Practical garbage recovery compression device

A compression device and garbage technology, applied in the direction of presses, manufacturing tools, etc., can solve problems such as low efficiency, difficult operation, and difficulty in meeting processing needs, and achieve the effects of improving work efficiency, improving uniformity, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

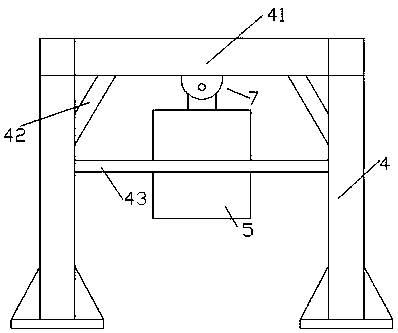

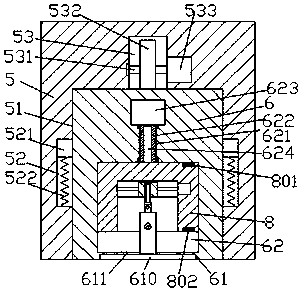

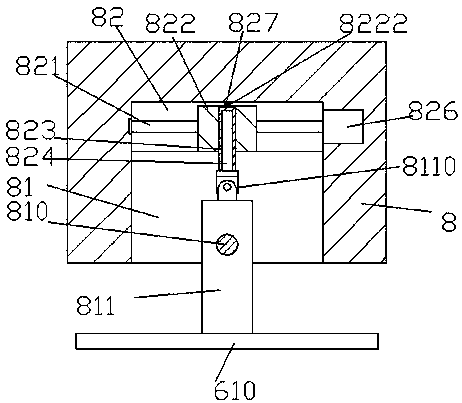

[0018] Such as figure 1 , figure 2 with image 3 As shown, a practical garbage recovery and compression device of the present invention includes an angle adjustment device 7 and a compressor 5 installed at the bottom of the angle adjustment device 7. The bottom surface of the compressor 5 is provided with a first accommodating groove 51, so A sliding compression block 6 is slidably connected to the first accommodation groove 51, and the inner walls on the left and right sides of the first accommodation groove 51 are commensurately provided with guiding devices that are respectively matched and connected to the outer walls on the left and right sides of the sliding compression block 6. The top wall of the first accommodation groove 51 is provided with a compression driving device, the bottom surface of the sliding compression block 6 is provided with a bottom groove 61, and the sliding compression block 6 on the upper side of the bottom groove 61 is provided with a sliding gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com