A kind of spectacle frame mold structure

A technology for spectacle frames and molds, which is applied to frames, household appliances, and other household appliances. It can solve problems such as long manufacturing time, high precision requirements, and lens frame strain, and achieve product quality assurance, simple mold structure, and low warpage. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

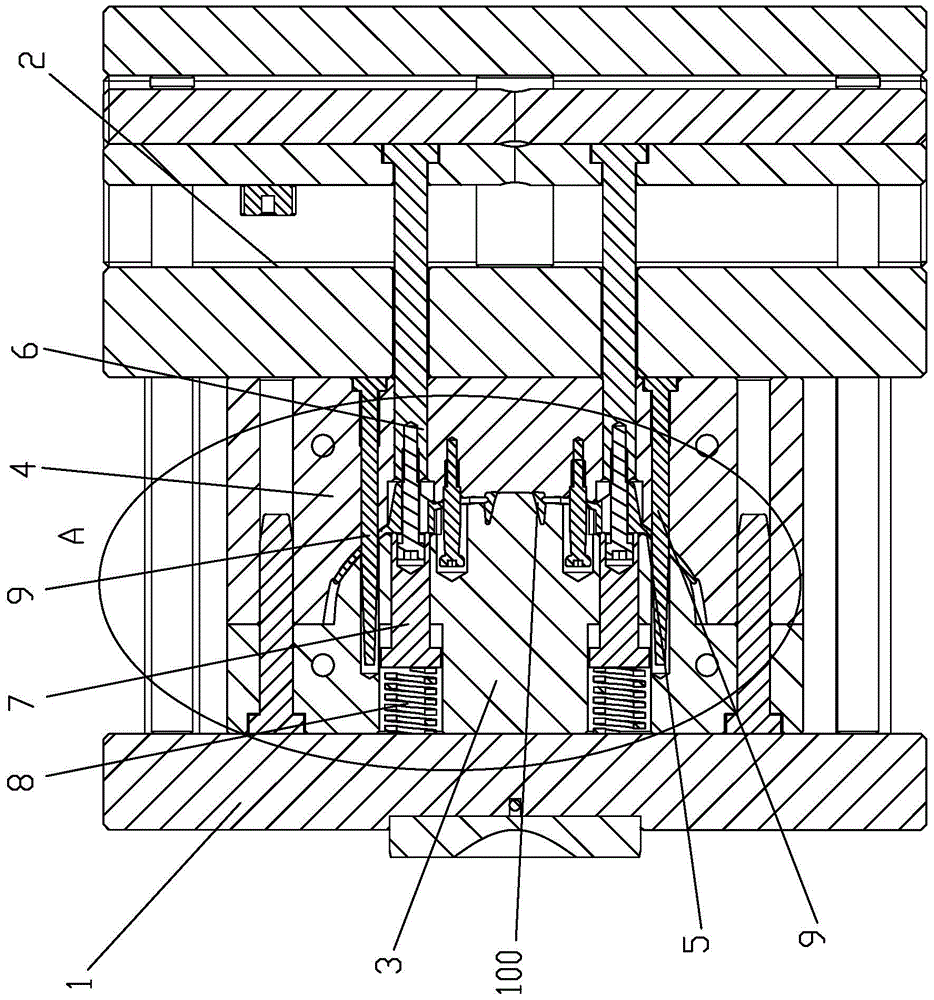

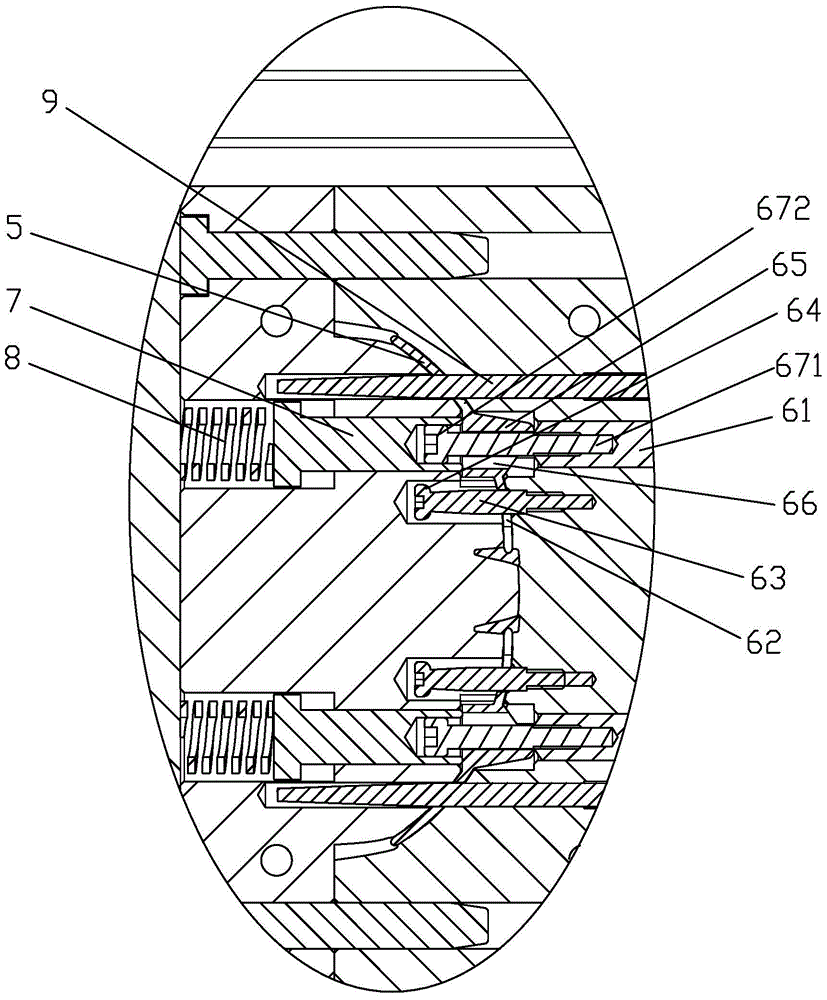

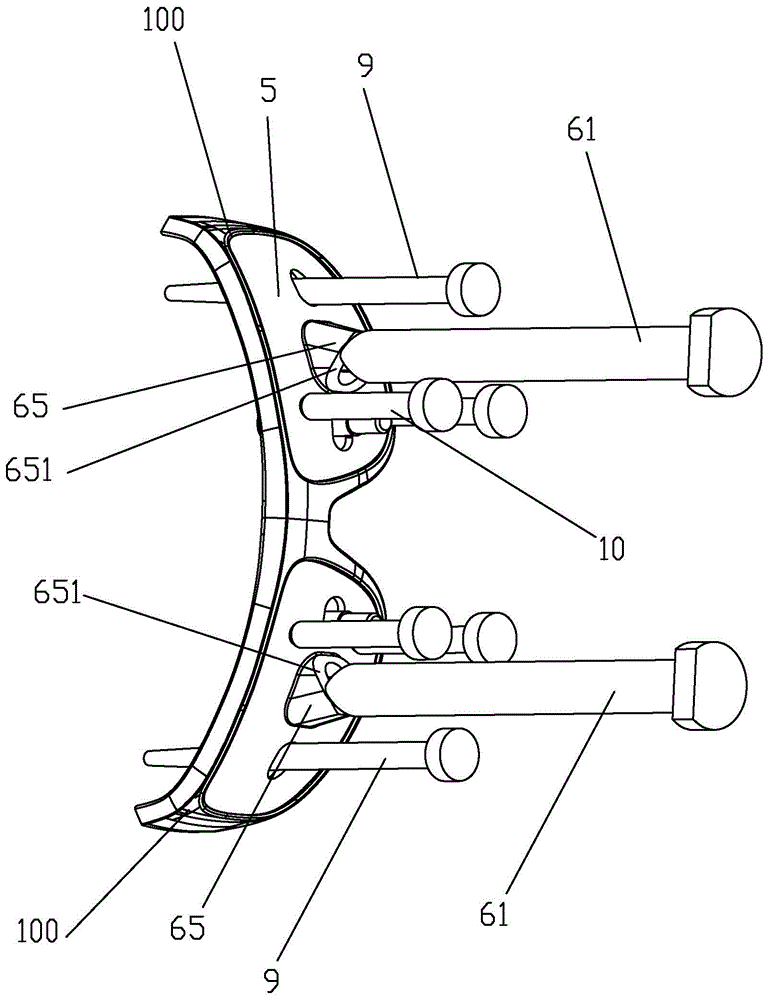

[0029] Such as figure 1 Shown, a kind of spectacle frame mold structure, comprises front formwork 1 and rear formwork 2, is provided with front formwork 3, rear formwork 4 and The lens frame mold core 5 is provided between the lens frame mold core 5 and the rear template 4. When the mold is opened, the lens frame mold core 5 can make the lens frame mold core 5 move in a straight line and then rotate to get out of the spectacle frame 100. When opening the mold, the demoulding device 6 makes the lens frame mold core 5 move linearly forward. When moving to the set distance, the demoulding device 6 makes the lens frame mold core 5 rotate relative to the spectacle frame 100, and the lens frame mold core 5. Warpage occurs during the rotation process. Due to the elasticity of the injection-molded spectacle frame 100, the spectacle frame 100 pops out and is demoulded. The spectacl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com