Forming device for PVC pipe

A PVC pipe and molding equipment technology, applied in the direction of tubular objects, other household appliances, household appliances, etc., can solve the problems of inability to close the mold, poor flexibility, slow mold closing speed, etc., to improve the injection quality, flexible use, and mold closing. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

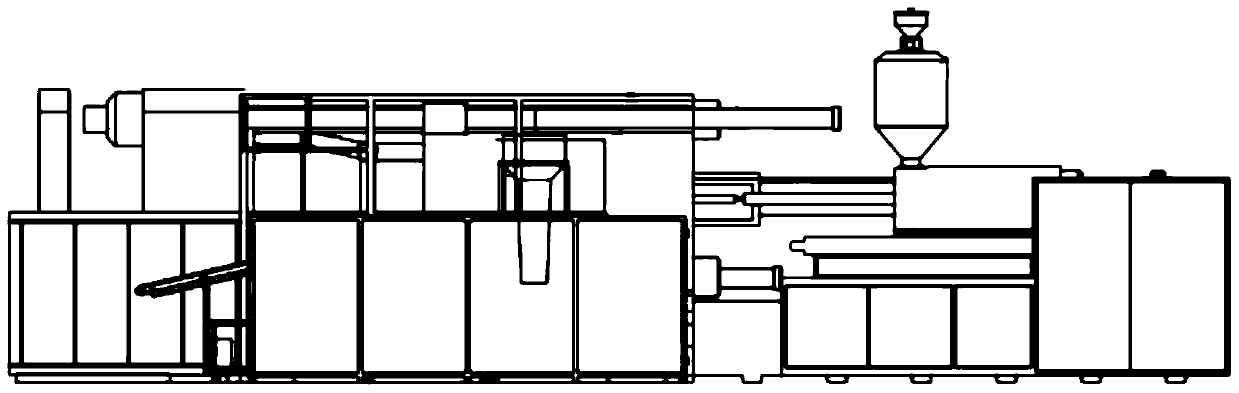

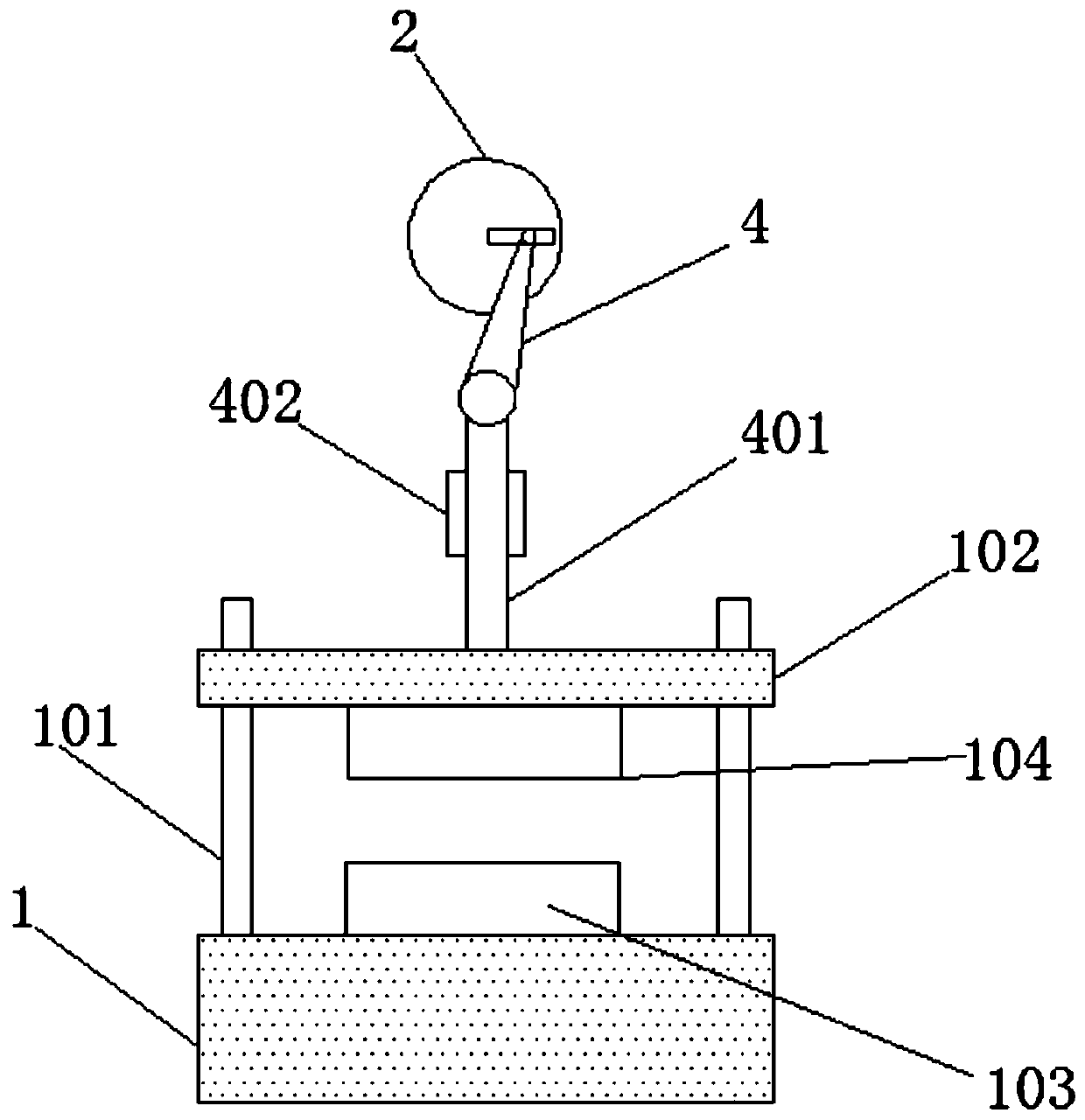

[0042] Such as Figure 1-11 As shown, the present invention relates to a molding equipment for PVC pipes, which is composed of a dryer, a feed hopper 6, an injection molding machine body, a molding mechanism, a screw extrusion mechanism, a cooling molding mechanism, and the like, and the feed hopper