Patents

Literature

89results about How to "Shear speed is fast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

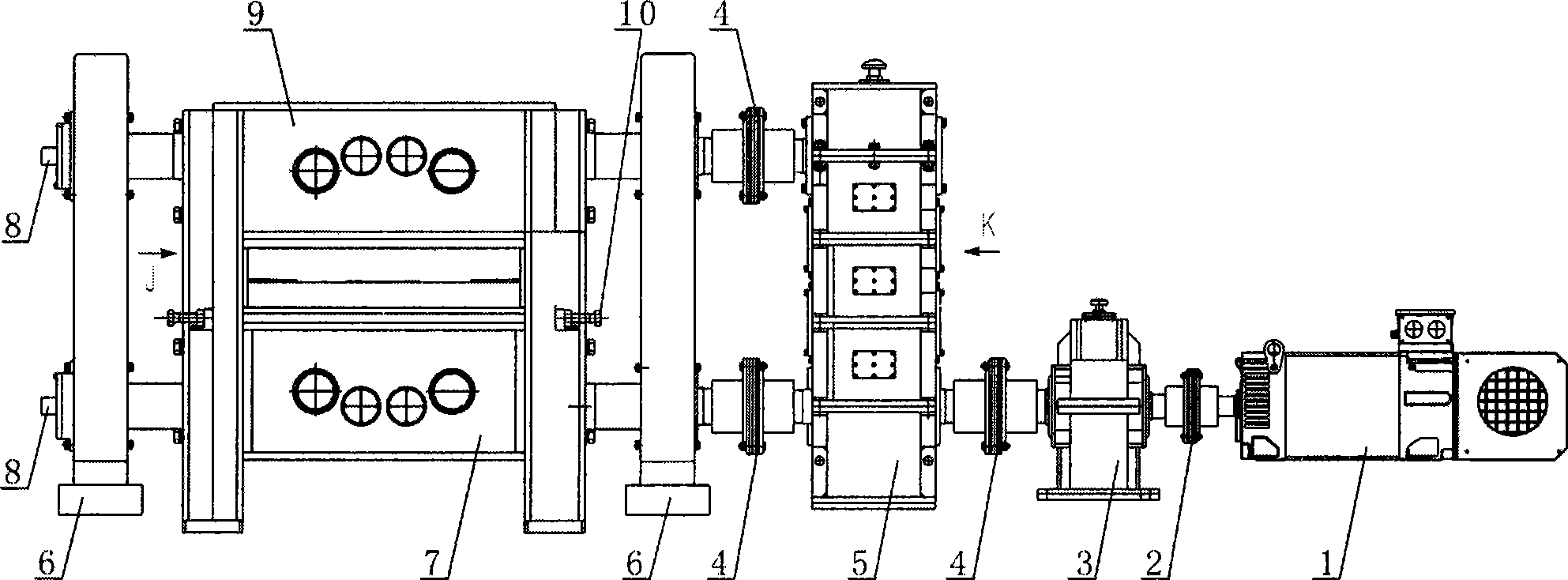

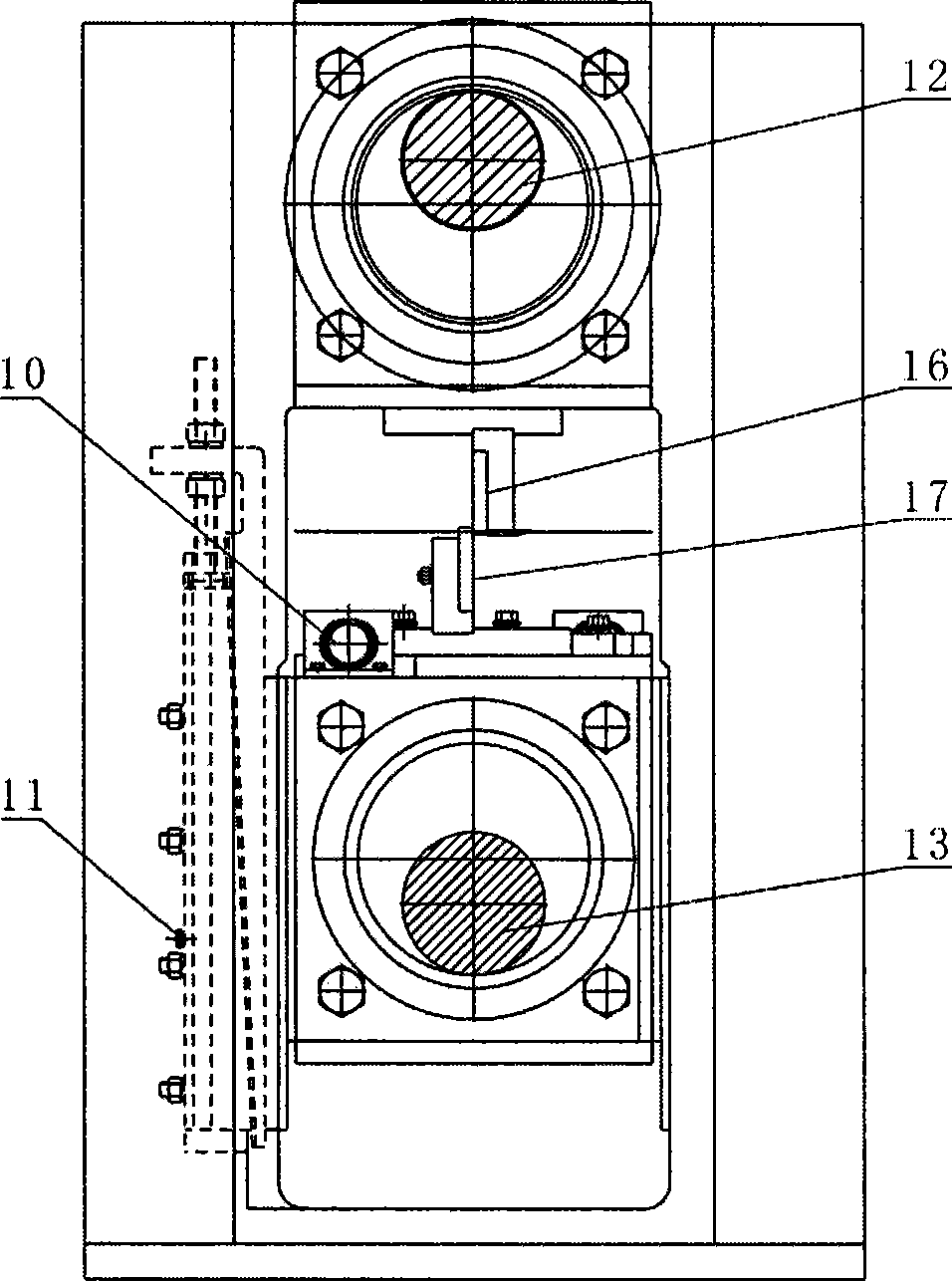

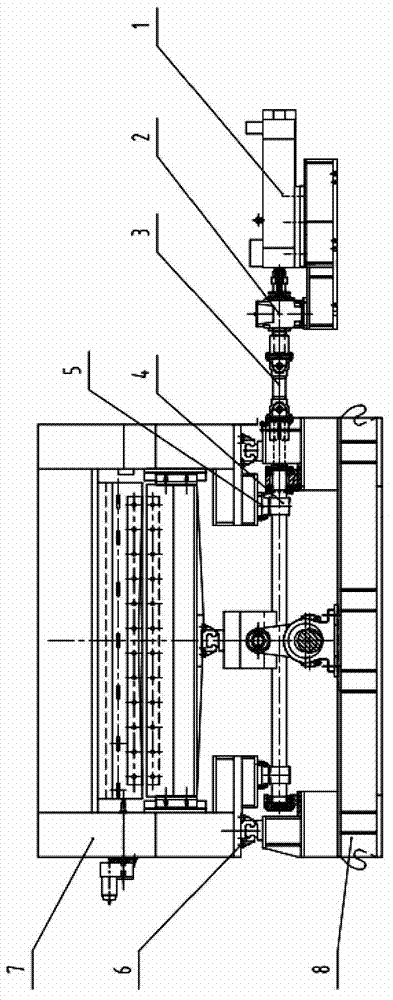

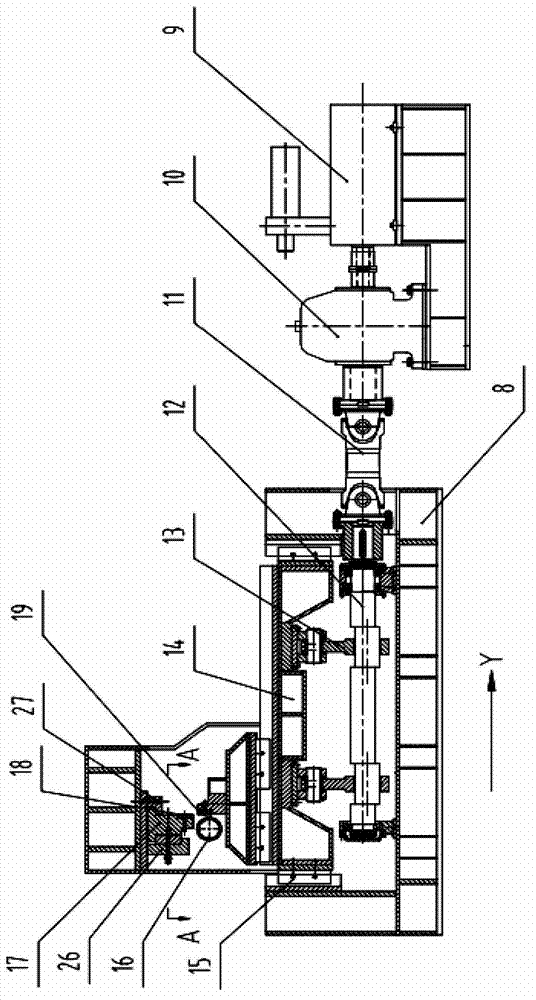

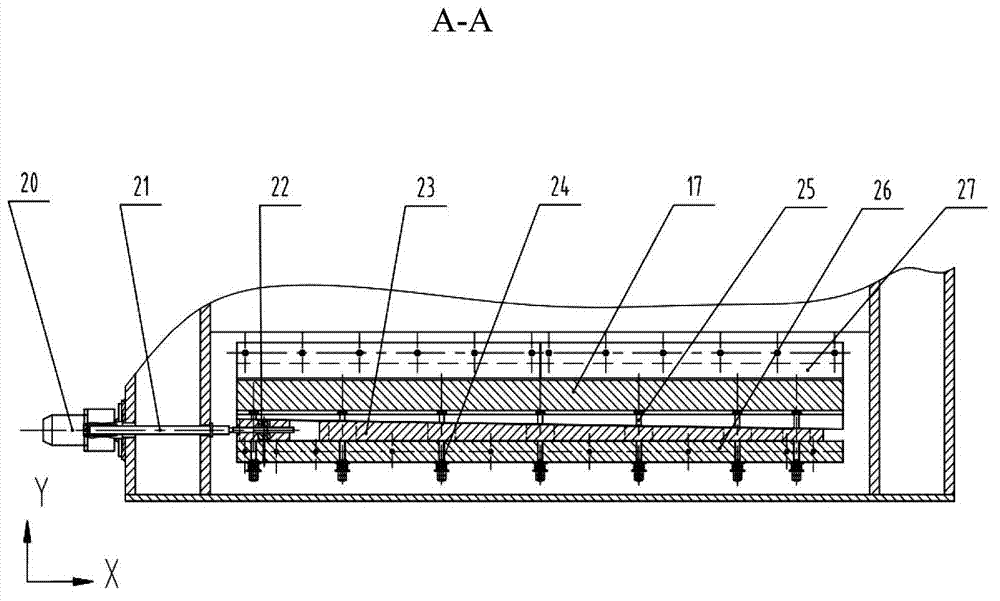

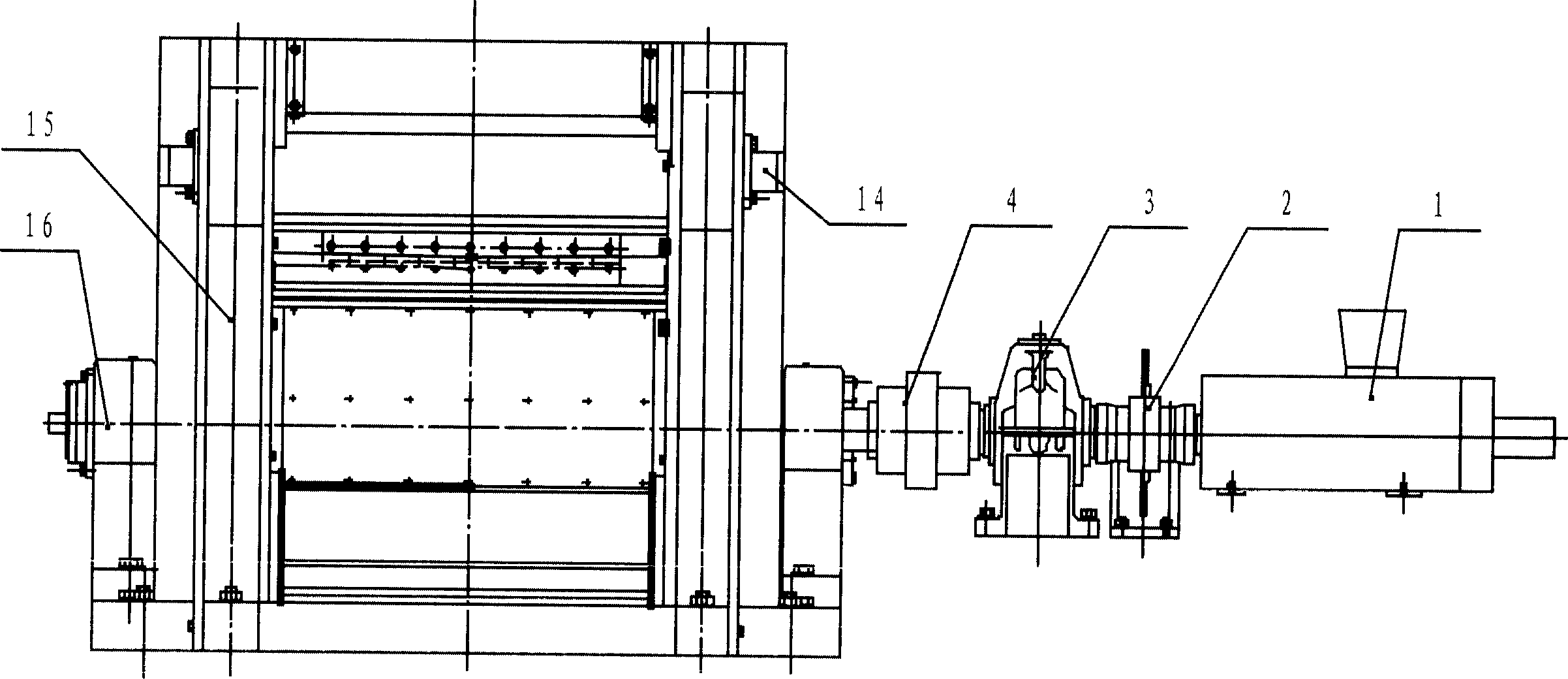

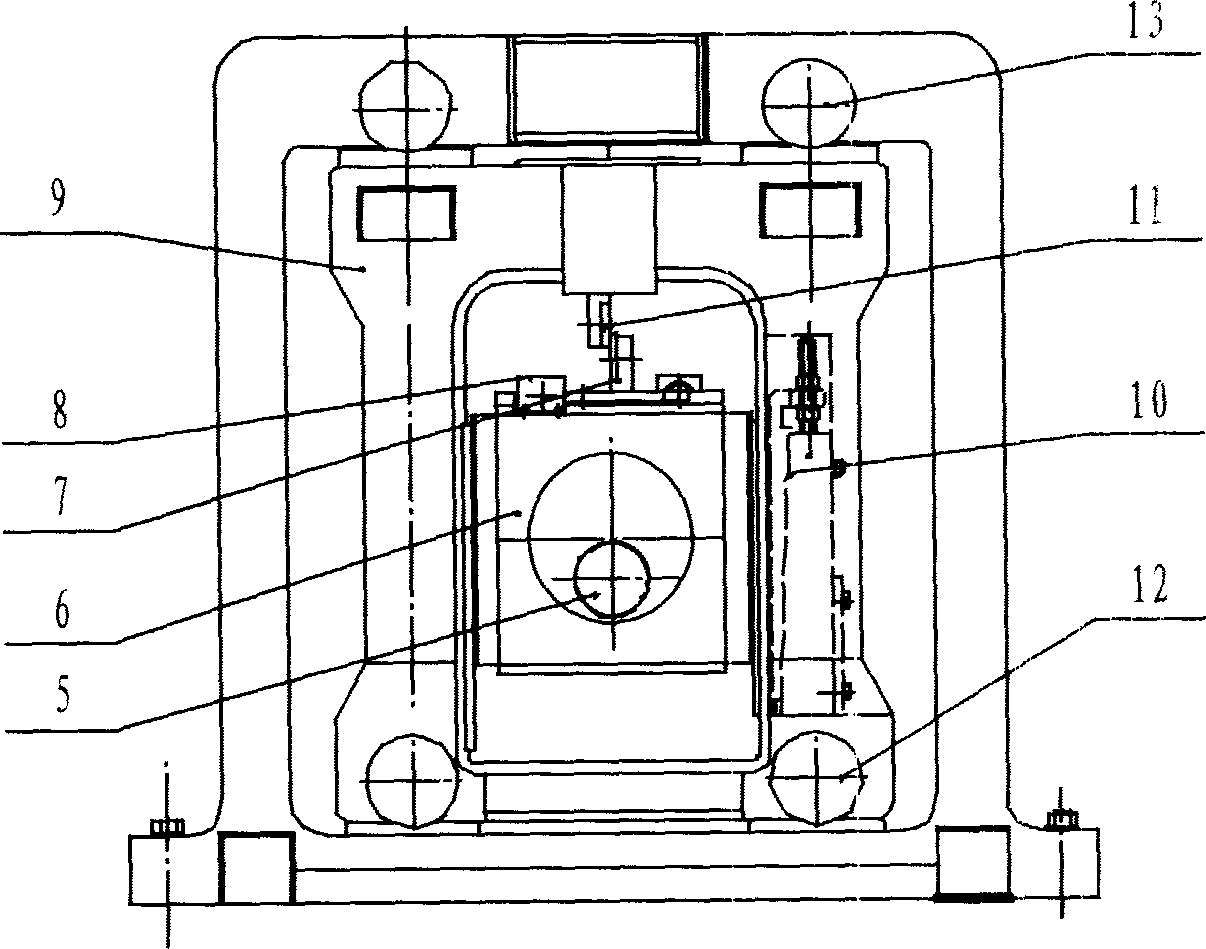

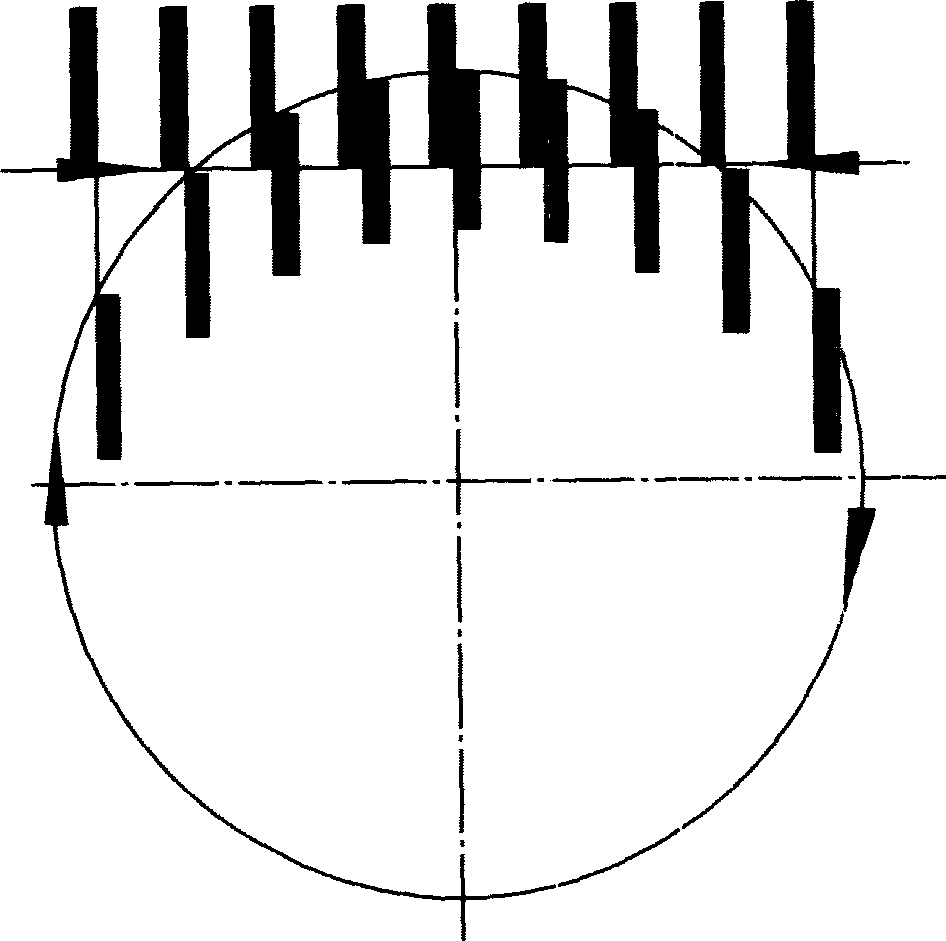

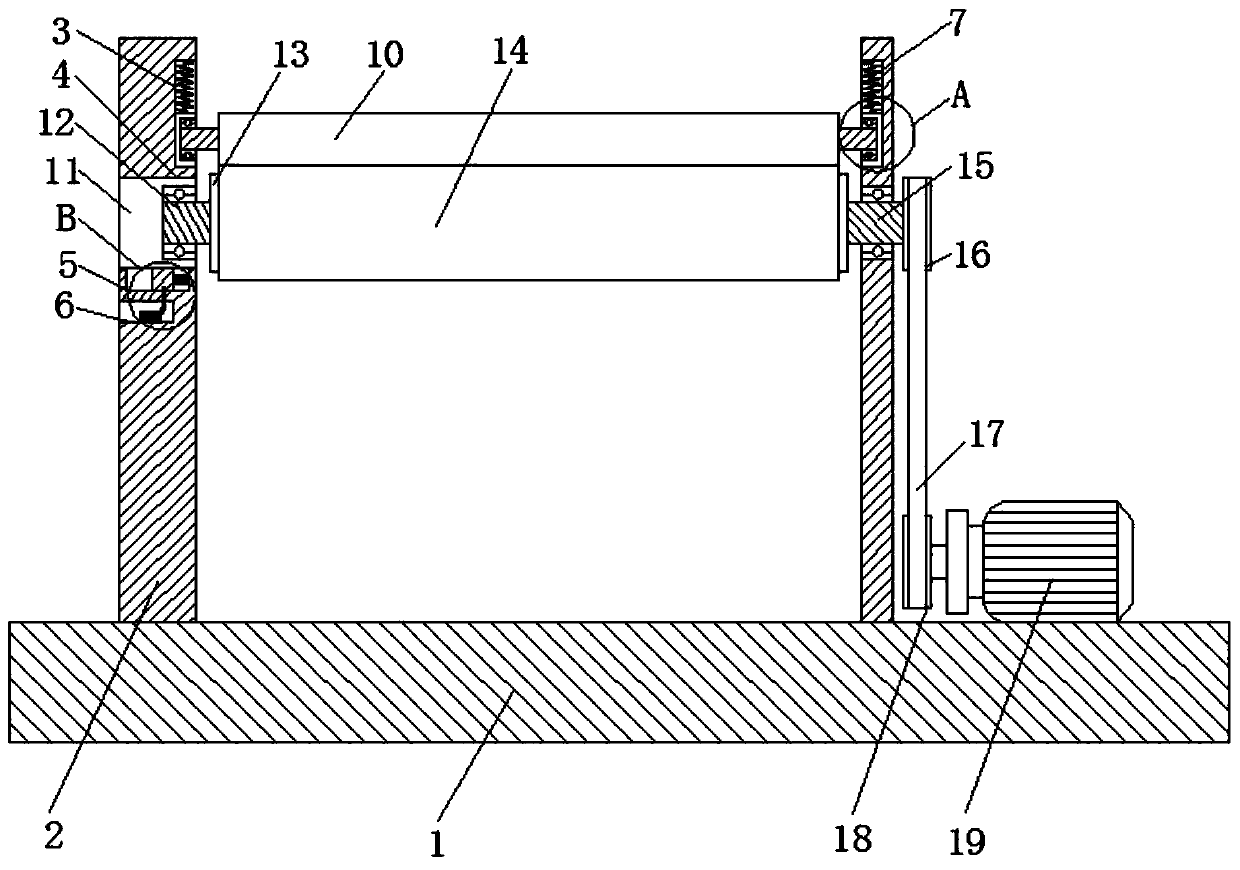

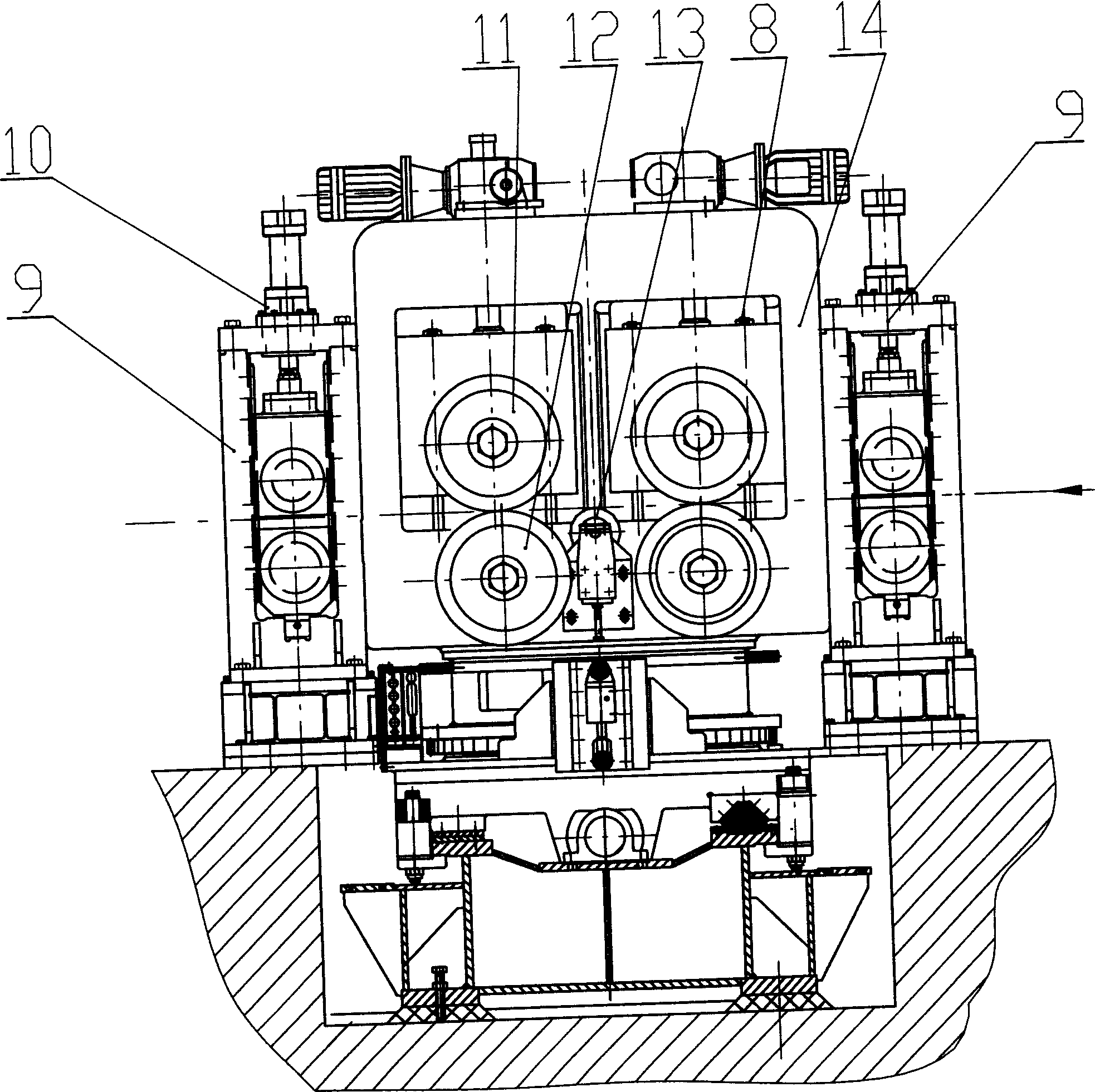

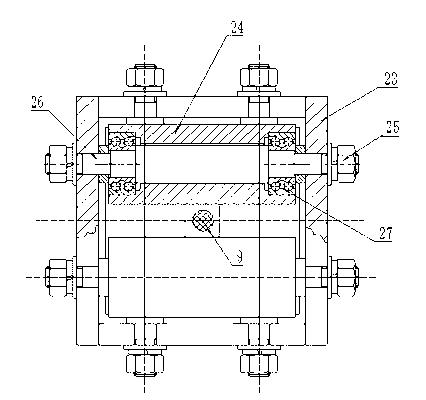

Double-crank frame type flying shears

InactiveCN101417354ASimple structureEasy to manufactureStock shearing machinesShearing machine accessoriesProduction lineReduction drive

The invention discloses a double crank frame type flying shear mainly used for a traverse production line which carries out continuous and synchronous cutting to black and non-ferrous metal cold and hot belt materials in the metallurgy. The flying shear drives a reducer and a gear distribution box by the driving of a motor, two crankshafts of a shearing mechanism are driven to drive an upper cutter block and a lower cutter block to carry out planar motion, and the vertical and horizontal planar motion ensures the synchronized motion while completing the shearing motion to the workpiece. The flying shear has the advantages of lighter weight, delicate and simple structure, high strength, flexible and convenient adjustment, easy manufacture and repair, smooth and straight incision, high cutting speed, high cutting precision, and the like.

