Straightening device for large-diameter material of cold header and straightening method

A straightening device and large-diameter technology, applied in the field of cold heading machine components, can solve problems such as poor product size, defective products, and adverse effects on quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

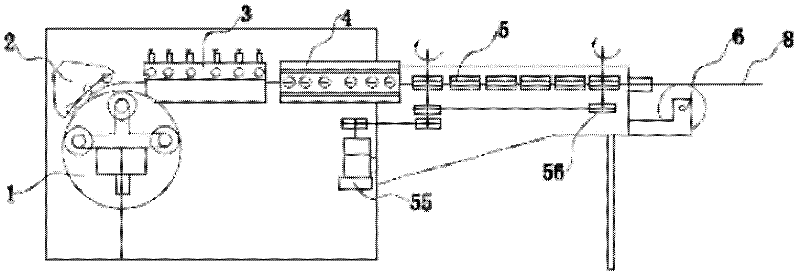

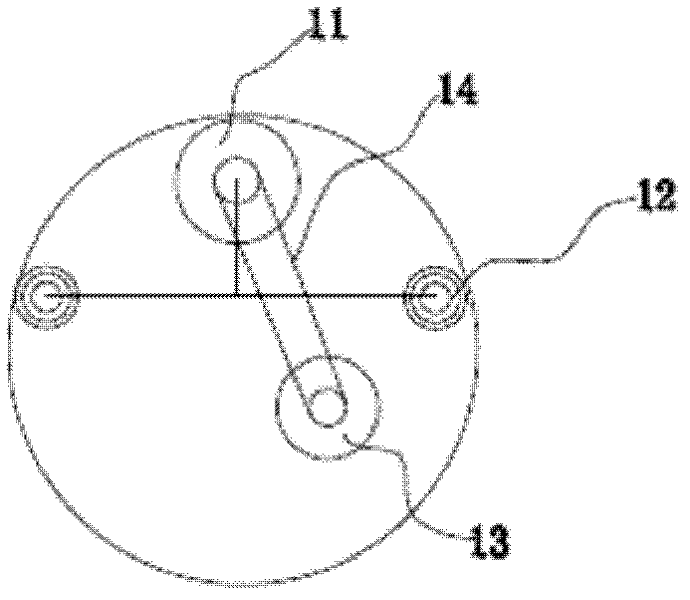

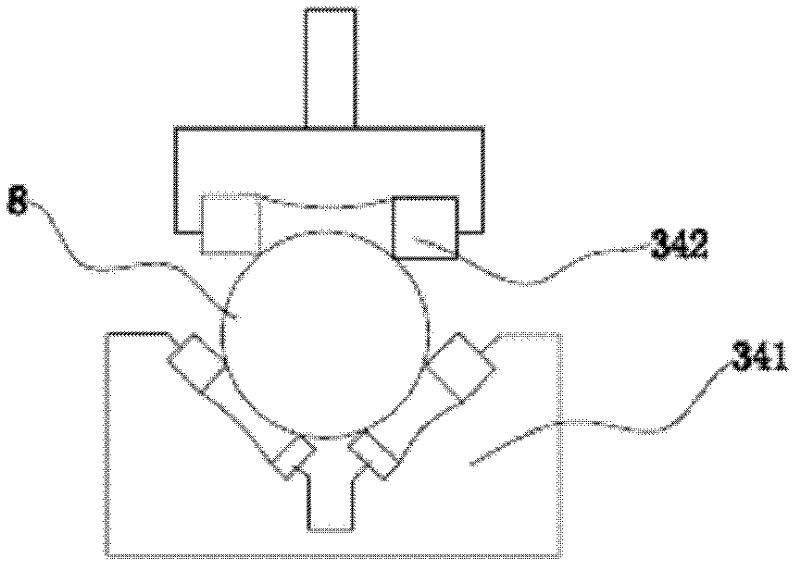

[0024] Such as figure 1 , image 3 , Figure 4 with Figure 5 As shown, the straightening device for the large-diameter material of the cold heading machine provided by this embodiment includes a disc assembly 1, a press frame 2 and a supporting wheel 6, the disc assembly 1 cooperates with the press frame 2, and the disc assembly 1 and supporting wheel 6 are provided with roller straightening A frame 3, roller straightening B frame 4 and roller straightening frame 5, roller straightening A frame 3, roller straightening B frame 4, and roller straightening frame 4. Straight frame 5 and supporting wheel 6 are coaxial structures. In the above structure, the optimized combination structure of the roller straightening A frame 3, the roller straightening B frame 4 and the roller straightening frame 5 is used to correct the multi-directional-multi-arc space bending shape of the material 8 before cold heading. straight purpose.

[0025] Both the roller straightening A frame 3 and ...

Embodiment 2

[0028] Such as Image 6 As shown, the straightening device for large-diameter materials of cold heading machines provided by this embodiment has a general structure consistent with that of Embodiment 1, but in order to ensure that the material 8 does not produce deflection during travel and smoothly enters the next straightening frame, The transition rings between the roller straightening A frame 3 , the roller straightening B frame 4 and the roller straightening frame 8 are all provided with guide pipes 7 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com