Super-strength steel hot stamping die capable of carrying out rapid spotting through gas assistance

A hot stamping die, gas-assisted technology, applied in the field of hot stamping, can solve the problems of uneven cooling, fast and slow cooling of the sheet, and achieve the effect of avoiding the temperature of the sheet falling too fast and closing the mold quickly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

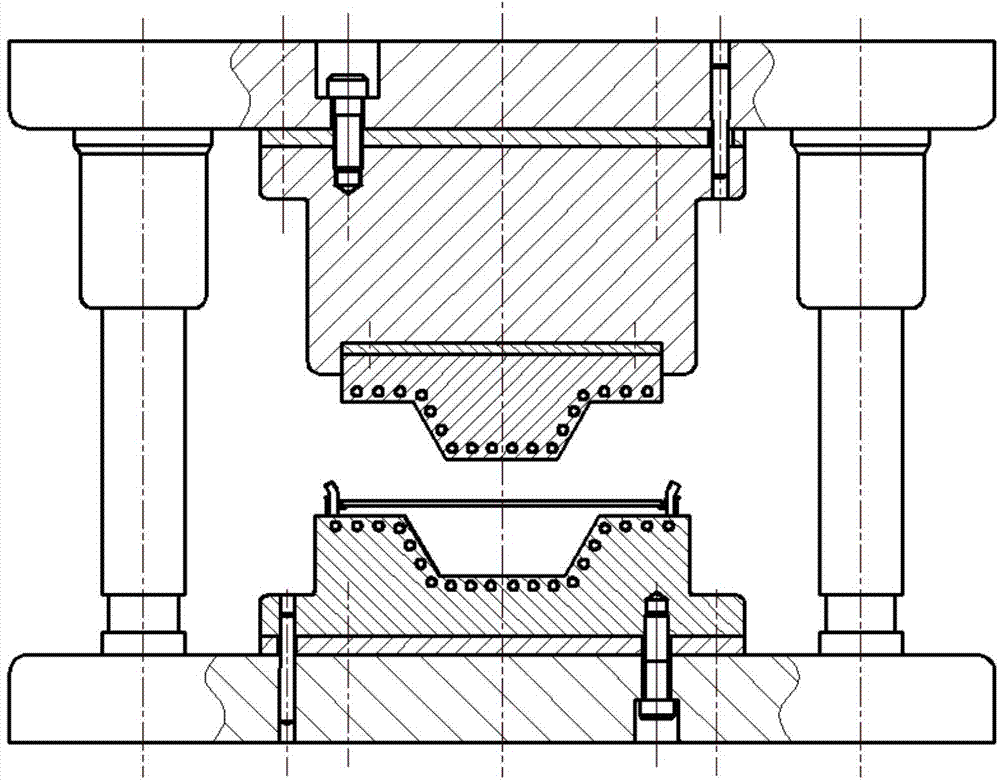

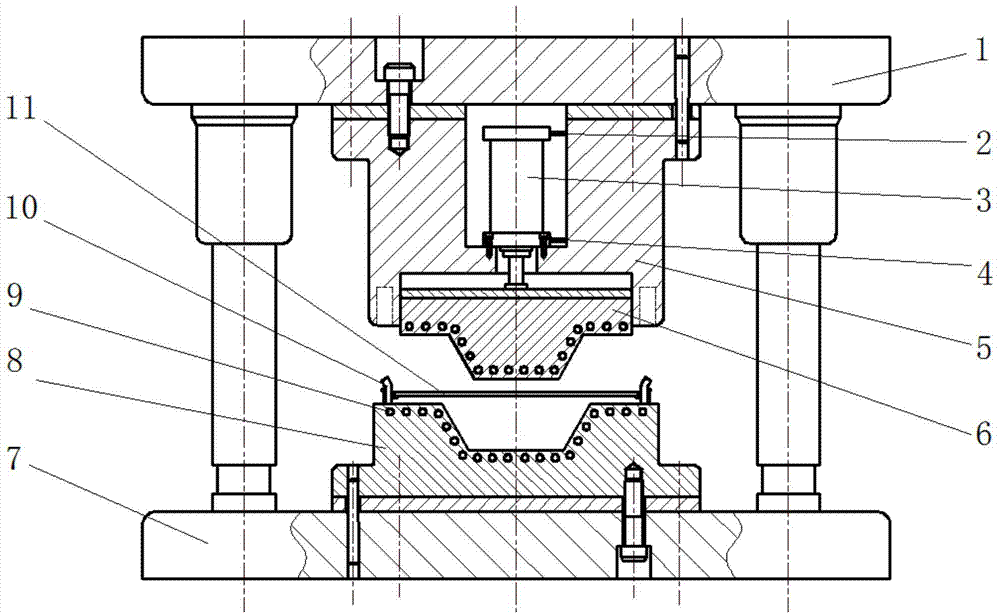

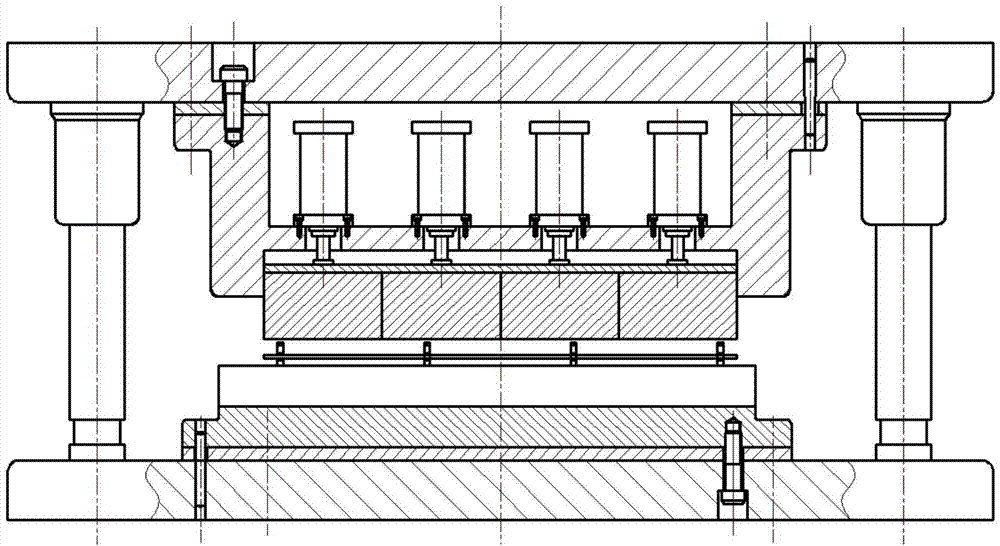

[0017] The mold refers to figure 2 , including: 1. Upper template, 2. Upper air pipe, 3. Cylinder, 4. Lower air pipe, 5. Fixed plate, 6. Punch die, 7. Lower die holder, 8. Die die, 9. Cooling pipe, 10. Positioning device and other main parts. First, put the heated and heat-preserved sheet 11 on the thermoforming mold, the hydraulic press starts the downward stroke, and its slider pushes the mold upper template 1 to go down, and at the same time, the air in the cylinder 3 pushes the punch 6 to go down quickly, and the sheet 11 is quickly stamped Forming and clamping with the die 8, the slider of the hydraulic press pushes the upper template 1 to continue downward (the gas in the cylinder 3 is compressed, and the piston rod retreats), until it reaches the bottom dead center of the press and stops, the punch 6 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com