Multi-straightening head-based quick straightening device and method

A straightening and fast technology, applied in the field of fast straightening devices based on multiple straightening heads, can solve the problems of manual adjustment of support blocks and low straightening efficiency, and achieve the effect of fast straightening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

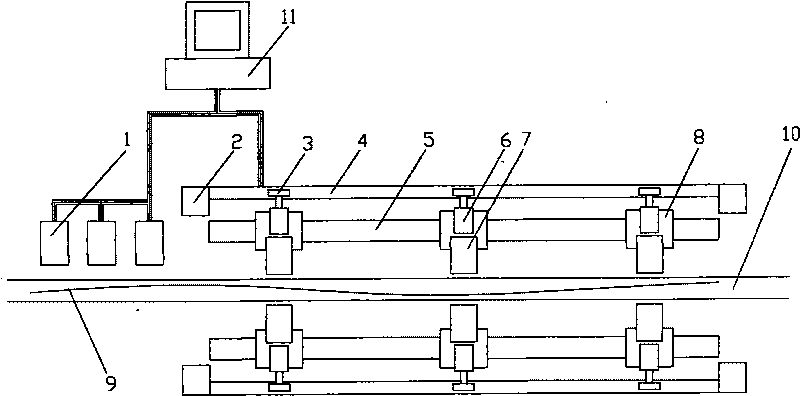

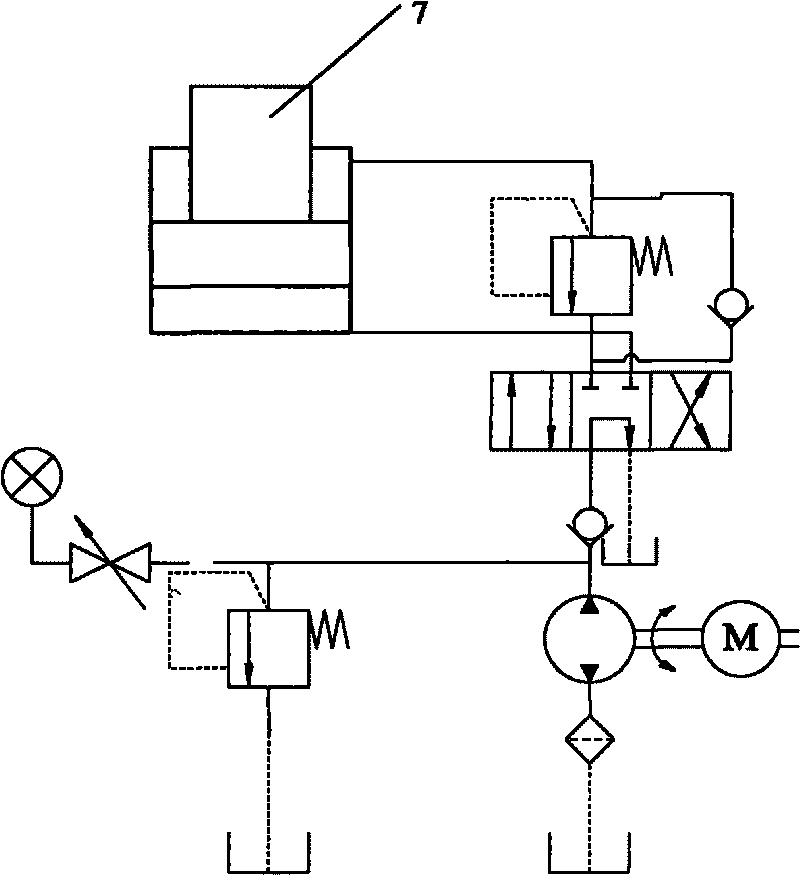

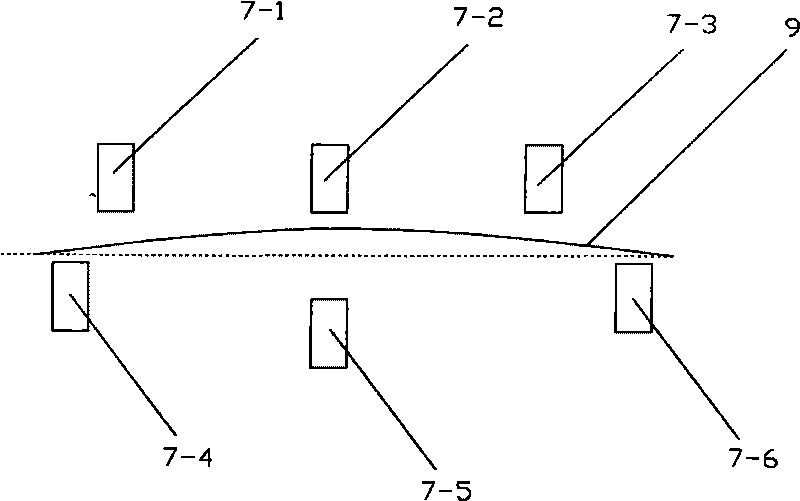

[0018] Such as figure 1 As shown, the present invention is equipped with linear guide rails 5 and racks 4 that are parallel to the transfer roller table 10 on both sides of the transmission roller table 10 respectively. Three slide blocks 8 are respectively housed on the two linear guide rails 5. One end of each is equipped with a stepping motor 6, the stepping motor 6 meshes with the rack 4 through the gear 3, the other end of the slider 8 is equipped with a straightening head 7, and each of the two ends of the two racks 4 has a limit block 2. Three laser sensors 1 are installed on one end of one of the linear guide rails 5 and on the side of the transmission channel 10. The laser sensors 1 are on the same straight line with equal spacing and parallel to the transmission channel 10. The three laser sensors 1 and the stepper The motors 6 are all connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com