Feeding device

A technology of feeding device and coiling material, applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc., can solve problems such as inconvenience of operation, and achieve the effect of saving time and labor, easy operation and reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

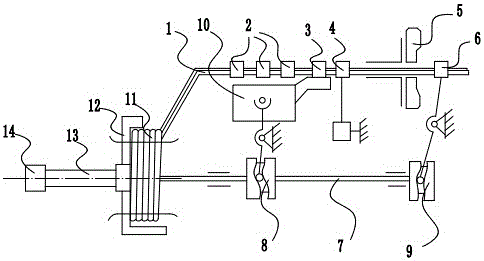

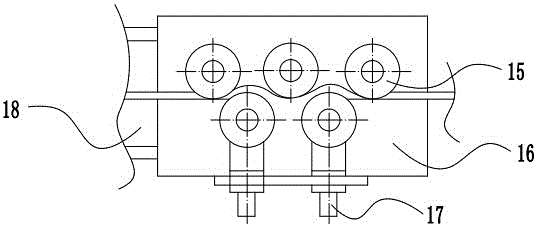

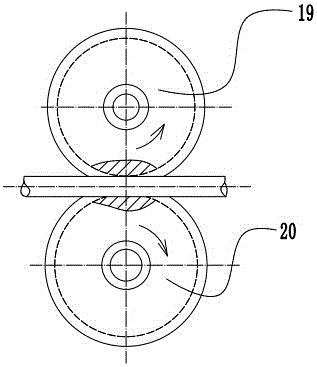

[0021] The reference signs in the drawings of the description include: workbench 1, straightening mechanism 2, transmission mechanism 3, front chuck 4, rotary knife 5, rear chuck 6, camshaft 7, first cam 8, second cam 9 , shift fork body 10, coil material 11, support plate 12, rotating shaft 13, motor 14, fixed pin 15, slide plate 16, adjustment screw 17, guide rail 18, first roller 19, second roller 20, jaw 21, first Spring 22, third cam 23, fixed block 24, slide block 25, second spring 26.

[0022] like figure 1 As shown, a feeding device includes a motor 14, a rotating shaft 13 connected to the motor 14, a support disc 12 screwed to the rotating shaft 13, the support disc 12 is a vertically placed cylindrical groove, and the center of the support disc 12 is socketed There is a camshaft 7, and the coil material 11 is placed on the supporting disk 12 and then the camshaft 7 is sleeved on the supporting disk 12. One end of the coil material 11 is drawn to three straightening...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com