Owner:刘海昌 +2

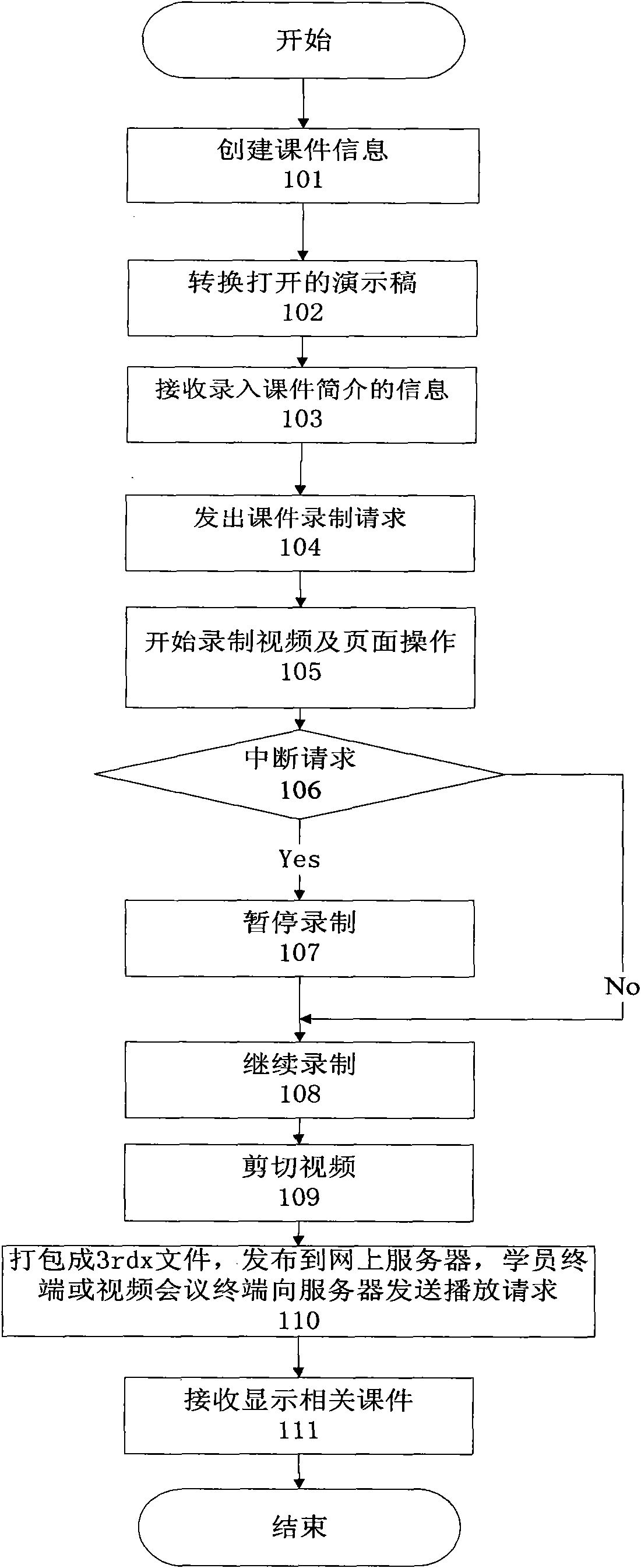

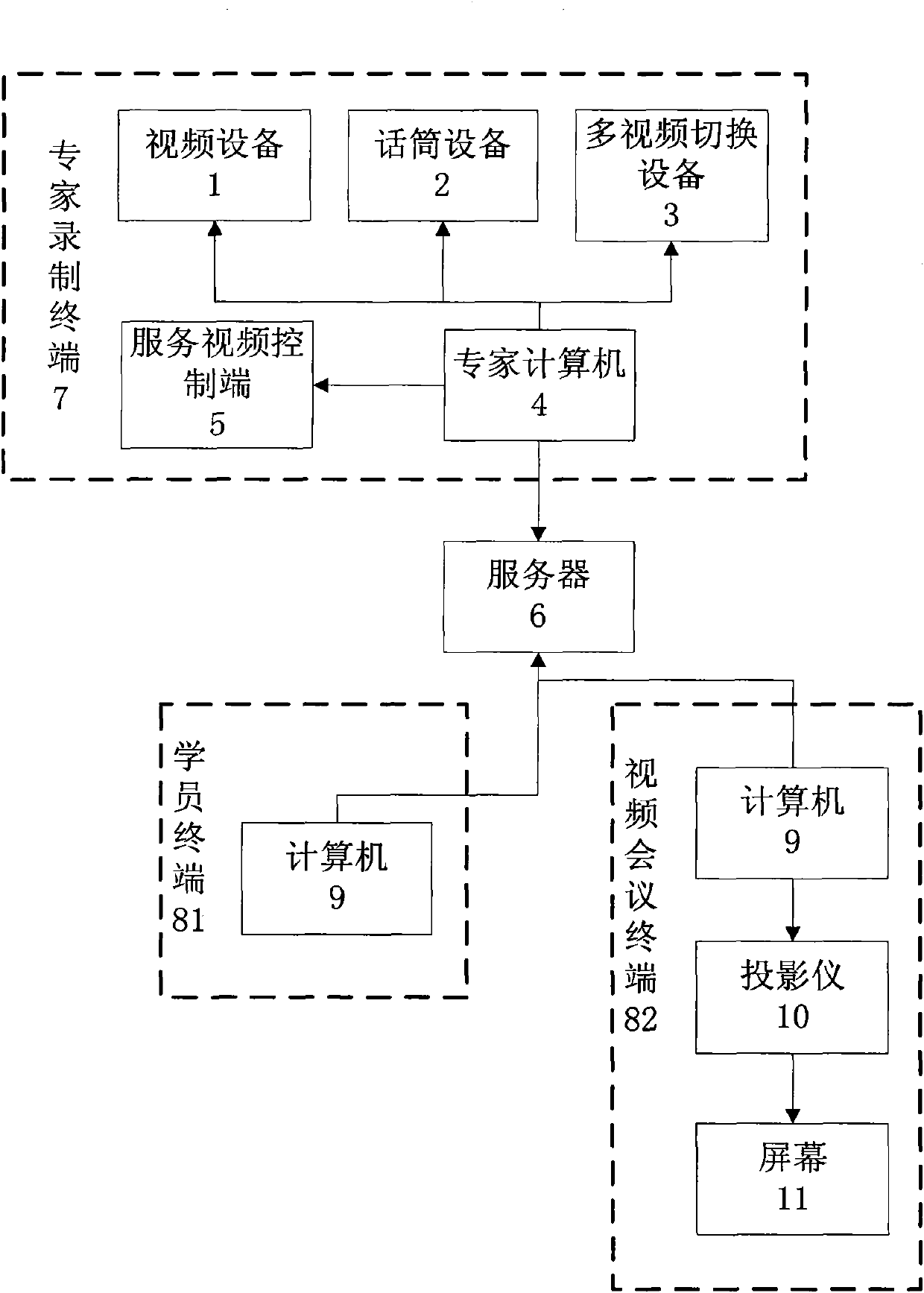

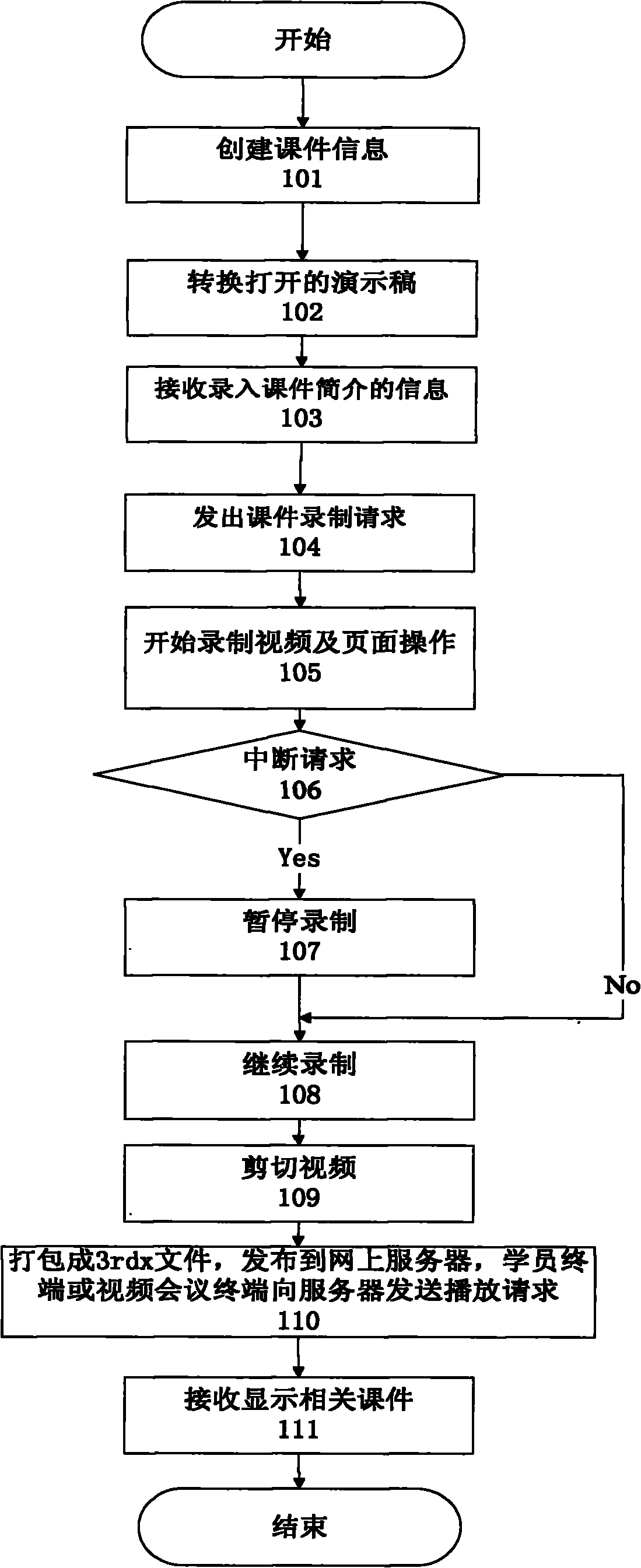

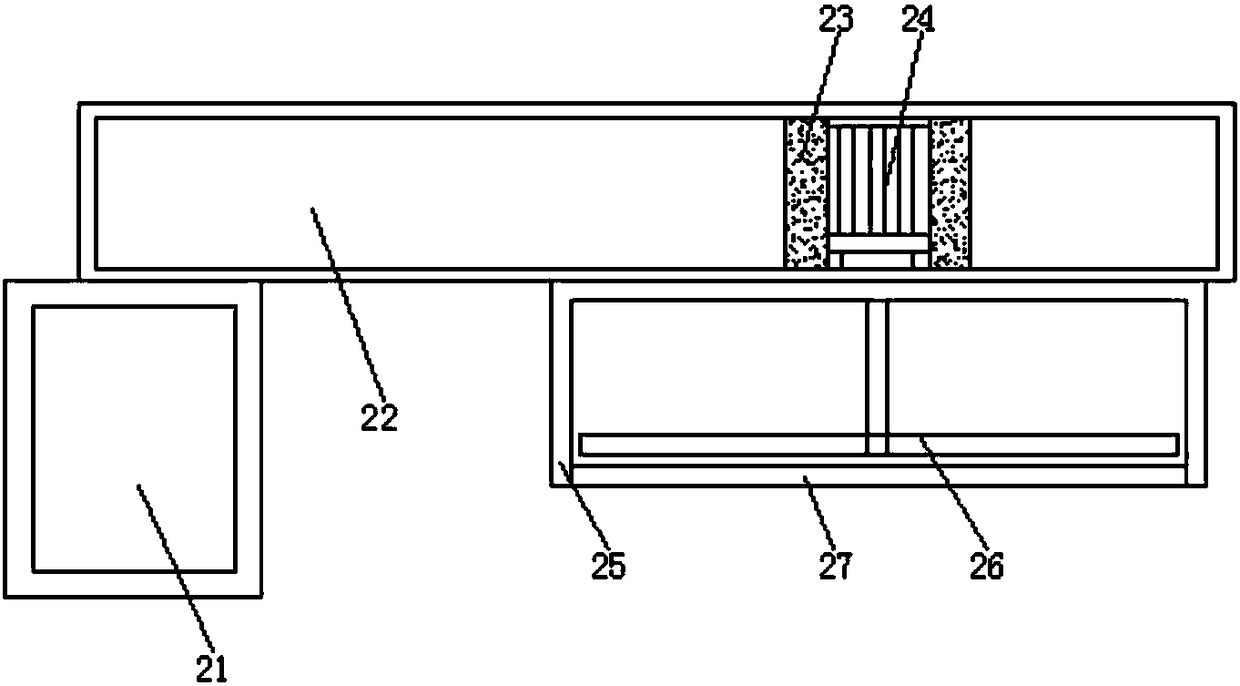

Video information processing method based on three-split screen courseware recording

InactiveCN102568260AReduce capacityIncrease the number of online viewingTelevision conference systemsTwo-way working systemsInformation processingComputer terminal

The invention relates to a video information processing method based on three-split screen courseware recording. The technology comprises the following steps of: (1) receiving input courseware basic information; (2) automatically converting the format of the input courseware basic information into a small web format (swf); (3) receiving type-in courseware information; (4) configuring video equipment and microphone equipment, and sending out a courseware recording request to a service video control end; (5) converting live recording video and sounds into a flash video (flv) streaming media formatted file; (6) judging whether an interrupt request exists or not; (7) splitting improper video sections; (8) packing into a 3rdx file, and releasing the 3rdx file to an Internet server for performing video on demand, and sending a playing request to the server after related courseware is searched on the Internet by a student terminal or a video conference terminal; and (9) receiving and displaying the picture information of the related courseware by the student terminal or the video conference terminal. Compared with the prior art, the video information processing method based on the three-split screen courseware recording has the advantages that the courseware capacity is low, the number of online watching people is great, the demonstration draft converting function is powerful, the video splitting speed is high, and the like.

Owner:SHANGHAI SHINEENERGY INFORMATION TECH DEV CO LTD +1

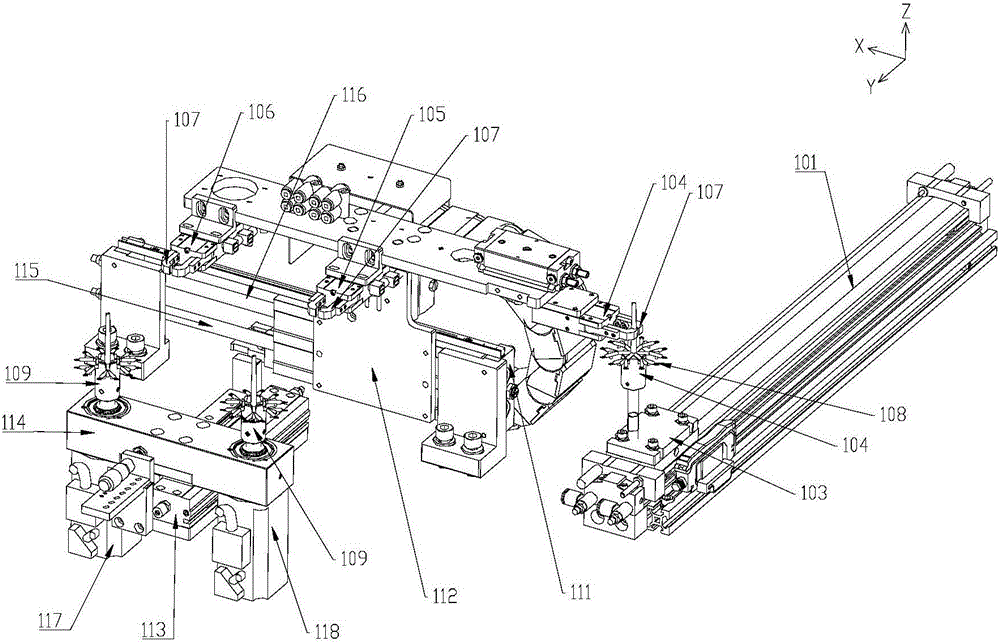

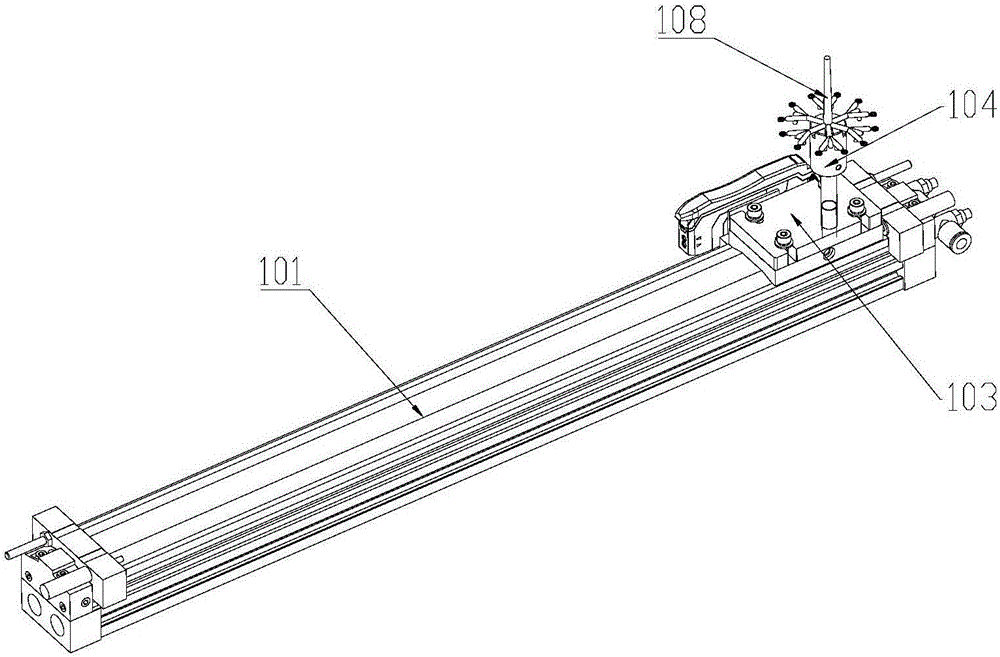

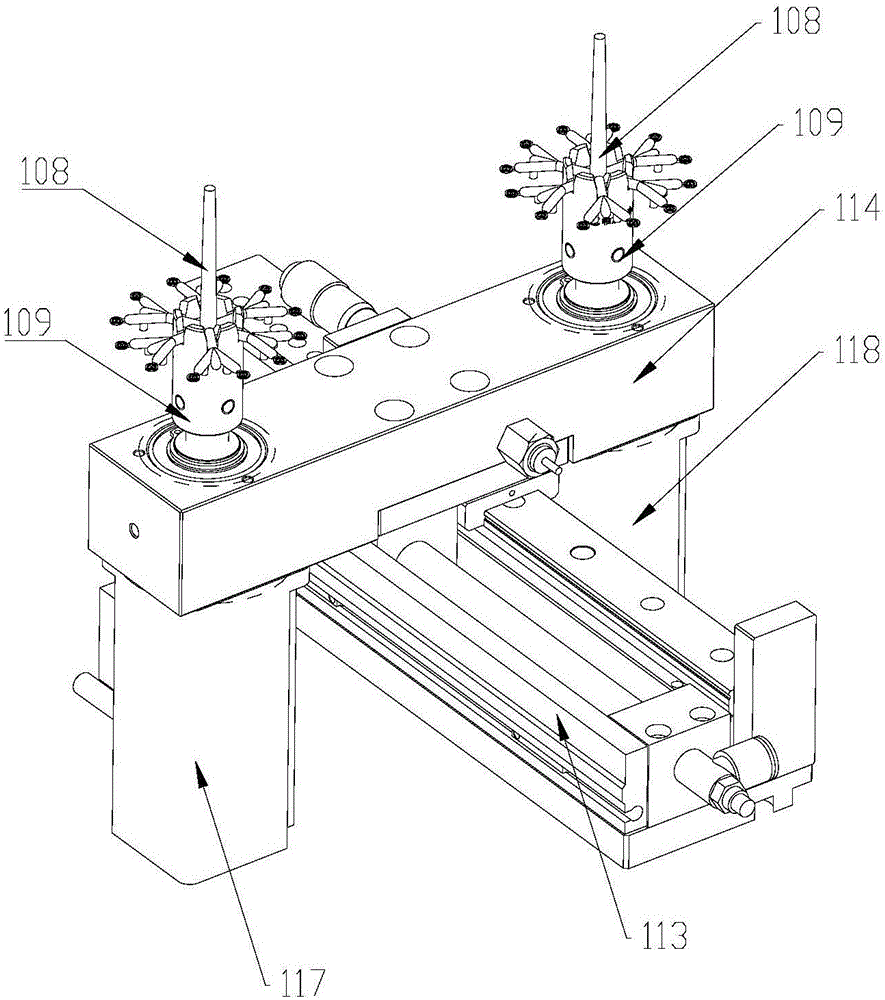

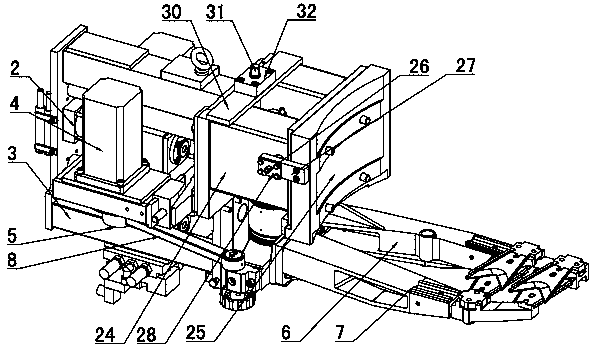

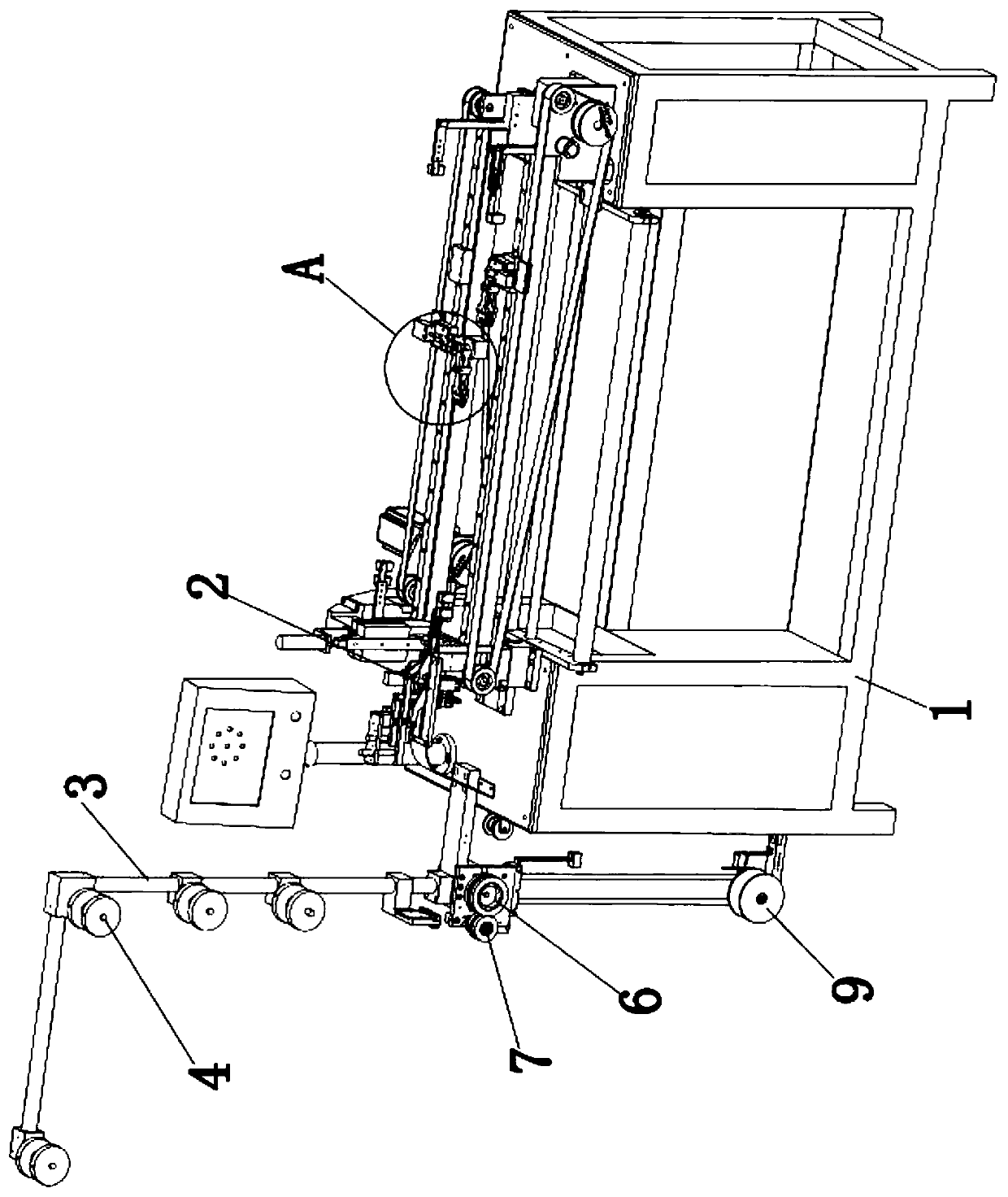

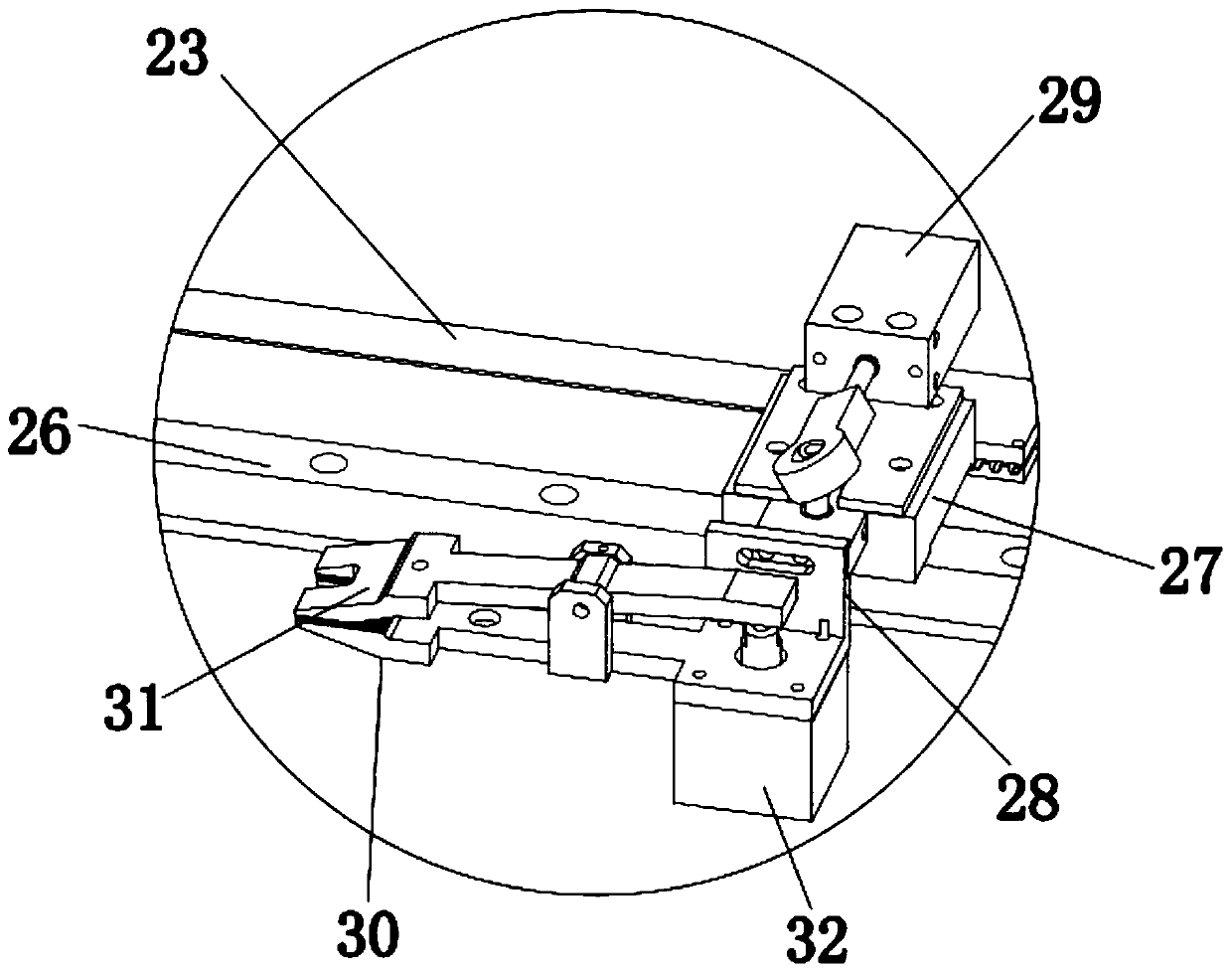

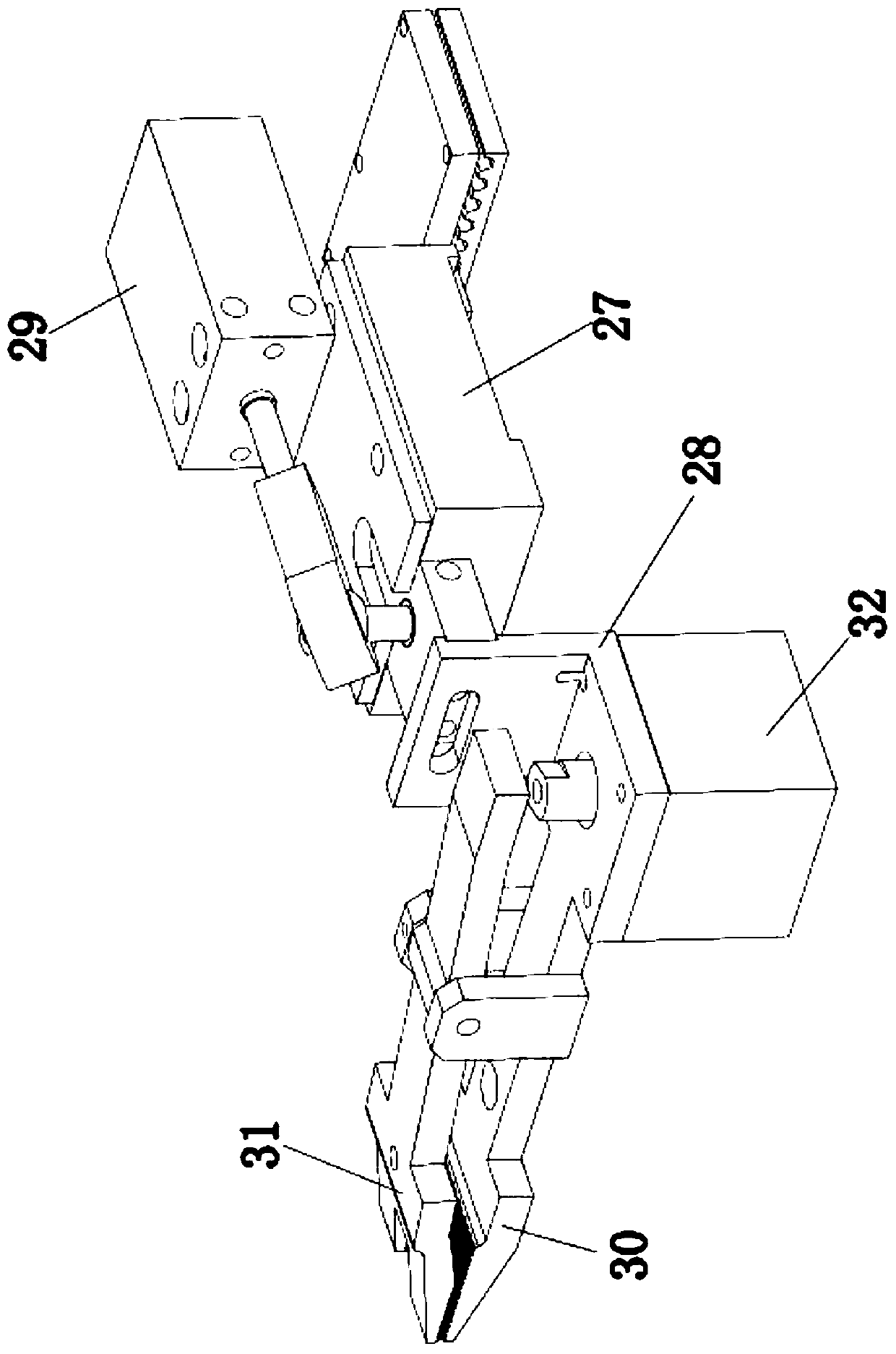

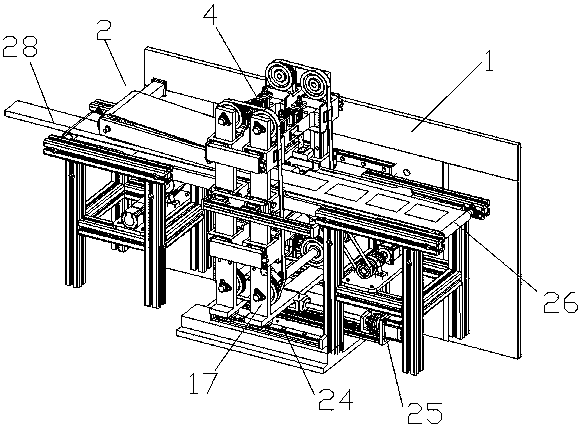

Shearing machine for injection molding lenses

InactiveCN106393217AImprove cutting efficiencyStable job qualityMetal working apparatusInjection molding machineMechanical engineering

The invention relates to a shearing machine for injection molding lenses. The shearing machine is characterized in that a feeding device comprises a positioning mechanism and a conveying device, and the conveying device comprises first swinging devices; each first swinging device comprises a clamping part for clamping injection molding parts, the multiple first swinging devices are configured to be capable of conveying the injection molding parts, and the positioning mechanism is configured to receive the injection molding parts conveyed from the conveying device for shearing; a shearing device comprises a first cutter, a second cutter and a drive device for driving the first cutter and the second cutter to do opposite or contrary motion, wherein the first cutter is opposite to the second cutter; a discharging device comprises a suction device for sucking and arranging the injection molding lens; and a warehousing device comprises a warehousing frame provided with an open end and capable of moving in the Z axis direction, the warehousing frame is provided with a supporting portion for supporting trays, and the supporting portion is of a multi-layer structure.

