Magnesium alloy asymmetric continuous large-deformation extrusion machining mold

An extrusion processing and asymmetric technology, applied in the direction of metal extrusion dies, etc., can solve the problems of limited grain refinement ability, rising production cost, and uneven structure, so as to change the distribution of inclusions and improve extrusion molding ability , improve the effectiveness of the organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further explained and described in the manner of specific embodiments below.

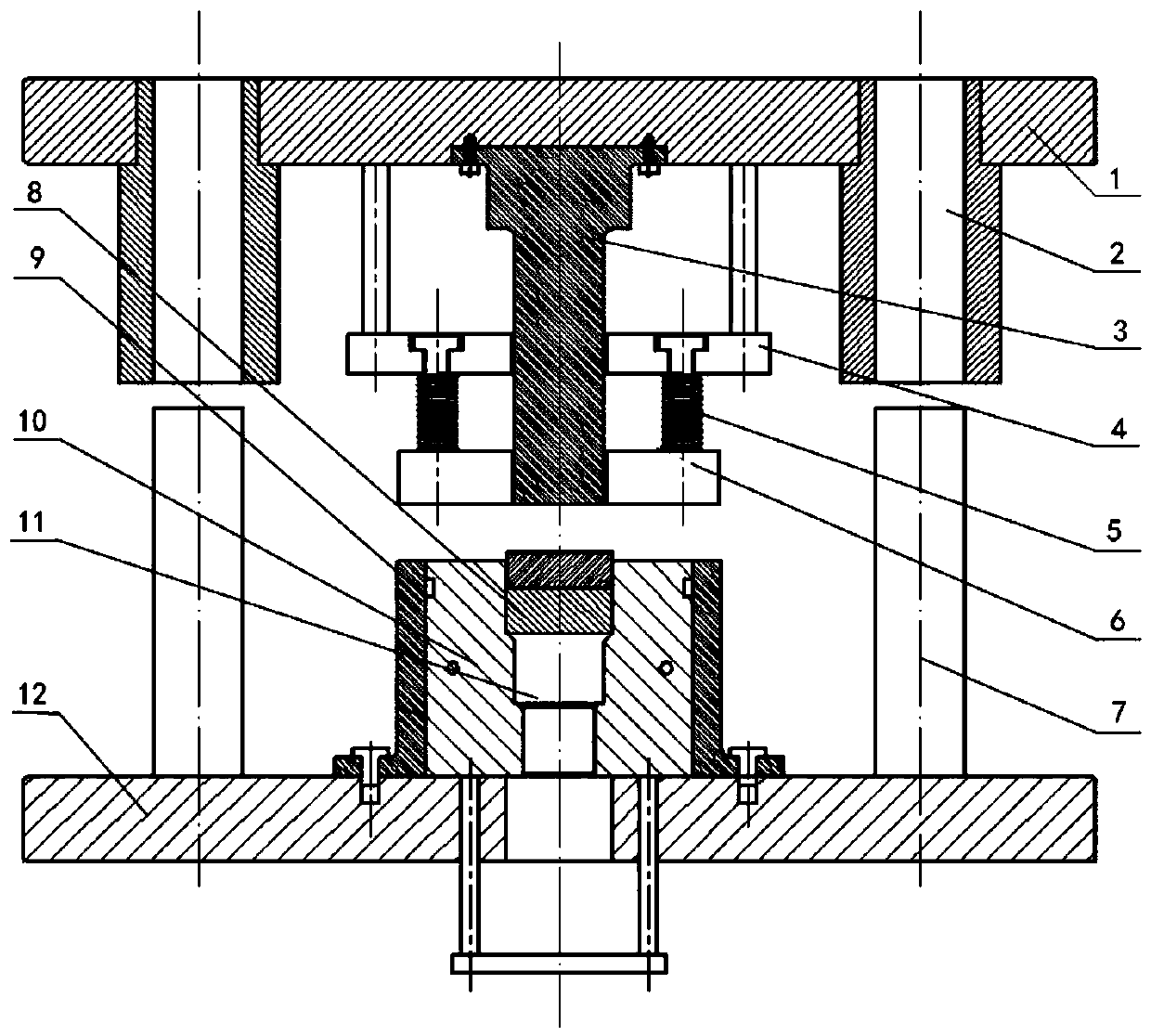

[0021] Such as figure 1 As shown, the magnesium alloy asymmetrical continuous large-deformation extrusion die is composed of a punch and a die.

[0022] The punch is composed of a top plate and an extruding rod 3. The extruding rod 3 is fixedly mounted on the upper die frame 1, and the top plate is installed on the die and pressed on the top of the blank 8;

