Casting machine capable of quickly locking mold

A casting machine and mold locking technology, which is applied in the field of fast mold locking casting machines, can solve problems such as insecurity and unreliable mold locking, and achieve the effects of convenient installation and adjustment, reduced processing costs, and reliable locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

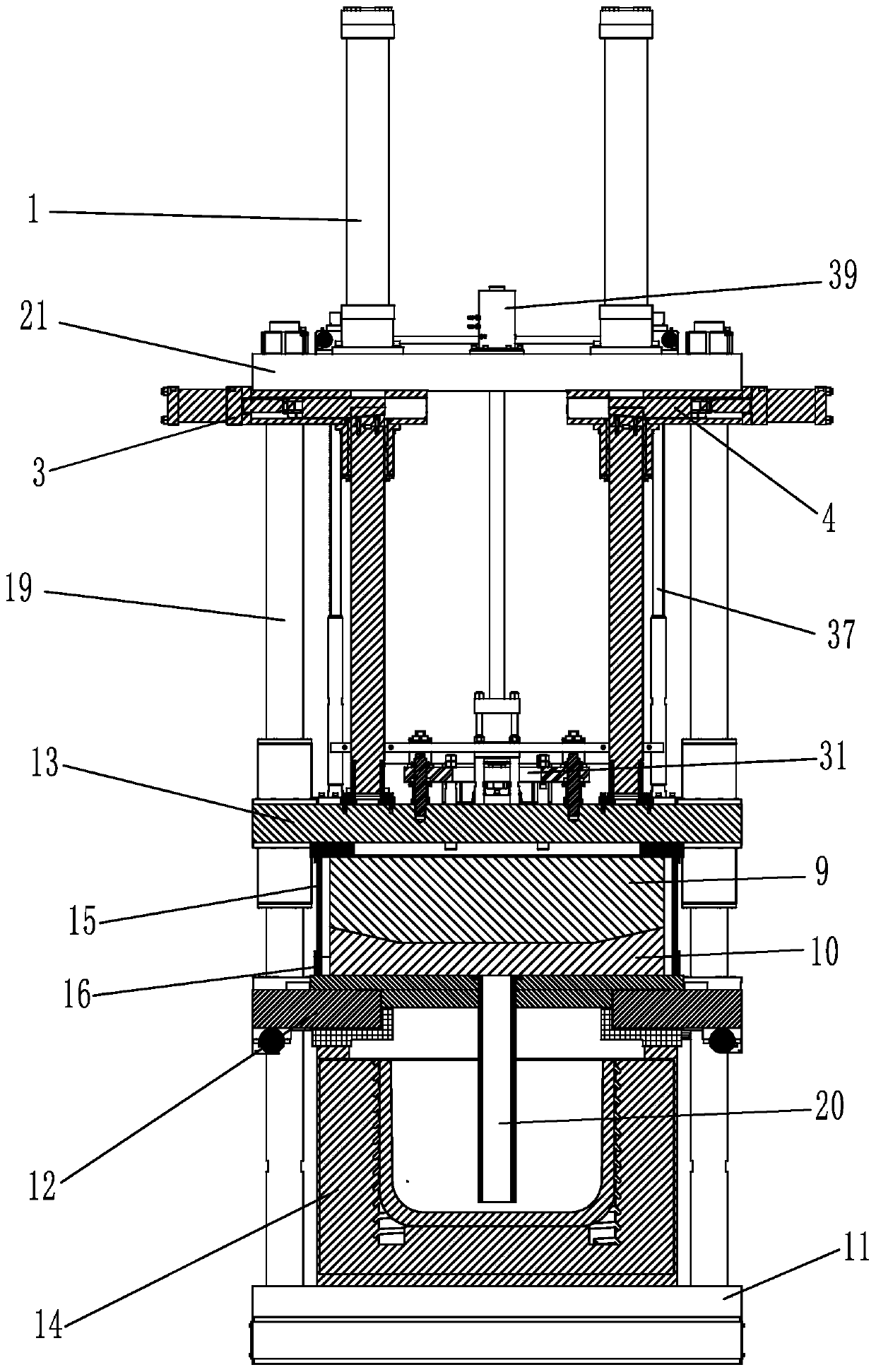

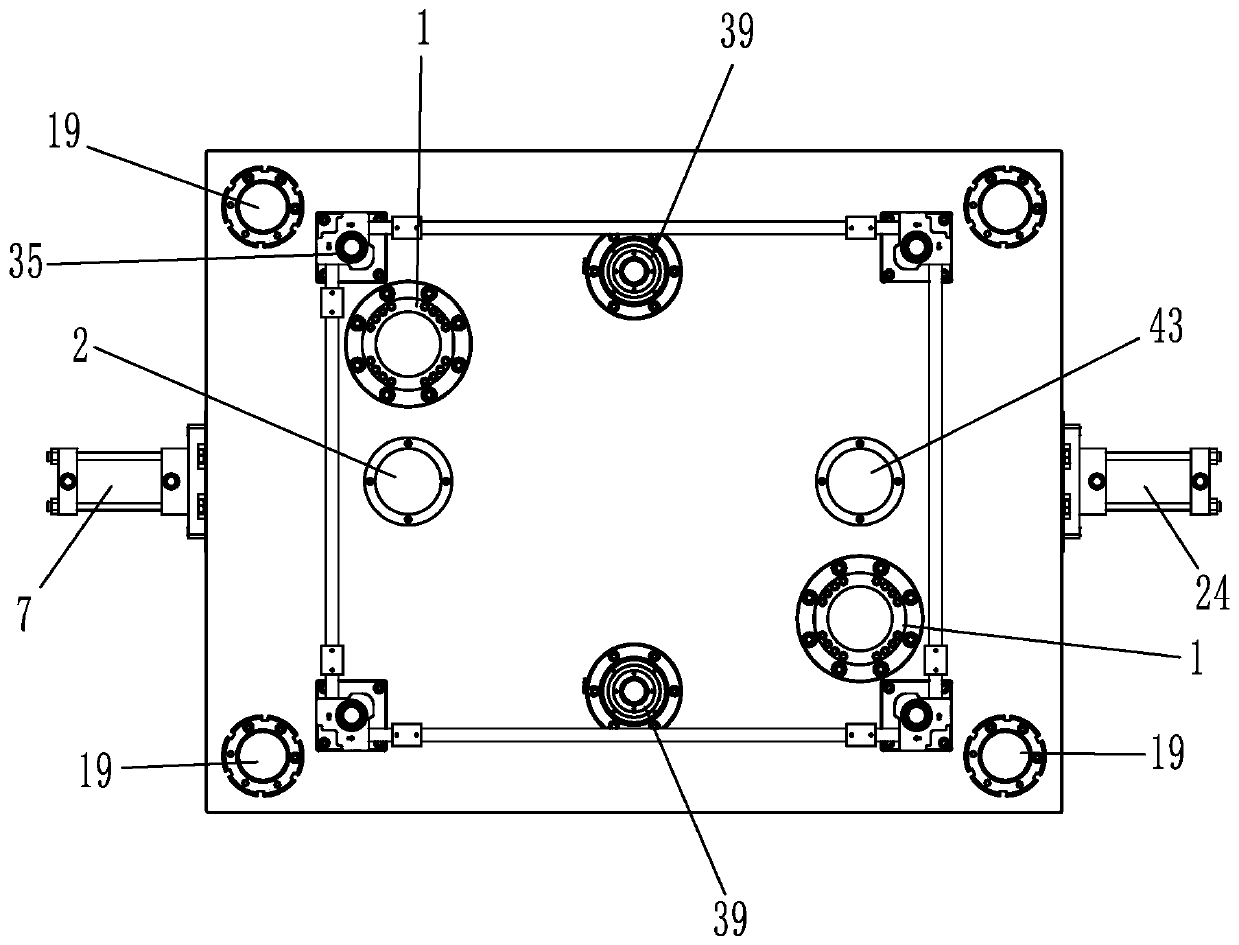

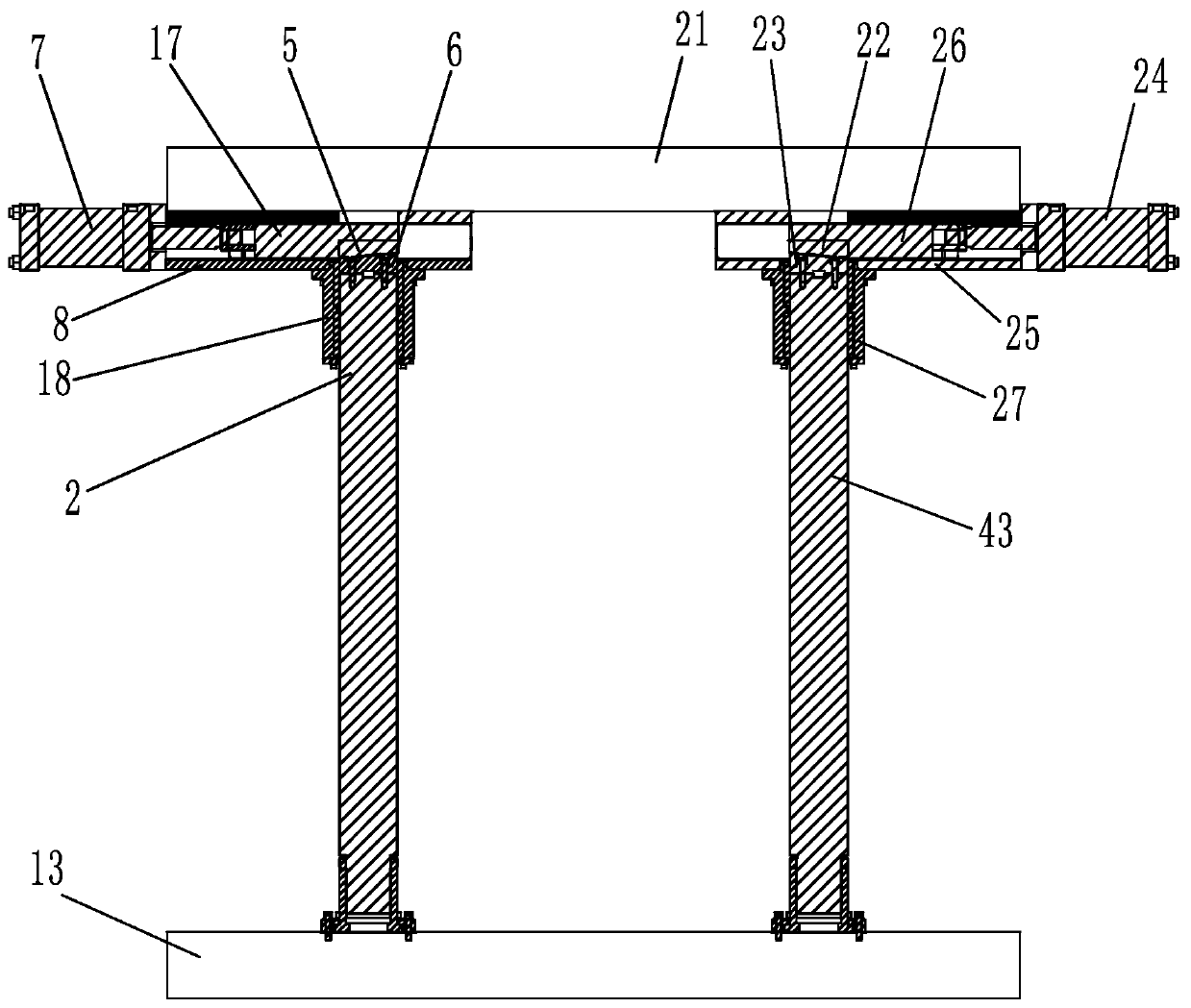

[0032] Example: A Differential Pressure Casting Machine Capable of Rapid Clamping

[0033] Refer to attached figure 1 to attach Figure 6 As shown, the differential pressure casting machine includes a host, a cooling cabinet and a control cabinet;

[0034] The main engine includes two main oil cylinders 1, a bottom plate 11, four columns 19, a middle partition 12, a movable plate 13, an upper top plate 21, a first mold clamping guide column 2, a second mold clamping guide column 43, and a holding furnace 14 , autoclave, mould, split-type wedge locking mechanism and material return mechanism, four columns 19 pass through the upper top plate 21, movable plate 13, middle partition 12 and bottom plate 11 from top to bottom to form a four-beam and four-column foundation frame , the movable plate 13 and the middle partition 12 can slide up and down along the column 19, the first clamping guide column 2 and the second clamping guide column 43 are all vertically supported between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com