Cable take-up and pay-off device

A retractable device and cable technology, which can be used in cable laying equipment, electronic waste recycling, and the layout of paper reels/photosensitive drums, etc. It can solve the problems of high cable weight, easy deformation of cables, and difficulty in laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

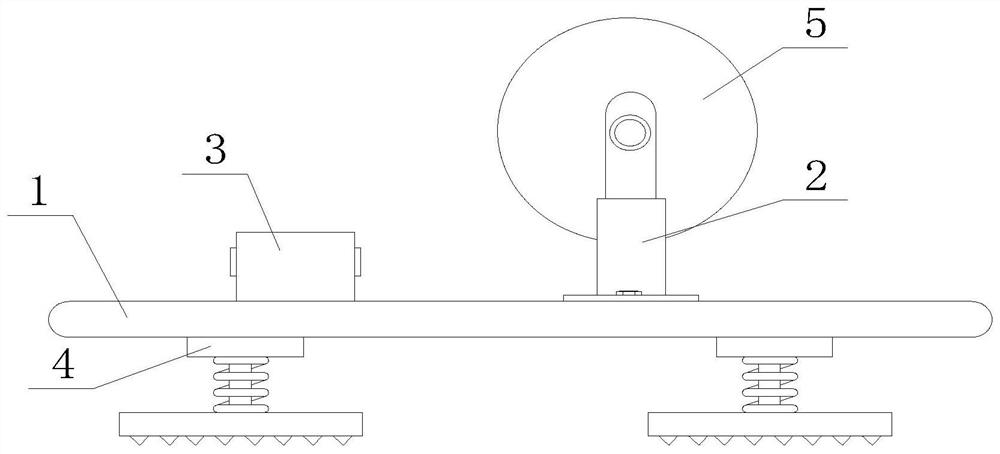

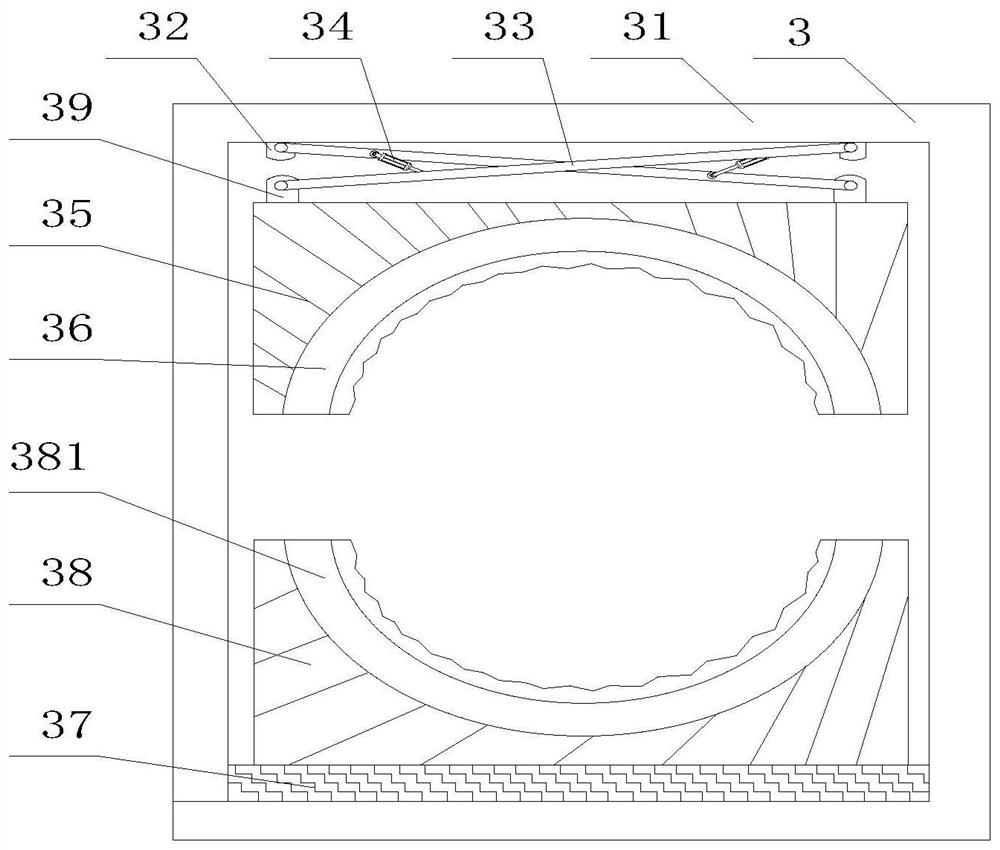

[0037] Such as Figure 1-7 As shown, the present invention provides a cable retractable device, including a cable workbench 1, the top of the cable workbench 1 is fixedly connected with a support device 2, and the top of the cable workbench 1 is fixedly connected with a cable on the left side away from the support device 2 Straightening device 3, the cable straightening device 3 includes a cable straightening box 31, the top of the cable straightening box 31 inner wall is fixedly connected with a No. 1 fixed buckle 32, and the front of the No. 1 fixed buckle 32 is movably connected with a cross link 33. The front of connecting rod 33 is movably connected with cylinder 34, and one end of cross-connecting rod 33 is movably connected with No. 2 fixed buckle 39, and the bottom of No. 2 fixed buckle 39 is fixedly connected with movable plate 35, and the bottom of movable plate 35 is fixedly connected with No. 1 arc Shaped plate 36, the bottom of No. 1 arc-shaped plate 36 is provide...

Embodiment 2

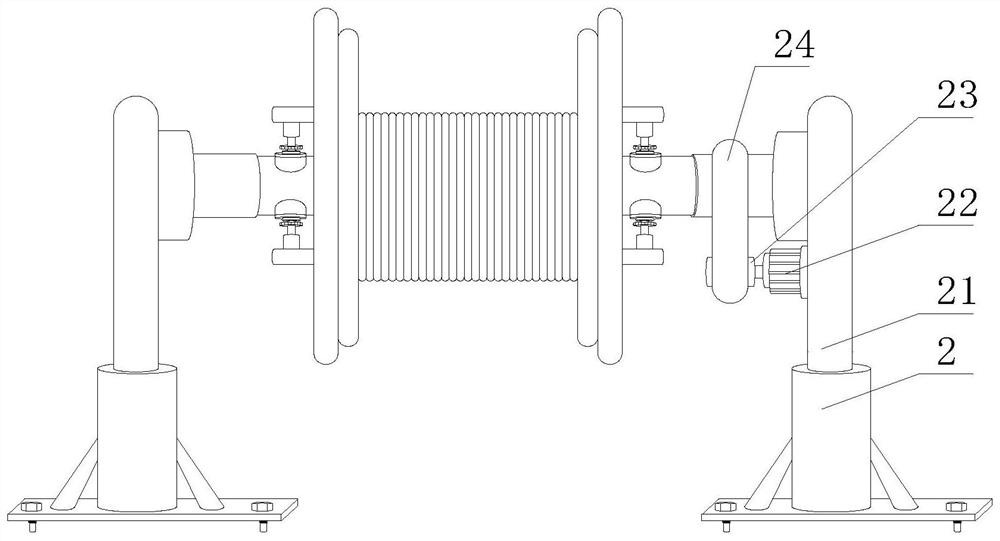