Owner:GOERTEK INC

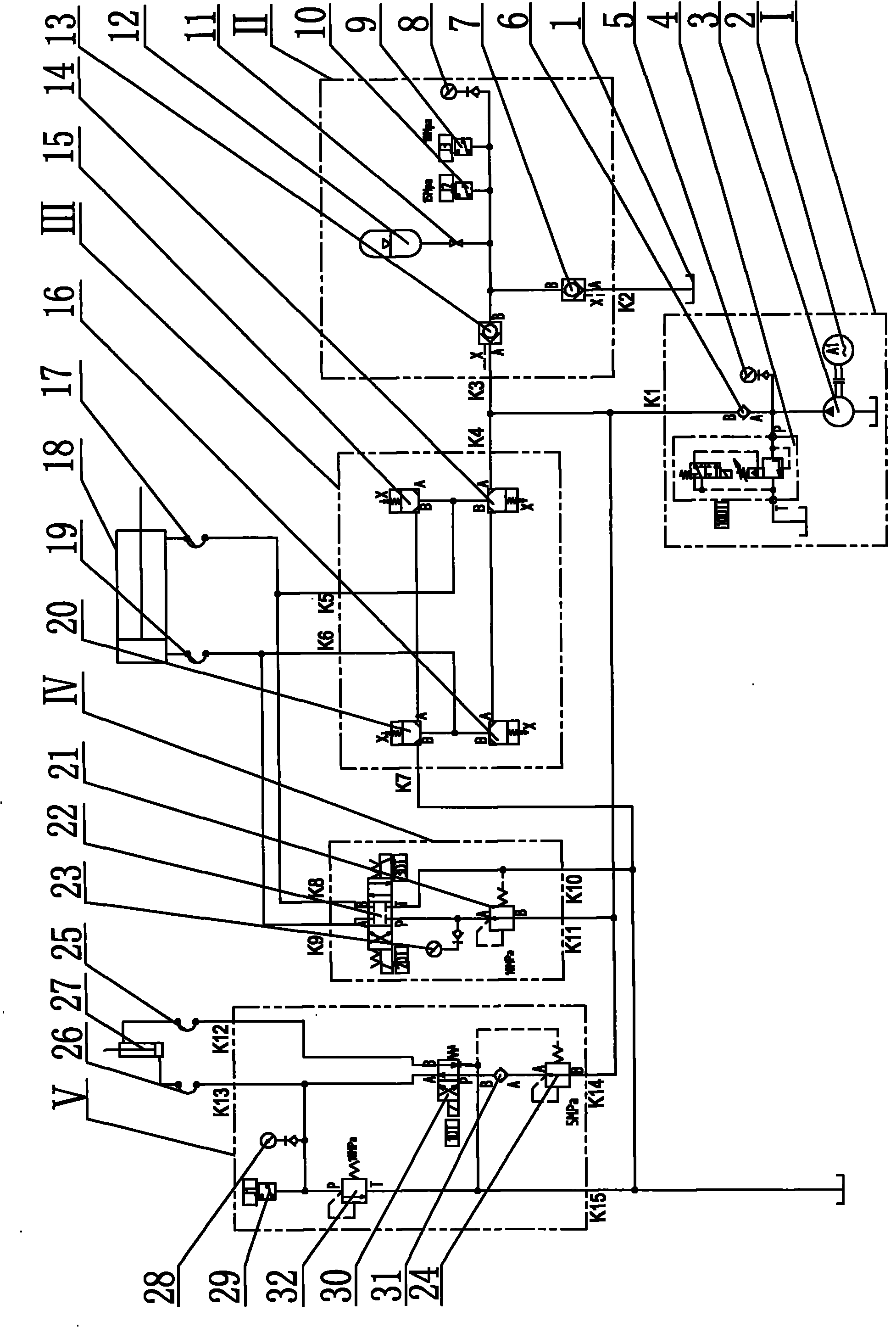

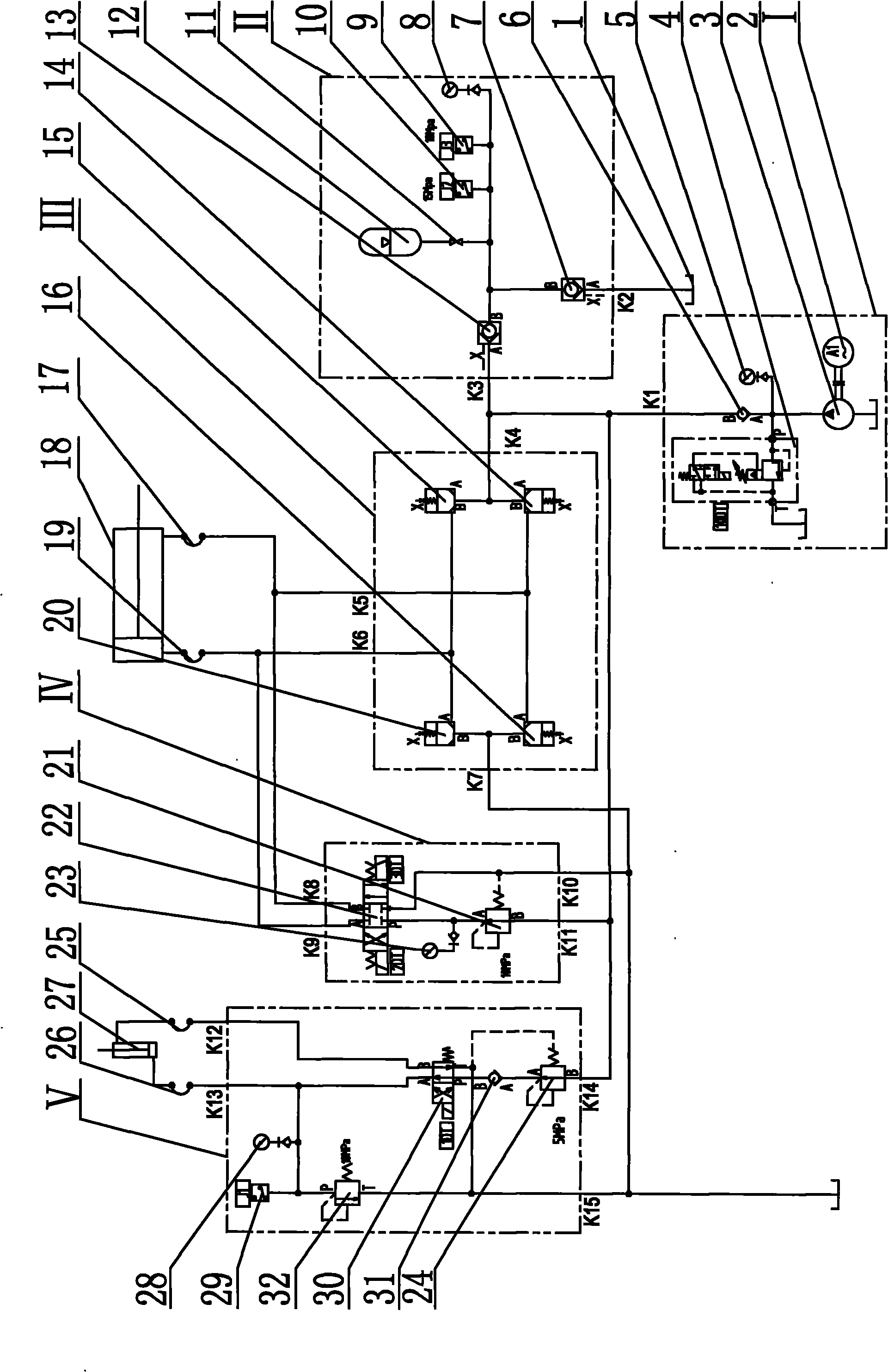

Hydraulic transmission loop of diagonal cutter shearing machine

InactiveCN101774042ASmall diameterAchieve regulationMechanical apparatusShearing machine accessoriesHigh pressureManufacturing line

The invention provides a hydraulic transmission loop of a diagonal cutter shearing machine, which belongs to the technical field of iron and steel sheet and plate processing. The invention is applicable to the hydraulic transmission of rolling production lines or experiment line shearing machines. The hydraulic transmission loop comprises a high-pressure pump source, an energy accumulator controller, a shearing oil cylinder controller, a shearing cutting edge regulation controller and a press plate oil cylinder controller, wherein a pressure oil opening K1 is respectively connected with a pressure oil opening K3, a pressure oil opening K4, a pressure oil opening K11 and a pressure oil opening K14, an oil return opening K2, an oil return opening K7, an oil return opening K10 and an oil return opening K15 are respectively connected with an oil tank, a work oil opening K6 is connected with the rod-free side of a shearing oil cylinder through a hydraulic rubber pipe, the work oil opening K5 is connected with the rod side of the shearing oil cylinder through a hydraulic rubber pipe, the work oil opening K9 is connected with the rod-free side of the shearing oil cylinder through a hydraulic rubber pipe, the work oil opening K8 is connected with the rod side of the shearing oil cylinder through a hydraulic rubber pipe, the work oil opening K13 is connected with the rod-free side of a press plate oil cylinder through a hydraulic rubber pipe, and the work oil opening K12 is connected with the rod side of the press plate oil cylinder through a hydraulic rubber pipe.

Owner:NORTHEASTERN UNIV

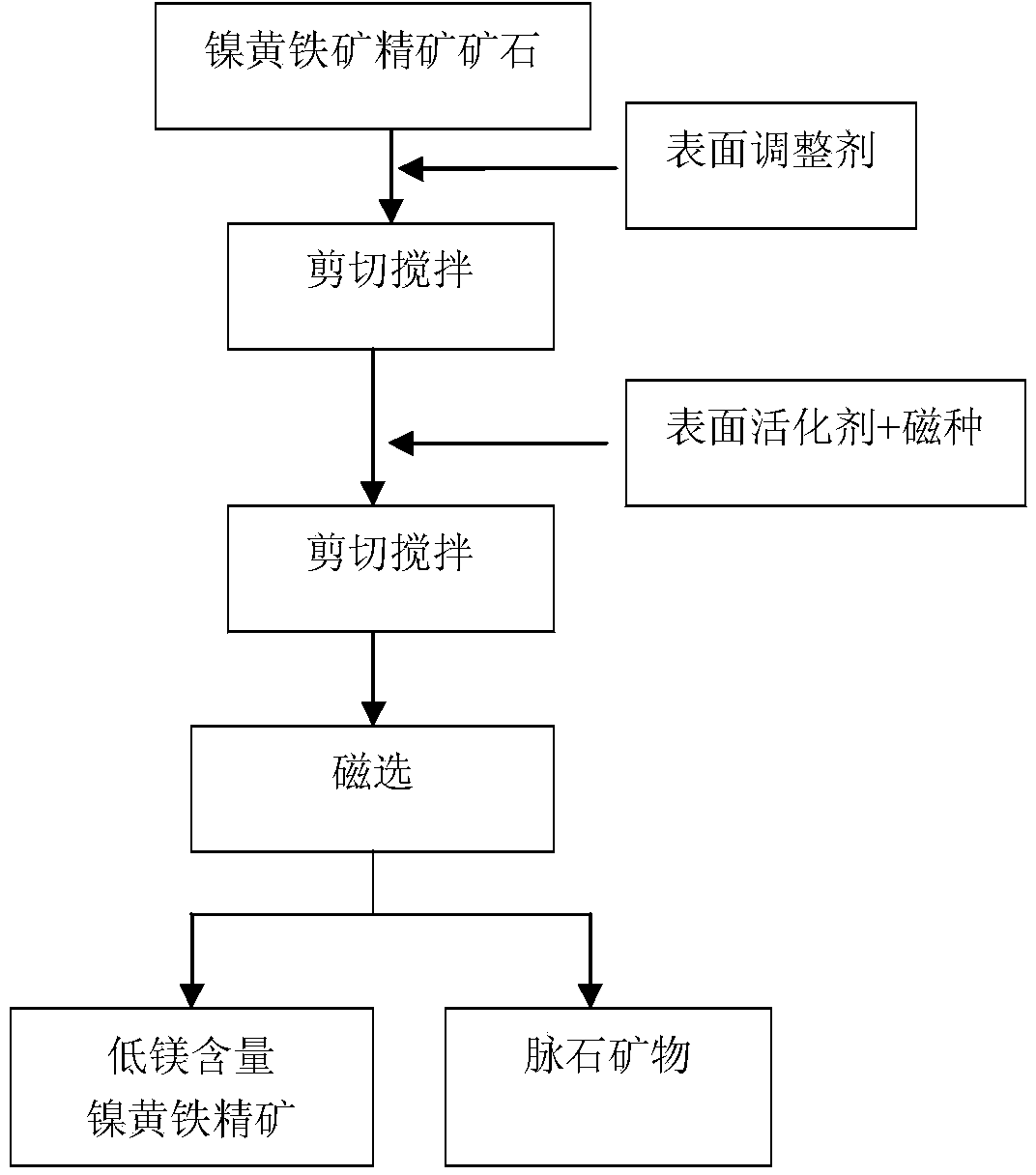

Method for lowering content of magnesium in pentlandite concentrate

ActiveCN103934099ALarge specific surface areaReduce repulsion energyMagnetic separationHigh magnesiumCorrosion

Nickel sulfide in low-grade ores is mainly recycled by a flotation method, but the defect is that the content of MgO in concentrate is high. As magnesium-containing minerals are high in smelting point and poor in mobility, when the content of MgO in concentrate is higher than 6.5%, adverse effects such as furnace body nodulation and furnace body corrosion are brought to a follow-up novel flash smelting process of nickel. In order to solve a problem that the content of magnesium in concentrate is high during separating of magnesium-nickel containing minerals, the invention provides a method for lowering the content of magnesium in pentlandite concentrate. The method comprises the following steps: adding surface conditioning agents such as sodium hexametaphosphate into the pentlandite concentrate, and uniformly dispersing ore pulp by stirring; then, adding magnetic seeds and a surfactant, and stirring to ensure that the magnetic seeds and the pentlandite concentrate generate adhesion agglomeration; and performing magnetic separation, thereby obtaining the pentlandite concentrate with the content of magnesium being lower than 6.5% (in terms of MgO). The method disclosed by the invention has the advantages of being good in pentlandite separation selectivity, environmentally friendly, low in energy consumption, easy to operate, high in efficiency, and the like, and solves a problem that the content of magnesium in nickel concentrate is high.

Owner:NORTHEASTERN UNIV

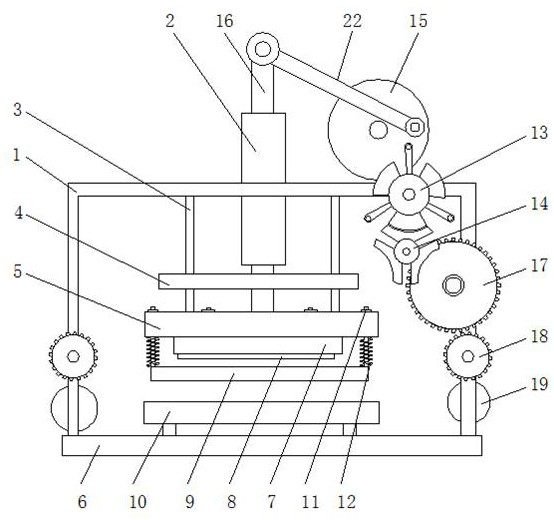

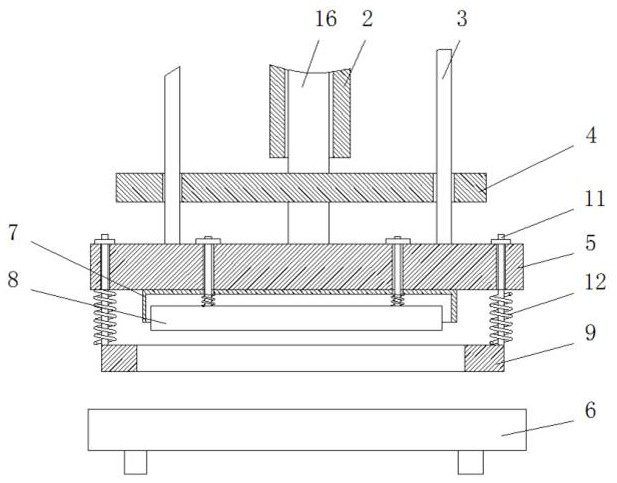

Garment fabric cutting device

ActiveCN108914528ACropping effectImprove shear efficiencySevering textilesUltimate tensile strengthUtilization rate

The invention belongs to the technical field of garment processing machinery and specifically relates to a garment fabric cutting device. The device comprises a box body; the device also comprises a drive unit, a cutting unit and a cutting table; the drive unit is used for driving the cutting unit to cut fabric; the cutting unit is used for cutting fabric; the cutting table is used for providing cutting position for fabric. By means of the cooperation of the drive unit, the cutting unit and the cutting table, the fabric is cut by the cutting unit which is driven by the drive unit, which not only alleviates labor intensity, but also increases fabric cutting efficiency; at the same time, the power source generated in the drive unit during driving is utilized so that the source utilization rate is increased; the fabric scraps in the fabric cutting drops to the bottom of the box to avoid the fabric scraps affecting the cutting of the fabric, thus improving the cutting effect of the fabric.

Owner:浙江平步服饰股份有限公司

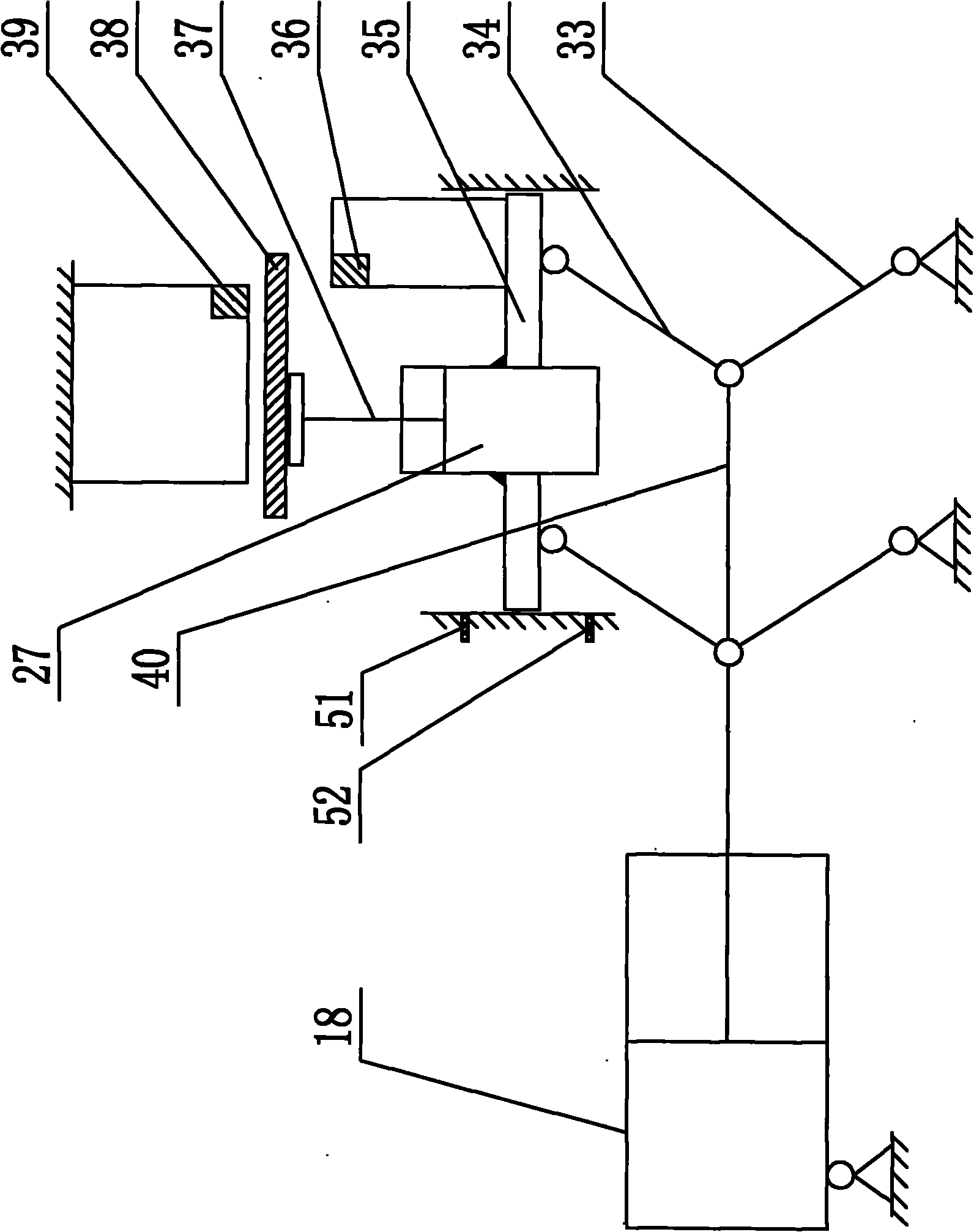

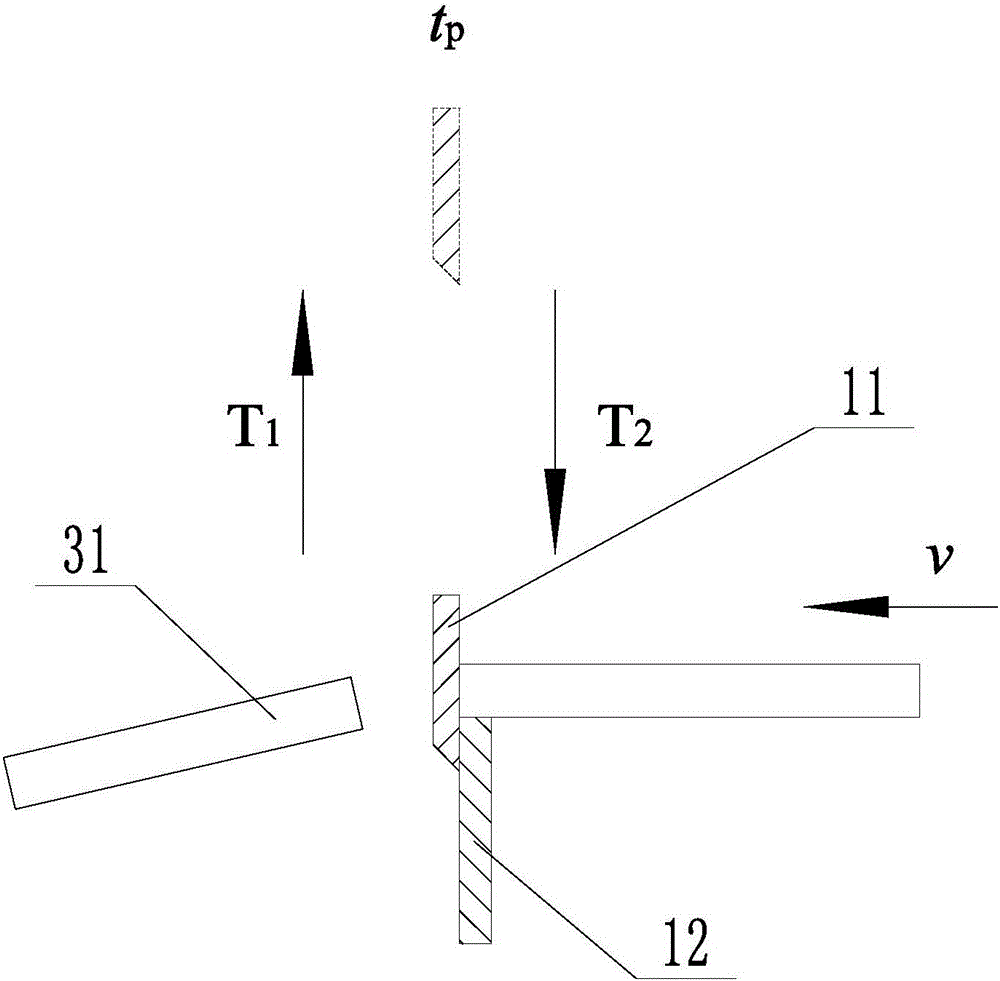

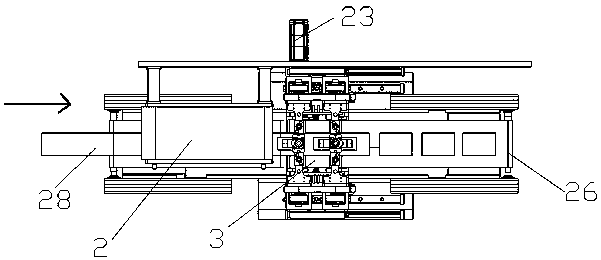

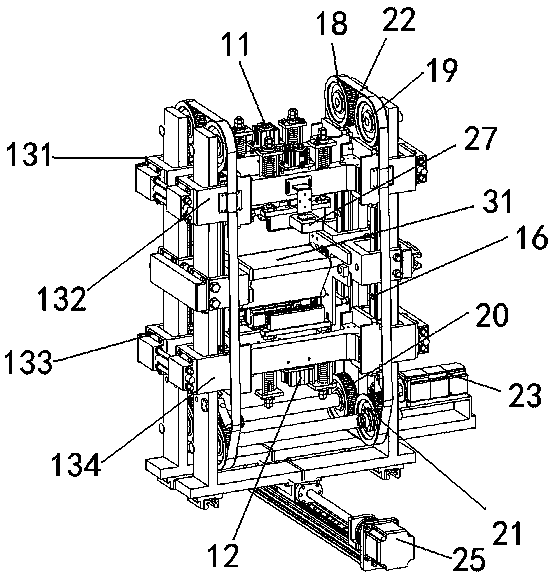

Flying shear device for finishing and shearing of thick metal strips

InactiveCN102873392AImprove speedIncrease shear frequencyStock shearing machinesShearing machine accessoriesEngineeringShear speed

The invention discloses a flying shear device for finishing and shearing of thick metal strips. The flying shear device mainly comprises a main driving device, a shearing device and a cutter clearance adjusting device. A main driving motor is connected with a shearing eccentric shaft through a speed reducer and a coupling, lower ends of two shearing links are mounted on the shearing eccentric shaft, upper ends of the two shearing links are fixedly connected with a lower shear holder, a lower cutter is fixed on the lower shear holder, an upper cutter is fixed on an upper shearing clamp, the upper shearing clamp is fixed on a base, and the cutter clearance adjusting device is used for adjusting clearance between the cutters. The flying shear device can realize high-speed continuous shearing operation. Compared with a general flying shear, the flying shear device has the advantages that the shearing speed of the flying shear device is increased by two to three times, the shearing precision is increased by two to four times, and shearing burrs and curls are eliminated thoroughly.

