Laser-induced printing method of solar cell grid lines based on double groove structure of silicon wafer

A solar cell and laser-induced technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems such as grid line width fluctuations, achieve stable width, reduce production costs, and save silver paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with specific embodiments.

[0037] The specific steps of the laser-induced printing method for solar cell grid lines based on the silicon wafer double groove structure implemented in this embodiment include:

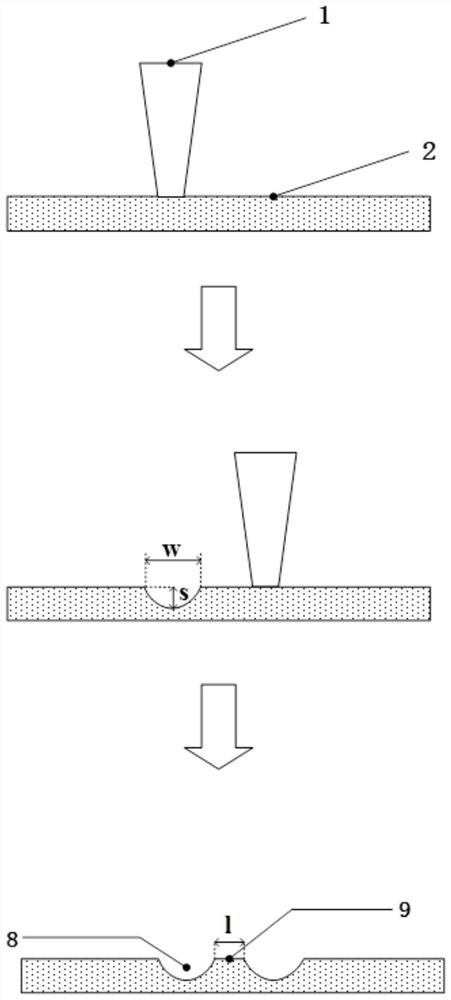

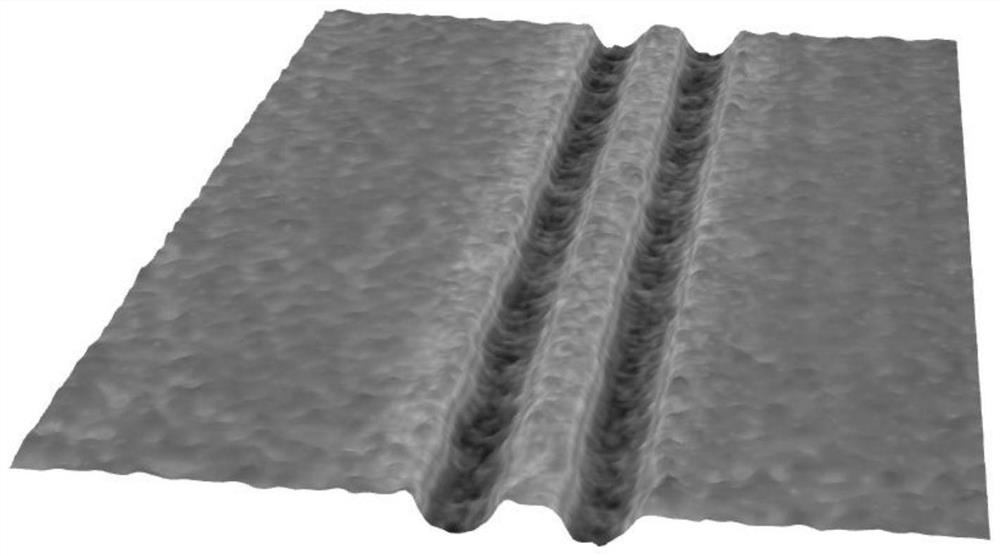

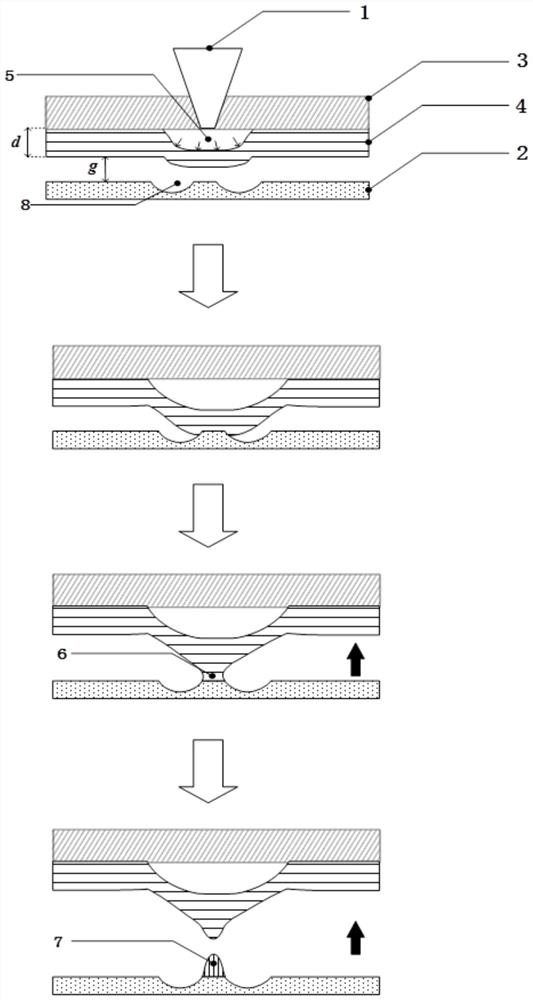

[0038] Step 1: Laser etching the double groove structure to limit the gate line printing area: Before the texturing of the silicon wafer 2, use the laser 1 to etch the left and right two grooves 8 at the predetermined printing position of the gate line on the silicon wafer 2. A certain distance l is maintained between the grooves 8. like Figure 1-2 shown, the groove depth is s and the groove width is w. At this time, the two groove-restricted areas 9 are the predetermined grid line printing areas, and the subsequent printing of the grid lines 7 will be limited in this area.

[0039] Step 2: Preparation of silver paste film: apply the silver paste on the front side of the solar cell...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com