A preparation method of soft skin-friendly slippers

A slipper and soft technology, which is applied in the field of soft skin-friendly slippers, can solve the problems of reduced vacuuming effect, stuck in the upper mold, high cost of accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

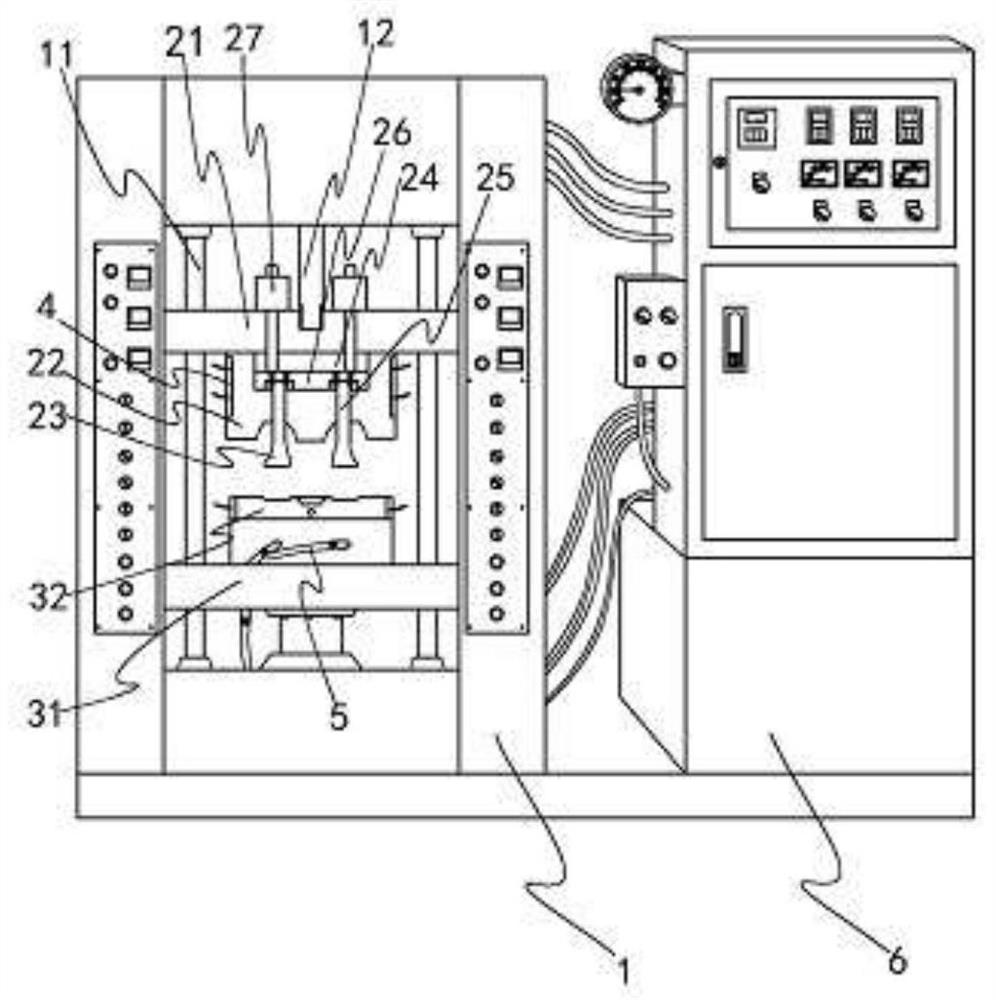

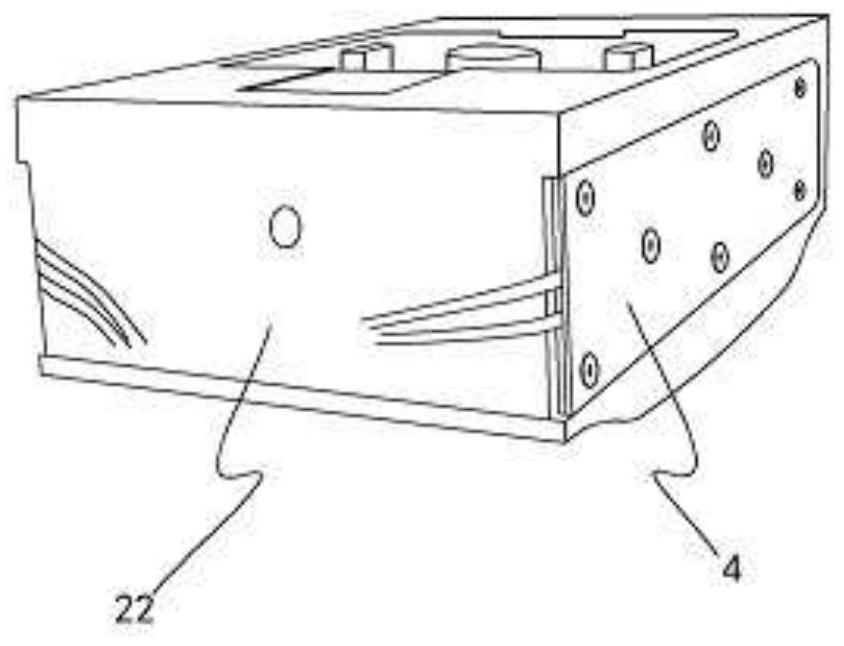

[0031] A preparation method of soft skin-friendly slippers, comprising the steps of:

[0032] Step 1. Preparation of polyamide mixture: in parts by weight, 45 parts of low-melting polyamide (DSC melting point 98° C.), 12 parts of superfine powder of hemp stalk core, 18 parts of EVA7470M, 1.5 parts of OBC907725 parts and zinc stearate, Premix in a high-speed mixer for 3 minutes, then pass the premixed material through a twin-screw extruder, melt extrude at 115° C., cool and granulate to obtain a polyamide mixture.