Owner:辽宁省机械研究院有限公司

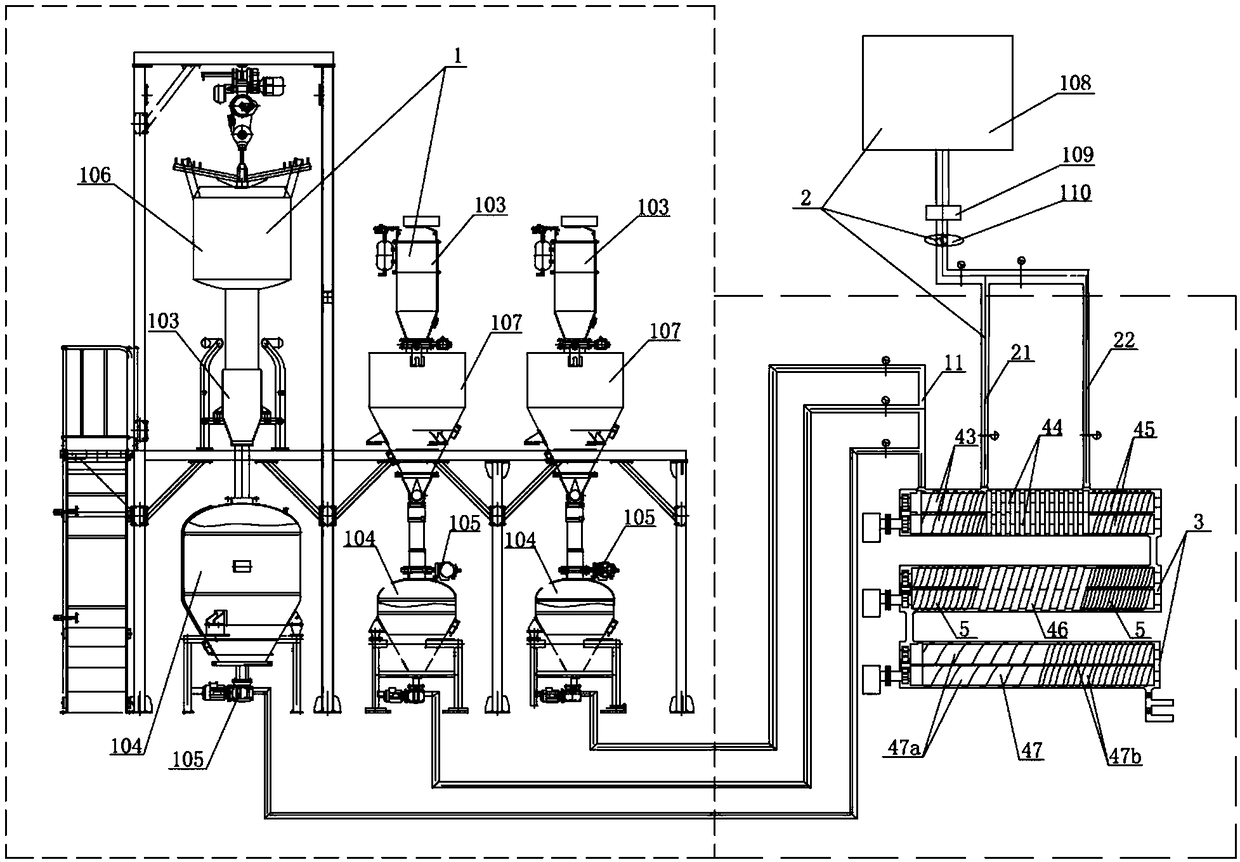

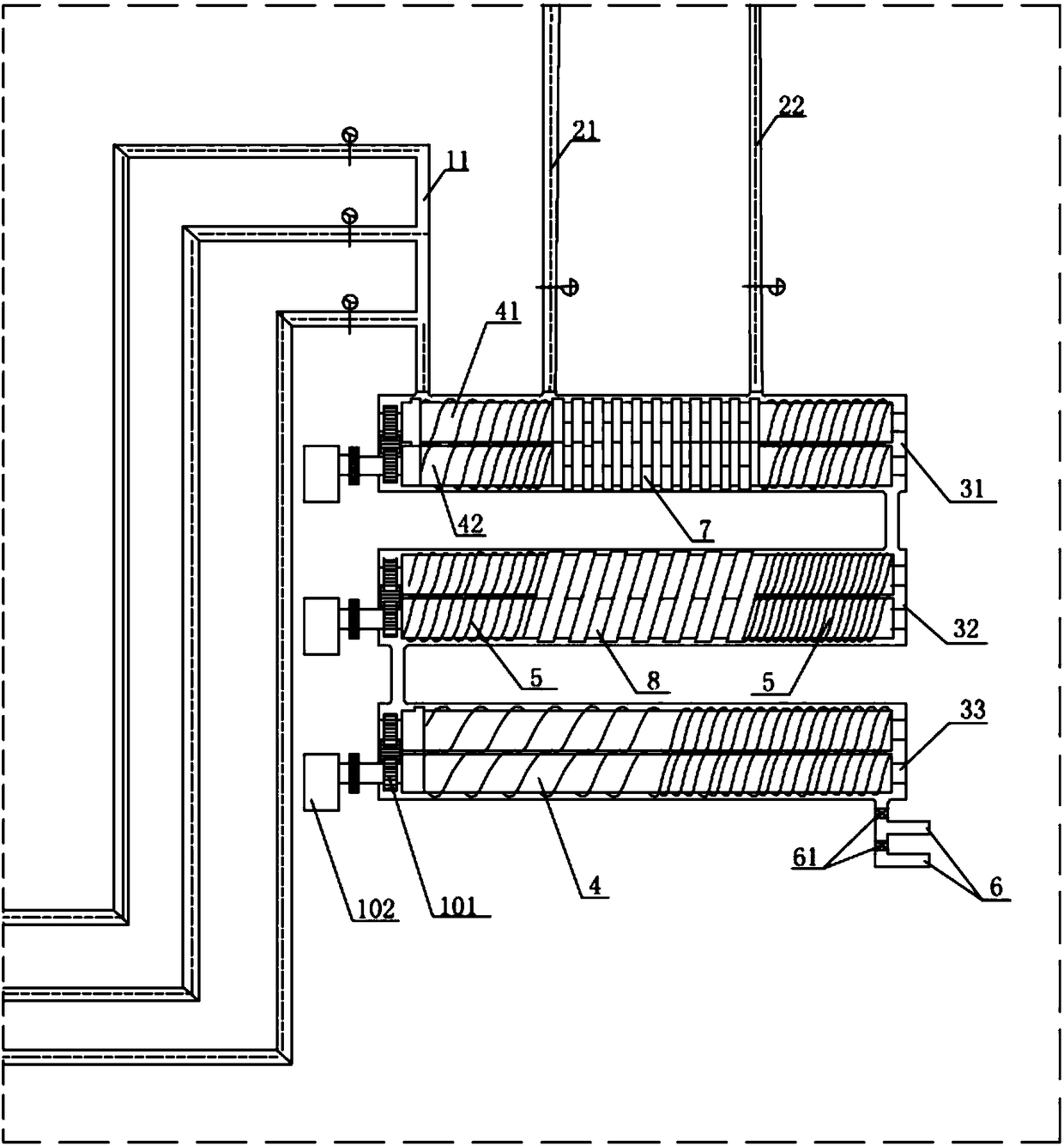

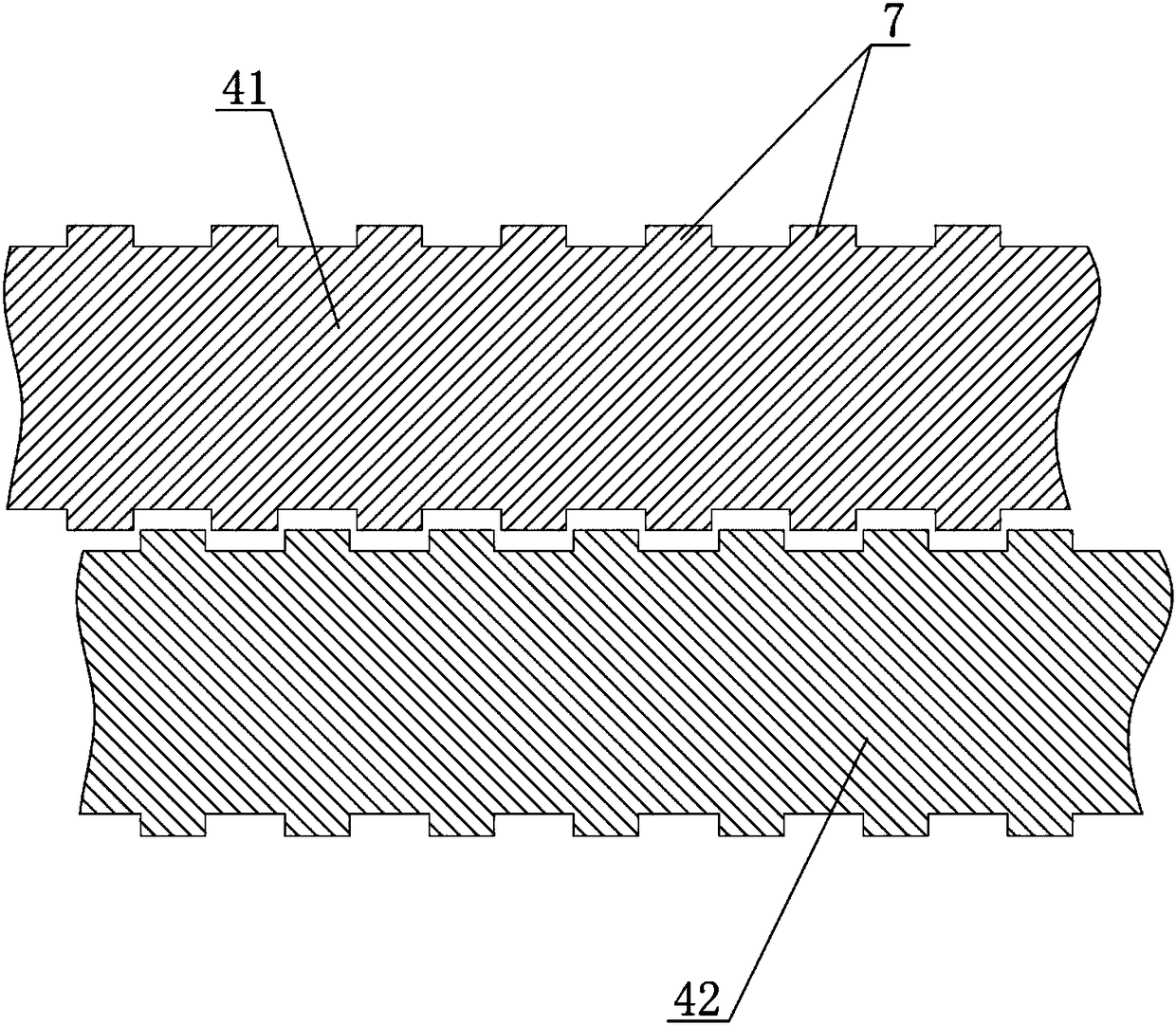

Electrode material production and processing system based on double screws

PendingCN108380078ASolve productivityFix stability issuesElectrode manufacturing processesRotary stirring mixersProduction lineAdhesive

The invention discloses an electrode material production and processing system based on double screws. The electrode material production and processing system comprises a feeding device and a materialstirring device; materials enter the material stirring device under the action of the feeding device, and is discharged after being stirred and mixed by means of the material stirring device; the first screw and the second screw are both arranged in a charging barrel, and the first screw and the second screw are arranged side by side and are meshed with each other; the first screw and the secondscrew rotate in the same direction, and the first screw and the second screw separately and sequentially comprise a mixing section, a kneading section, a slurry forming section, a shear mixing sectionand a bubble elimination section. The materials are added into the combined double screws by means of an automatic feeding system for mixing materials, and the slurry can be continuously produced andsupplied in a way of a production line, so that the problems that the traditional material stirring process adopts intermittent production, thus being poor in stability of different batches of materials, causing the contact between powder particles and adhesive to be uneven, enabling the product to be easy to stratify and prone to hard precipitation, and the like can be solved.

Owner:四川西丹孚能源科技有限公司

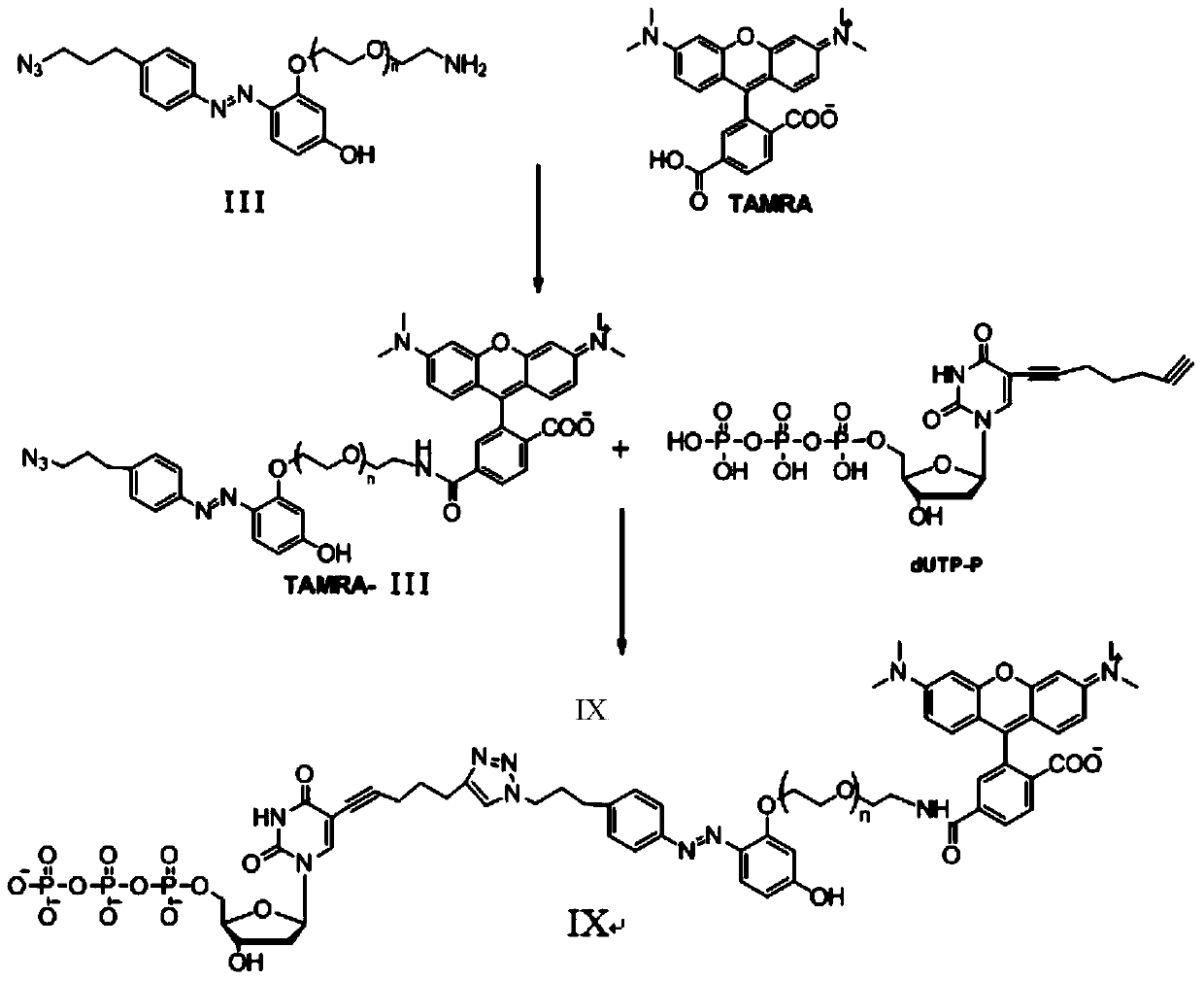

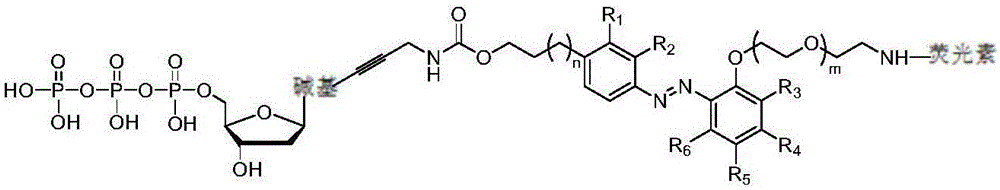

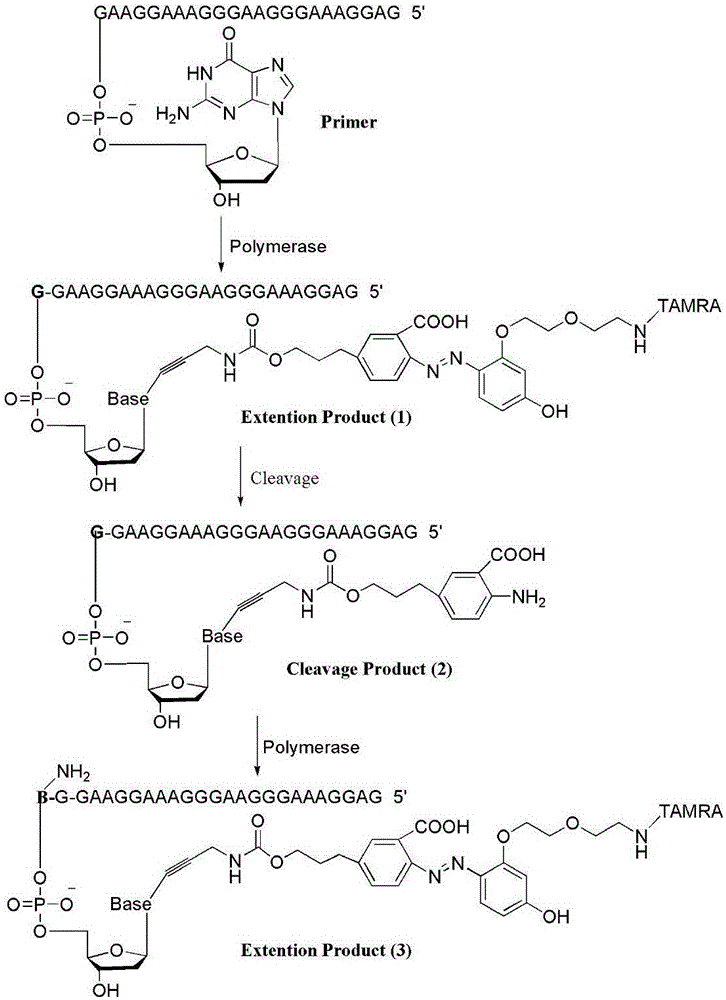

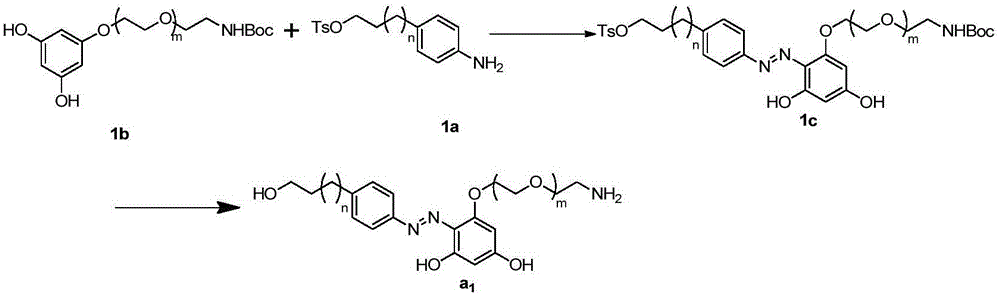

Azo linkage unit based fluorescence labeled nucleotide and applications thereof

ActiveCN104725453AChange sensitivityReduce generationSugar derivativesMicrobiological testing/measurementLinkage conceptFluorescent labelling

The invention provides an azo linkage unit based fluorescence labeled nucleotide and applications thereof. The structural formula of the nucleotide is shown in a formula VI in the specification, wherein fluorescein is selected from one of BODIPY, rhodamine, coumarin, xanthene, cyanin, pyrene, phthalocyanine, Alexa, Squaring dye, a combination producing energy transfer dyes and derivatives thereof; R1, R2, R3 R4 and R6 are various substituent groups, R5 is a substituent group except -C2H5, and R1, R2, R3, R4, R5 and R6 are not H simultaneously; and n is an integer between 0 and 10. Compared with the prior art, a kind of new azo linkage unit based reversible terminals is synthesized according to the invention; the kind of reversible terminals can realize high-efficiency shearing under moderate conditions, so that the kind of reversible terminals can be used for DNA sequencing; and raw materials required by synthesis are simple and easy to obtain, and reactions in the synthetic process are all conventional chemical reactions, therefore, the nucleotide can be subjected to large-scale promotion and application.

Owner:SHANGHAI JIAO TONG UNIV

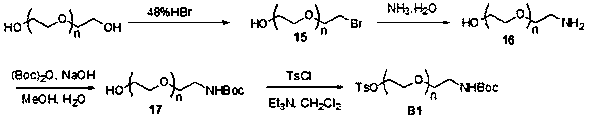

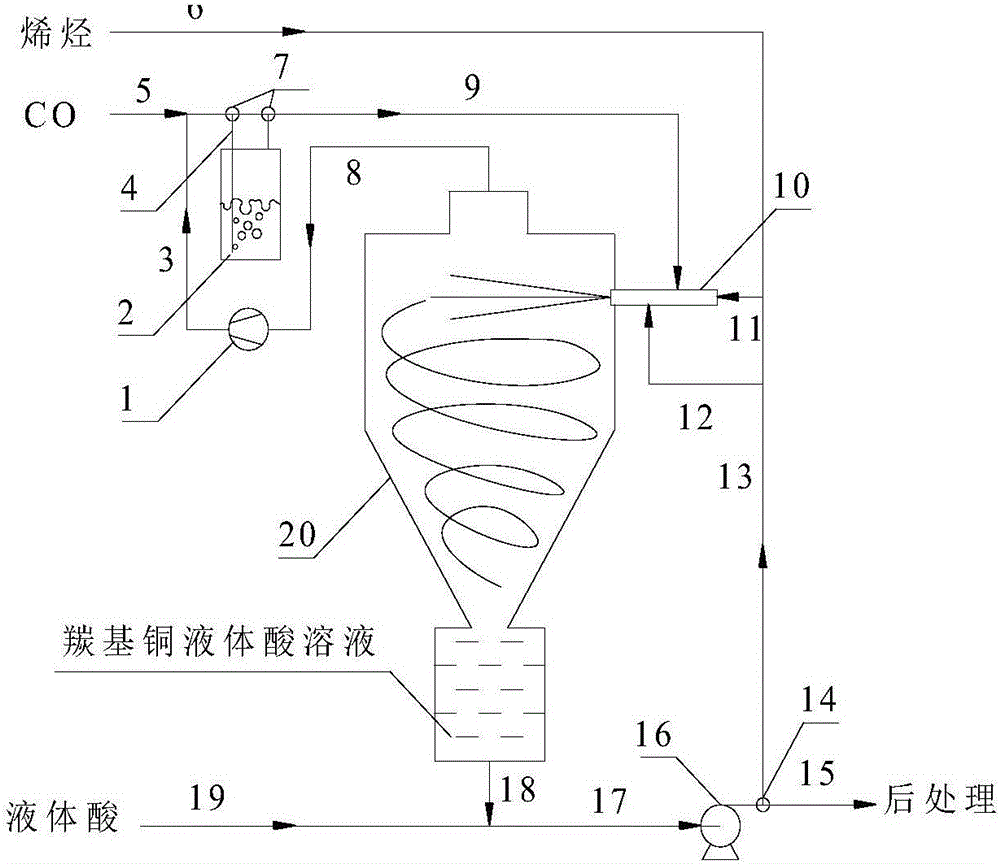

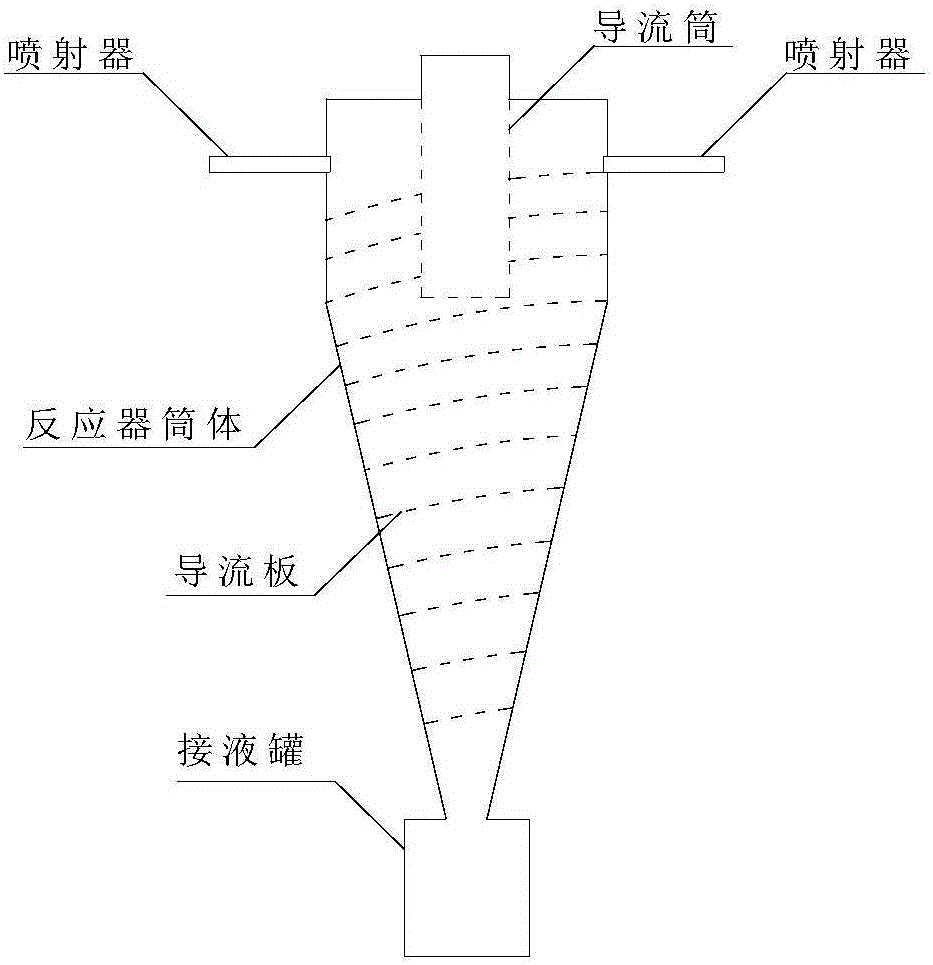

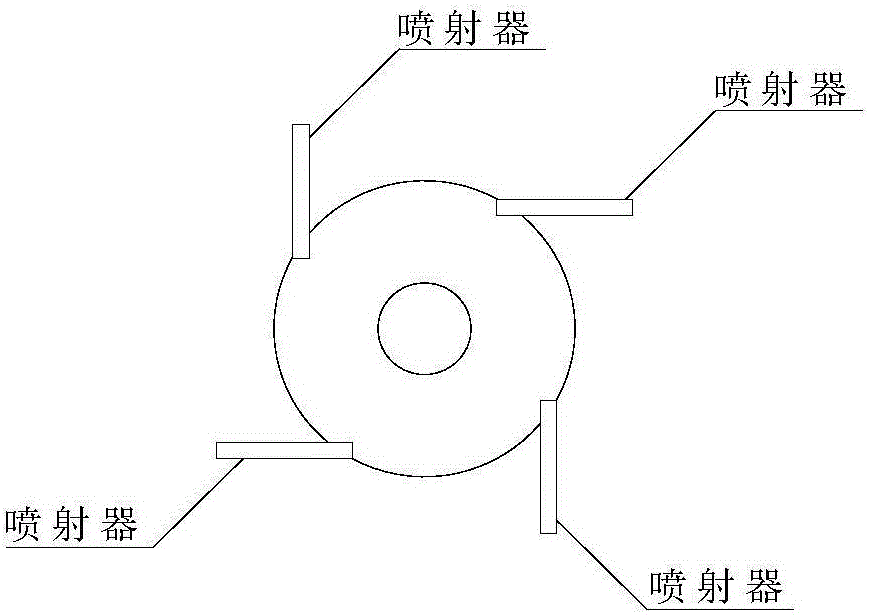

Centrifugal inner swirl type multiphase jetting reactor and method for preparing tert-carbonic acid with centrifugal inner swirl type multiphase jetting reactor

ActiveCN105688759AAvoid carryingAchieve recyclingCarboxylic preparation from carbon monoxide reactionChemical/physical processesSuspended particlesCentrifugation

The invention discloses a centrifugal inner swirl type multiphase jetting reactor and a method for preparing tert-carbonic acid with the multiphase jetting reactor. A cylinder is arranged at the upper end of the reactor, a conical reactor body which is connected with the cylinder and shrinks gradually is arranged at the lower end of the reactor, and the bottom of the conical reactor body is connected with a liquid receiving tank of the cylinder. The method comprises the steps that superfine cuprous oxide powder is added into the reactor in the form of CO gas suspending sol, under the action of liquid strong acid, cuprous oxide suspending particles are mixed in the form of thin film jet flow, subjected to a reaction and converted into a multicarbonyl copper compound, and the multicarbonyl copper compound further reacts with olefin, so that the tert-carbonic acid is prepared. By means of the centrifugal inner swirl type multiphase jetting reactor and the method for preparing tert-carbonic acid with the centrifugal inner swirl type multiphase jetting reactor, preparation of tert-carbonic acid and recycling of unreacted CO are achieved, the problem that in traditional kettle type processes, when cuprous oxide powder and liquid acid are mixed, caking is caused easily is solved, interphase mass transfer efficiency is remarkably improved, production efficiency is greatly improved, olefin polymerization is effectively inhibited, and the reaction yield is raised.

