Injection mold of coffee maker material box

A technology for injection molding and coffee machines, which is applied to home appliances, other home appliances, household components, etc., can solve the problems of uneven thickness of coffee machine material box, difficult to meet the requirements of use, and rough surface, so as to facilitate calibration, High injection molding efficiency and smooth surface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

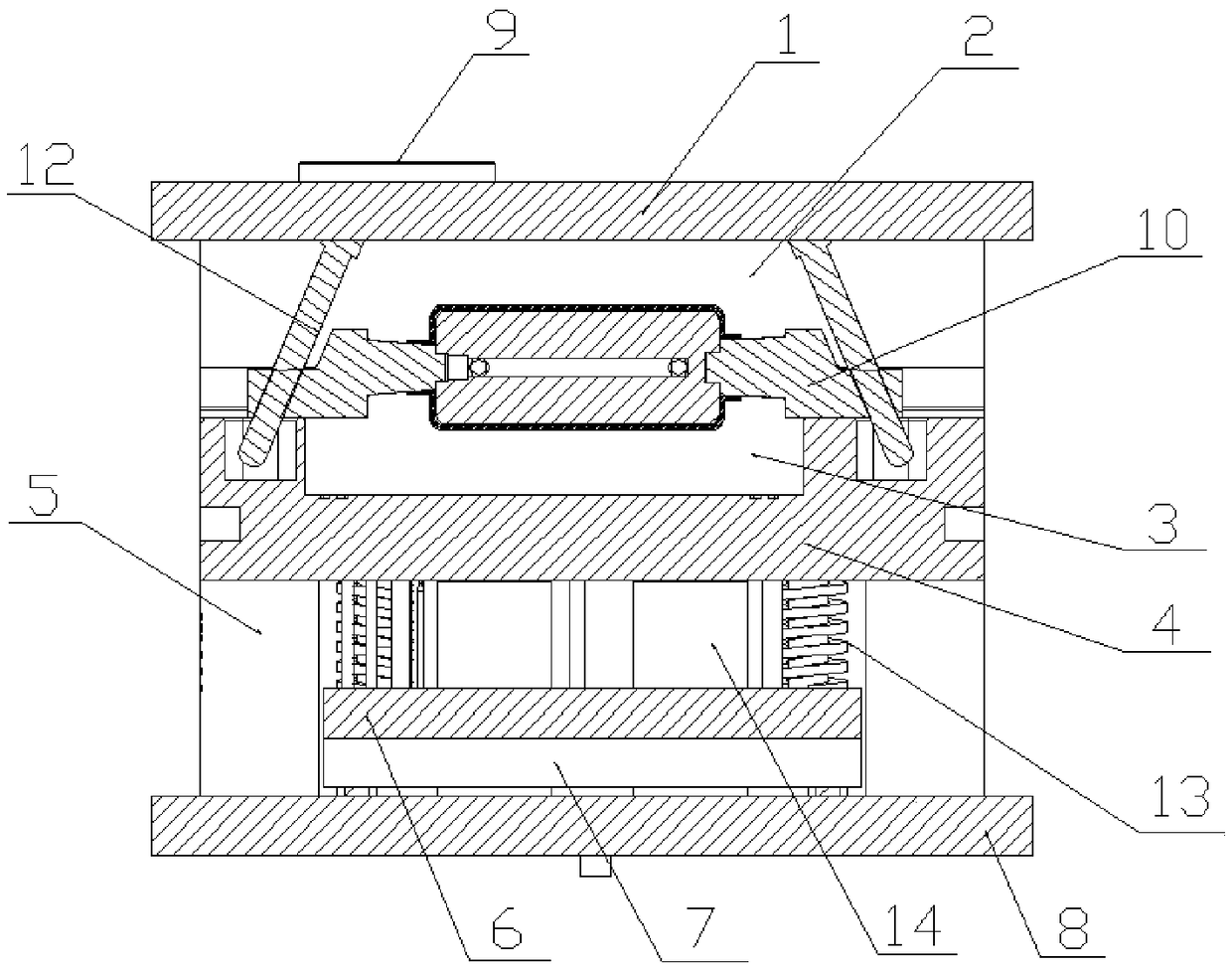

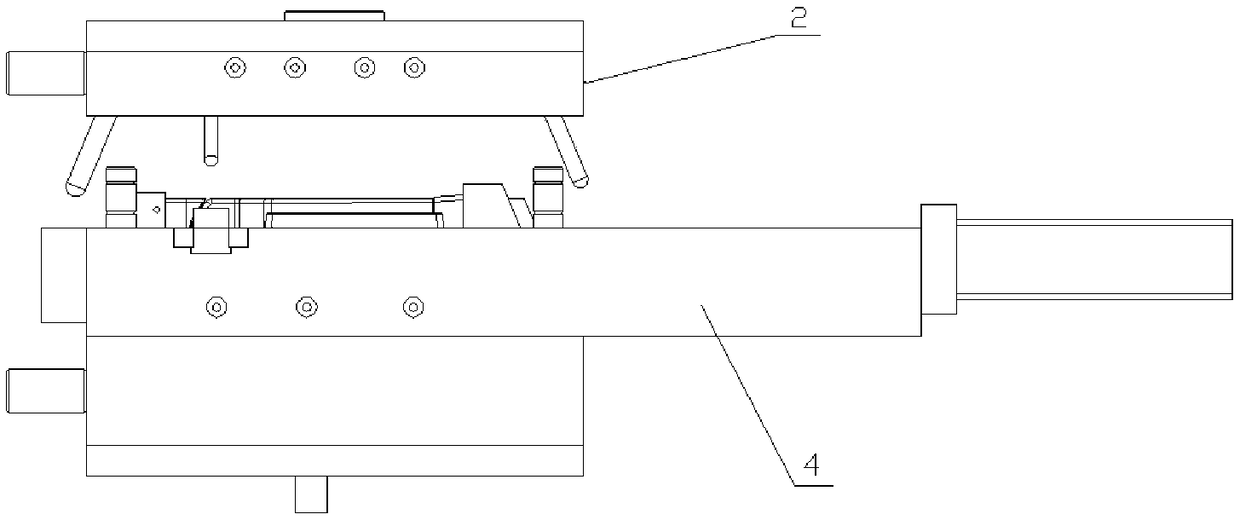

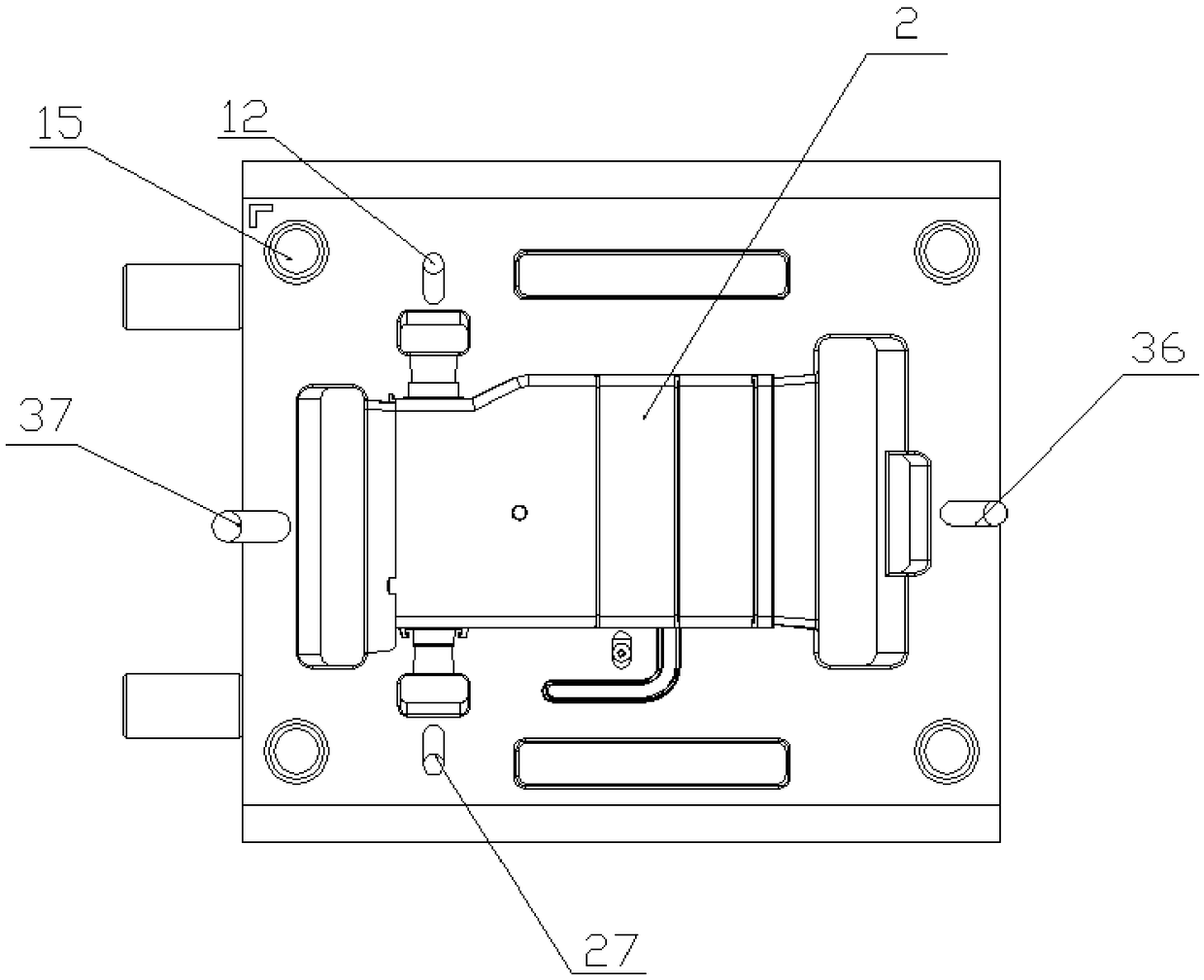

[0027] See Figure 1 to Figure 5 The shown injection mold for a coffee machine cartridge includes an upper panel 1, A panel 2, a lower core 3, a B panel 4, a square iron 5, a thimble panel 6, a thimble bottom plate 7, a lower panel 8 and a cylinder 16, The upper plate 1 and the A plate 2 are connected by bolts. The upper end of the upper plate 1 is provided with a positioning ring 9. The B plate 4, the square iron 5 and the lower plate 8 are connected by bolts. The square iron 4 is two pieces, and the thimble The panel 6 and the thimble bottom plate 7 are installed between the two square irons 5. The lower mold core 3 is installed on the upper end of the B board 4, and the lower mold core 3 and the B board 4 are connected by screws. The upper end of the B board 4 is provided There are a first slider 18, a second slider 24, a third slider 28, a fourth slider 30, and a fifth slider 10. The first slider 18, the second slider 24, the third slider 28, and the A coffee maker injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com