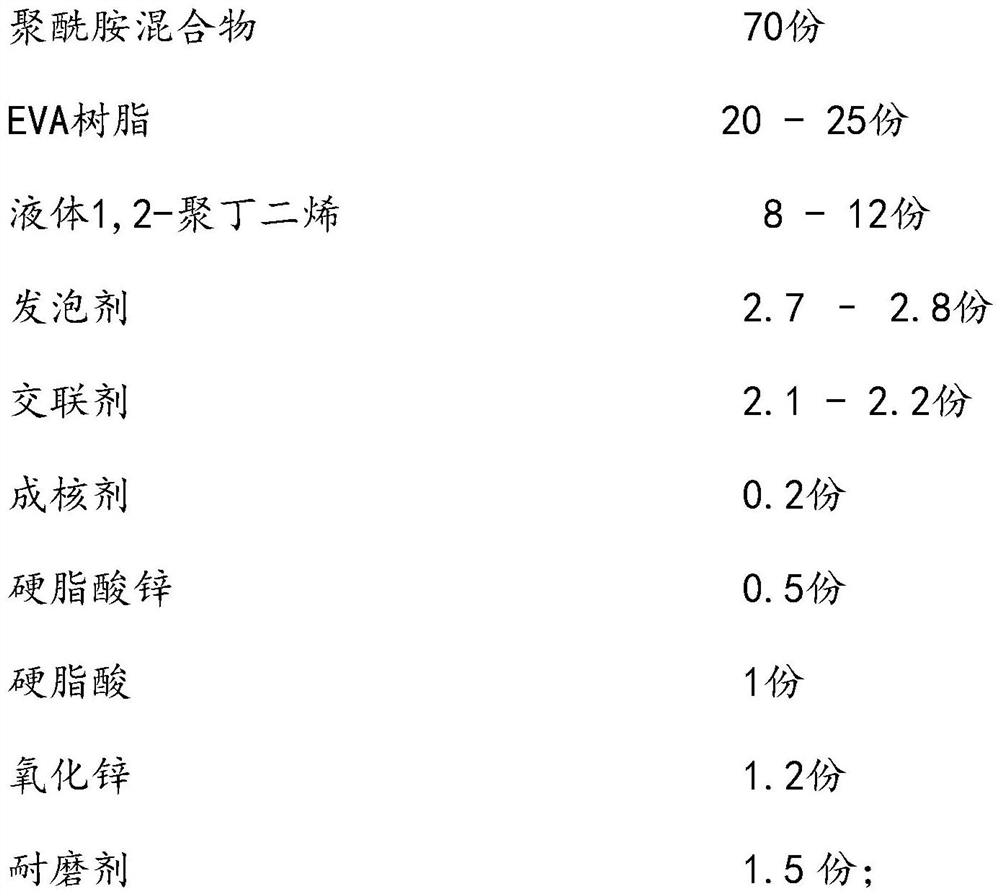

[0033] Step 2, preparing plastic rice: the plastic rice is prepared from the following components according to the following raw materials in parts by weight:

[0034]

[0035]

[0036] First mix other raw materials except foaming agent and cross-linking agent for banburying, turn over 5 times, the turning temperature is 80°C, 85°C, 89°C, 93°C, 97°C; then add foaming agent And cross-linking agent, continue to turn material 3 times, turning material temperatur...

Embodiment 2

[0047] The preparation method of soft skin-friendly slippers described in embodiment 2 is the same as the preparation method in embodiment 1, the difference is: in embodiment 2

[0048] In step 1, the DSC melting point of the low-melting polyamide is 85°C, and the twin-screw extrusion temperature is 95°C.

[0049] In step 2, 17 parts of EVA7470M, 12 parts of liquid 1,2-polybutadiene.

[0050] The soft skin-friendly slippers prepared above have a sole specific gravity of 0.19g / cm 3 , hardness 34C, DIN wear resistance 174mm 3 , Size shrinkage 1.4%, compression deformation 53%, anti-slip coefficient (smooth) dry 0.70 wet 0.49.

Embodiment 3

[0052] The preparation method of the soft skin-friendly slippers described in embodiment 3 is the same as the preparation method in embodiment 1, the difference is: in embodiment 3

[0053] In step 1, the DSC melting point of the low-melting polyamide is 110°C, and the twin-screw extrusion temperature is 125°C.

[0054] In step 2, there are 6 parts of EVA7470M, 14 parts of EVA 40W, 8 parts of liquid 1,2-polybutadiene, 2.8 parts of foaming agent AC, and 2.2 parts of crosslinking agent V-40.

[0055] In step 3, the vulcanization time is 250 seconds.

[0056] The soft skin-friendly slippers prepared above have a sole specific gravity of 0.20g / cm 3 , hardness 37C, DIN wear resistance 183mm 3 , Size shrinkage 1.7%, compression deformation 50%, anti-slip coefficient (smooth) dry 0.59 wet 0.40.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com