[0042] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the number of supporting devices 2 is two, and the two supporting devices 2 are symmetrically arranged on the top of the cable workbench 1, and the two supporting devices 2 include Support plate 28, the top of support plate 28 is fixedly connected with electric lifting column 21, and the both sides of electric lifting column 21 is fixedly connected with support column 29, and the bottom of support column 29 is fixedly connected with the top of support plate 28, and support column 29 has increased The force bearing area between the bottom of the electric lifting column 21 and the top of the support plate 28 makes the electric lifting column 21 more stable and reliable. One side of the electric lifting column 21 is fixedly connected with a No. The side is fixedly connected with an electric telescopic rod 26, and one end of the electric telescopic rod 26 is fixe...

Embodiment 3

[0044] Such as Figure 1-7 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, one side of the electric lifting column 21 is fixedly connected with a DC drive motor 22, and the output end of the DC drive motor 22 is fixedly connected with a rotating shaft 23, The outer wall of the rotating shaft 23 is movably socketed with crawler belts 24 , and the inner wall at the top of the crawler belts 24 is movably socketed on the outer wall of the electric telescopic rod 26 to start the DC drive motor 22 , and at the same time the DC drive motor 22 drives the rotating shaft 23 to rotate, while the rotating shaft 23 drives the crawler belt 24 to rotate , crawler belt 24 simultaneously drives electric telescoping bar 26, fixed block 27, cable rack 5 No. 1 turntable 25 rotations, makes cable downwards and breaks away from cable rack 5 quickly, avoids when laying cable, usually the staff adopts manual pull cable, because The high weight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com