Exposure pattern forming method

An exposure pattern and exposed technology, which is applied in microlithography exposure equipment, photolithographic process exposure devices, optics, etc., can solve the problems of increased mask cost, difficulty in achieving, and problem of functional pattern overlapping accuracy, and achieves The effect of suppressing cost increase, eliminating the deterioration of the overlapping accuracy, and improving the overlapping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

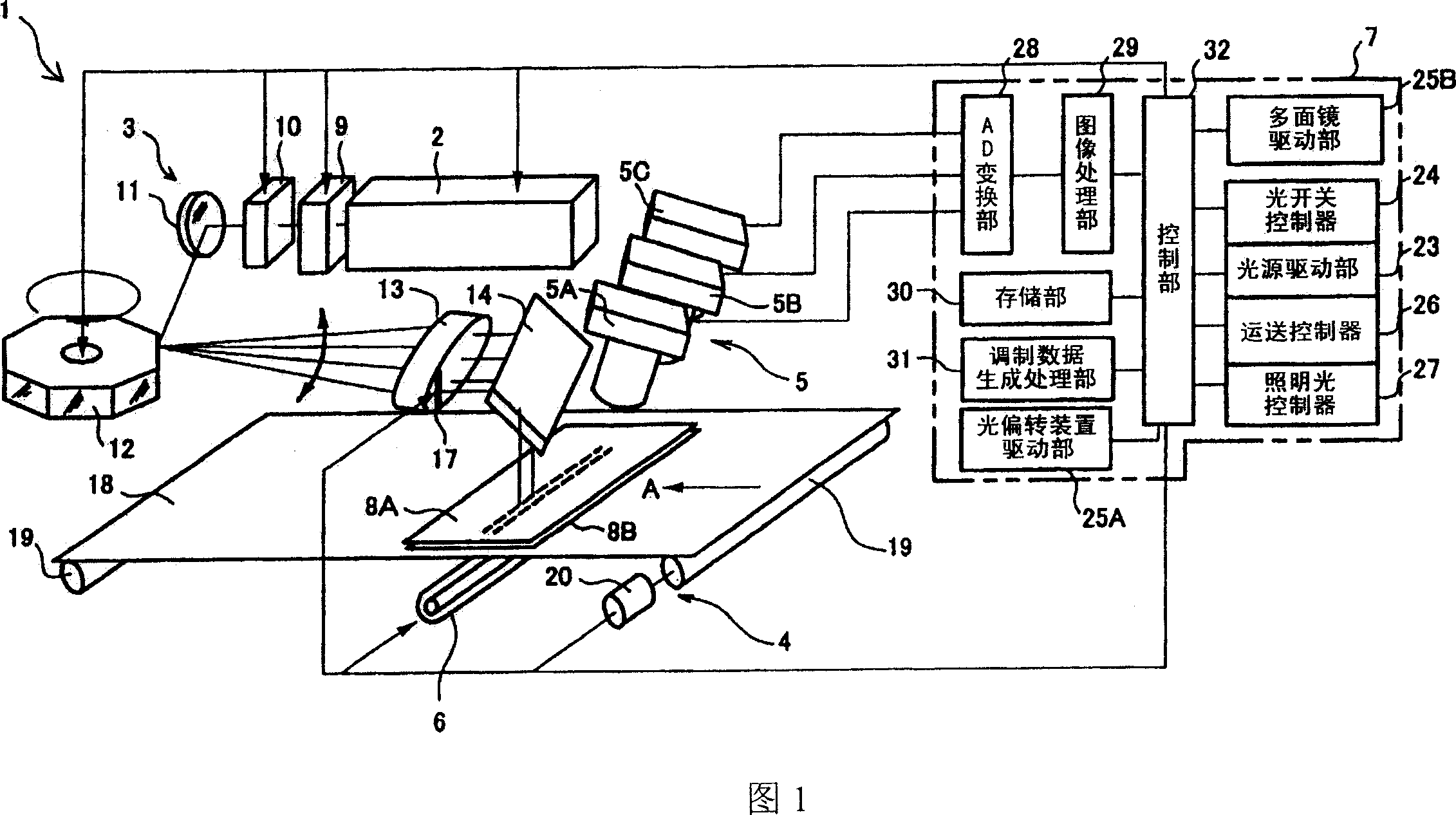

[0032] Embodiments of the present invention will be described in detail below with reference to the drawings.

[0033] FIG. 1 is a schematic diagram illustrating an embodiment of an exposure apparatus to which the exposure pattern forming method of the present invention is applied. The exposure device 1 directly exposes a functional pattern on an object to be exposed, and includes a laser light source 2 , an exposure optical system 3 , a transport device 4 , an imaging device 5 , an illumination device 6 , and an optical system control means 7 . In addition, the above functional pattern refers to the pattern of the components of the product that are required to perform the original target action. For example, for a color filter, it is a pixel pattern of a black dot matrix or a red, blue, and green color filter. Sheet patterns, and for semiconductor components, wiring patterns or various electrode patterns, etc. In the following description, an example in which a glass substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com