Expanding die for expanding head of longitudinal welded pipe and manufacturing process of expanding die

A technology of straight seam welded pipe and manufacturing process, which is applied in the field of straight seam welded pipe expansion head expansion mold and its manufacturing technology, which can solve the problem of insufficient mold strength, wear resistance and impact toughness, inconvenience of rapid insertion of straight seam welded pipe, and inability to Realize problems such as fast and accurate positioning, and achieve the effects of improving production efficiency, facilitating quick mold closing, and better practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

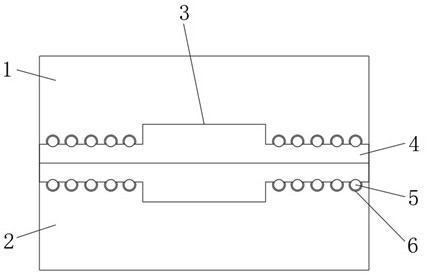

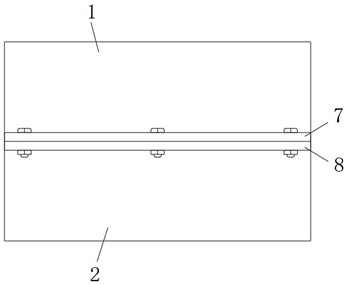

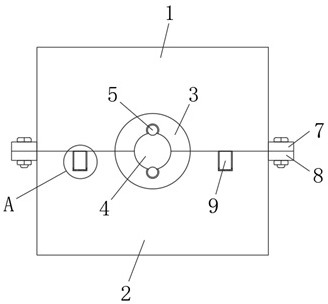

[0039] Embodiment one: 1, please refer to Figure 1-Figure 5 As shown, a diameter expanding mold for straight seam welded pipe expansion head includes an upper mold 1 and a lower mold 2, the upper mold 1 is covered above the lower mold 2, and the inner middle of the upper mold 1 and the lower mold 2 are provided with Semi-circular groove, and two semi-circular grooves combined forming cavity 3, upper mold 1 and lower mold 2 are located on both sides of cavity 3, and channels 4 are symmetrically opened, and the two channels 4 are respectively connected to the cavity 3, so that the cavity 3 communicates with the two passages 4, and the top and bottom of the inner walls of the two passages 4 are provided with ball grooves 6 distributed equidistantly along the horizontal direction, and the inside of the ball groove 6 is movable. Ball 5.

[0040] Further, the bottom of the upper mold 1 is equipped with four positioning pins 9 distributed in a rectangular array, while the top of th...

Embodiment 2

[0059] Embodiment two: 1, please refer to Figure 1-Figure 5 As shown, a diameter expanding mold for straight seam welded pipe expansion head includes an upper mold 1 and a lower mold 2, the upper mold 1 is covered above the lower mold 2, and the inner middle of the upper mold 1 and the lower mold 2 are provided with Semi-circular groove, and two semi-circular grooves combined forming cavity 3, upper mold 1 and lower mold 2 are located on both sides of cavity 3, and channels 4 are symmetrically opened, and the two channels 4 are respectively connected to the cavity 3, so that the cavity 3 communicates with the two passages 4, and the top and bottom of the inner walls of the two passages 4 are provided with ball grooves 6 distributed equidistantly along the horizontal direction, and the inside of the ball groove 6 is movable. Ball 5.

[0060] Further, the bottom of the upper mold 1 is equipped with four positioning pins 9 distributed in a rectangular array, while the top of th...

Embodiment 3

[0079] Embodiment three: 1, please refer to Figure 1-Figure 5 As shown, a diameter expanding mold for straight seam welded pipe expansion head includes an upper mold 1 and a lower mold 2, the upper mold 1 is covered above the lower mold 2, and the inner middle of the upper mold 1 and the lower mold 2 are provided with Semi-circular groove, and two semi-circular grooves combined forming cavity 3, upper mold 1 and lower mold 2 are located on both sides of cavity 3, and channels 4 are symmetrically opened, and the two channels 4 are respectively connected to the cavity 3, so that the cavity 3 communicates with the two passages 4, and the top and bottom of the inner walls of the two passages 4 are provided with ball grooves 6 distributed equidistantly along the horizontal direction, and the inside of the ball groove 6 is movable. Ball 5.

[0080] Further, the bottom of the upper mold 1 is equipped with four positioning pins 9 distributed in a rectangular array, while the top of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com