Powder metallurgy bearing bush production forming die

A technology for powder metallurgy and forming molds, which is applied in other manufacturing equipment/tools, turbines, engine components, etc., and can solve problems such as reduced work efficiency, the inability of molds to be quickly closed and demolded, and the inability to mass-produce multiple bearing bushes. , to achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, the creation of the present invention, the purpose and energy is easy to understand, the following combinations Figure 1 to 9 Further, the invention is further illustrated.

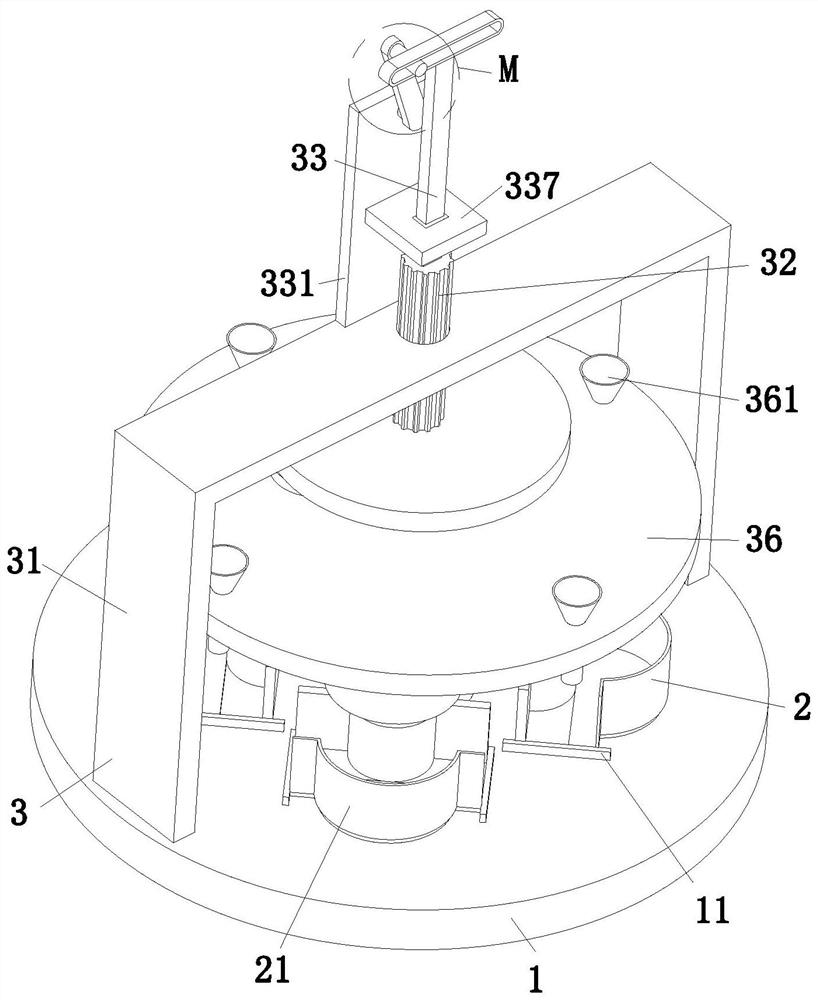

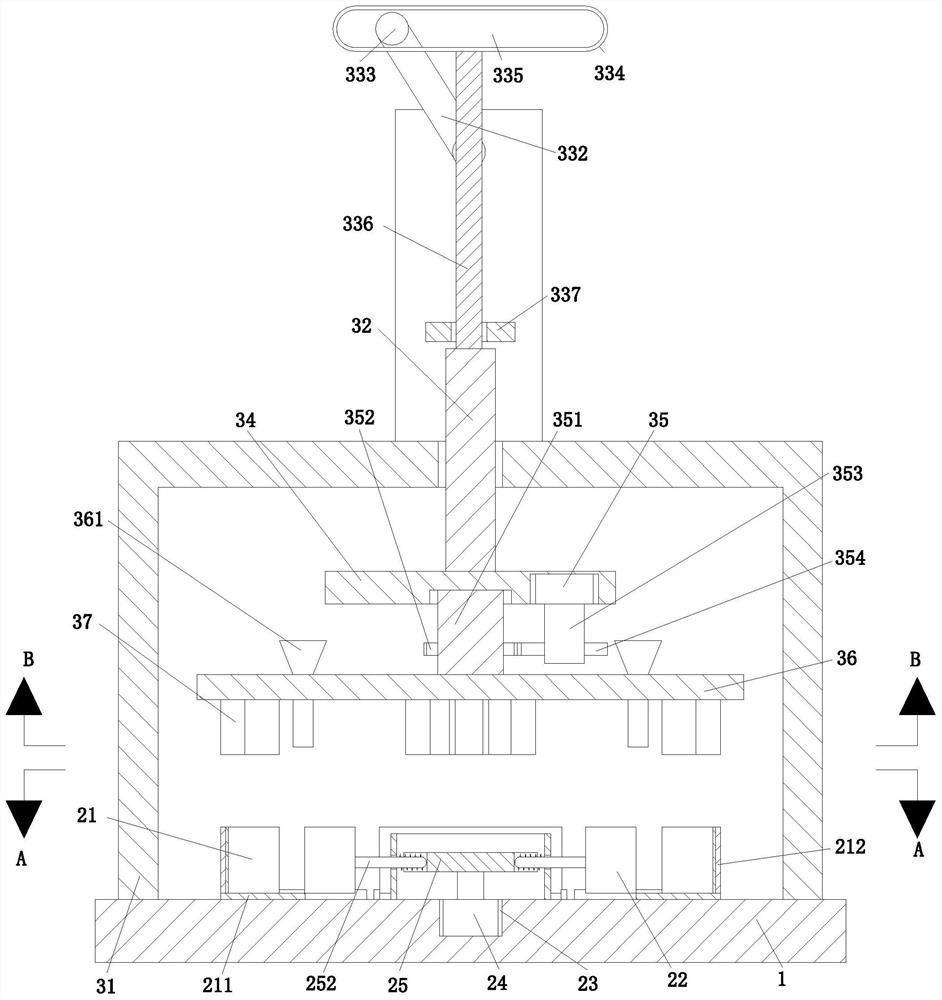

[0032] A powder metallurgical shaft watt-forming die comprising a table 1, a fixture 2, and a molding apparatus 3, the top of the table 1 is provided with a fixing device 2, and the top of the table 1 is located outside the fixture 2 Set a molded device 3;

[0033] The fixing device 2 includes an outer mold 21, a placed groove 23, a driving motor 24, and a rotating frame 25, and the top of the table 1 is remote from the center, and the outer mold 21 is provided in the circumferential direction 21. The position of the table 1 is adjacent to the center in the circumferential direction, and the multi-form outer mold 21, and the multi-set internal mold 22 corresponds to the top center position of the top center position of the table 1. The slot 23 is placed, and the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com