is connected to the injection molding machine. On the top of the body, the dryer is connected to the feed hopper 6. After the material is dried, it is passed into the molding mechanism to be pressed, and then extruded through the screw extrusion mechanism, and finally cooled and formed;

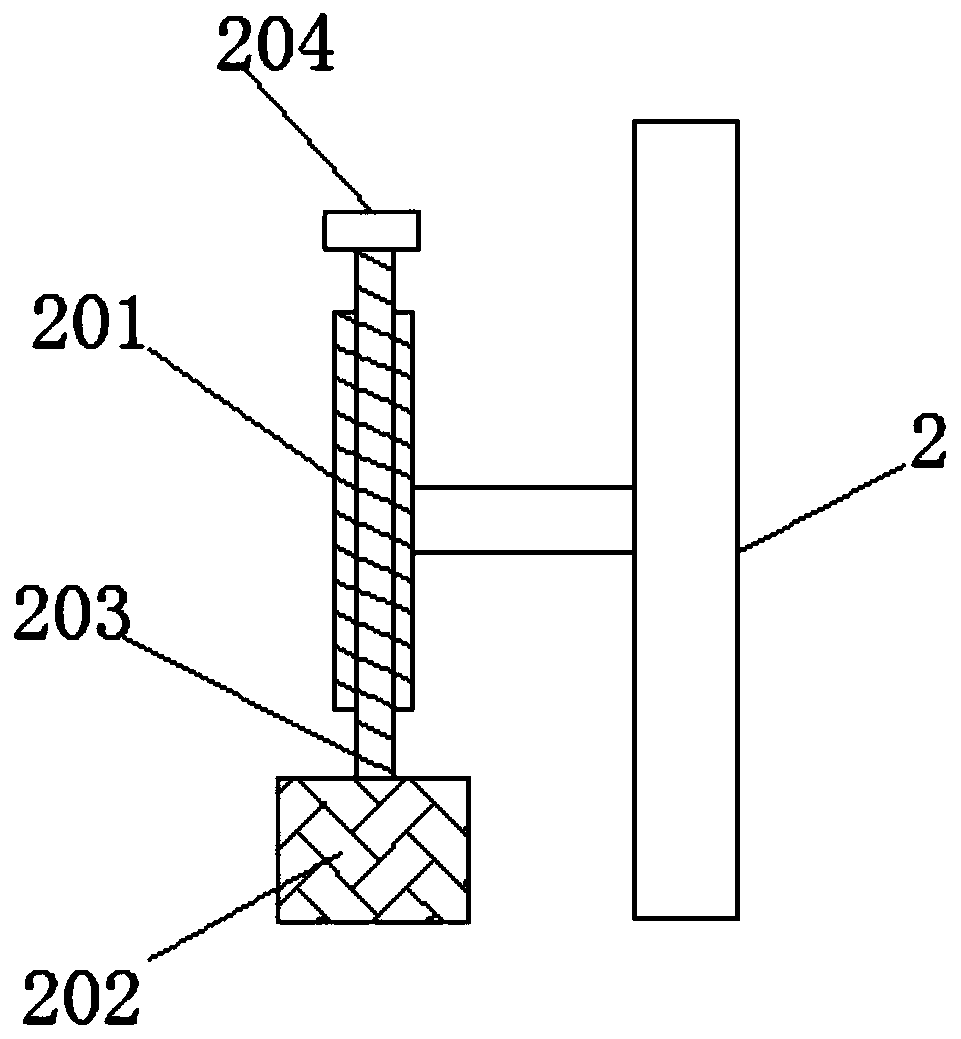

[0043] A feeding pipe 7 is installed at the bottom of the feeding hopper 6, a valve 701 is installed at one end of the feeding pipe 7, a base 8 is installed on one side of the bottom surface of the inner cavity of the feeding hopper 6, and a base 8 is installed on the top surface of the base 8. There is a pressure sensor 9, a control mechanism 10 is installed on the outer wall surface of the feedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com