Composite door and window sectional material with combination of internal and external metal sectional materials and middle integral heat-insulation sectional materials

A technology for metal profiles and door and window profiles, which is applied in windows/doors, building components, buildings, etc., and can solve the problem of low strength of joints without groups

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

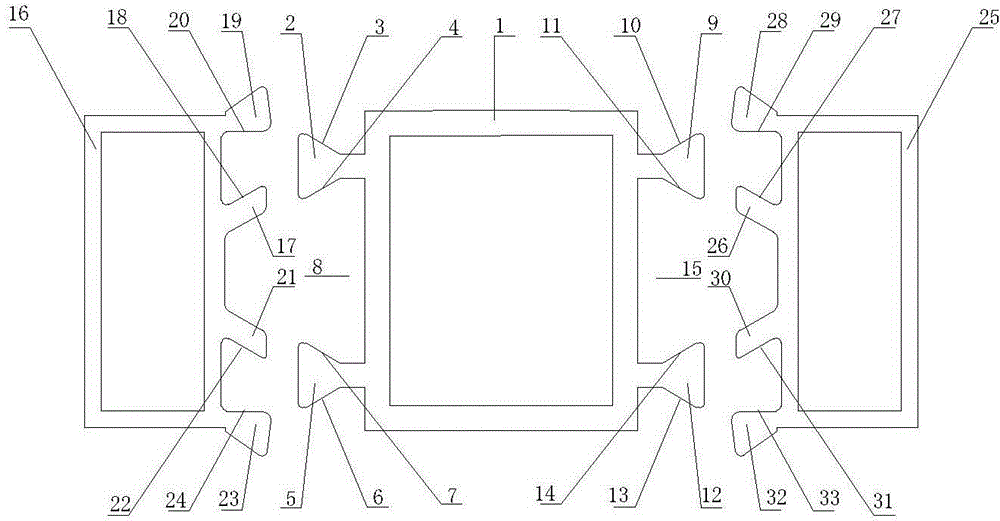

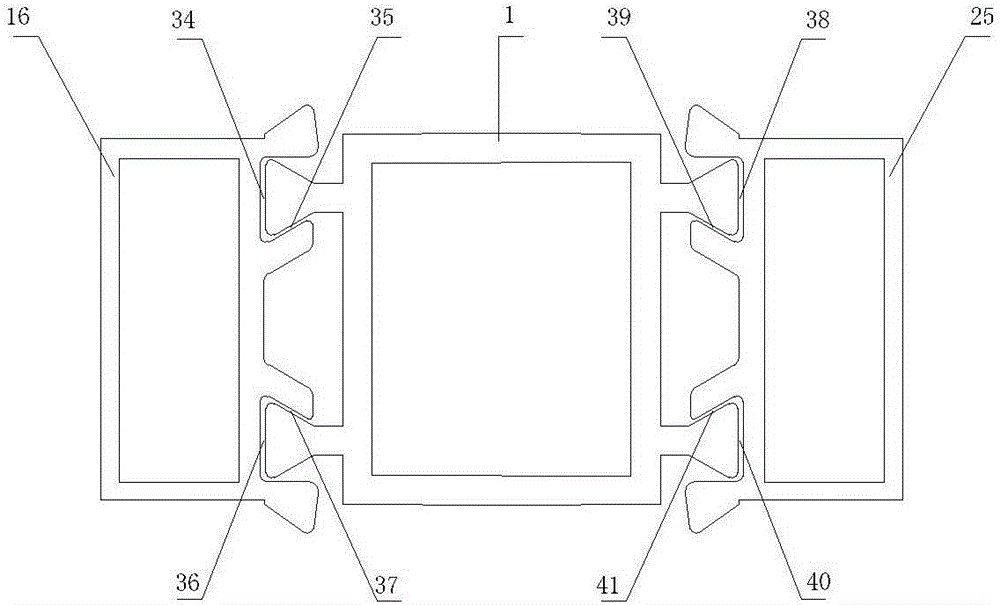

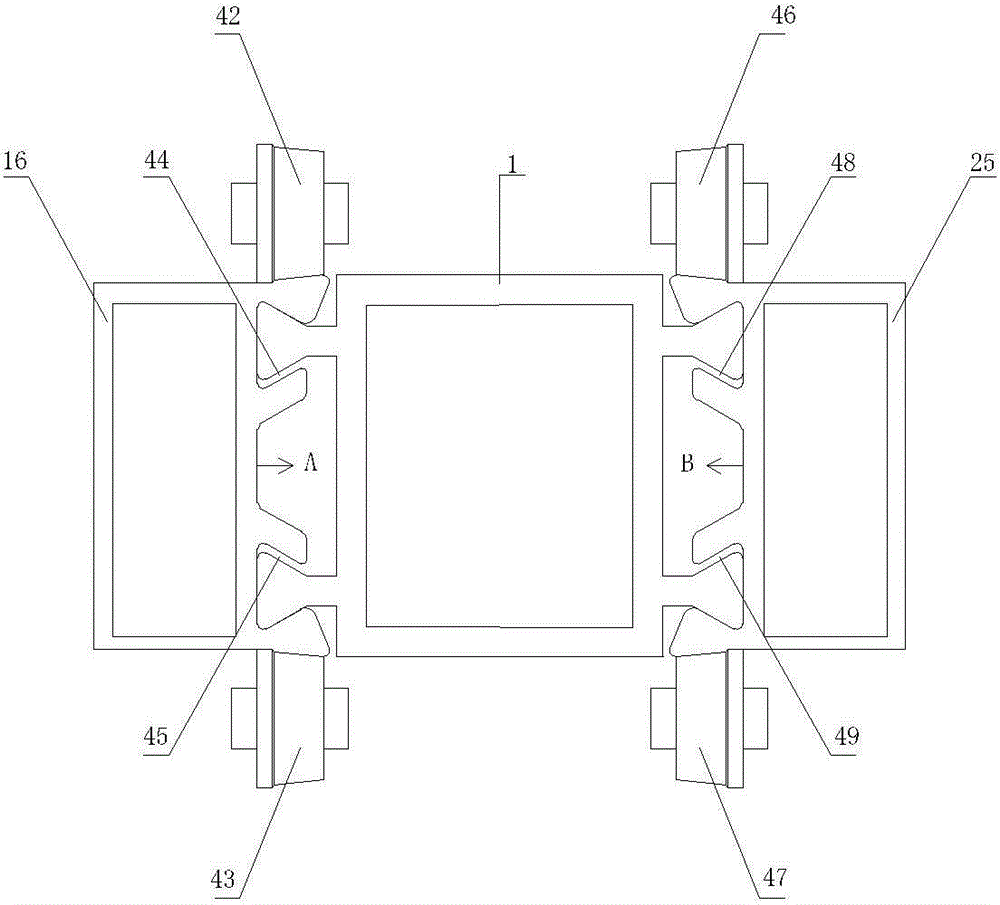

[0042] The schematic diagram of the partial assembly end face structure decomposition of the existing metal profiles and heat insulation profiles is as follows: figure 1 as shown, figure 2 yes figure 1 Schematic diagram of the longitudinal threading state of existing metal profiles and heat-insulating profiles, image 3 yes figure 1 Schematic diagram of the pressing state of the existing metal profiles and heat-insulating profiles, in which: 1 is the middle heat-insulating profile, 2 is the upper left fixing foot of the outer large and inner small dovetail, 3 is the pressing inclined surface of the upper left fixing foot, 4 is the inclined surface of the upper left fixing foot, 5 is the lower left fixed foot of the outer large inner small dovetail, 6 is the pressing slope of the lower left fixed foot, 7 is the upper slope of the lower left fixed foot, 8 is the outer small inner large dovetail groove on the left side of the heat insulation profile, 9 is the upper right of th...

Embodiment 2