Owner:WANHUA CHEM GRP CO LTD

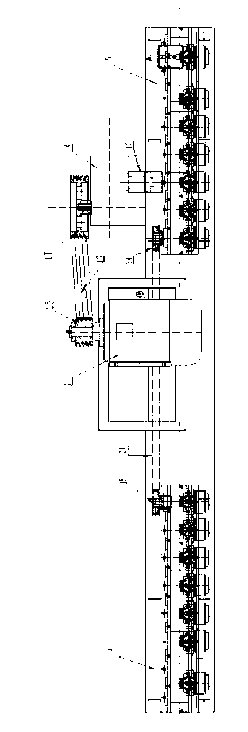

Single crank reciprocated flying shear

InactiveCN1803356ASynchronous motion speedLine speed synchronizationStock shearing machinesShearing control devicesProduction lineMotor drive

The invention discloses a single-crank swinging flying-shear in the continual synchronizing transverse-cut production line, which is characterized by the following: the servo motor drives the single-crank swinging flying-shear to rotate, which anchors the box-shaped liner to move vertically and horizontally; the linear speed of up-and-down blades keeps the same speed, which synchronizes the material-carrying speed with the shearing speed in the cutting region.

Owner:朱照铭 +1

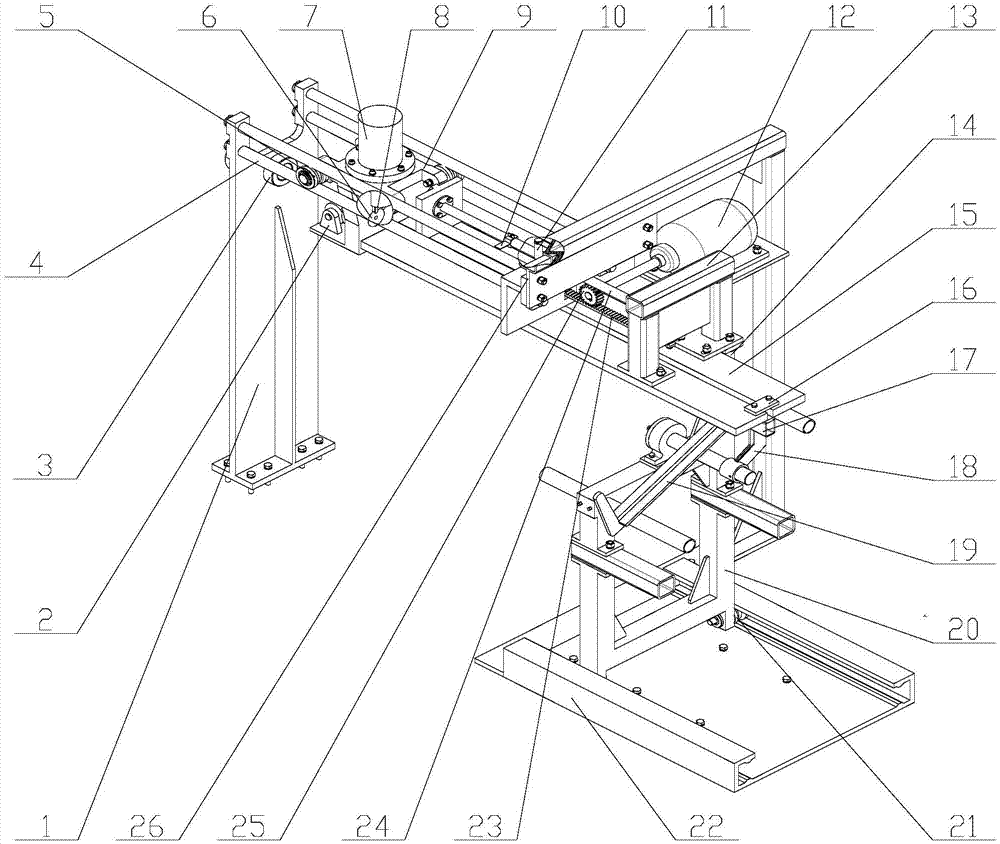

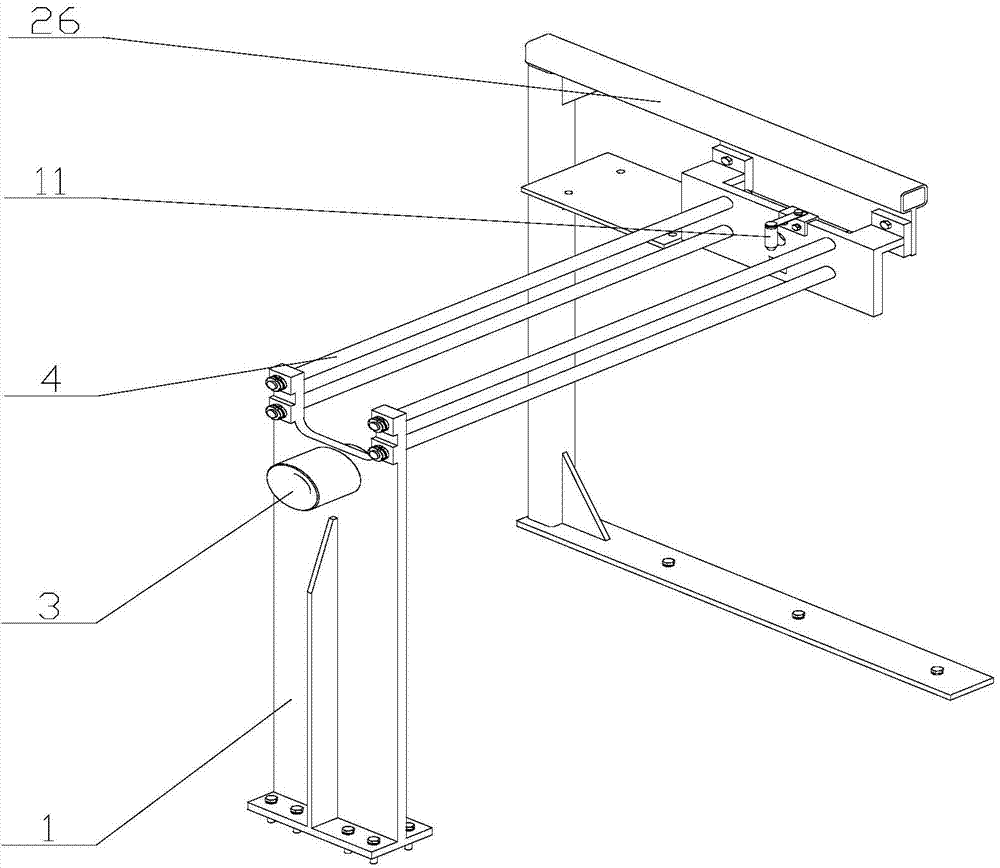

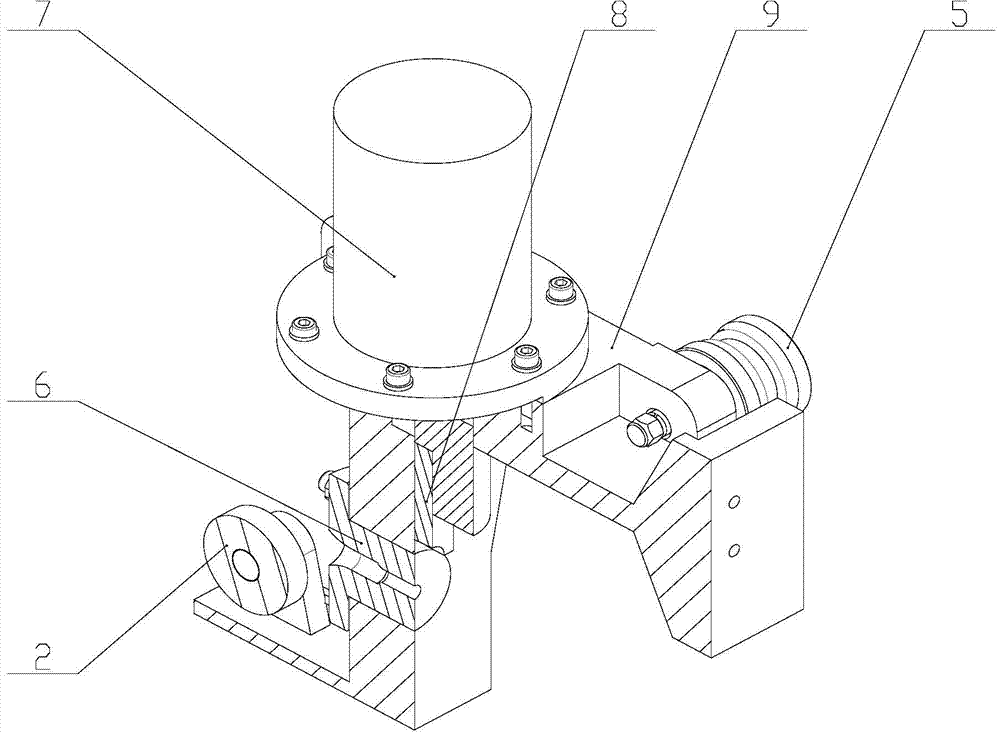

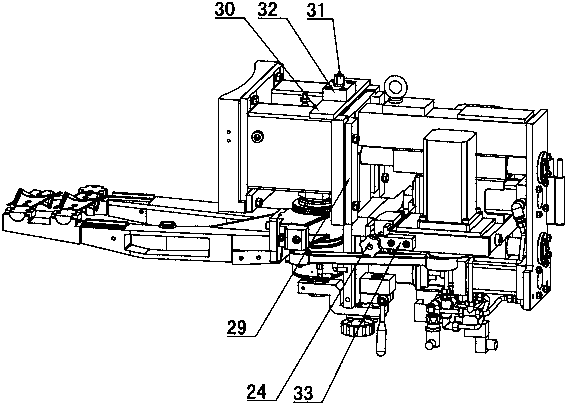

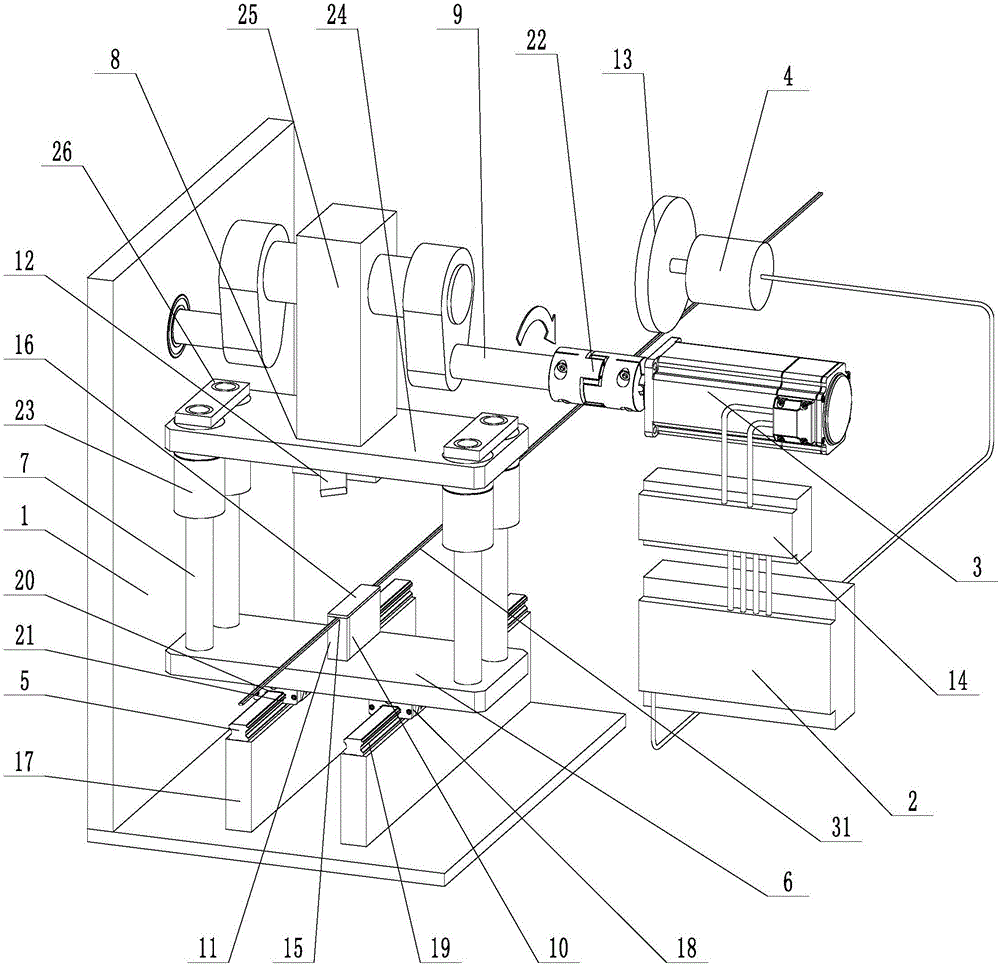

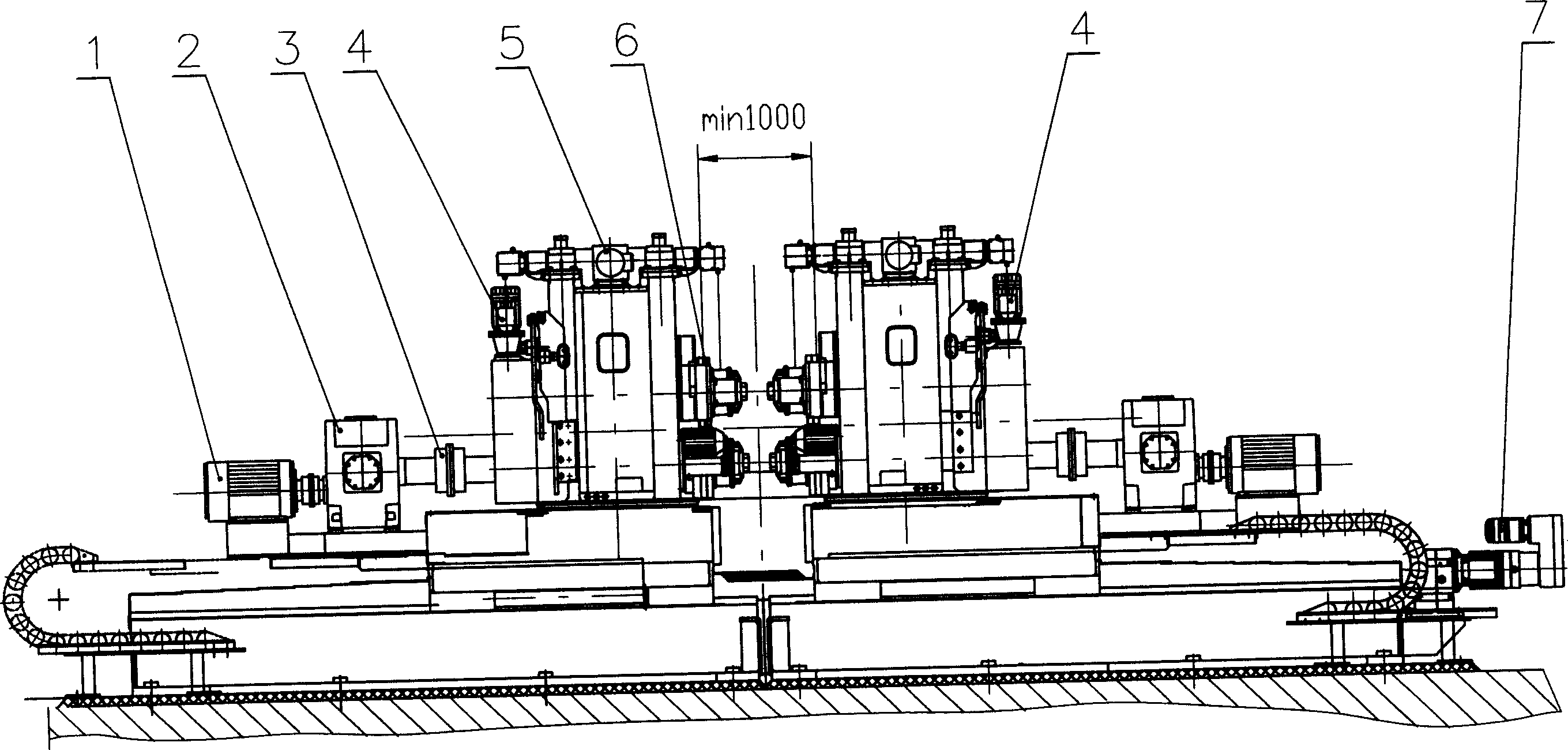

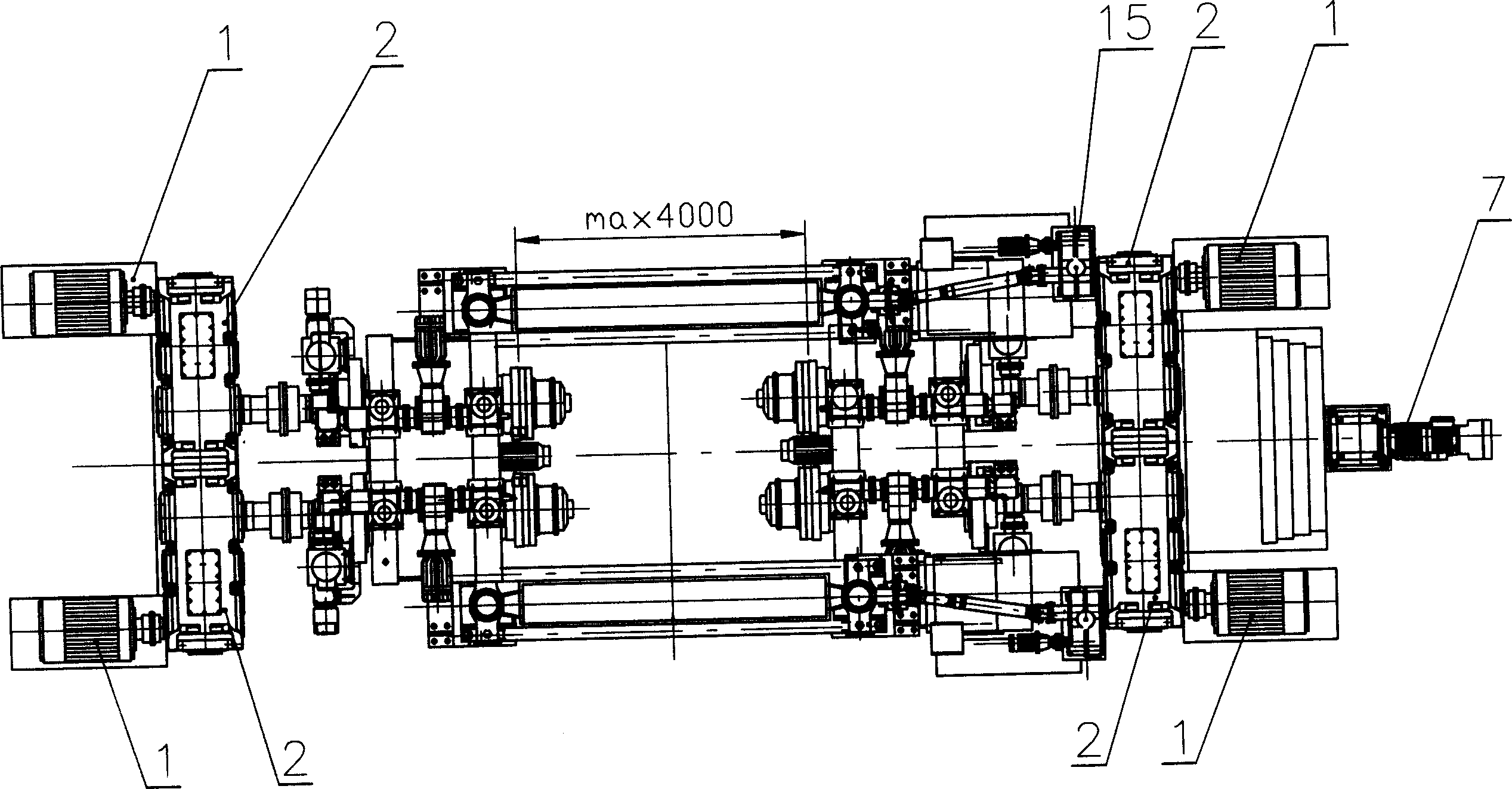

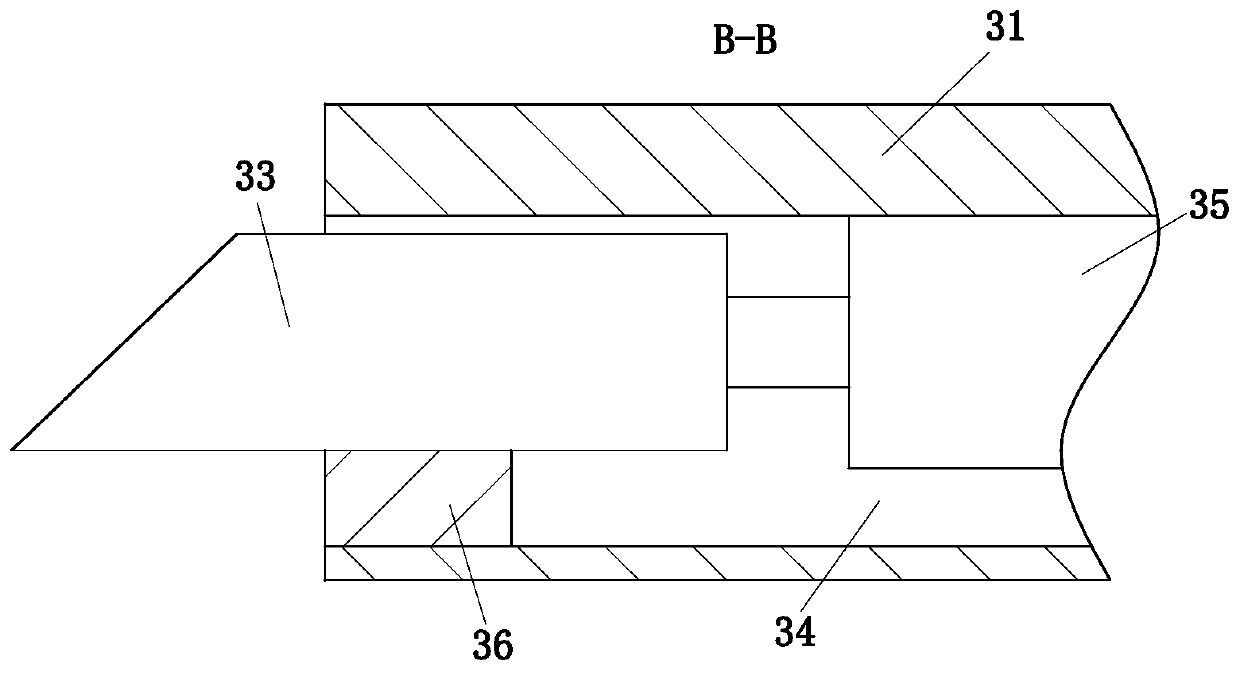

Online servo large-diameter bar hydraulic follow-up fixed-length shearing mechanism

InactiveCN104259548AImprove continuityHigh speed online shearingShearing machinesShearing machine accessoriesHydraulic cylinderEngineering

The invention discloses an online servo large-diameter bar hydraulic follow-up fixed-length shearing mechanism. The online servo large-diameter bar hydraulic follow-up fixed-length shearing mechanism mainly comprises a fixed bracket, a hydraulic shearing machine, a mechanical connecting mechanism and a bearing frame, wherein the fixed bracket mainly comprises a left bracket, a right bracket, a shearing machine guide rail, a guide sleeve, a photoelectric sensor and the like. The hydraulic shearing machine mainly comprises a hydraulic cylinder, an upper cutting knife, a lower cutting knife, a shearing machine roller, a speed measuring support wheel and a bracket. The bearing frame mainly comprises an upper bracket, a lower horizontal rod, a lower bracket, a lower bracket roller, a linear guide rail, a wide guide rail, a baffle rod, a turning arm, a bracket and a fixed-length baffle plate. The mechanical connecting mechanism comprises a servo motor, a gear, a rack, a connecting rod and a touch plate. The online servo large-diameter bar hydraulic follow-up fixed-length shearing mechanism can largely quicken the bar speed to realize high-speed online production, and prevents secondary processing and resource waste to achieve high practical value.

