High-pressure grouting machine applied to domestic ceramic

A high-pressure grouting machine and ceramic technology, which is applied in ceramic molding machines, die-casting molds, auxiliary molding equipment, etc., can solve the problems of low qualified rate of molding blanks, poor mold clamping accuracy, and lack of work efficiency to ensure stability. performance, fast mold clamping, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0054] The orientations in this embodiment are all subject to the drawings in the specification.

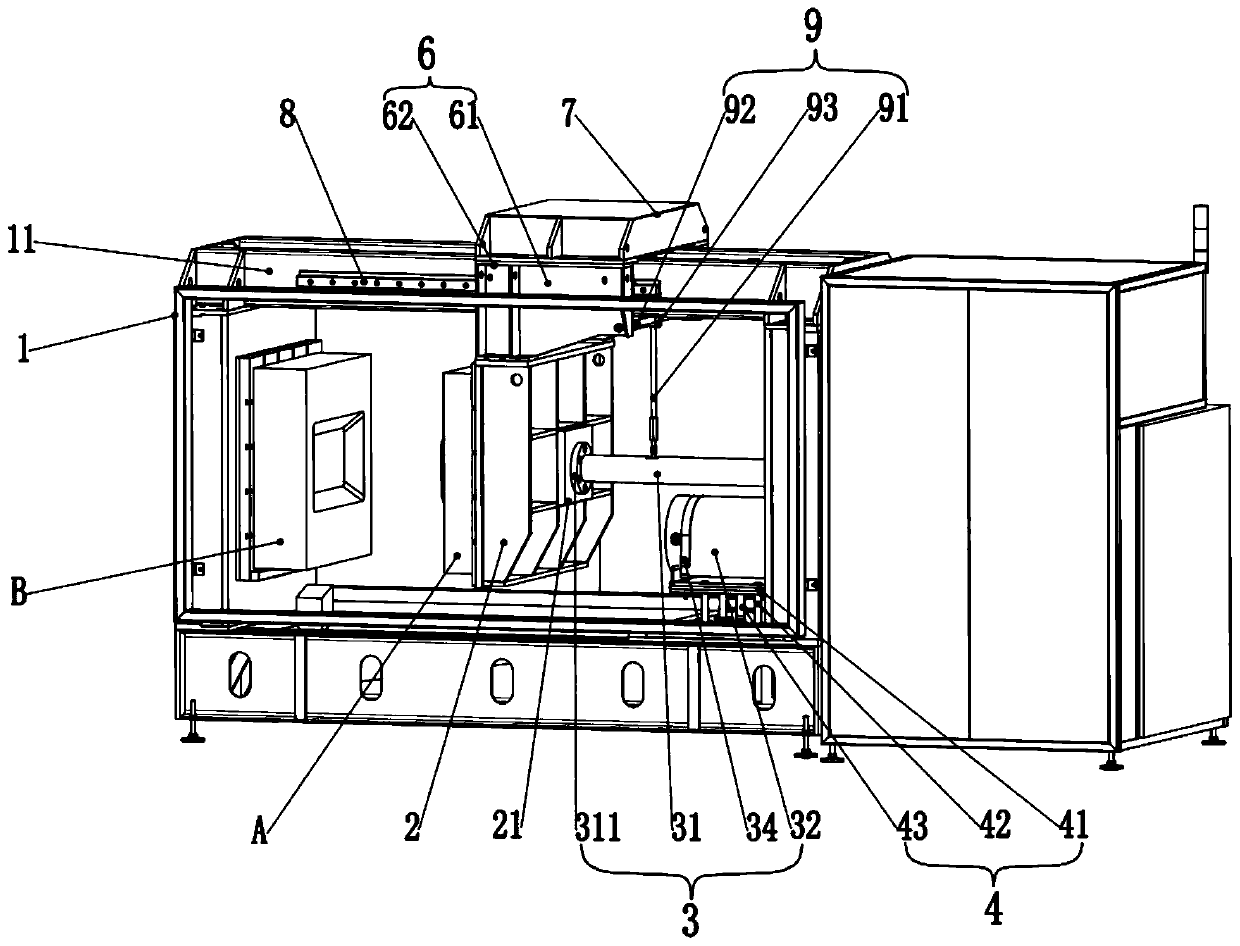

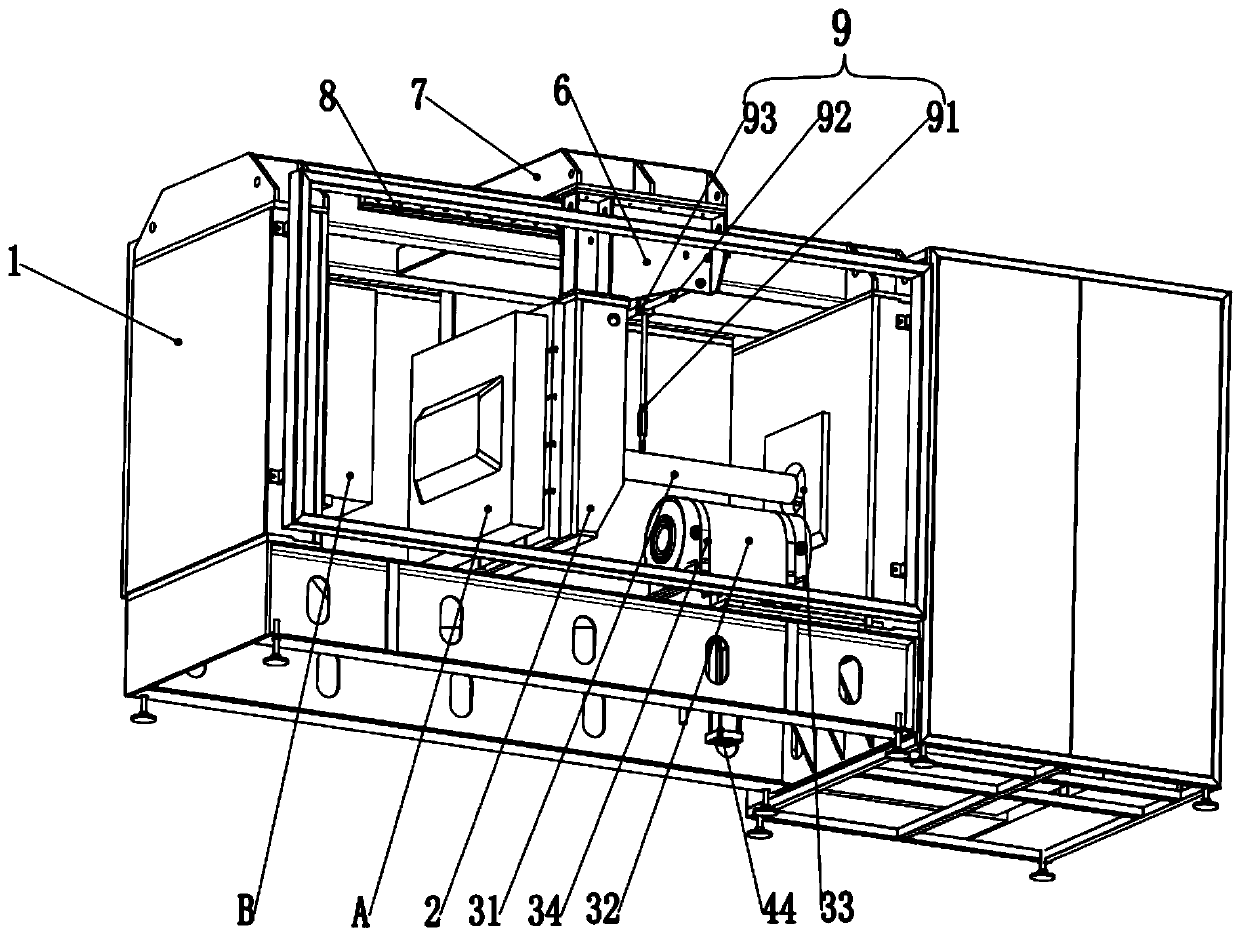

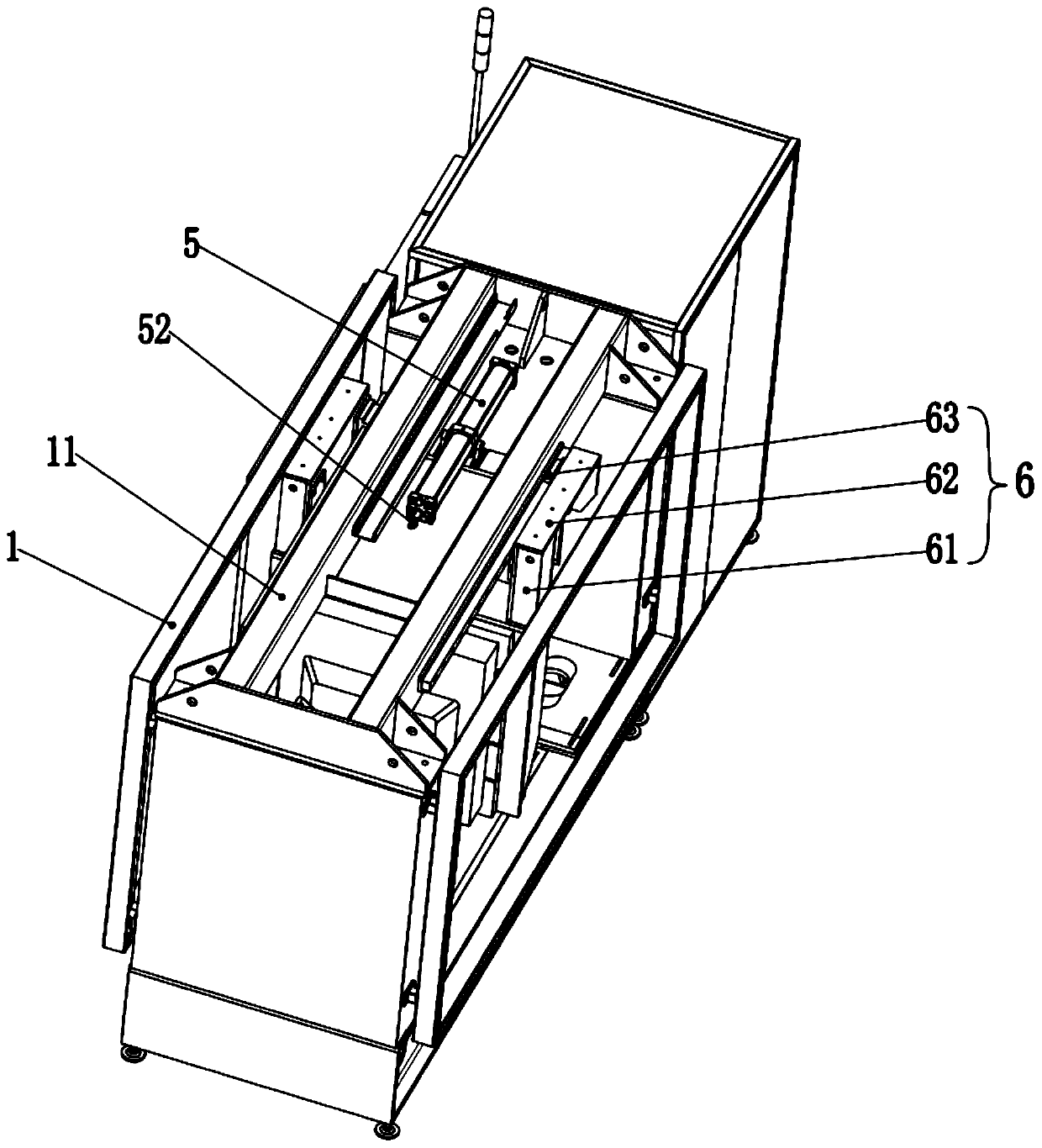

[0055] A kind of daily-use ceramic high-pressure grouting machine of the present invention, such as Figure 1-Figure 3 As shown, it includes a frame 1, the middle part of the frame 1 is fixed with a movable mold mounting frame 2, the rear end of the movable mold mounting frame 2 is provided with a push rod 31, and the rear portion of the frame 1 is provided with a push rod The pushing device 3 of the push rod 31;

[0056] The bottom of the rear end of the frame 1 is equipped with a lifting device 4, the pushing device 3 is installed on the lifting device 4, and the lifting device 4 drives the pushing device 3 to lift;

[0057] The pushing device 3 is located below the push rod 31 after it is lowered,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com