A kind of self-resistance heating incremental forming device and forming method

A progressive forming and self-resistance technology, applied in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of large forming force, small elastic modulus, large yield ratio, etc., to prevent local temperature from being too high, reducing The effect of small current loss and reduced heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

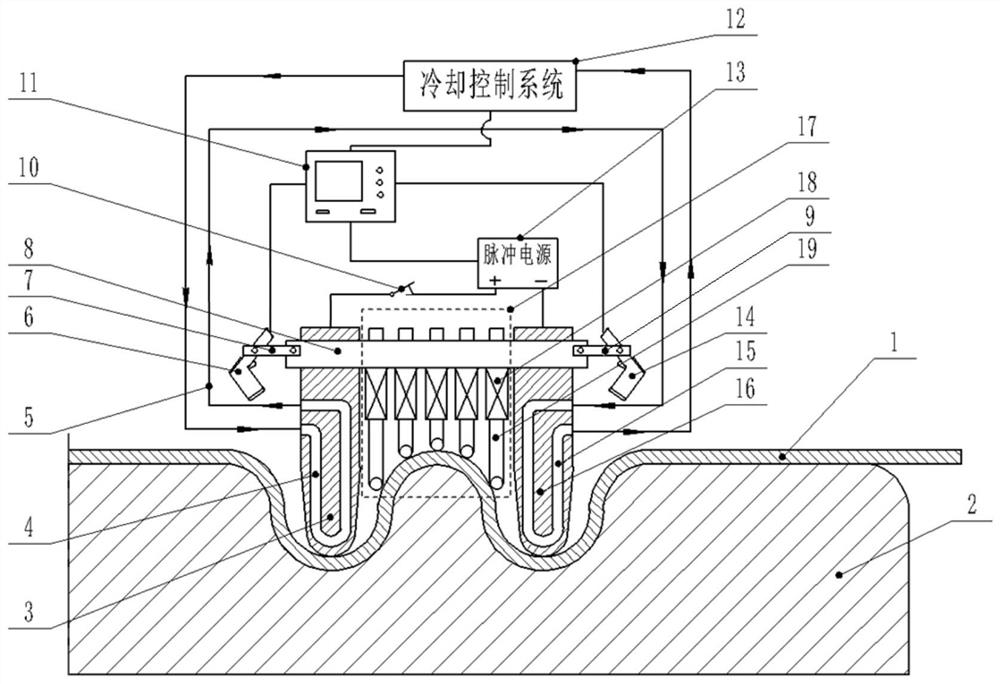

[0036] The invention discloses a self-resistance heating progressive forming device. The selective area progressive forming process is not limited by the forming track, and is suitable for titanium alloy corrugated discs that are difficult to deform at room temperature, have large local deformation of the geometric characteristics of parts, and have large springback and low forming precision. Parts that are difficult to form are formed.

[0037] refer to figure 1 , is a structural schematic diagram of a self-resistance heating progressive forming device in the present invention. The self-resistance heating progressive forming device includes: a thin plate to be formed 1, a support model 2, a first rigid tool head 3, an insulating connecting rod 8, a second Rigid tool head 16, adjustable flexible tool head group 17 and low-voltage high-current pulse power supply 13.

[0038] The thin plate 1 to be formed is fixed on the support model 2; the first rigid tool head 3, the adjusta...

Embodiment 2

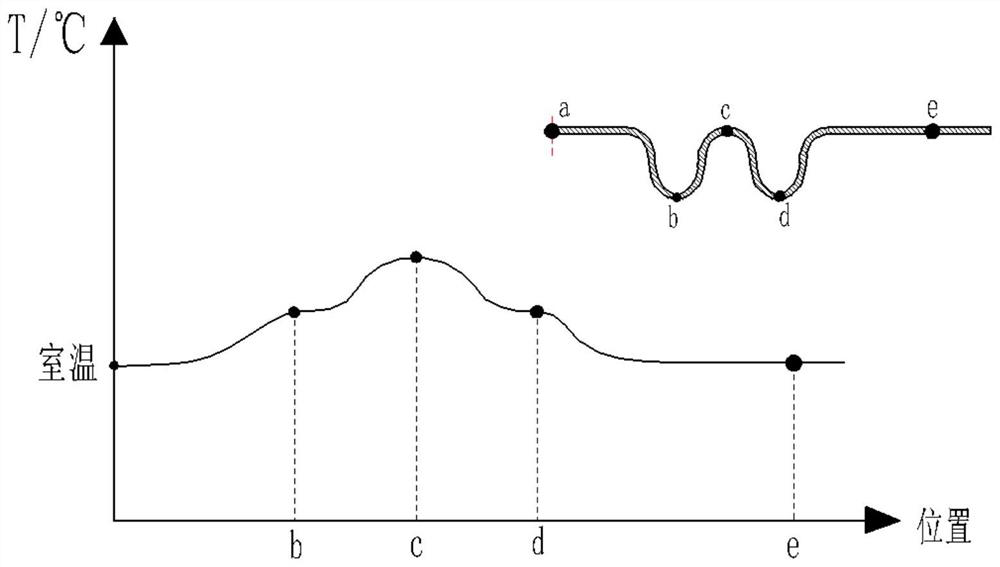

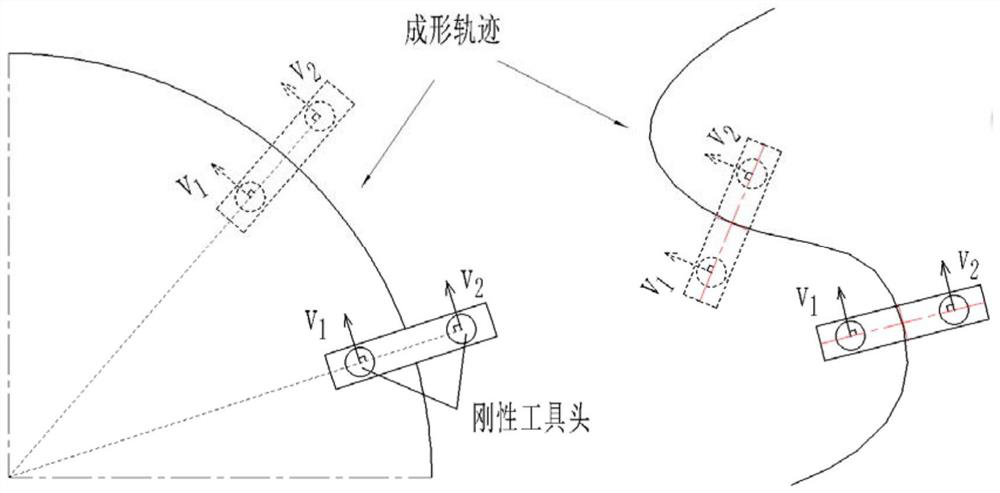

[0047] The invention also discloses a self-resistance heating progressive forming method, which includes: fixing the thin plate to be formed on the support model; installing each tool head on the insulating connecting rod in turn; wherein, the tool head includes: a first rigid tool head , adjustable flexible tool head group and the second rigid tool head; connect the first rigid tool head and the second rigid tool head to a low-voltage high-current pulse power supply to form a local self-resistance heating circuit; connect the first infrared thermal imager and the second Two infrared thermal imagers are respectively fixed on the two ends of the insulating connecting rod through the first insulating bracket and the second insulating bracket, so as to realize the temperature monitoring between each tool head and the contact area between each tool head and the thin plate to be formed; through temperature control The system sets the temperature that needs to be reached in the proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com