Owner:YANSHAN UNIV

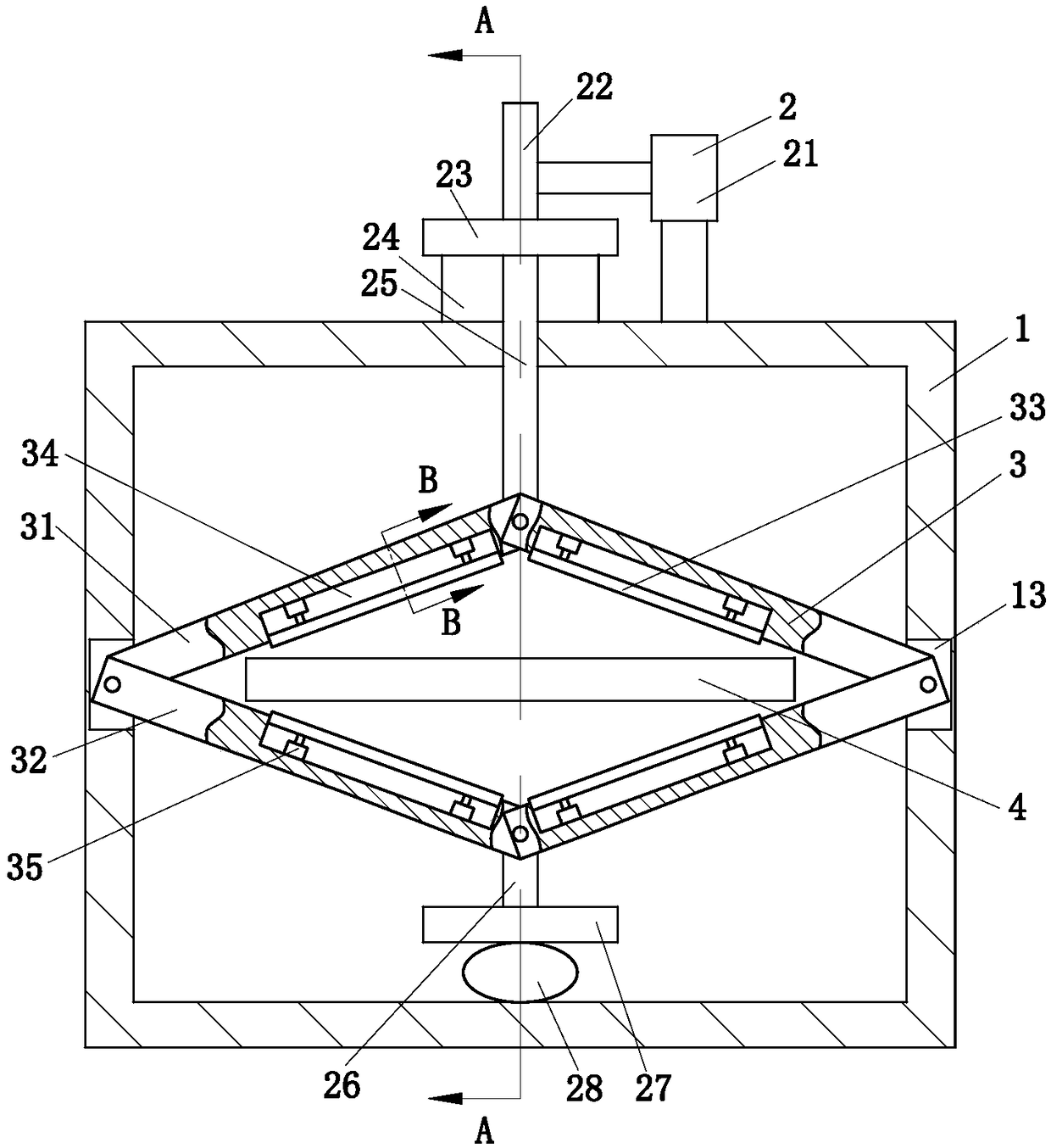

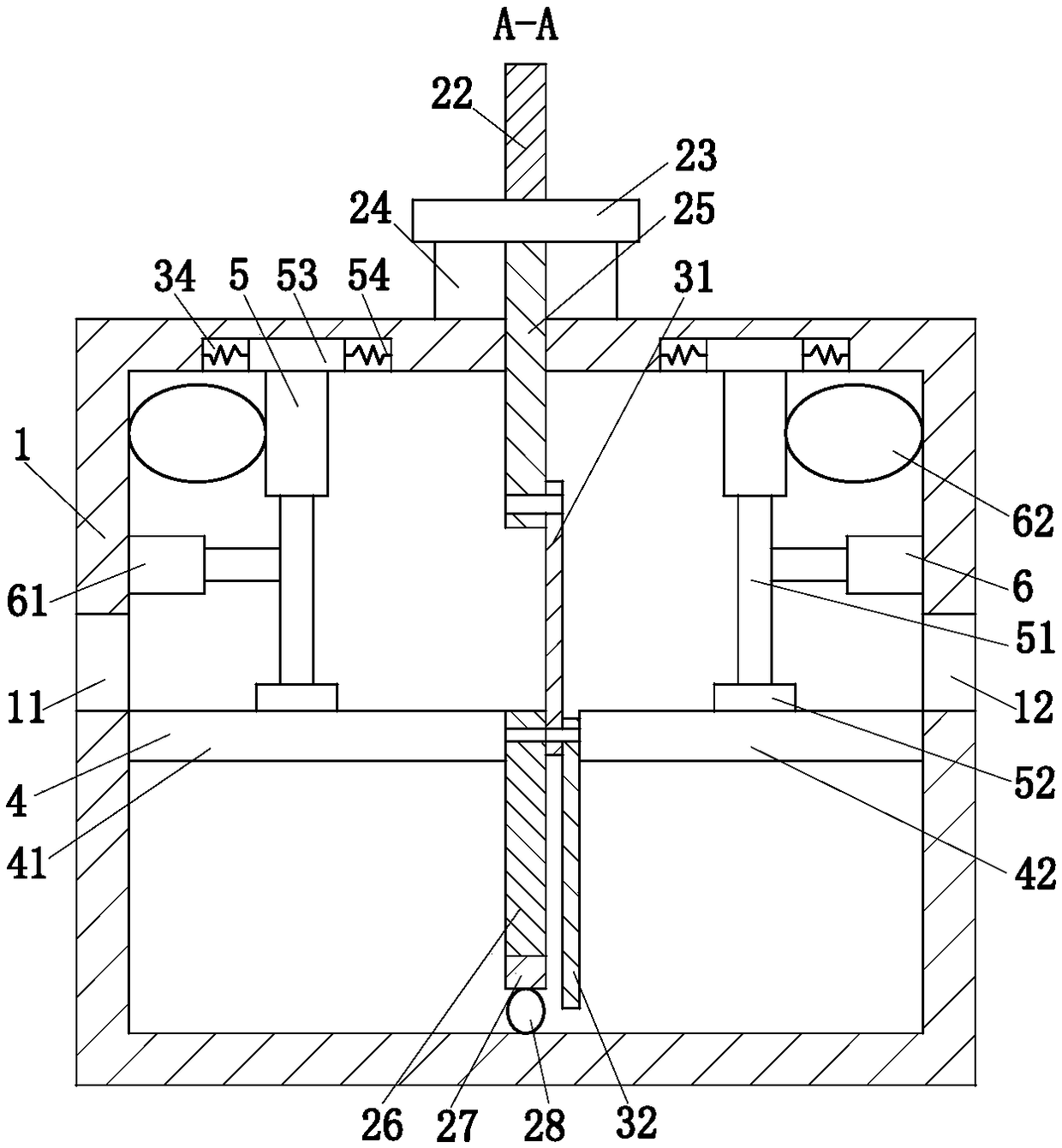

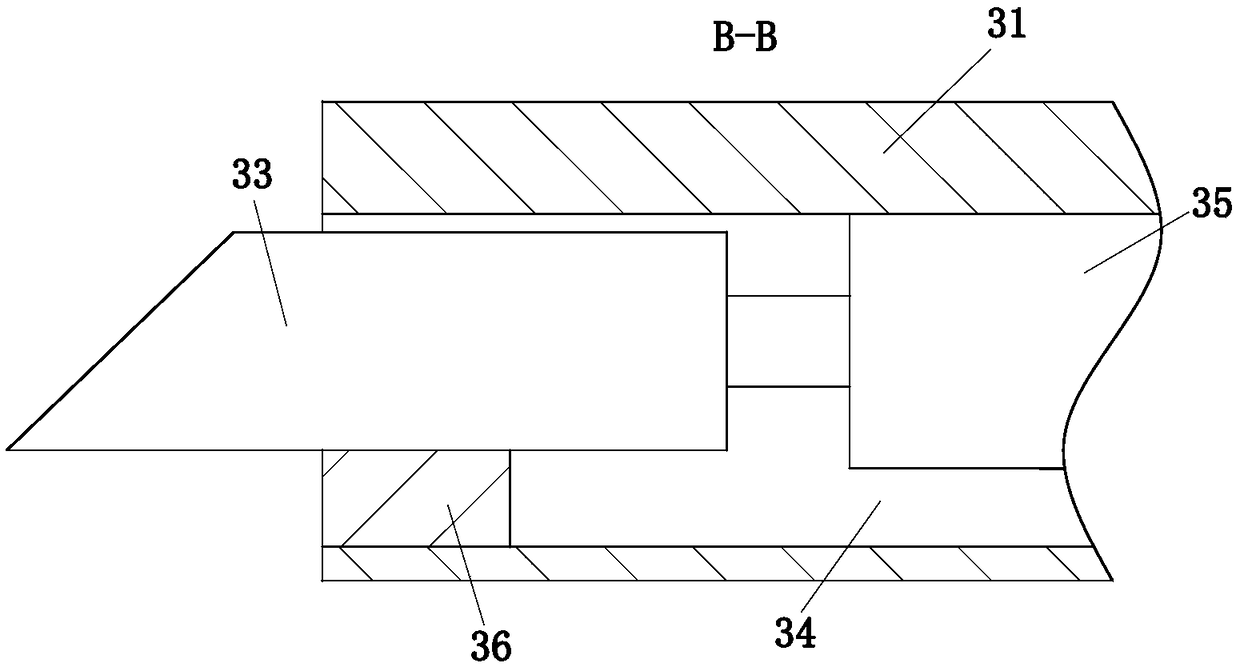

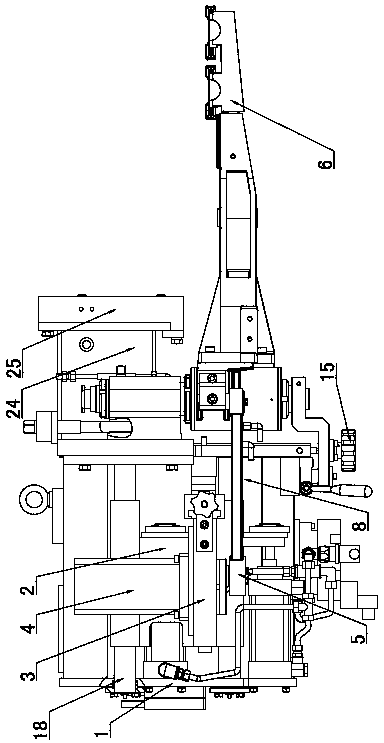

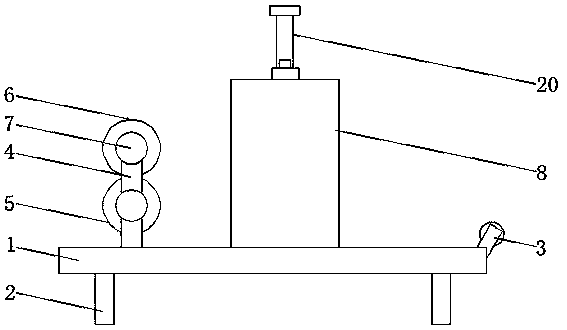

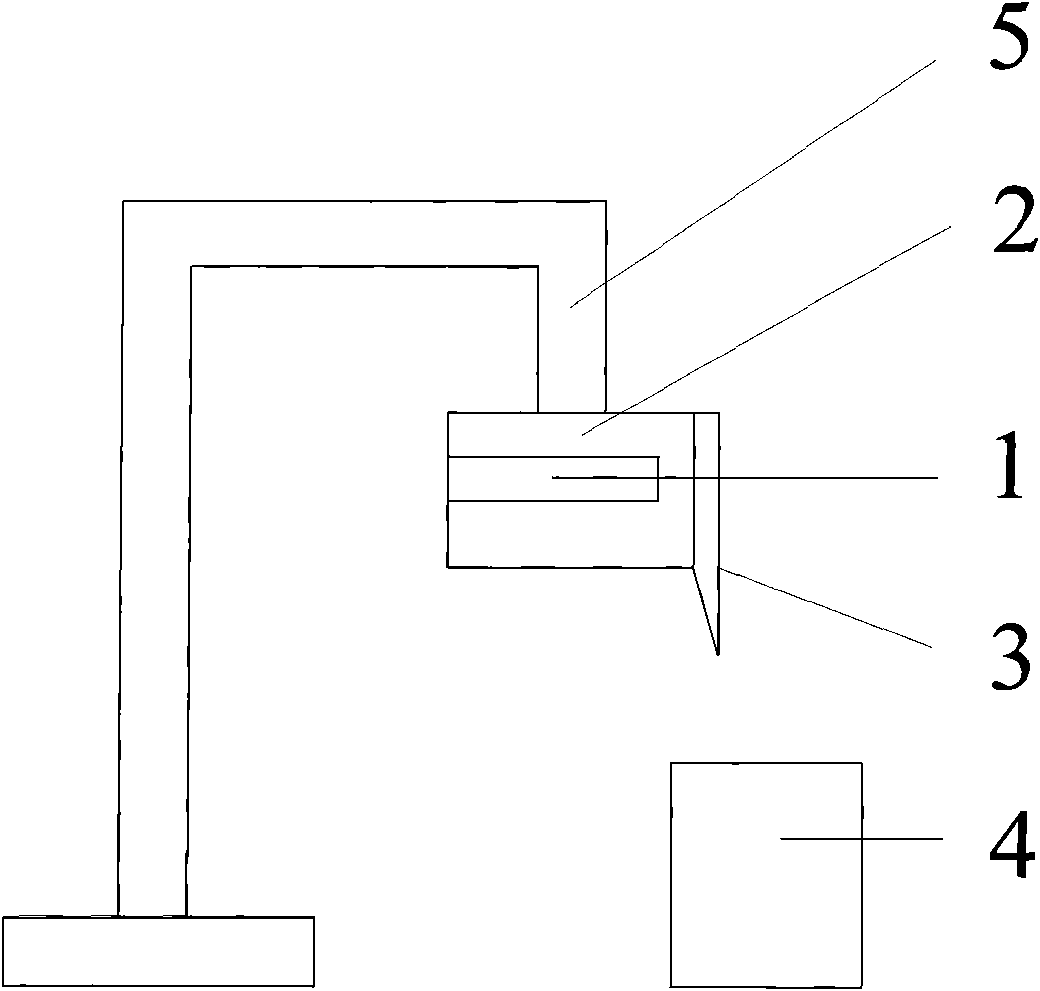

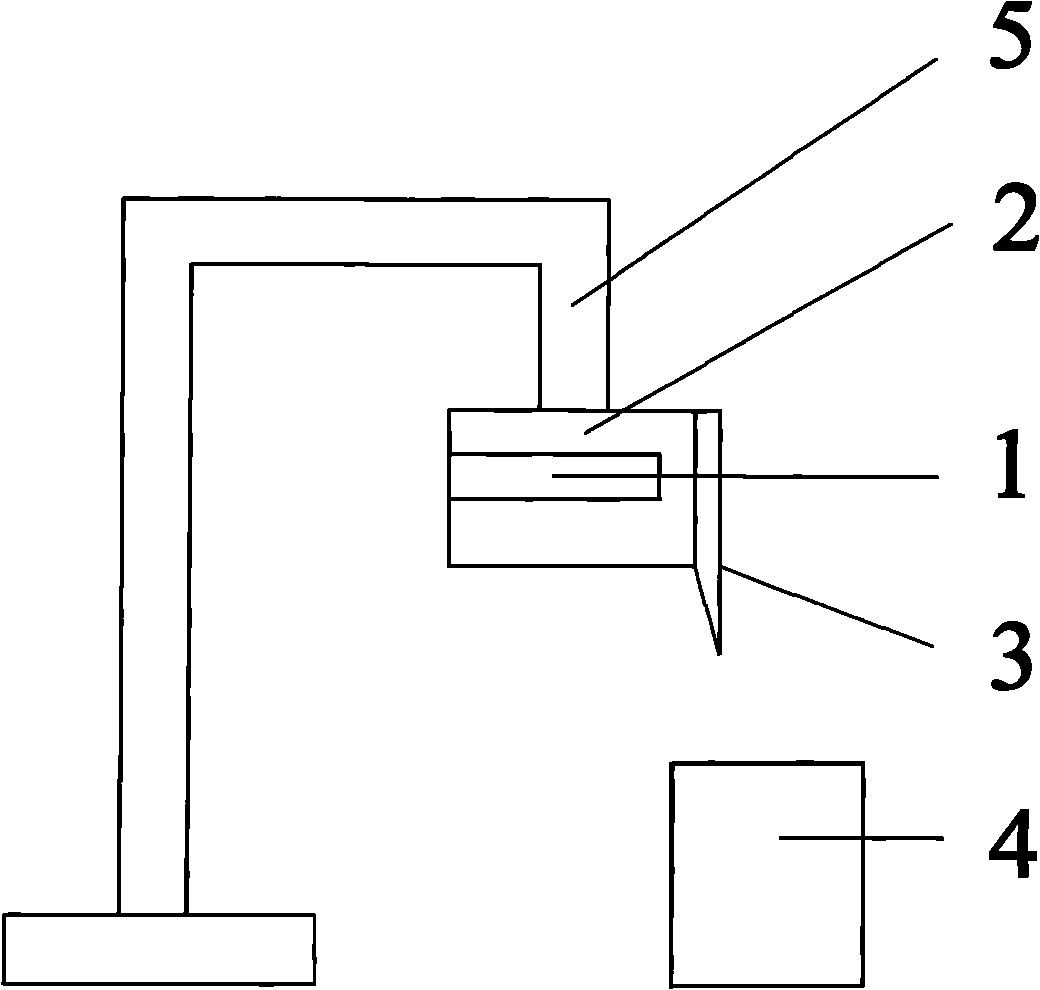

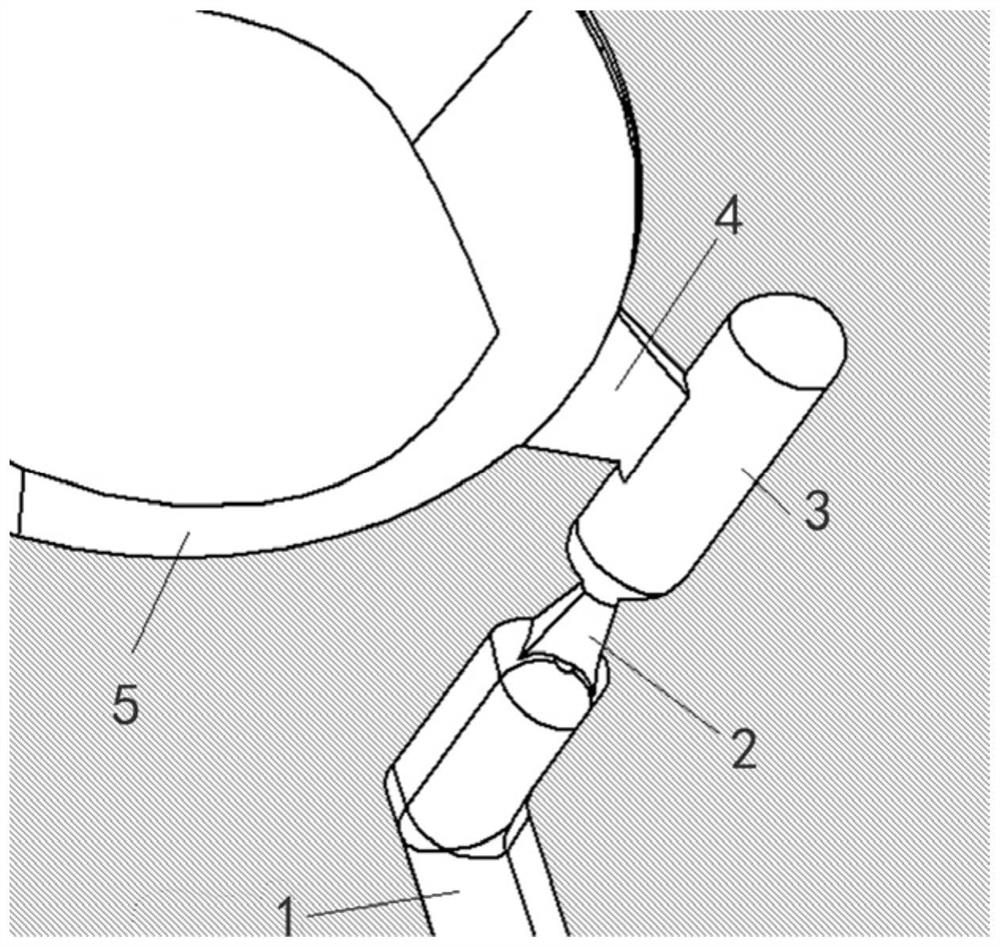

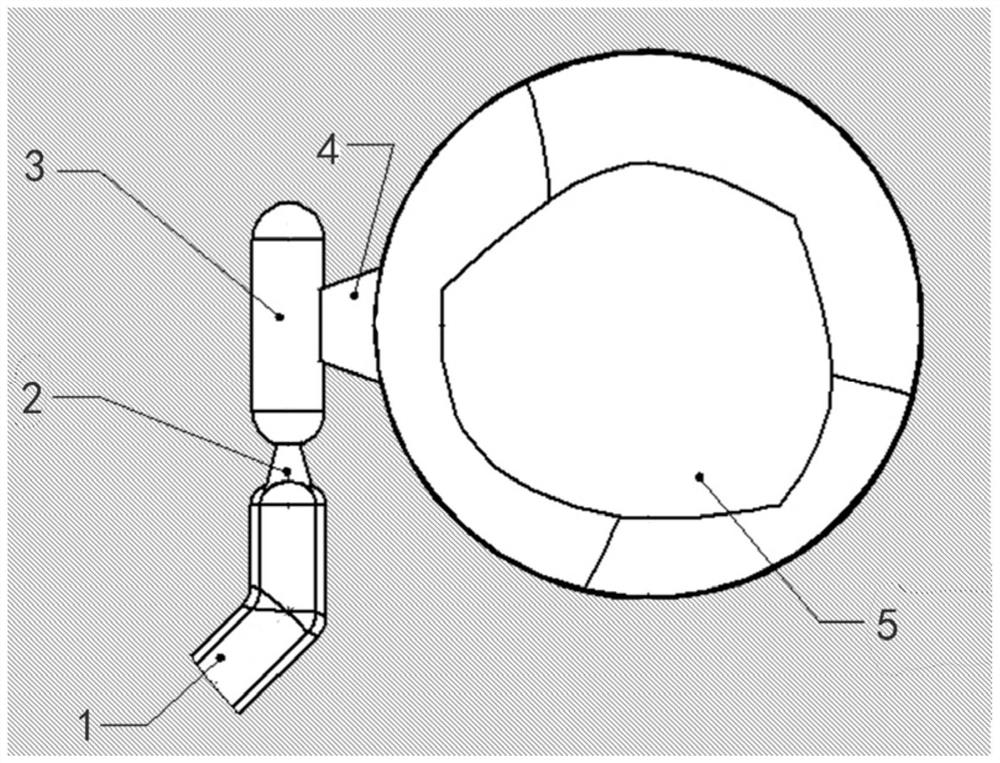

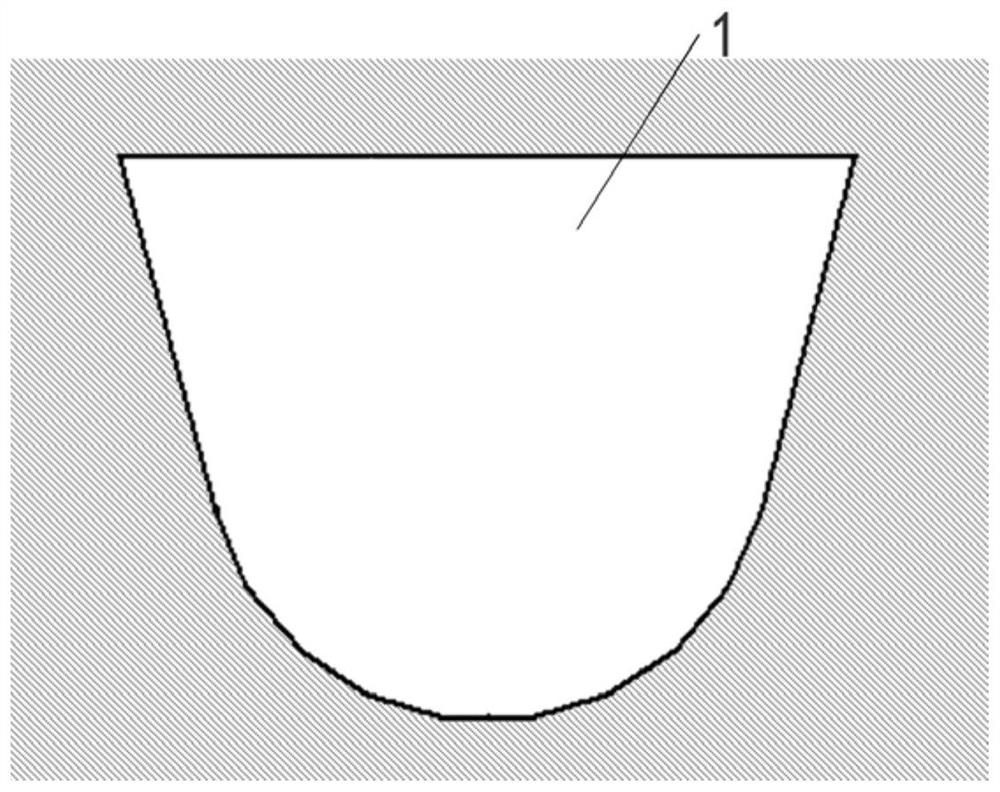

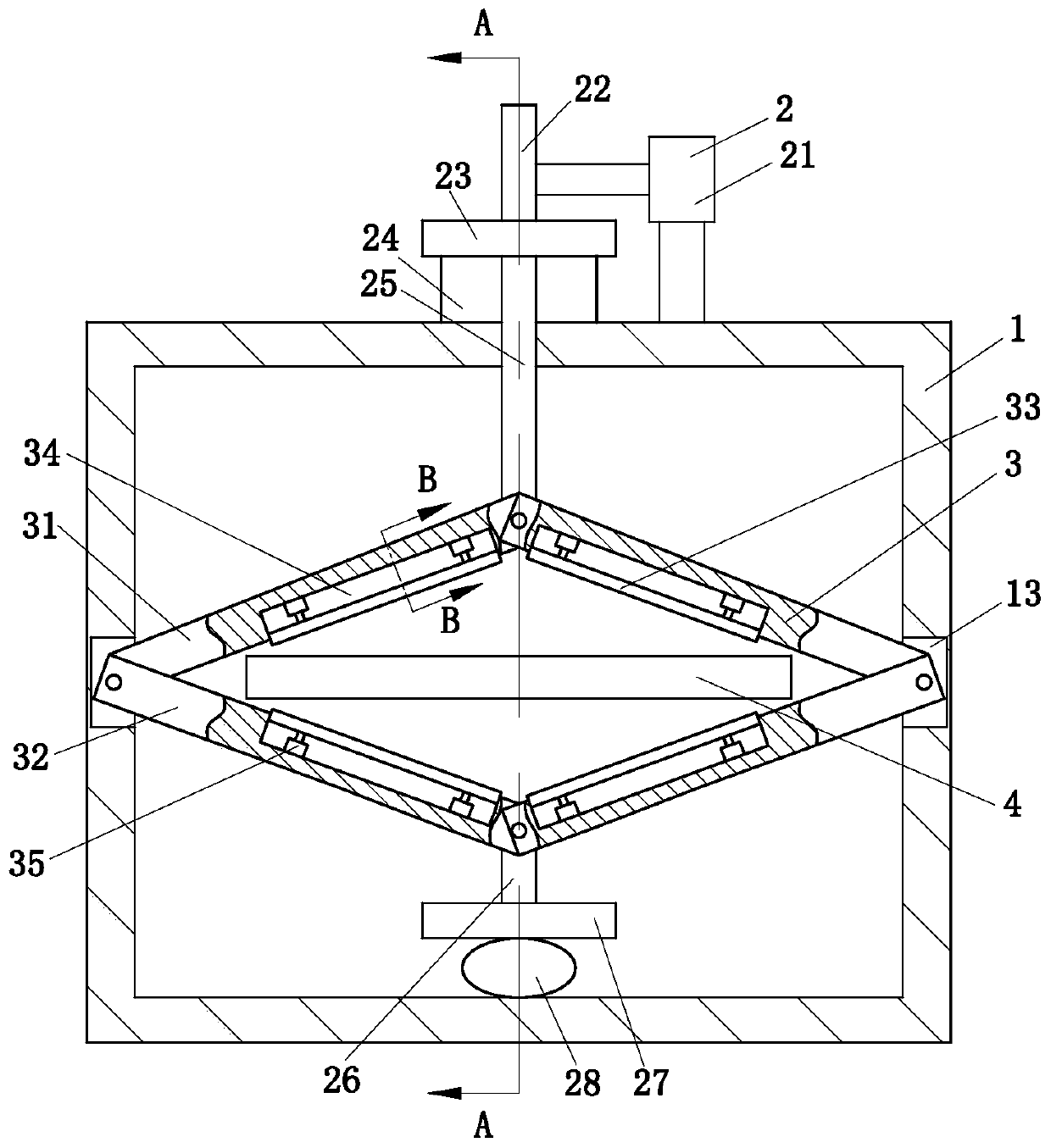

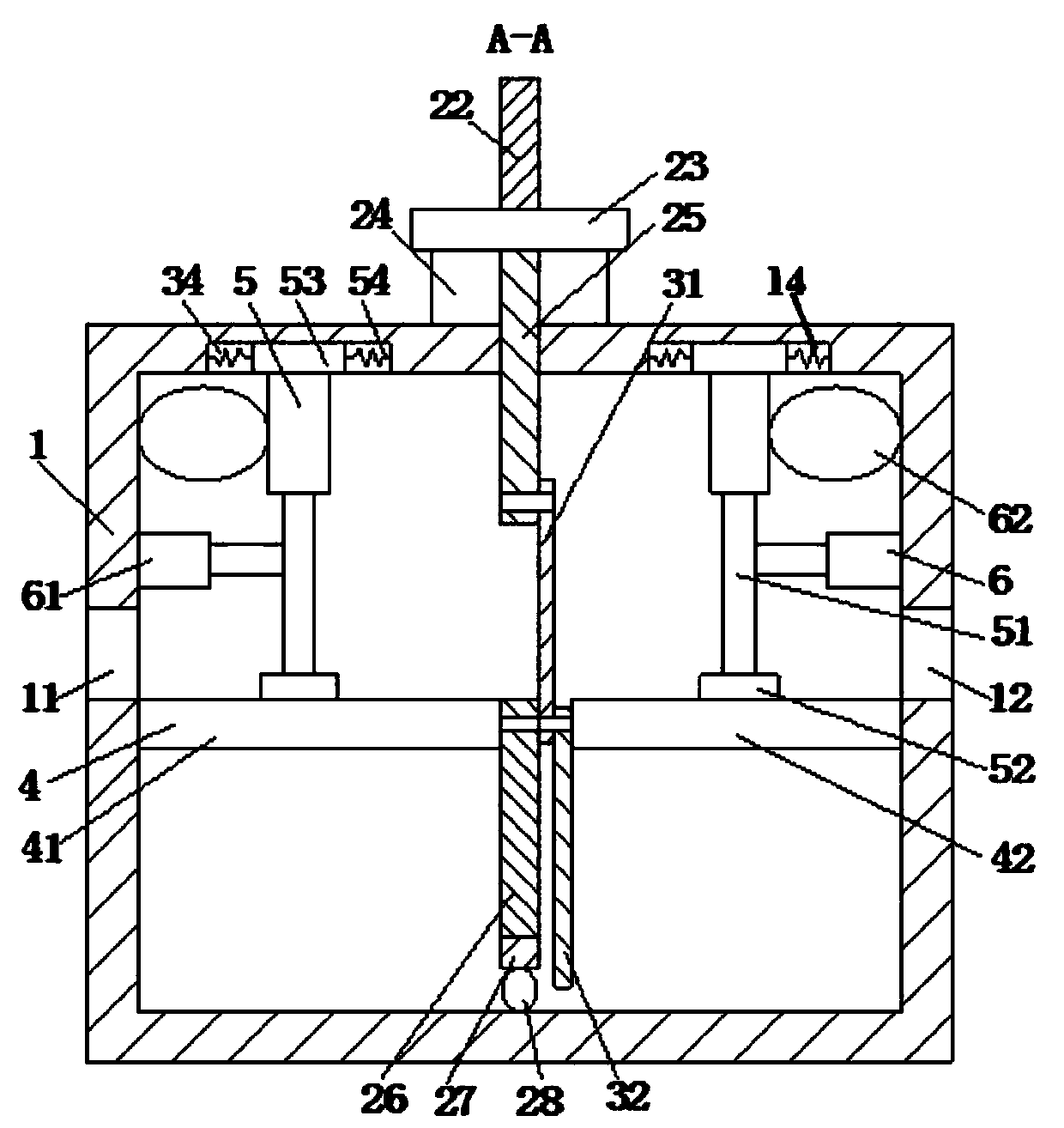

Dual-servo-motor angle shear machine

The invention discloses a dual-servo-motor angle shear machine and belongs to the field of feeding machines of glass bottle machinery. The dual-motor servo angle shear machine is characterized in that a support frame comprises a support bracket (1) and a motor bracket (3); a shear device comprises two servo motors (4), a left connecting rod mechanism, a right connecting rod mechanism, shear arm support devices, a left shear arm (6) and a right shear arm (7); the two servo motors (4) are mounted on the motor bracket (3); the output ends of the servo motors (4) vertically and downwardly extend out of the lower plane of the motor bracket (3) and are connected with two cranks (5) respectively; the two cranks (5) are connected with the left connecting rod mechanism and the right connecting rod mechanism respectively; the other end of each of the left connecting rod mechanism and the right connecting rod mechanism is connected with each shear arm support device; the shear arm support devices are connected with the left and right shear arms (6, 7) which can be occluded with each other. According to the dual-servo-motor angle shear machine, the shearing operation is stable, the reversing motion cannot be made, the shearing quality is good, and the shearing position can be adjusted.

