A hydraulic pressurized mold clamping device for flap closing molds

A mold clamping device and flap closing technology, which is applied in the field of metal plastic processing, can solve the problems of affecting product precision and low mold rigidity, and achieve the effect of increasing mold opening space, large mold clamping rigidity, and convenient process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

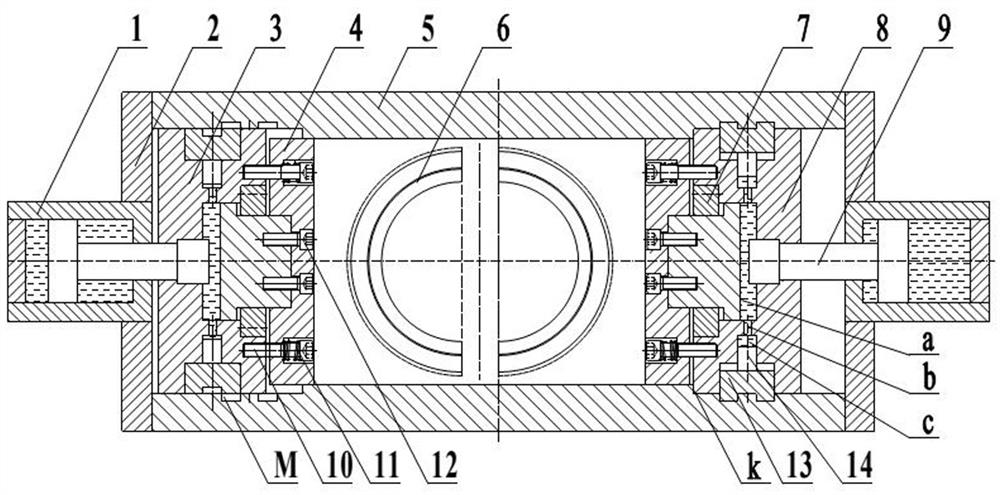

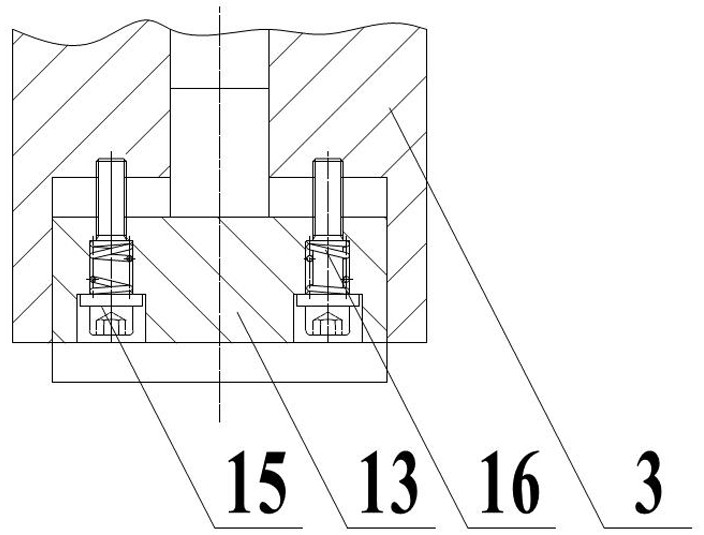

[0033] The specific structure of one of the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings: figure 1 As shown, the present embodiment takes two valve-closing modules to form a valve-closing female mold as an example:

[0034] A hydraulic pressurized mold clamping device for flap-closing molds, comprising a frame, a mold-closing mechanism arranged on the frame for driving a flap-closing module to perform mold clamping, and a pressurizing mechanism connected between the mold-closing mechanism and the flap-closing module locking mechanism; the frame is formed by the fixed connection of the beam 2 and the side beam 5, and the inner side of the side beam 5 is symmetrically provided with two sets of side beam shoulders k and pin holes m; the clamping mechanism is fixed on the beam 2 The left and right symmetrically arranged main hydraulic cylinder 1;

[0035] The pressurization locking mechanism includes a pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com