Reinforcement steel bar no-twist straightening shearing machine

A shearing machine and steel bar technology, applied in the field of steel bar twist-free straightening and shearing machine, can solve the problems that the steel bar cannot be prevented from twisting, the steel bar structure is complicated, and the adjustment is inconvenient, etc., and the structure is simple, straightening and shearing speed are fast , Adjust the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

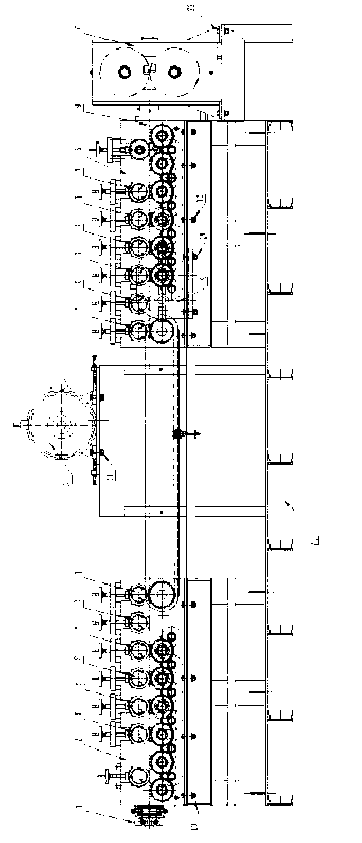

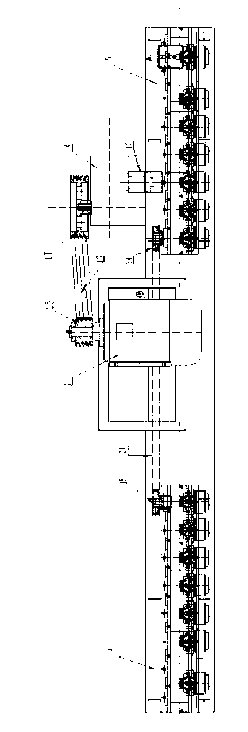

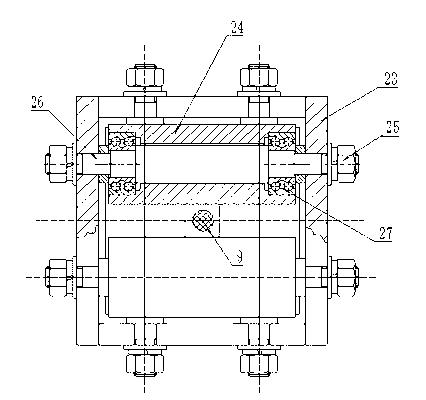

[0025] Below in conjunction with accompanying drawing, further illustrate structure of the present invention and use state:

[0026] see figure 1 with Figure 1A , the rigid rib non-twist straightening and shearing machine includes a frame 21, a guiding and limiting device 1, a straightening assembly 2, a motor 3, a reducer 4, a traction assembly 5 and a shearing assembly 6. The straightening assembly 2 is fixed on the frame 21 through connecting bolts 10, the guide and stop device 1 is welded and fixed on the front end of the straightening assembly 2, the traction assembly 5 and the shearing assembly 6 are respectively fixed through connecting bolts 12 and 22 On the frame 21, and in turn located behind the straightening assembly 2. The distance between the straightening assembly 2 and the traction assembly 5 is more than 10cm, so that the reinforcement can be extended better. The motor 3 is arranged between the straightening assembly 2 and the traction assembly 5 through c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com