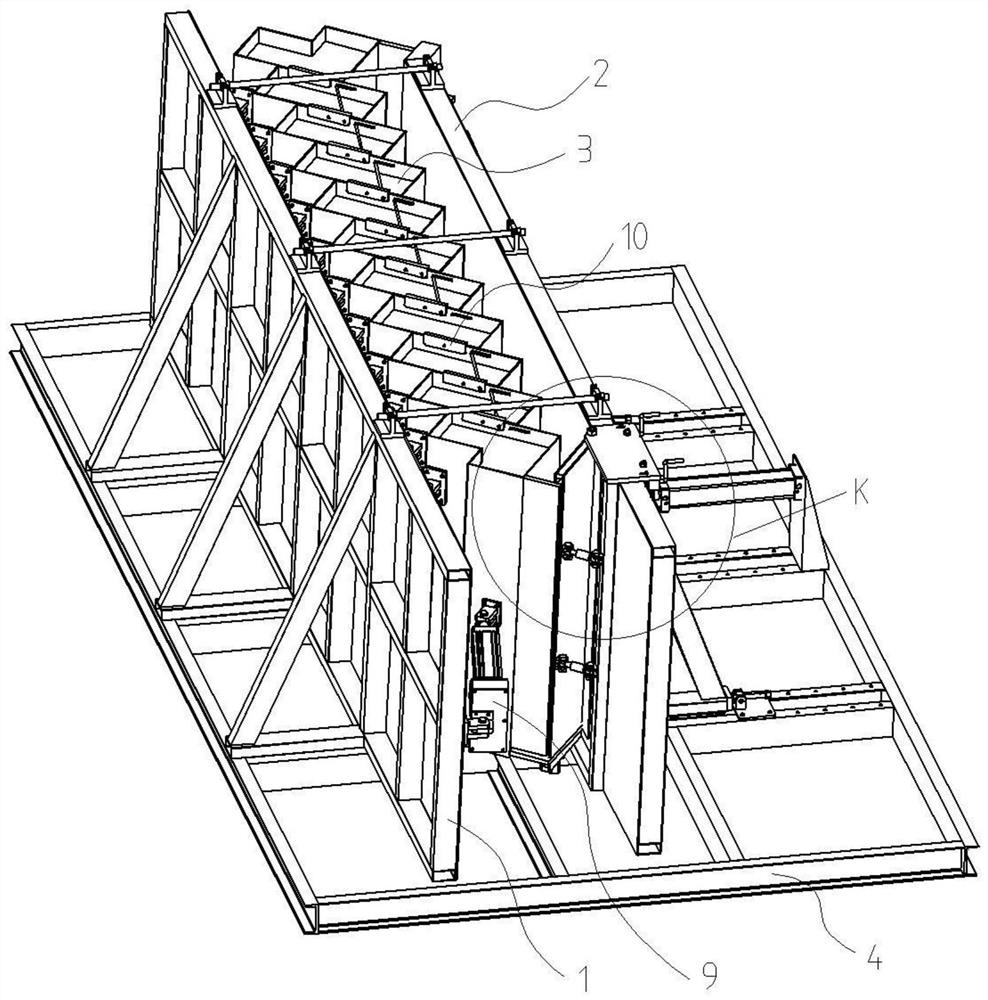

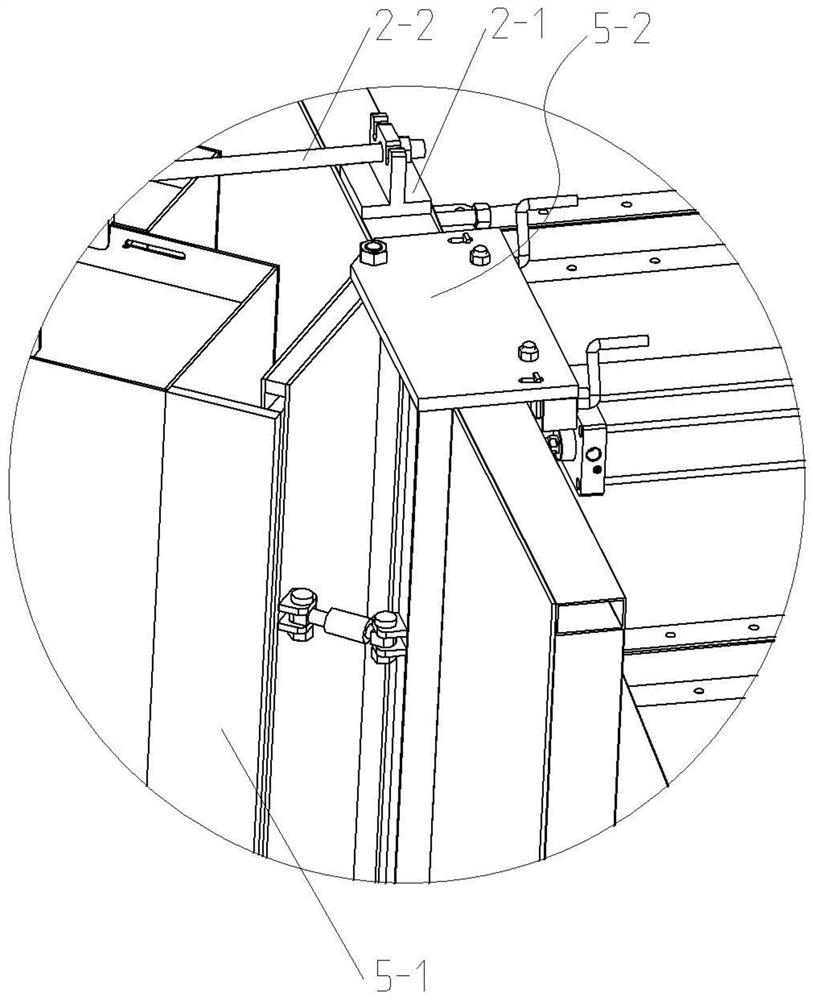

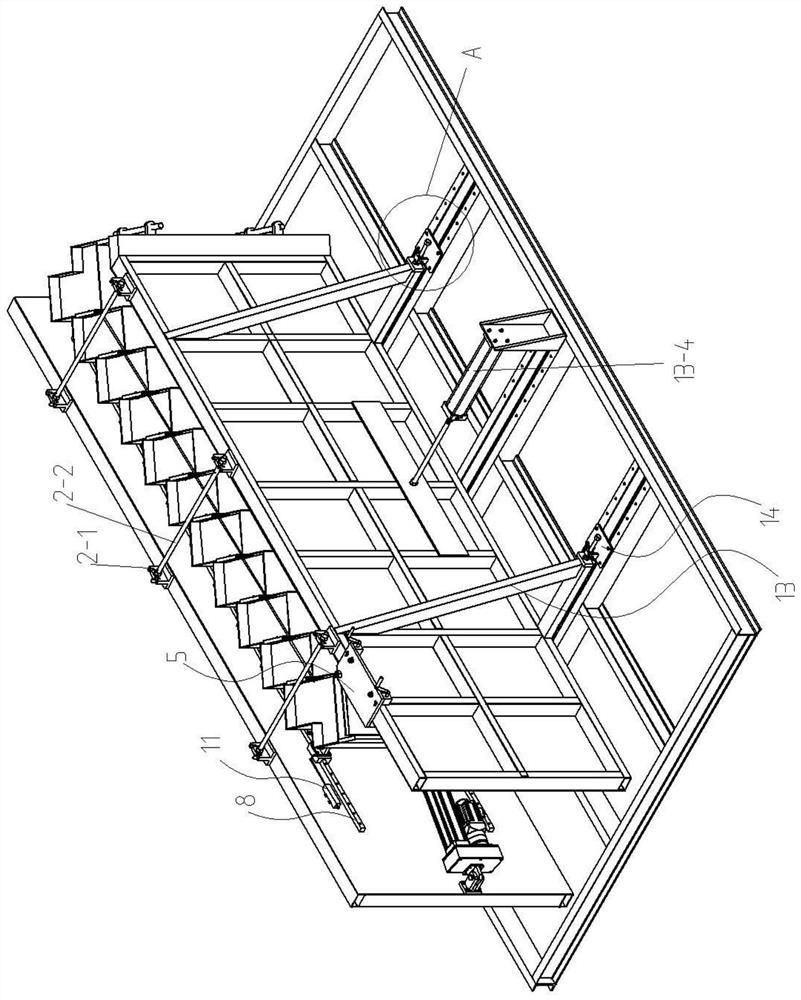

Vertical adjustable modulus prefabricated staircase forming equipment and its step height adjustment method

The invention relates to a vertical adjustable module prefabricated stair forming equipment and a step height adjustment method. The vertical adjustable module prefabricated stair forming equipment includes a fixed side mold, a movable side mold and a stair step module, and also includes a guide device, Drive control module, chute synchronizer, detection control module, bottom mold lifting module, quick mold opening and closing device, mechanical locking device, quick disassembly and assembly module; a vertical adjustable module prefabricated staircase forming equipment using this solution It has the stepless adjustable modulus of stair mold step height, stair width, and stair step number. One piece of equipment can meet the production requirements of various types of stairs, and realize flexible and automated production of prefabricated components, while greatly improving production efficiency. It also has the advantage of significantly reducing the production cost of prefabricated stairs.

Owner:重庆市涪陵区大业建材有限公司

A kind of spectacle frame mold structure

Owner:中山兆鸿精密模具注塑有限公司

Impeller mold

The invention relates to an impeller mold. The impeller mold comprises a fixed mold assembly, a movable mold assembly, and a mold core assembly, wherein a cavity is formed by the fixed mold assembly and the movable mold assembly, the mold core assembly is arranged in the cavity, the mold core assembly comprises a fixed mold core, a movable mold core, block body mechanisms, and guide pieces, the fixed mold core is connected with the fixed mold assembly, the movable mold core is connected with the movable mold assembly and connected with the fixed mold core, the block body mechanisms are arranged at the periphery of the fixed mold core in a surrounding mode, an impeller cavity is formed by the block body mechanisms, the fixed mold core, and the movable mold core, and the guide pieces are used for guiding the movement direction of the block body mechanisms; and the impeller mold further comprises oil cylinder mechanisms connected with the block body mechanisms, and the oil cylinder mechanisms are connected with an external machine table to control the block body mechanisms to slide along the guide pieces, so that a mold opening action or a mold closing action is carried out. Accordingto the impeller mold, the fastness and the convenience can be achieved when an impeller product is taken out, and meanwhile, the product quality is not influenced.

Owner:苏州宥安骏精密科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com