Middle plate structure of horizontal rotary disc opposite-injection machine

A technology of plate structure and injection machine, which is applied in the field of the plate structure of the horizontal rotary table injection machine, which can solve the problems of the large-scale and flat horizontal rotary plate center plate of the two-color injection molding machine that are not described in detail, and achieve a stable rotation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

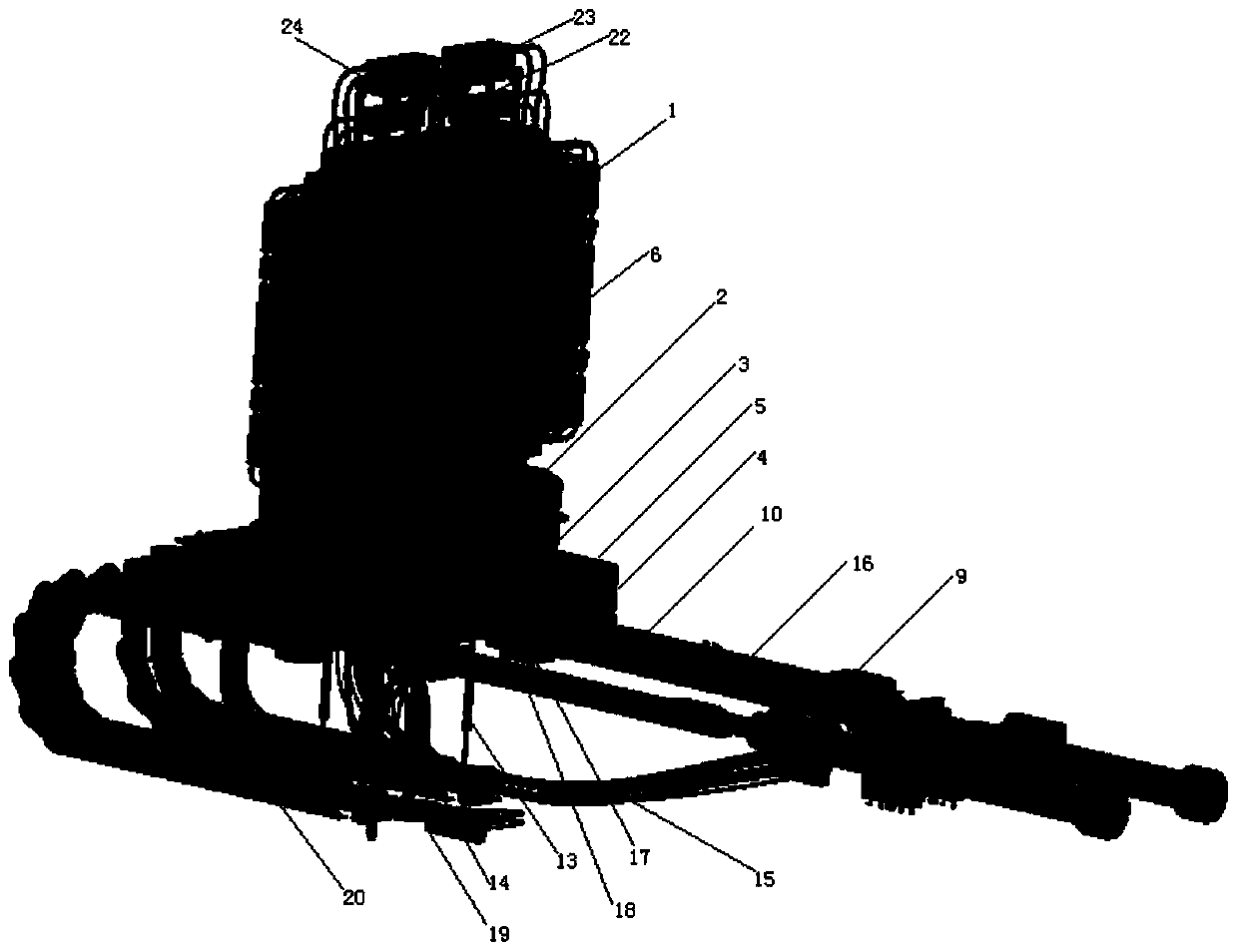

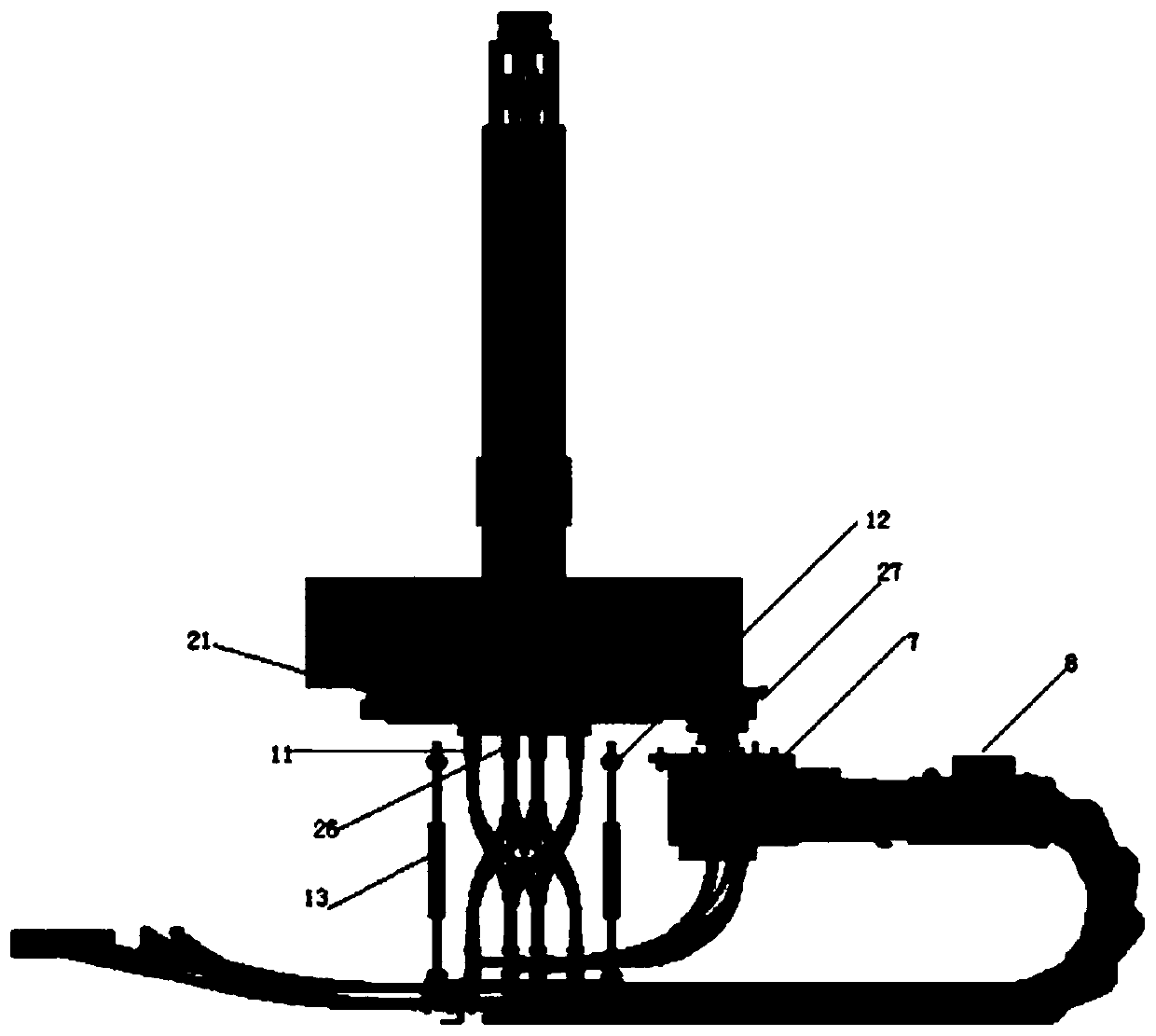

[0019] The present invention provides a middle plate structure of a horizontal turntable butt-injection machine. The middle plate structure is quickly closed by a middle plate moving device. After the injection and pressure holding is completed, the rotation