FPC cover film laser automatic cutting equipment

An automatic cutting and covering film technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of affecting the cutting accuracy of laser cutting equipment, increasing the labor intensity of operators, and unable to install and cut FPC covering film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

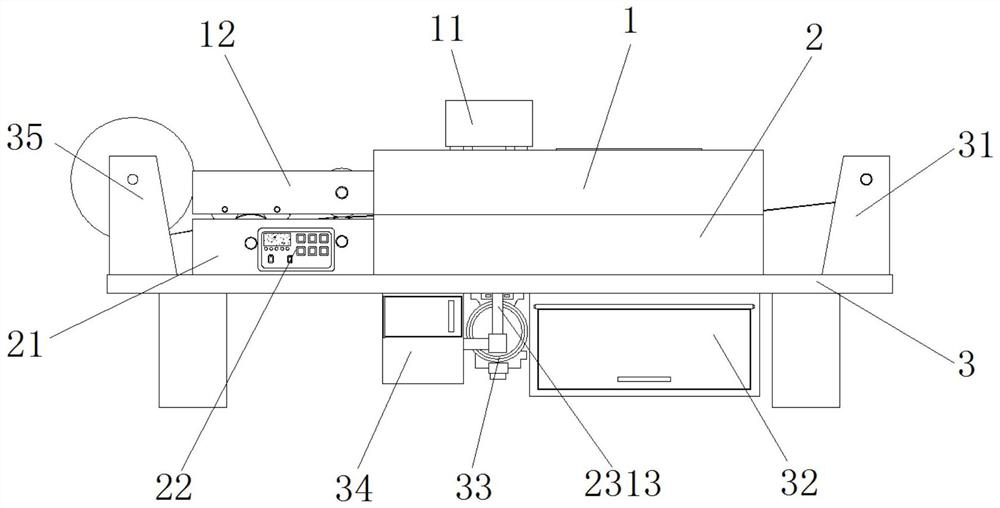

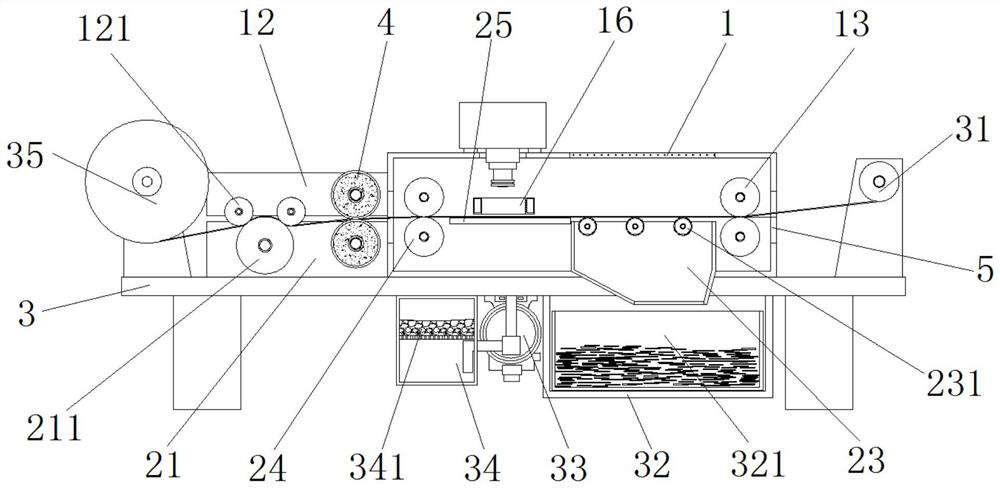

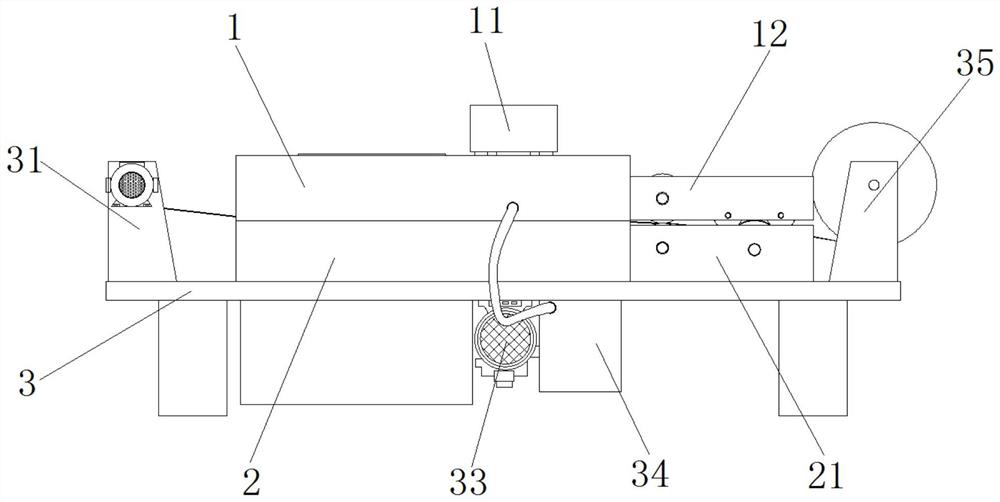

[0044] Example 1, such as figure 1 , 2 5, 7 and 9, when replacing a new volume FPC cover film, first control the four sets of electric rod 27 elongation so that the upper housing 1 gradually increases, and the upper casing 1 and the lower casing 2 are gradually separated. Open, at this time, the interior of the lower housing 2 is completely exposed, and the upper mounting frame 12 connected to the upper casing 1 is equally increased with the auxiliary guide roller 121 and the first set of cooling guide rollers, followed by the operator The FPC covers the film to the arranging device 35, and then secured to the roller of the mounting table 3 after the upper housing 1 and the lower casing 2 of the upper housing 1 and the lower casing 2, then control the four sets of electric rod 27. Drop, until the upper housing 1 and the lower housing 2 are reinable into a complete bin room, the two sets of the auxiliary guide roller 121 close to the surface of the electromagnetic heating roller 21...

Embodiment 2

[0045] Example 2, such as figure 1 , 2 3, 5, 7, and 9, if necessary, the flexible circuit board is required to separate from the FPC cover film, and the bottom of the hollow guide roller 231 is close to the bottom of the FPC cover film, control the opening of the pump 33 And periodically open the solenoid valve 2314 corresponding to the hollow guide roller 231 such that the suction hole 2311 corresponding to the hollow guide roller 231 produces suction to produce the bottom of the FPC cover film, and when the hollow guide roller 231 is rotated It will generate a force pulled, and the flexible circuit board cut from the FPC cover is automatically pulled out from the FPC cover film to avoid that some flexible circuit boards cannot be separated from the FPC after laser cutting. The air hole 2311 pulled the flexible circuit board and turned to the bottom, and the corresponding solenoid valve 2314 closed, the external air entered the hollow guide roller 231 through some of the suction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com