Garbage extrusion processing unit

A treatment device and garbage technology, applied in the direction of presses, stamping machines, recycling technology, etc., can solve the problems of difficult to meet processing requirements, difficult operation, high cost of use, etc., to achieve enhanced extrusion molding effect, convenient operation, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

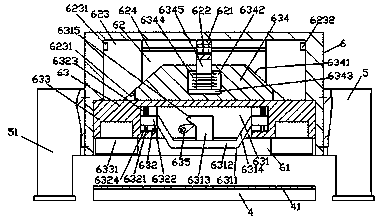

[0016] Such as figure 1 and figure 2 As shown, a garbage extrusion processing device of the present invention includes a machine base 5 and a compressor 6 fixedly installed in the machine base 5, and a first accommodation groove 61 is provided in the bottom surface of the compressor 6, and the The top wall of the first accommodation groove 61 communicates with the second accommodation groove 62 that is extended upwards. The sliding movement in the first accommodation groove 61 is connected with a lifting sliding block 63. The top of the lifting sliding block 63 is A derivation block 634 that penetrates into the second accommodating groove 62 and is slidably connected is fixed. The left and right sides of the derivation block 634 are oppositely provided with first oblique ends 6341 , and the top of the derivation block 634 is opposite. The inner top wall of the second accommodating groove 62 is fixed with a raised block 621, and the bottom surface of the lifting and sliding b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com