Method for lowering content of magnesium in pentlandite concentrate

A technology of pentlandite and magnesium content, which is applied in the field of mineral separation, can solve the problems of high energy consumption, high MgO content, waste of resources, etc., achieve good separation selectivity, increase specific surface area, and reduce repulsion energy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

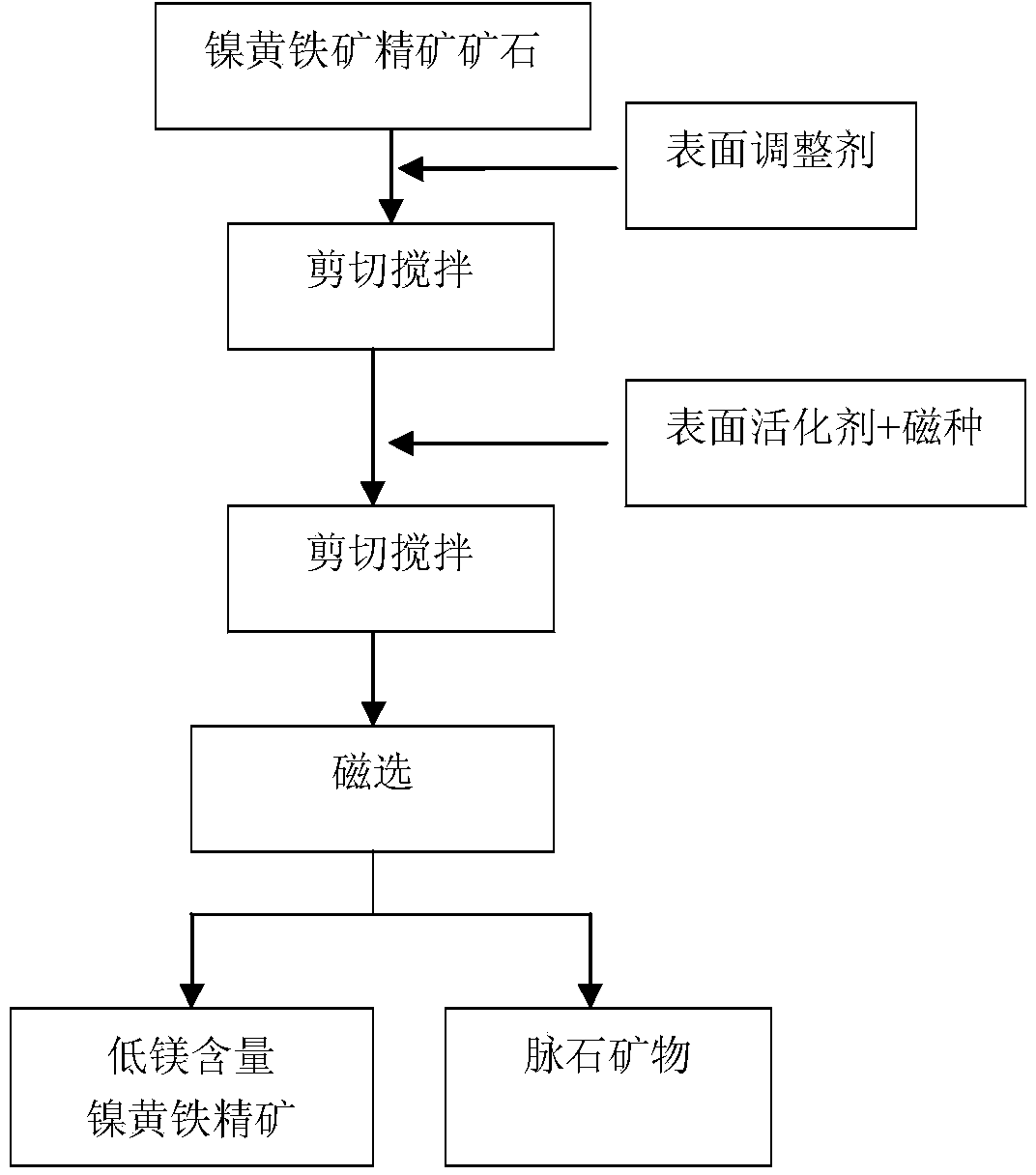

Image

Examples

Embodiment 1

[0033] The actual ore is Jinchuan low-grade pentlandite concentrate, containing 3.25% Ni, 9.49% pentlandite, 8.58% MgO, and 90% with a particle size of <0.075mm.

[0034] A method for reducing magnesium content in pentlandite concentrate, comprising the following steps:

[0035] 1. Disperse pulp

[0036] Add 100g of low-grade pentlandite concentrate to 400mL of water, mix well, pour it into a high-speed shear mixer at a speed of 1500r / min, adjust the pH value of the slurry to 10.5-11.0 with sodium carbonate while stirring; Add 20mg of sodium hexametaphosphate to the mixture, the rotation speed is 1500r / min, shear and stir for 5min, so that the pulp is evenly dispersed;

[0037] 2. Add magnetic seeds and surfactants

[0038] Add 4g of magnetite powder with a particle size of <10μm, 10mg of oleic acid and 10mg of kerosene to the stirred and dispersed pulp; adjust the rotation speed to 1200r / min, and shear and stir for 4min;

[0039] 3. Magnetic separation

[0040] Pour the o...

Embodiment 2

[0052] 1. Disperse pulp

[0053] Mix pentlandite concentrate and serpentine pure minerals according to the mass ratio of 1:1 to obtain artificial mixed ore; add 70g of mixed ore to 200mL of water, mix well, put it into a high-speed shear mixer, and the speed is 2500r / Min, while stirring, use sodium bicarbonate to adjust the pH value of the pulp between 10.0 and 10.5; then add 35 mg of sodium hexametaphosphate to the pulp, at a speed of 2500 r / min, shear and stir for 3 minutes, so that the pulp is evenly dispersed;

[0054] 2. Add magnetic seeds and surfactants

[0055] Add 3.5g of magnetite powder with a particle size of <10μm, 17.5mg of oleic acid and 17.5mg of kerosene to the stirred and dispersed pulp; adjust the speed to 1500r / min, and shear and stir for 6min;

[0056] 3. Magnetic separation

[0057] Pour the ore slurry stirred in step 2 into the feeding cylinder of the XCSQ-50×70 wet strong magnetic machine, and set the background magnetic field strength to 6.5×10 5 A...

Embodiment 3

[0060] 1. Disperse pulp

[0061] Mix pentlandite concentrate and serpentine pure minerals according to the mass ratio of 2:1 to obtain artificial mixed ore; add 100g of mixed ore to 300mL of water, mix well, and put it into a high-speed shear mixer with a speed of 2200r / Min, while stirring, use sodium carbonate to adjust the pH value of the pulp between 9.5 and 10.0; then add 40mg of water glass to the pulp, the speed is 2200r / min, shear and stir for 5min, so that the pulp is evenly dispersed;

[0062] 2. Add magnetic seeds and surfactants

[0063] Add 4g titanomagnetite powder with a particle size of <10μm, 20mg oleic acid and 20mg kerosene to the stirred and dispersed pulp; adjust the rotation speed to 1300r / min, and shear and stir for 5min;

[0064] 3. Magnetic separation

[0065] Pour the ore slurry stirred in step 2 into the feeding cylinder of XCSQ-50×70 wet strong magnetic machine, set the background magnetic field strength to 5.0×10 5 A / m, for magnetic separation t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com