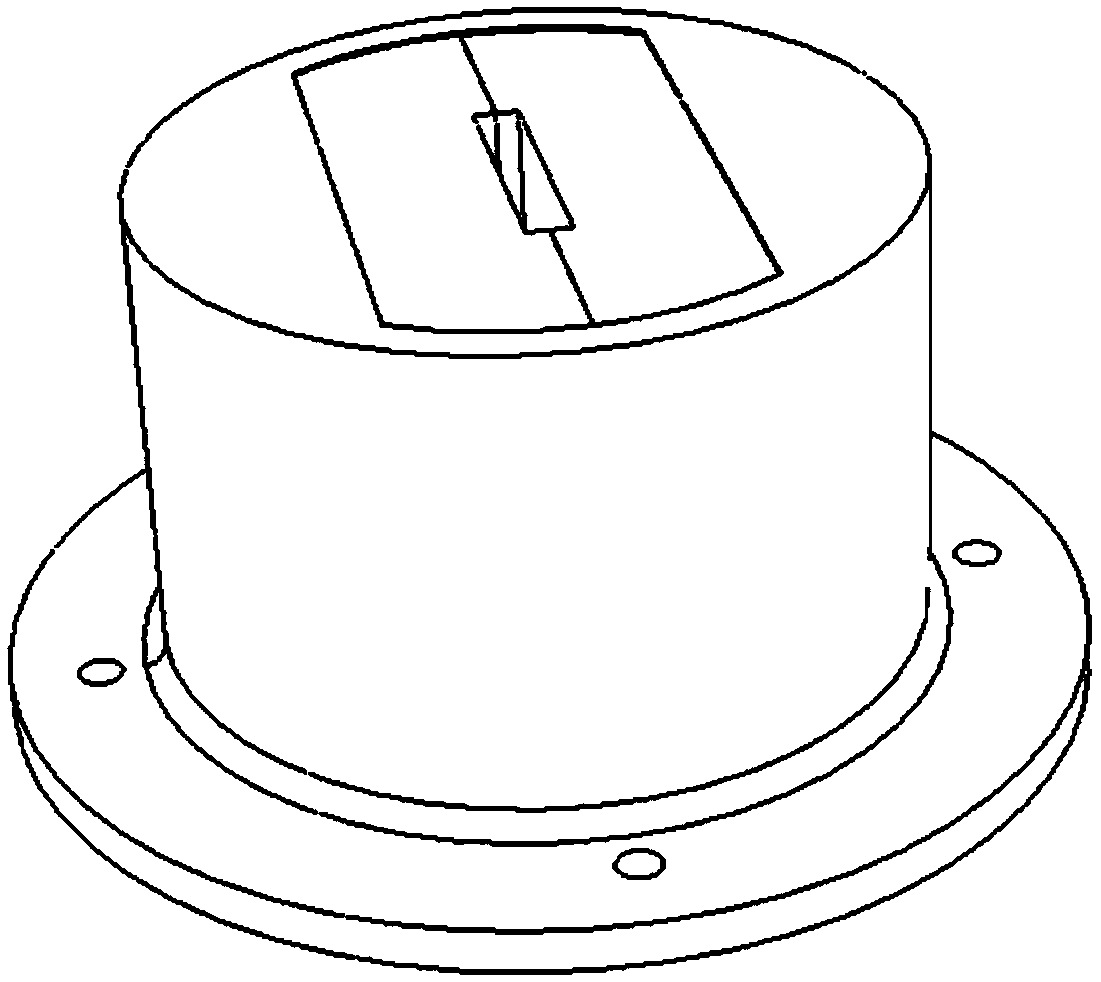

[0023] Such as figure 2 As shown, the die is composed of a die outer ring 9 and two detachable mold cores 10; Assembled into a flat cylinder installed in the outer ring 9 of the die; the middle of the assembled flat cylinder is the mold cavity;

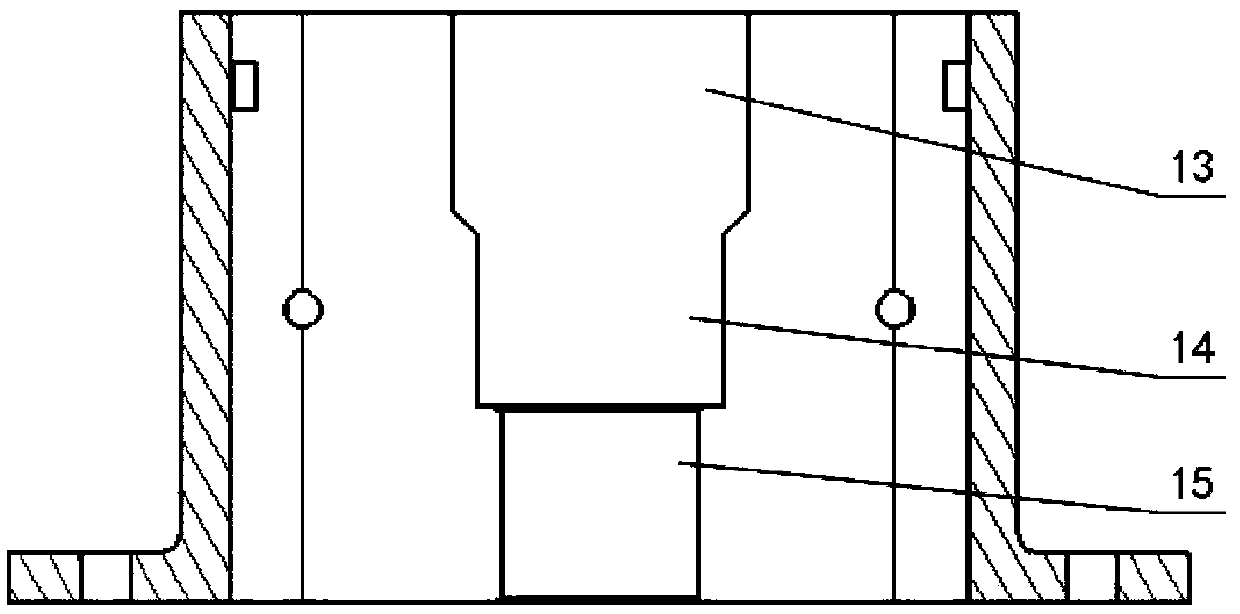

[0024] Such as image 3 and Figure 4 As shown, the mold cavity includes an upsetting cavity 13 and an extrusion cavity 14; the upsetting cavity 13 is arranged on the feeding side of the mold cavity, and the cross section is rectangul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com