Owner:SHANDONG SANJIN GLASS MASCH CO LTD

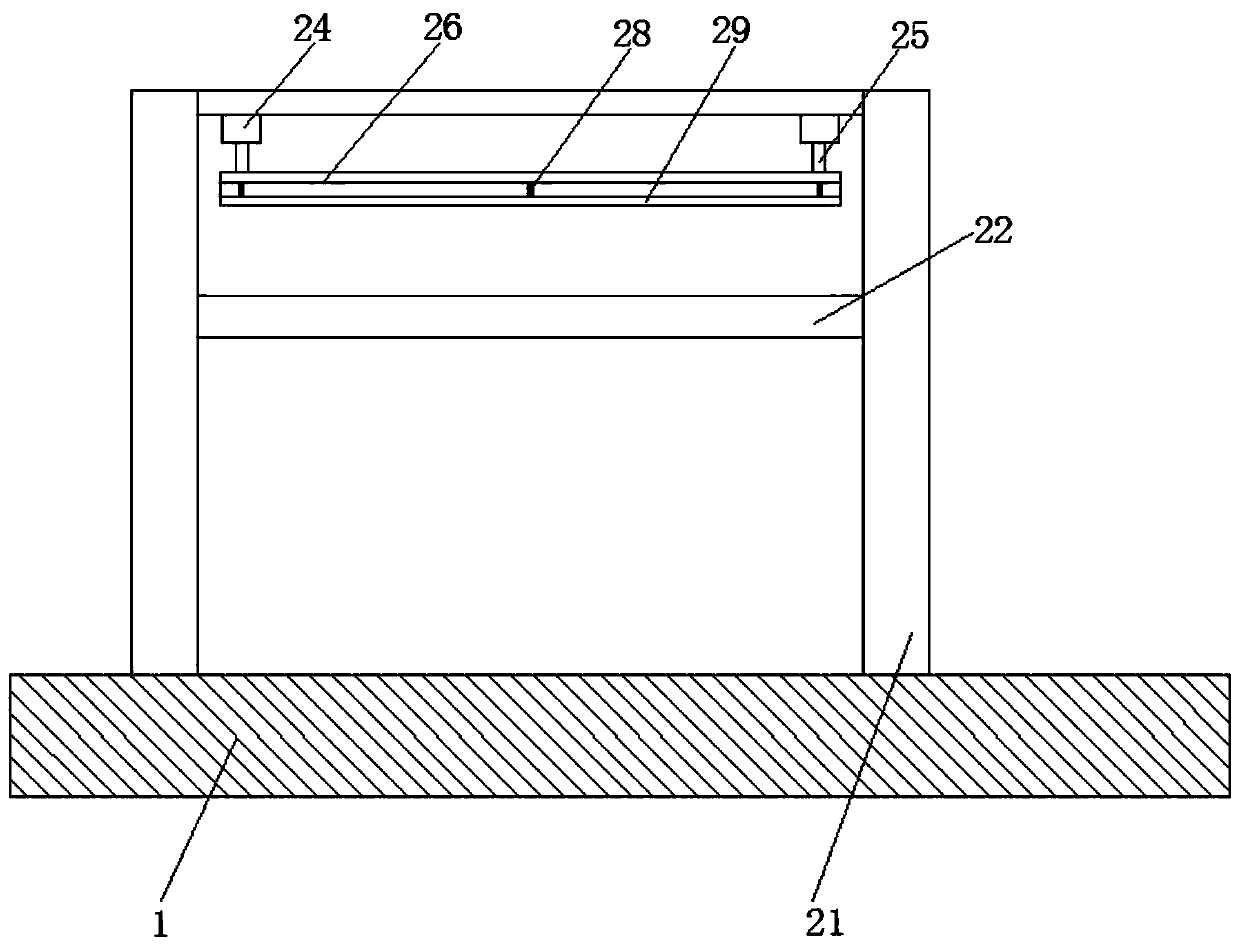

Film cutting equipment for agricultural greenhouse

InactiveCN108789527AAvoid manual pullingShear speed is fastMetal working apparatusArticle deliveryGreenhouseAgricultural engineering

The invention discloses film cutting equipment for an agricultural greenhouse. The film cutting equipment comprises a workbench; a vertical plate is fixedly connected to the upper surface of the workbench, and the back surface of the vertical plate is rotationally connected with a lower rotary roller and an upper rotary roller; the axis of the lower rotary roller and the axis of the upper rotary roller are fixedly connected with motors; one side of the vertical plate is provided with a cutting frame fixedly connected to the top of the workbench, and the bottom of the cutting frame is fixedly connected to a base; the top of the base is fixedly connected with a side plate, the back surface of the side plate is rotationally connected with a traction roller, and one side of the traction rolleris provided with a cutter holder fixedly connected to the base; and the inner wall of the cutting frame is fixedly connected with a slide seat. According to the film cutting equipment, by arranging aguide roller, the vertical plate, the lower rotary roller, the upper rotary roller, the motors, the traction roller, the cutter holder, a cutter groove, an elastic plate, slide seats, slide rods, fixed blocks, springs, a cutter handle and a cutter, the problems that manual pulling is needed, the cutting speed is low, and the greenhouse building efficiency is reduced are solved.

Owner:徐州佳联农业发展有限公司

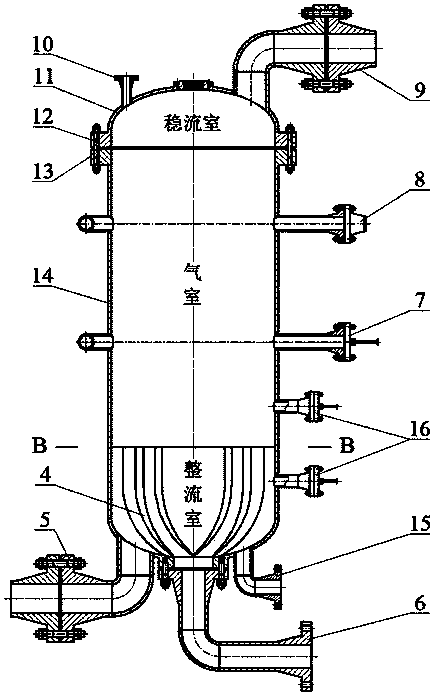

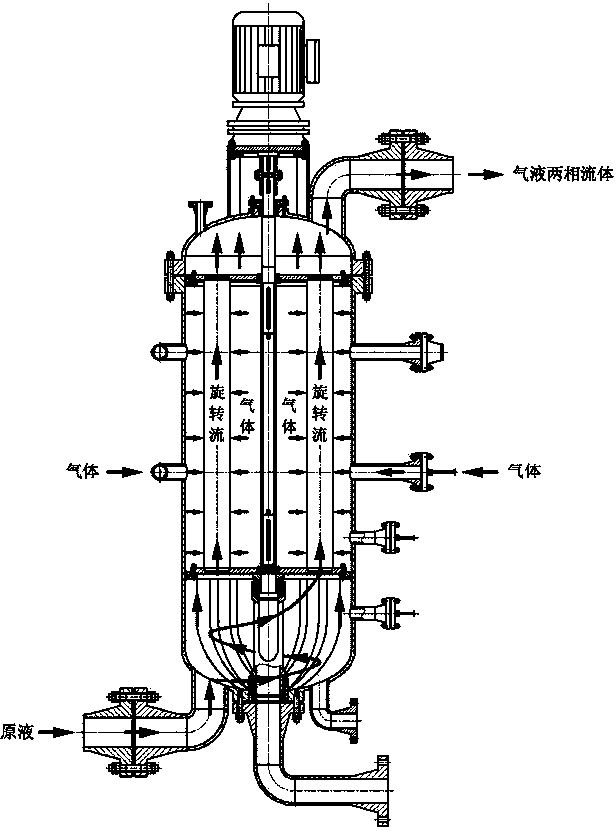

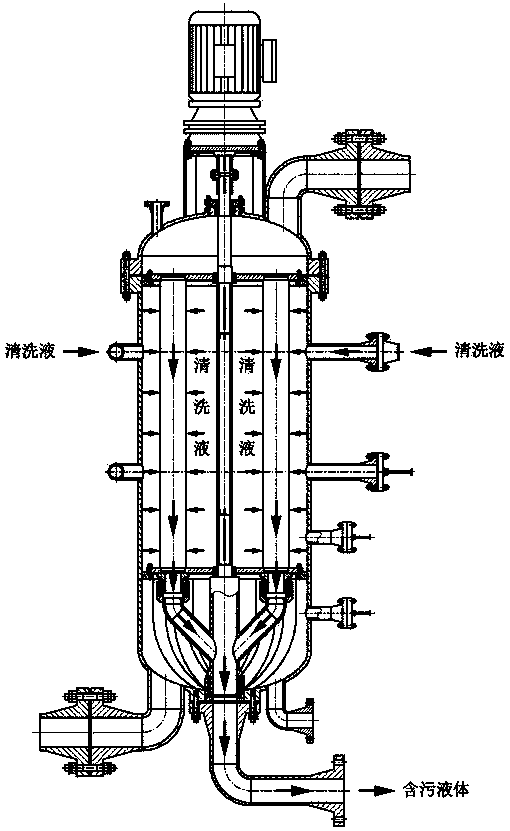

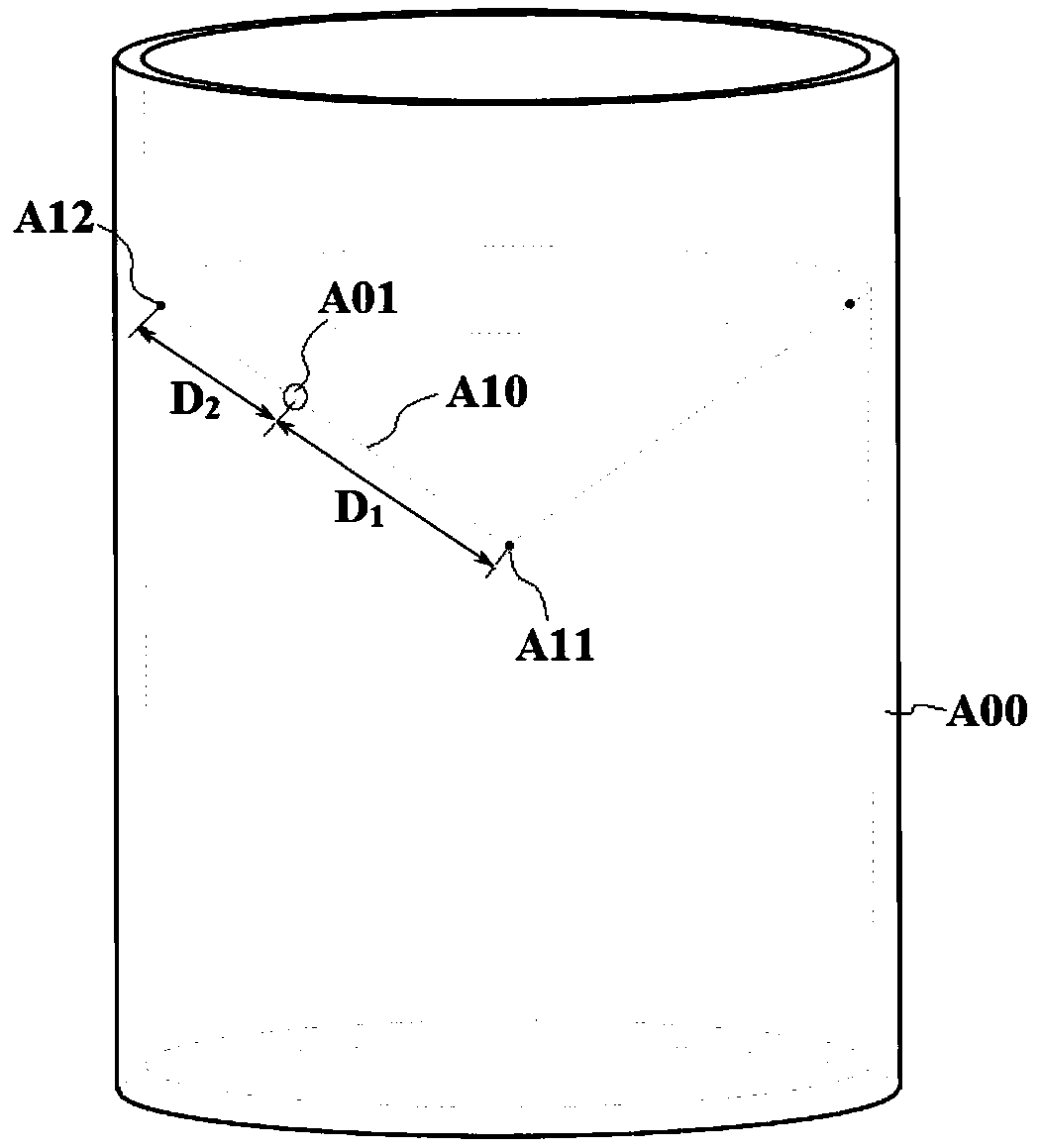

Squirrel-cage type self-rinsing micro-bubble generator

InactiveCN103880106AShear speed is fastCompact structureWater/sewage treatment by flotationDifferential pressureEngineering

The invention provides a squirrel-cage type self-rinsing micro-bubble generator applied to air floatation treatment of oily sewage and industrial wastewater. A stock solution forms rotating flow on a rotating blade, and then enters a micro-porous membrane pipe to improve the utilization rate of gas; a ceramic-membrane membrane pipe ensures that generated micro-bubbles are fine and uniform in granularity and large in amount by adopting a squirrel-cage type arrangement and a honeycomb micro-fine pore structure and matching with an air inlet manifold; a control valve, a pressure safety valve and a differential pressure transmitter are arranged on the squirrel-cage type self-rinsing micro-bubble generator to ensure that the device is high in degree of automation; a motor drives a rinsing jacket and a rinsing pipe to continuously rotate to sequentially rinse the micro-porous membrane pipe until regeneration so as to finish the self-rinsing operation; the dirt of the micro-porous membrane pipe can be thoroughly cleaned by using the dual-cleaning of the combination of cleaning liquid rinsing operation and gas purging operation; a micro-bubble tank is designed with three closed chambers, namely a rectification chamber, a gas chamber and a steady-flow chamber; moreover, upper and lower division plates are connected with an annular plate by adopting screws, so that the micro-porous membrane pipe can be disassembled and replaced. The whole set of the device is compact in structure, easy in arrangement, operation and maintenance, and low in running cost.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

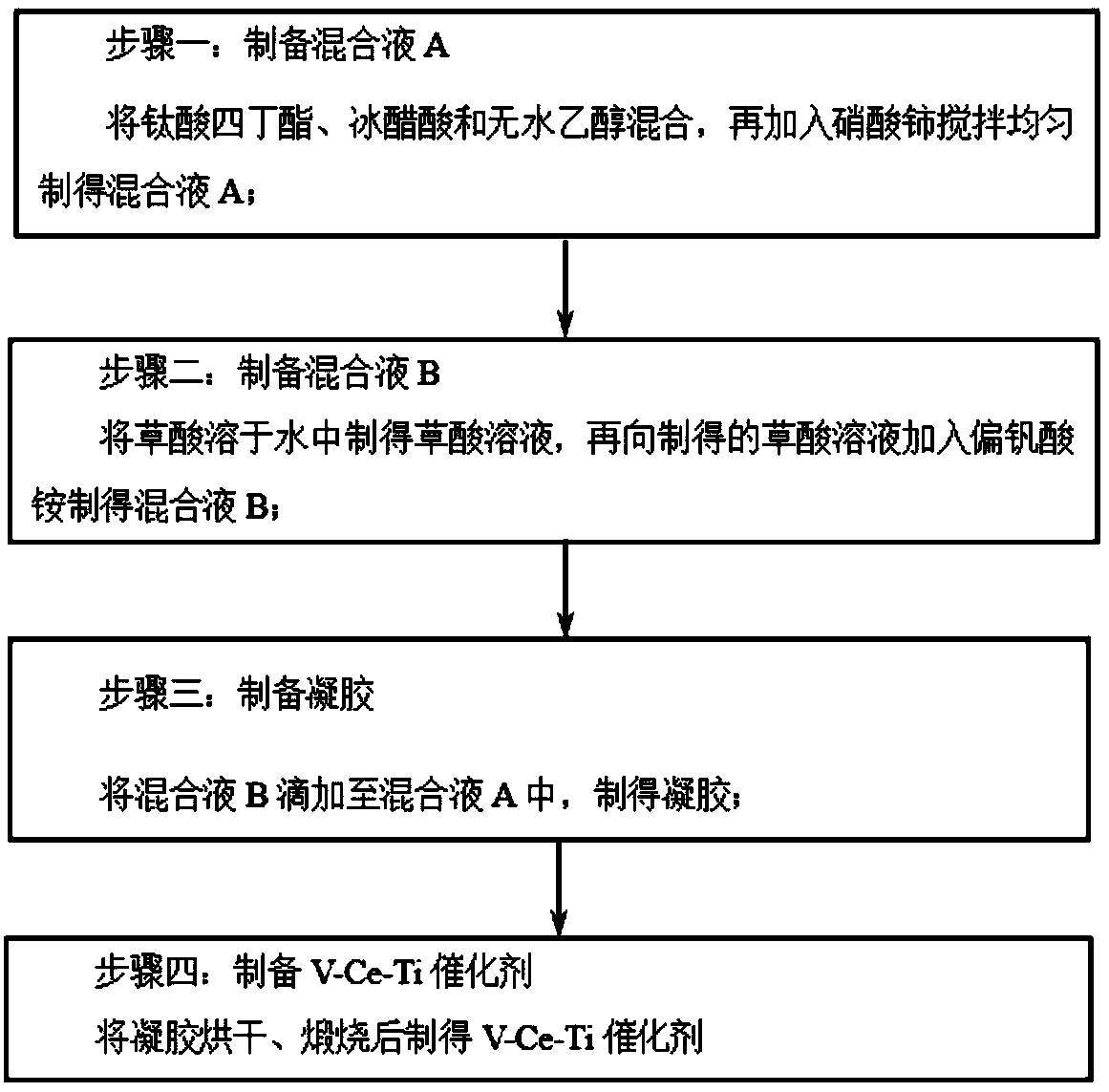

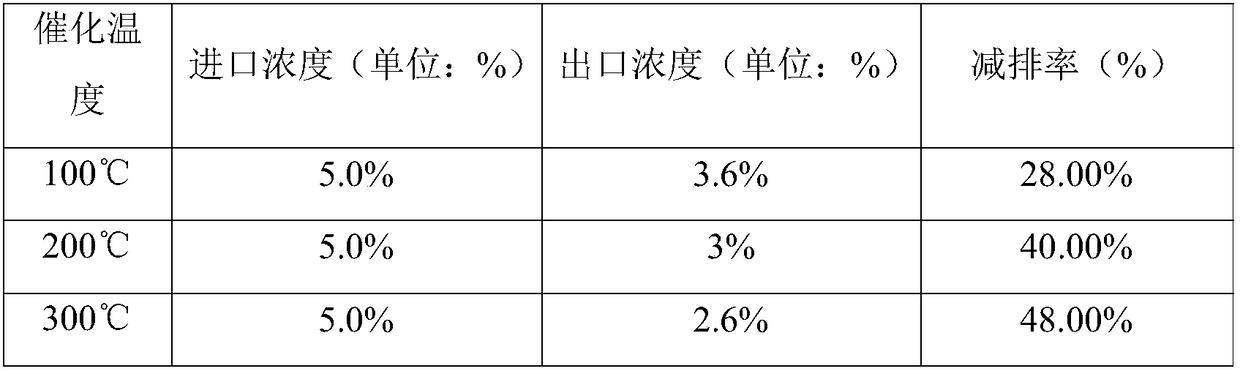

V-Ce-Ti (vanadium-cerium-titanium) catalyst for joint denitrification to remove dioxin

InactiveCN109225200AEmission reductionSolve pollutionGas treatmentHeterogenous catalyst chemical elementsFlue gasCerium

The invention discloses a V-Ce-Ti (vanadium-cerium-titanium) catalyst for joint denitrification to remove dioxin, and belongs to the technical field of treatment on flue gas pollutants. The V-Ce-Ti catalyst is characterized in that the mass ratio of V and Ce oxides is 0.5 to 1; the mass ratio of Ce and Ti oxides is 0.05 to 0.16; the mass ratio of V, Ce and Ti oxides is 1:1:18; the specific surfacearea is 95.7219m<2> / g. The V-Ce-Ti catalyst for joint denitrification to remove dioxin has the advantages that when the flue gas is treated, the produced dioxin and oxynitride in the sintering process can be removed, the emission of dioxin and oxynitride in the sintering flue gas is reduced, and the powerful guarantee is provided for the clean production of steel and iron industry.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Quantitative cutting device of compound cloth

InactiveCN108316004AConvenience to workQuantitative tailoring is goodMechanical cleaningPressure cleaningAgricultural engineeringConductor Coil

The invention relates to the technical field of textile machinery and discloses a quantitative cutting device of compound cloth. The device comprises a workbench, wherein a conveying sleeve is fixedlyconnected with the side face of the workbench; the bottom of an inner cavity of the conveying sleeve is fixedly connected with a positioning shaft; the middle of the positioning shaft is fixedly connected with a fixing shaft in a sleeving manner; the middle of the fixing shaft is fixedly connected with a stop block in a sleeving manner; the middle of the fixing shaft is movably connected with a cloth winding shaft in a sleeving manner; the cloth winding shaft is located on the side face of the stop block; the top of an inner cavity of a side wall of the conveying sleeve is fixedly connected with an opening and closing column in a sleeving manner; and the middle of the opening and closing column is movably connected with an enclosing cover in a sleeving manner. The better operation of thequantitative cutting device of the compound cloth is facilitated due to the matching of the workbench and the conveying sleeve; at the same time, quantitative cutting can be performed stably; a shearing error is avoided, so that the problem of cutting failure due to failure in accurate length control in a cutting process of the compound cloth is solved; and the cutting quality is improved.

Owner:叶微微

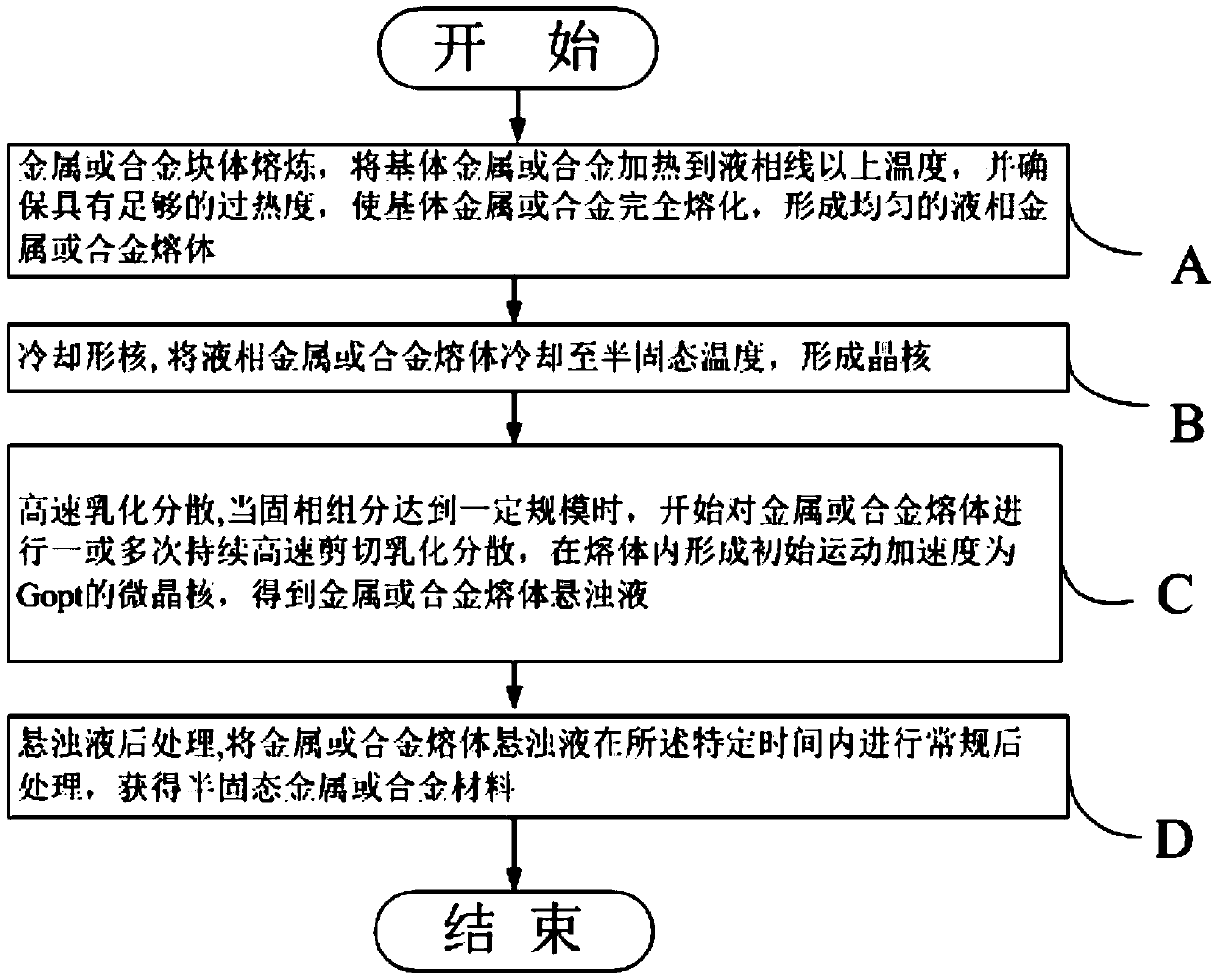

Method for preparing semi-solid metal or alloy

InactiveCN110625076ASolve for uniformitySolve crystal agglomeration nucleation and growthSemi solidNucleation

The invention relates to a method for preparing a semi-solid metal or alloy. The method for preparing the semi-solid metal or the alloy comprises the following steps that a base metal or the alloy isheated to a temperature of a liquid phase line or above, and sufficient superheat is ensured to enable the base metal or the alloy to be completely melt to form a homogeneous liquid phase metal or alloy melt; the liquid phase metal or the alloy melt is cooled to a semi-solid temperature, so that crystal nucleus begin to form; when a solid-phase component reaches a certain scale, one or more continuous high-speed shearing emulsification dispersion is carried out on the melt, and the micro-crystal nucleus with an initial motion acceleration Gopt is formed in the melt to obtain a metal or alloy melt suspension; and before the metal or alloy melt suspension is agglomerated, the metal or the alloy melt suspension is prepared into the semi-solid metal or an alloy material. The method for preparing the semi-solid metal or the alloy successfully solves the problems of uneven crystal nucleus dispersion, crystal agglomeration nucleation and growth, low grain sphericity and the like in a traditional method, and is suitable for industrial production.

Owner:BEIJING COMPO ADVANCED TECH

Cloth cutting machine capable of tidily cutting clothes for rapid production of clothes

InactiveCN112813668ANeatly croppedKeep StraighteningSevering textilesEngineeringMechanical engineering

The invention relates to the technical field of garment production, and discloses a cloth cutting machine capable of tidily cutting clothes for rapid production of clothes. The cloth cutting machine comprises a frame body, wherein a fixing sleeve is fixedly connected to the top of the frame body, a limiting rod is fixedly connected to the inner top wall of the frame body, a movable rod is connected to the interior of the fixing sleeve in a sliding mode, a rocker is movably connected to the top of the movable rod, a fixing plate is fixedly connected to the position, located under the fixing sleeve, of the outer side of the movable rod, and a mounting base is fixedly connected to the bottom of the movable rod. Through the matched use of an inner pressing plate, an upper template and an anti-falling body, when the machine is cutting cloth, the mounting base moves downwards, a transportation gear does not move, the upper template and the inner pressing plate compress the cloth, and the upper template and the anti-falling body on the inner pressing plate can keep compressing the cloth when the cutting device moves downwards, so that the cloth is kept in a tight state when being cut, and the cut edge is kept neat.

Owner:HUNAN UNIV OF TECH

Gate cutting device

InactiveCN102009455APrecise cut sizeImprove work efficiencyMetal working apparatusPunch pressHeat conducting

The invention relates to a gate cutting device, which comprises a heater, a heat conducting part, a cutting blade, a product fixing seat and a punch. The heater is connected to the heat conducting part, the cutting blade is arranged at one end of the heat conducting part, the product fixing seat is arranged below the heat conducting part and the punch is connected to the upper part of the heat conducting part. Compared with the prior art, the invention has the advantages of accurate positioning, capability of controlling cutting size, greater batch cutting speed, nearly no scratching risk in use, high work efficiency, reduced defective products and wide scope of application.