[0048] Combining the inner and outer metal profiles with corner cavities and the integral heat-insulating profiles with corner cavities in the middle, the decomposed end surface structure diagram of window frame profiles is as follows Figure 4 as shown, Figure 4 The combined end face structure diagram is as follows Figure 5 As shown, among them: 50 is a heat insulation profile with a group corner cavity, 51 is an upper horizontal rib, 52 is an upper groove, 53 is a lower horizontal rib, 54 is a lower groove, 55 is an inner vertical rib, 56 is an inner small outer Large inner trapezoidal positioning groove, 57 is the inner upper connection protrusion, 58 is the inner upper connection groove, 59 is the lower support surface of the inner upper connection protrusion, 60 is the inner lower connection protrusion, 61 is the inner lower connection groove, 62 63 is an outer vertical rib, 64 is an outer trapezoidal positioning groove with a small inside and a large outside, 65 is an...

Embodiment 3

[0053] The structure diagram of the end surface of the window frame is composed of the metal profile with a set of corner cavities inside and outside and the overall heat-insulating profile in the middle cavity filled with thermal insulation materials. Figure 6 as shown, Figure 6 The combined end face structure diagram is as follows Figure 7 As shown, among them: 96 is a heat insulation profile with a group corner cavity, 97 is an inner vertical rib, 98 is an inner trapezoidal positioning groove with a small inside and a big outside, 99 is an inner upper connection protrusion, and 100 is an inner upper connection groove , 101 is the lower support surface of the inner upper connection protrusion, 102 is the inner lower connection protrusion, 103 is the inner lower connection groove, 104 is the upper support surface of the inner lower connection protrusion, 105 is the outer vertical rib, 106 is the inner small outer large 107 is the outer upper connection protrusion, 108 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com