A device and method for installing and pre-adjusting molds of transformer coils based on APG

A technology for transformers and regulating devices, applied in coil manufacturing, inductance/transformer/magnet manufacturing, electrical components, etc., can solve problems such as rapid drop in temperature of transformer coils, lower product quality of transformers, burn workers, etc., to achieve The effect of reducing temperature drop, fast mold closing and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

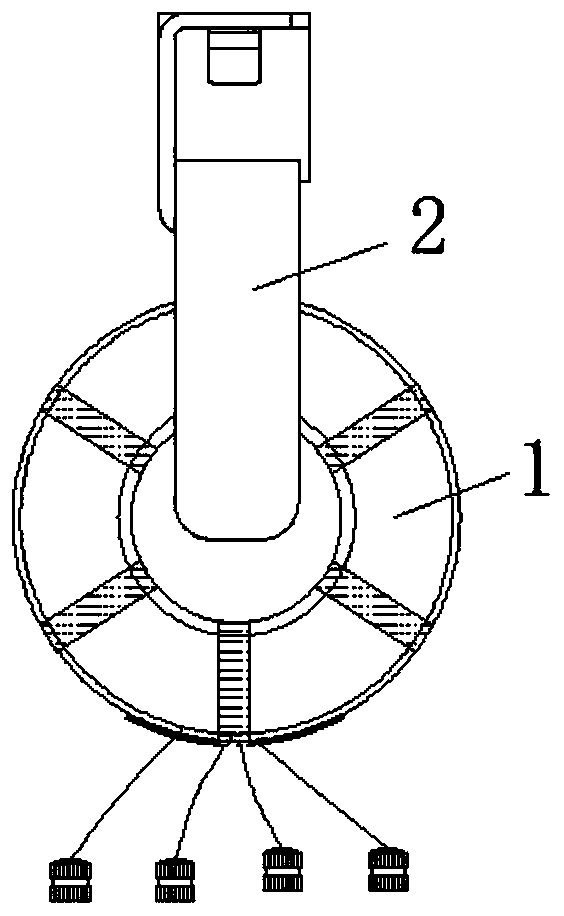

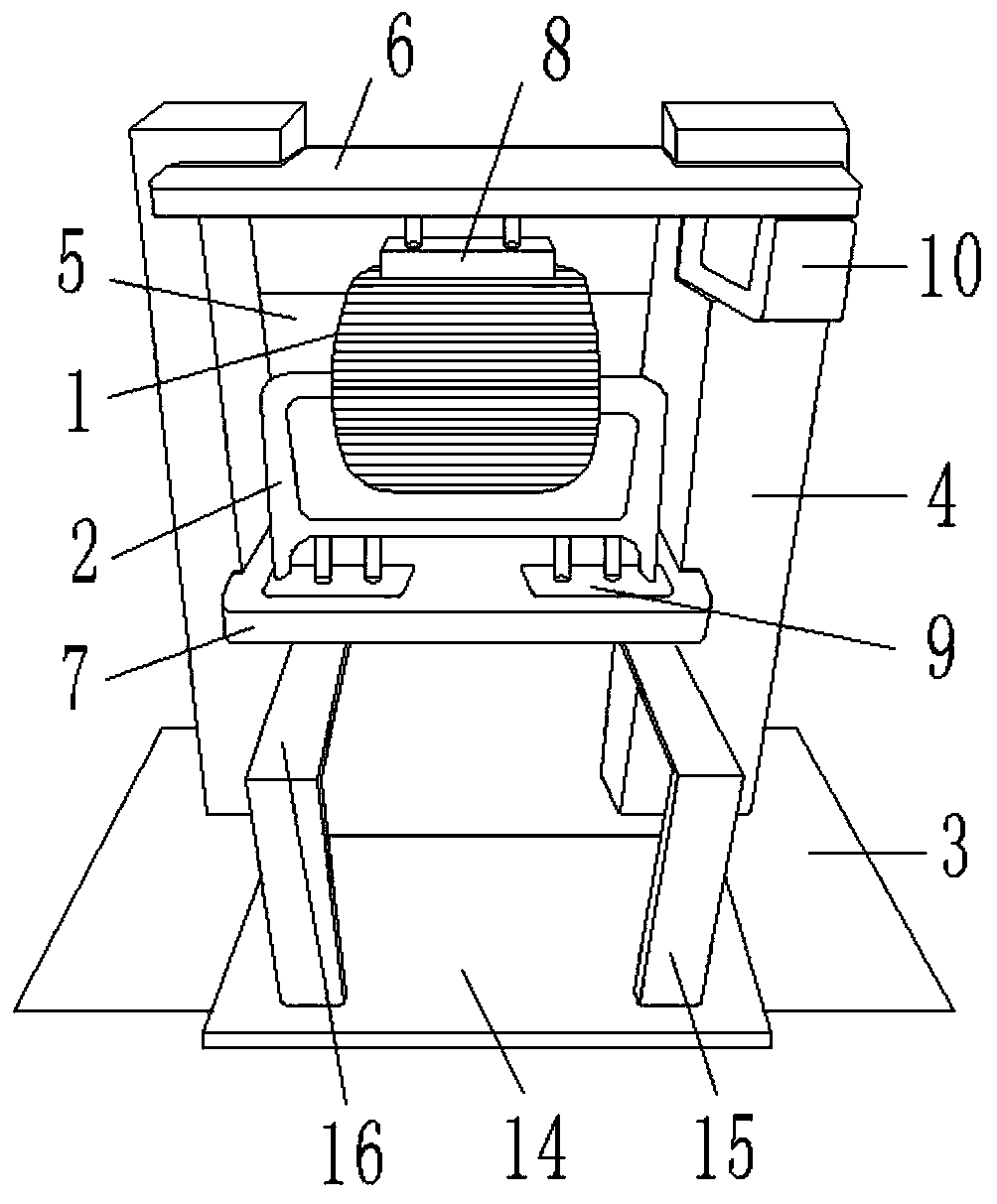

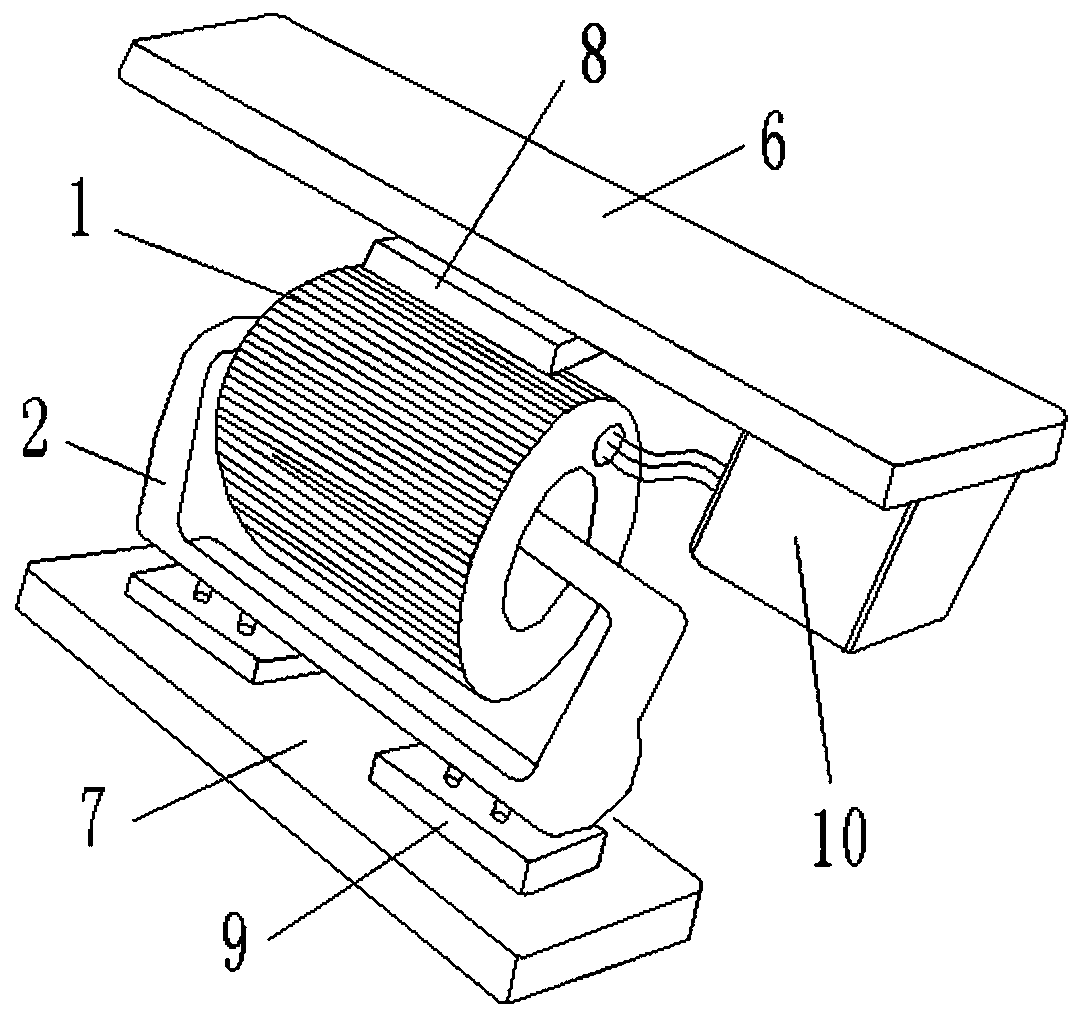

[0034] Reference Figure 2~Figure 8 , An APG-based instrument transformer coil pre-adjustment device, including a limit device and an adjustment device, the limit device includes a base 3, two vertical plates 4 and a back plate 5, the two vertical plates are installed on the base relative to each other The backplane is installed horizontally between the two vertical plates; the adjusting device includes a first mounting plate 6, a second mounting plate 7, a first fixing block 8, a second fixing block 9 and a winding fixing block 10. One fixing block is used to fix the first transformer wire 1, the second fixing block is used to fix the second transformer coil 2, and the winding fixing block is used to install the connecting wire 22 of the first transformer coil, The first fixing block can be fixedly mounted on the first mounting plate, the second fixing block can be fixedly mounted on the second mounting plate, and the winding fixing block can be fixedly mounted on the first mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com