Owner:SHANGHAI FUJITECH PLASTIC

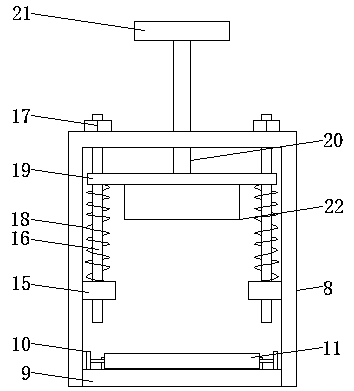

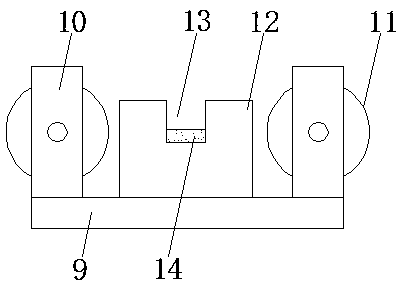

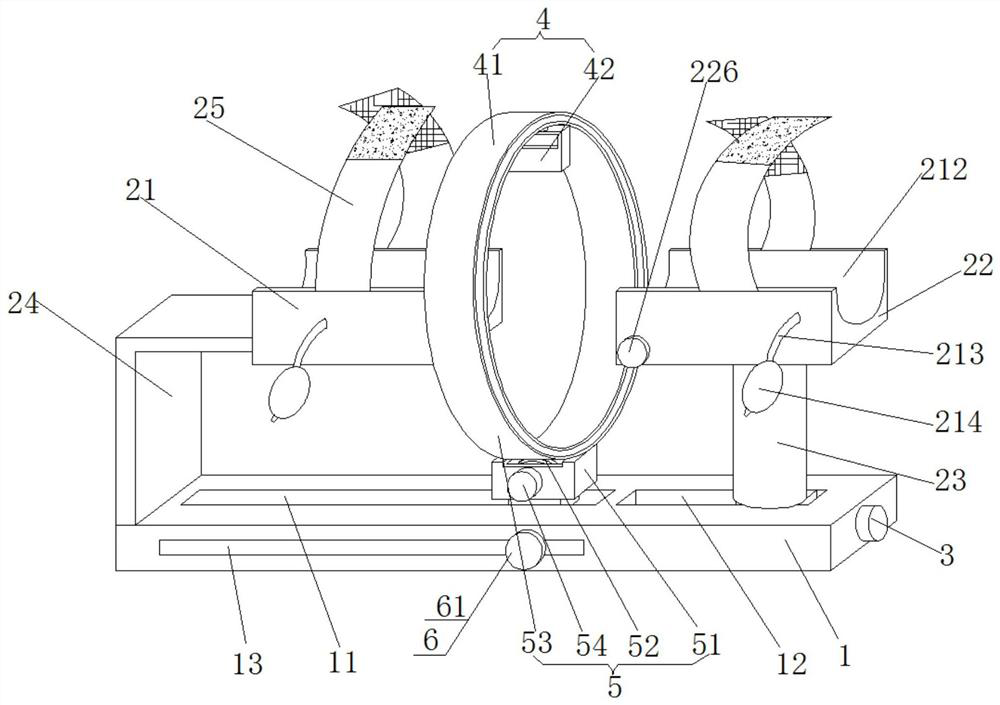

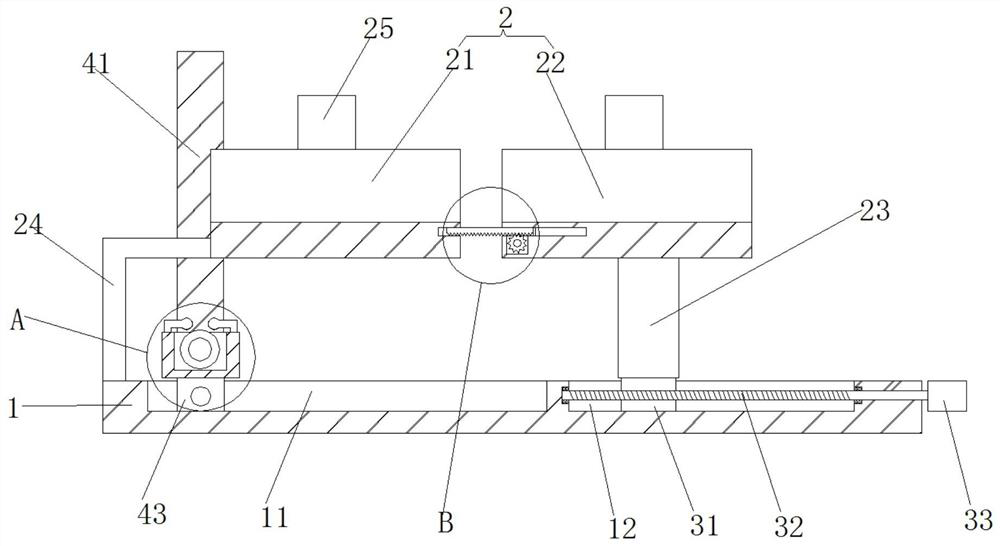

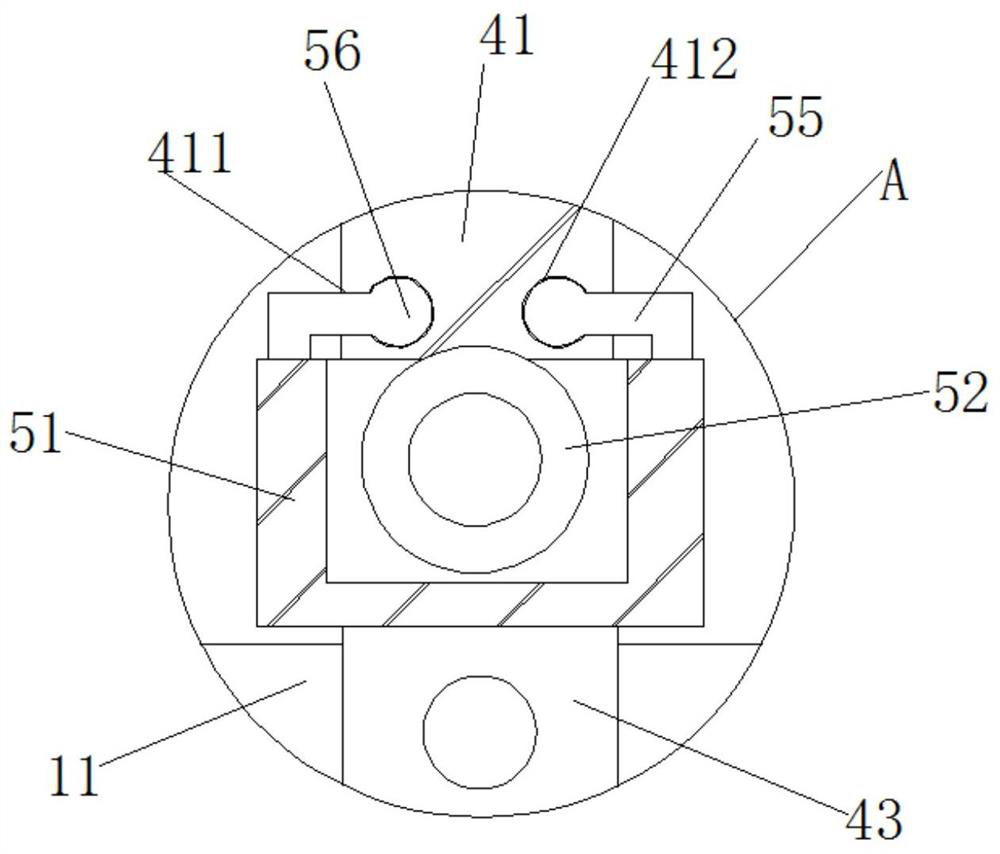

Welding rod shearing machine capable of adjusting shearing length

ActiveCN105904014AImprove shear efficiencyNo archingShearing machinesShearing machine accessoriesEngineeringMotor controller

The invention discloses a welding rod shearing machine capable of adjusting shearing length. The welding rod shearing machine aims at overcoming the defects that existing shearing equipment is inconvenient to adjust and operate the welding rod shearing length and low in shearing efficiency. The welding rod shearing machine comprises a rack, a PLC controller, a driving motor and a photoelectric encoder. A linear guide rail is installed on the rack. A lower installation base is slidably connected to the linear guide rail in a matched mode and provided with a plurality of vertical guide rods. An upper installation base is arranged above the lower installation base and connected to the vertical guide rods in a lifting and sleeving mode. A crank shaft is connected to the upper installation base and is in transmission connection with an output shaft of the driving motor. The lower installation base is provided with a clamping block used for clamping a welding rod. A lower blade is installed on the side surface of the clamping block. An upper blade is installed at the lower end of the upper installation base. A friction wheel used for making contact with the surface of the welding rod is installed on the photoelectric encoder. The driving motor is electrically connected with a motor controller. The motor controller and the photoelectric encoder are both electrically connected with the PLC controller.

Owner:HANGHOU ACAD OF MACHINERY SCI & TECHCO +1

Anti-crease cloth rolling device capable of automatically shearing for spinning

The invention relates to the technical field of textiles, and discloses an anti-crease cloth rolling device capable of automatically shearing for spinning. The device comprises a base, the top portionof the base is fixedly connected with a cloth rolling frame, the cloth rolling frame is internally provided with a vertical sliding groove, a transverse sliding groove, a sliding cavity and a mounting cavity, the top of the vertical sliding groove is fixedly connected with a pressure spring, the bottom of the pressing spring is fixedly connected with a pressing sliding block, a pressing shaft ismovably connected to the interior of the pressing sliding block, the outer portion of the pressing shaft is movably connected with a pressing roller, the interior of the transverse sliding groove is movably connected with a disassembly and assembly sliding block, and a first cloth winding shaft is movably connected into the dismounting and mounting sliding block, and a mounting piece is fixedly connected to the outer portion of the first cloth winding shaft. Through cooperative use of the pressing spring and the pressing roller, cloth is always jacked and rolled, so that the cloth is preventedfrom wrinkling and overlapping, and the quality of the cloth is improved.

Owner:黄泽

Inflatable binding and fixing device for traumatic orthopedics department

PendingCN114366449ARelieve painAvoid secondary damageNursing accommodationBandagesOrthopedic departmentMechanical engineering

The invention provides an inflatable bandaging fixing device for traumatic orthopedics. The inflatable bandaging fixing device comprises a base, according to the supporting and fixing device, a front supporting bracket is erected on the front side of the upper end of a base through an inverted-L-shaped support, a rear supporting bracket is arranged on the rear side of the upper end of the base in a sliding mode through a supporting rod, and the supporting rod is fixedly connected with the base through a first sliding positioning assembly; the binding device comprises an annular binding ring, a bandage winding device arranged on the inner wall of the annular binding ring and a binding ring driving mechanism arranged at the lower end of the outer wall of the annular binding ring, and the bottom end of the binding ring driving mechanism is slidably arranged on the base through a first sliding block; the annular binding ring can slide back and forth in a non-contact mode on the transverse plate of the inverted-L-shaped support and the periphery of the front supporting bracket. And the shearing device is fixedly arranged at the lower end of the bandage winding device. Possible secondary injury to the affected limb is effectively avoided, and pain of a patient is relieved; the operation standardization is high, the operation is convenient and fast, the manpower is saved, and the binding efficiency and the binding quality are greatly improved.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Zipper cutting-off machine

ActiveCN110154107AShear speed is fastImprove shear efficiencySlide fastenersMetal working apparatusMechanical engineeringEngineering

The invention relates to a zipper cutting-off machine. The zipper cutting-off machine comprises a base, a belt feeding device, a belt guiding track, a pneumatic cutting device and belt drawing devices, wherein the belt feeding device, the belt guiding track, the pneumatic cutting device and the belt drawing devices are sequentially mounted on the base. The belt feeding device is mounted at the corresponding position of the feeding end of the belt guiding track. The pneumatic cutting device is mounted at the corresponding position of the discharging end of the belt guiding track. The two belt drawing devices are mounted at one side of the discharging end of the belt guiding track. By means of the zipper cutting-off machine, a zipper can be cut conveniently; the production efficiency is improved; and the zipper cutting-off machine is suitable for large-scale production.

Owner:义乌市华灵拉链有限公司

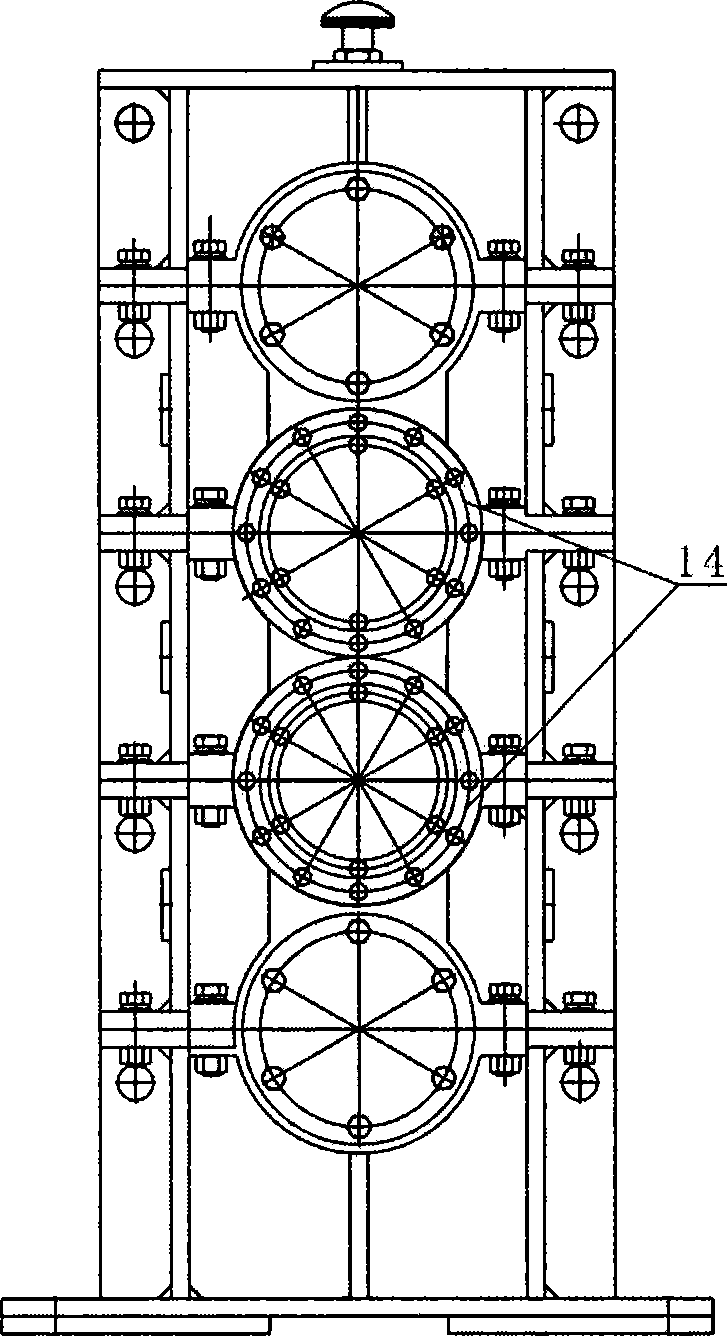

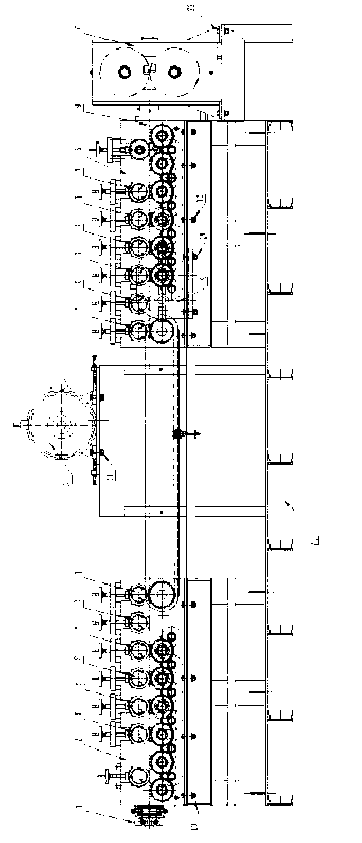

Multi-cutter disk type combined disk-shear

The present invention relates to a multi-cutter disk combined rotary shear, and is characterized by that on the machine frame of the rotary shear four pairs of cutter disks capable of shearing two side edges of the steel sheet simultaneously, its upper and lower cutter disks are equipped with gap-regulating mechanism and coincidence-regulating mechanism, and the front portion and back portion of the rotary shear are equipped with strong pinch roll respectively, every pair of cutter disks is equipped with press roll, and on left and right two machine frames of the rotary shear the electric screw-rod device is mounted respectively. Said invention can continuously shear the sheet steel whose thickness is up to 40-50 mm.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

Reinforcement steel bar no-twist straightening shearing machine

A reinforcement steel bar no-twist straightening shearing machine comprises a straightening assembly, a dragging assembly, a shearing assembly and a dynamic assembly. The straightening assembly is arranged before the dragging assembly, the shearing assembly is arranged after the dragging assembly, and the dynamic assembly is arranged between the straightening assembly and the dragging assembly. The dragging assembly is provided with a dragging wheel set and an acceleration chain wheel, wherein the dragging wheel set is connected with the output end of the dynamic assembly, and the acceleration chain wheel is driven by the dragging wheel set. The straightening assembly is provided with a deceleration chain wheel and an aligning wheel set, wherein the deceleration wheel is connected with the acceleration chain wheel of the dragging assembly, the straightening assembly is driven by the deceleration chain wheel, and the number of teeth of the deceleration chain wheel is larger than that of the acceleration chain wheel. The dragging wheel set and the straightening wheel set both are provided with a plurality of pairs of plane anti-twist wheels and groove location wheels, wherein the plurality of pairs of plane anti-twist wheels and groove location wheels are arranged at intervals, an outer circle of each plane anti-twist wheel is a smooth cylindrical surface, a rectangular narrow slit used for passage of a reinforcement steel bar is formed between each pair of plane anti-twist wheels and prevents the reinforcement steel bar from twisting. An outer circle of each groove location wheel is a cylindrical surface with an annular groove, and a circular channel is formed between each pair of groove location wheels and used for passage of the reinforcement steel bar and locating the reinforcement steel bar. The reinforcement steel bar no-twist straightening shearing machine utilizes the speed difference between the straightening assembly and the dragging assembly to enable the reinforcement steel bar to generate plastic deformation, and therefore the purpose of straightening the reinforcement steel bar is achieved.

Owner:广西国盾人防工程有限公司

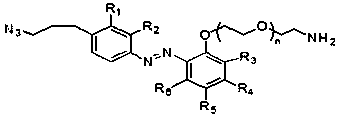

Fluorescence-labeled azo-modified nucleotide and application thereof in DNA sequencing

ActiveCN105085591AChange sensitivityImprove performanceSugar derivativesMicrobiological testing/measurementChemical reactionFluorescence

The invention discloses a fluorescence-labeled azo-modified nucleotide and application thereof in DNA sequencing. The nucleotide has a structural formula as shown in a formula I, wherein R1, R2, R3, R4, R5 and R6 may not synchronously be H, and m and n are integers of 0 to 10. Compared with the prior art, novel reversible terminators based on azo connection units are synthesized; a denaturing PAGE gel, i.e. a sequencing gel proves that the reversible terminators can only extend a reversible terminator at a time and has extension efficiency of 100% when a template is a plurality of continuous same basic groups; thus, under the action of a reducing agent, highly-efficient, rapid and full shearing can be realized, and great potential and value applied in the DNA sequencing are obtained; meanwhile, raw materials needed by synthesis of the azo-modified nucleotide are simple and easily available, and synthetic process is a conventional chemical reaction and can be used for popularization and application.

Owner:SHANGHAI JIAO TONG UNIV

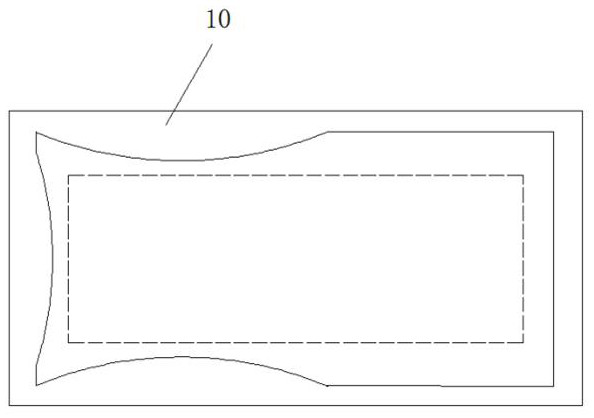

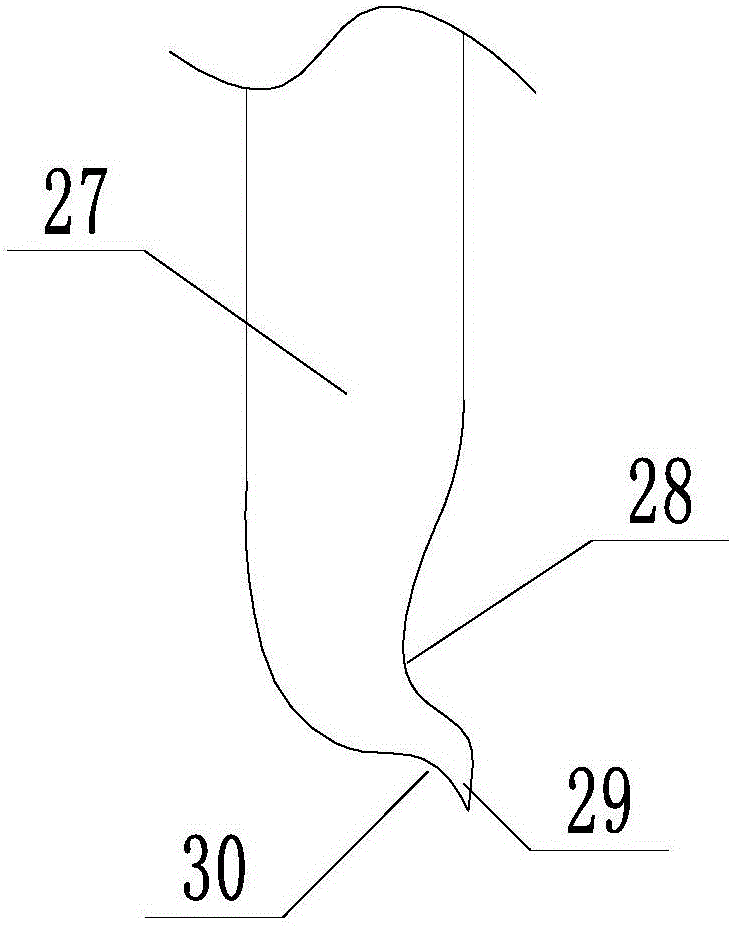

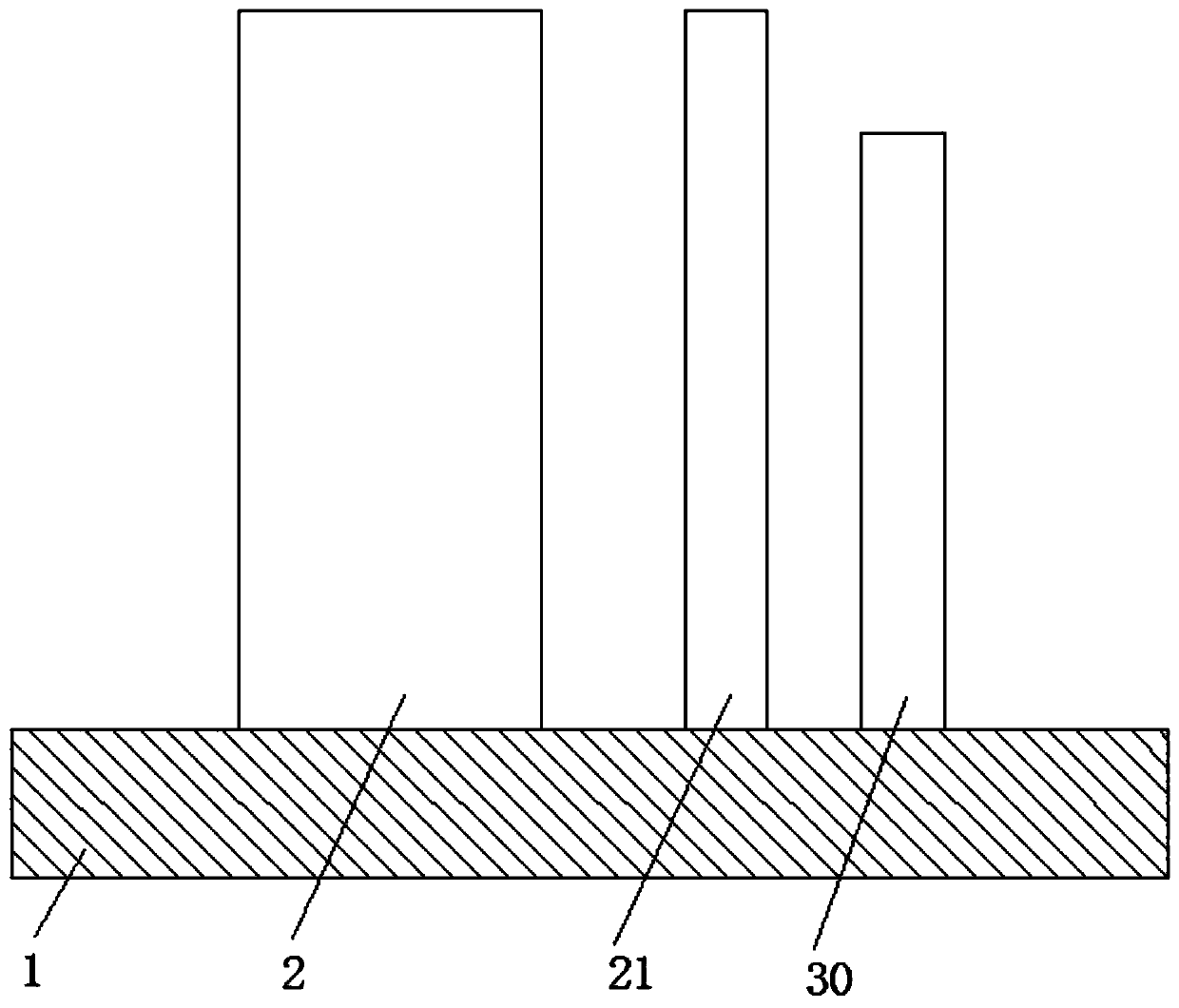

Sprue structure used for injection mold and injection mold

The invention relates to a sprue structure used for an injection mold and the injection mold. The sprue structure comprises a first-stage runner, a limiting sprue, a second-stage runner and a non-limiting sprue. A pouring port is arranged at one end of the first-stage runner, and an inlet connected with the limiting sprue is connected to the other end of the first-stage runner. An outlet of the limiting sprue is connected with the second-stage runner. An inlet of the non-limiting sprue is connected with the second-stage runner, and an outlet of the non-limiting sprue is connected with a forming cavity. The sectional area of the first-stage runner is larger than that of the second-stage runner, the sectional area of the inlet of the limiting sprue is larger than the sectional area of the outlet, and the sectional area of the inlet of the non-limiting sprue is smaller than that of the outlet. Compared with the prior art, plastic melt is subjected to acceleration and friction through thelimiting sprue, the temperature of the melt is increased, the ideal flowing state is achieved, the second-stage runner is rapidly full, and meanwhile the function of preventing the melt from flowing back is achieved; the melt in the second-stage runner is guided by the non-limiting sprue to fill the forming cavity, the phenomena of plastic eddies, turbulence and the like are not prone to being generated, and the forming quality of a final injection molded product is effectively improved.

Owner:MANSHENG PACKAGING SHANGHAI

Wet tissue outer packing double-station synchronous heat seal shearing mechanism and working method thereof

ActiveCN109606847AImprove heat sealing efficiencySimple structureWrapper twisting/gatheringEngineeringWorking set

The invention provides a wet tissue outer packing double-station synchronous heat seal shearing mechanism and a working method thereof. The wet tissue outer packing double-station synchronous heat seal shearing mechanism comprises a machine frame, wherein the machine frame is transversely provided with a group of flattening and conveying devices which are used for conveying strip-shaped wet tissueraw materials and clamping the strip-shaped wet tissue raw materials up and down, a transition conveying device is further arranged at the discharge ports of the flattening and conveying devices, andthe two ends of the transition conveying device are provided with two groups of double-heat seal head shearing devices which are synchronously meshed with the wet strip-shaped tissue raw materials and are matched with the strip-shaped wet tissue raw materials. The wet tissue outer packing double-station synchronous heat seal shearing mechanism is simple in structure, convenient to adjust and operate, and high in flexibility, and improves the heat sealing quality and has practicability.

Owner:FUZHOU UNIV

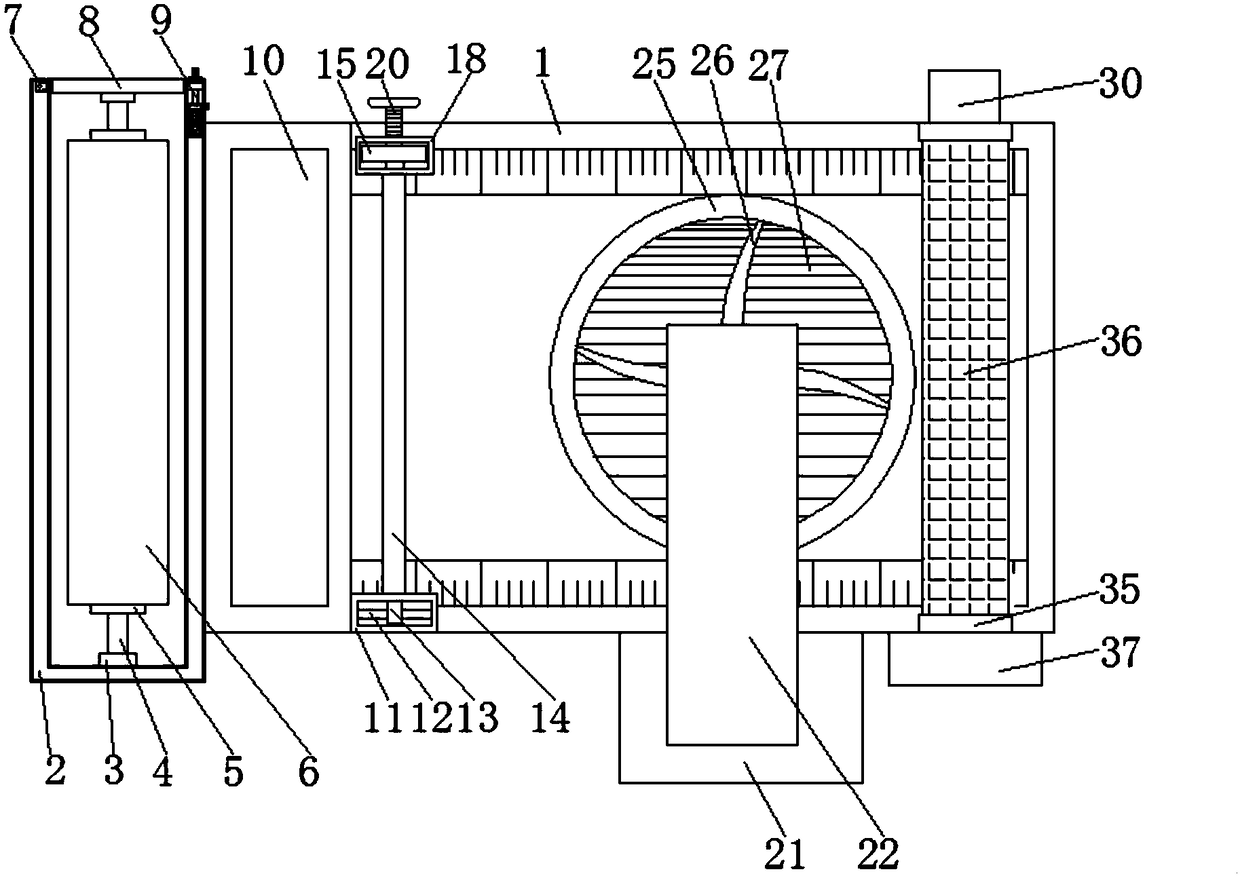

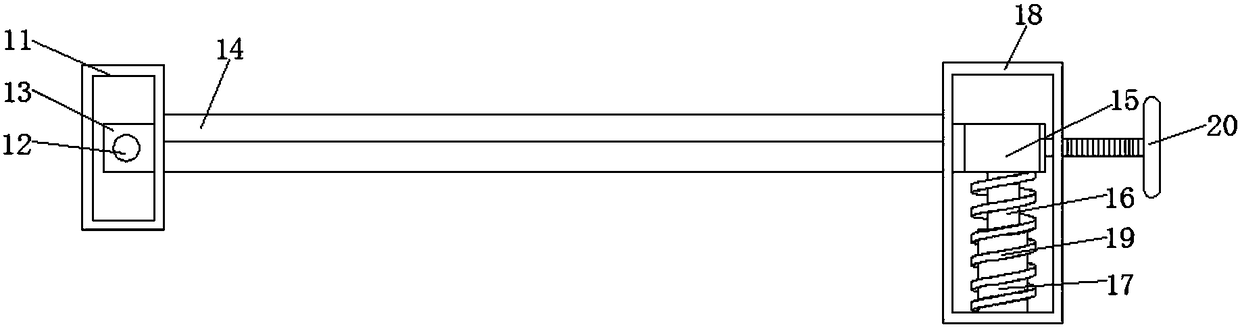

Apparel fabric cutting device

ActiveCN108914528BCropping effectImprove shear efficiencySevering textilesMechanical engineeringIndustrial engineering

The invention belongs to the technical field of garment processing machinery and specifically relates to a garment fabric cutting device. The device comprises a box body; the device also comprises a drive unit, a cutting unit and a cutting table; the drive unit is used for driving the cutting unit to cut fabric; the cutting unit is used for cutting fabric; the cutting table is used for providing cutting position for fabric. By means of the cooperation of the drive unit, the cutting unit and the cutting table, the fabric is cut by the cutting unit which is driven by the drive unit, which not only alleviates labor intensity, but also increases fabric cutting efficiency; at the same time, the power source generated in the drive unit during driving is utilized so that the source utilization rate is increased; the fabric scraps in the fabric cutting drops to the bottom of the box to avoid the fabric scraps affecting the cutting of the fabric, thus improving the cutting effect of the fabric.

Owner:浙江平步服饰股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com