Manual self-centering clamp plate

A self-centering, splint technology, applied in the direction of positioning device, feeding device, storage device, etc., can solve the problem of not having fast clamping bar material, complex and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

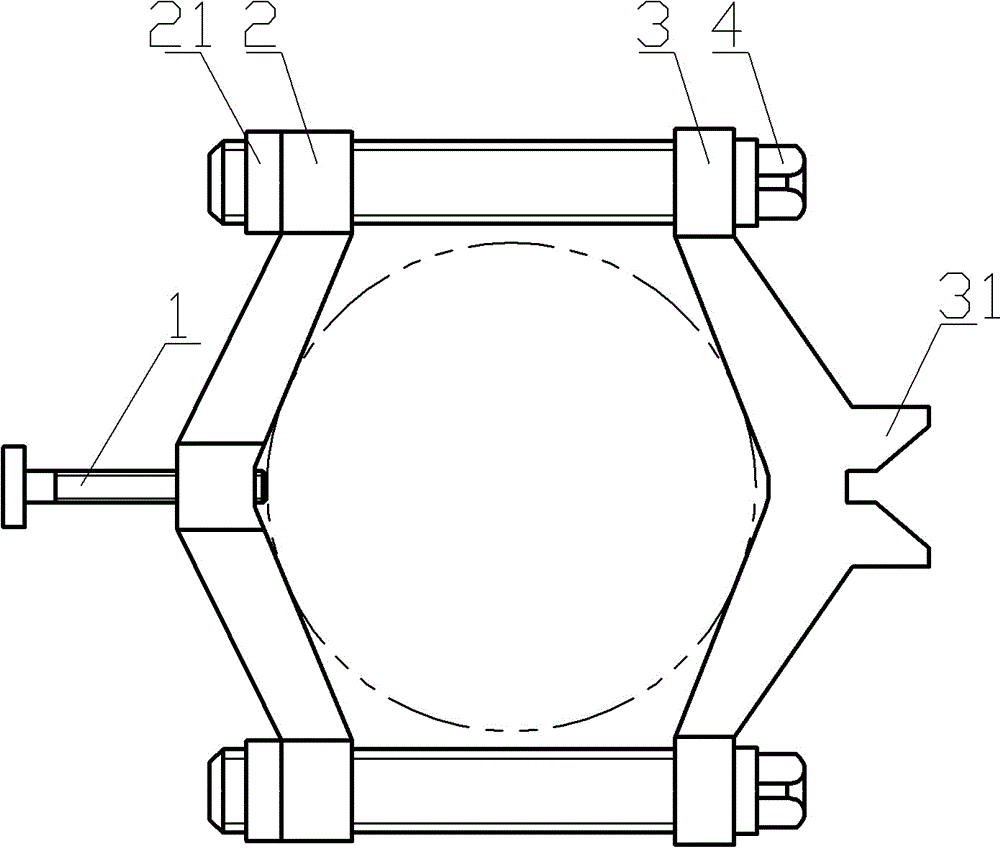

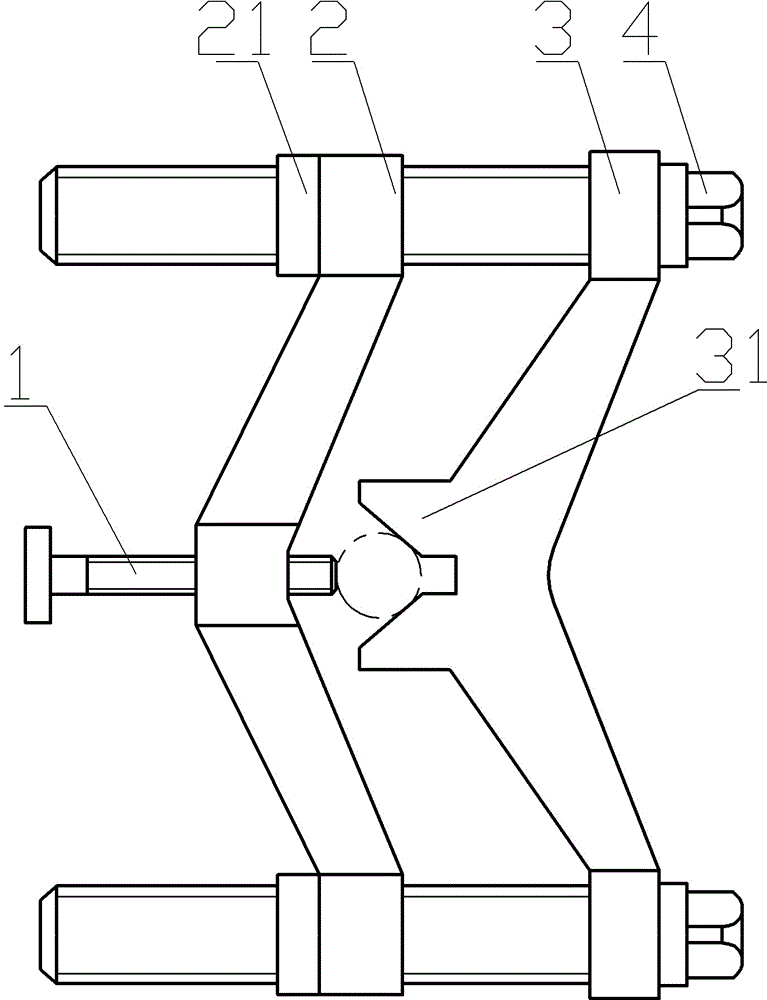

[0017] Embodiment one is basically as attached figure 1 , figure 2 As shown: the manual self-centering splint includes upper bolt 3, lower bolt, left splint 2, right splint 3 and jacking screw 1; the upper bolt and lower bolt are arranged side by side, and it is best to keep it horizontal, and the upper end of the right splint is set on the upper bolt. The lower end of the right clamping plate is covered with the lower bolt, and the right clamping plate can slide on the upper bolt and the lower bolt. One side of the right clamping plate is a V-shaped positioning