direction and speed of the middle plate structure are controlled by the turntable rotation control device. Achieve smooth rotation process.

[0020] The present invention will be described in detail below with reference to the accompanying drawings.

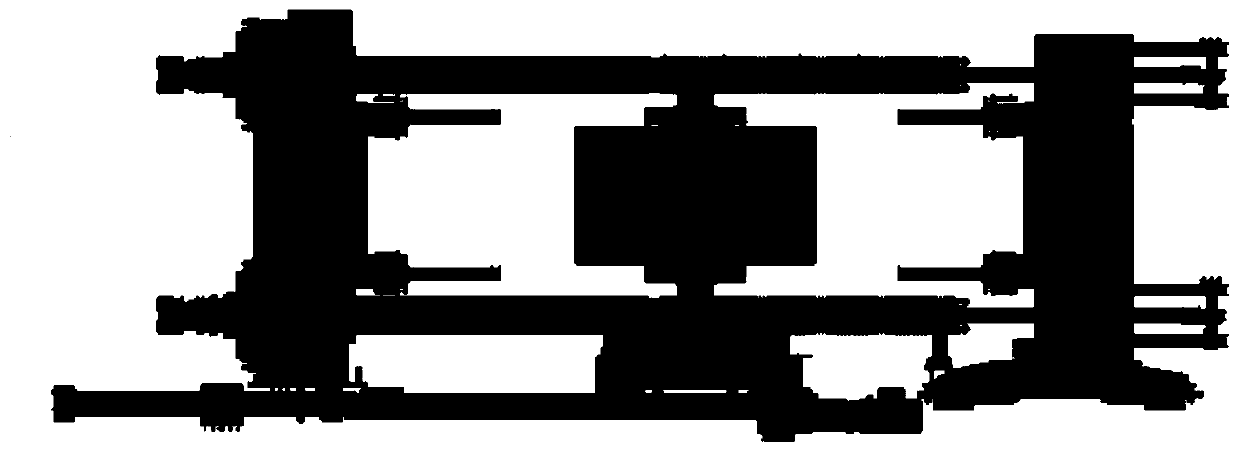

[0021] In order to realize the above technical scheme, the structure of the middle plate of the horizontal turntable of the present invention is as follows: figure 1 As shown, it mainly consists of a middle plate device, a middle plate moving device, a transition connection device, a turntable core pulling device, and a turntable rotation control device. The middle plate device is mainly composed of the middle plate 1, the middle plate fixing seat 2, the middle plate rotating seat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com