surface, and the other side of the right clamping plate is a small V-shaped block portion 31; The upper end of the splint and the lower end of the left splint are respectively socketed with upper bolts and lower bolts. Nuts 21 are provided on the upper end of the left splint and the outer side of the lower end of the left splint. Good bar material, the middle part of the left splint is threaded to connect the jacking...

Embodiment 2

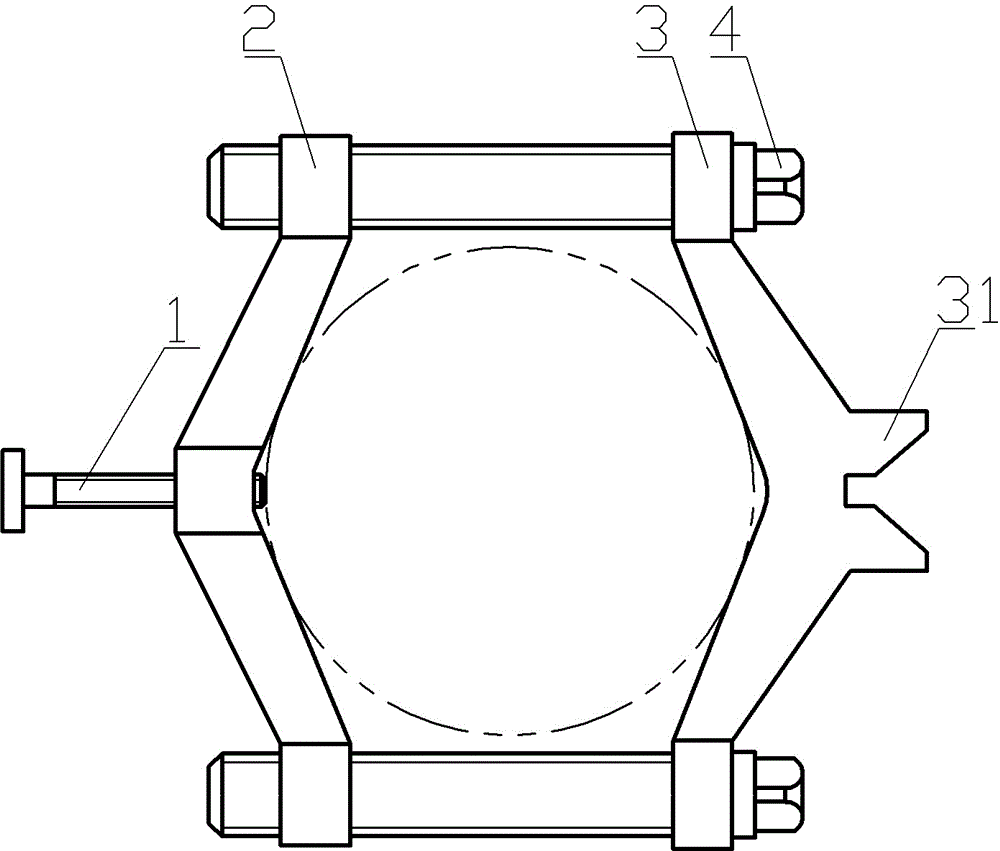

[0020] Such as image 3 , Figure 4 As shown, the difference between the second embodiment and the first embodiment is only that the nut 21 is not included, the upper end of the left splint is threaded with the upper bolt; the lower end of the left splint is threaded with the lower bolt. The lower bolt can lock the upper end of the left splint and the lower end of the left splint, thereby clamping and fixing the bar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com