V-Ce-Ti (vanadium-cerium-titanium) catalyst for joint denitrification to remove dioxin

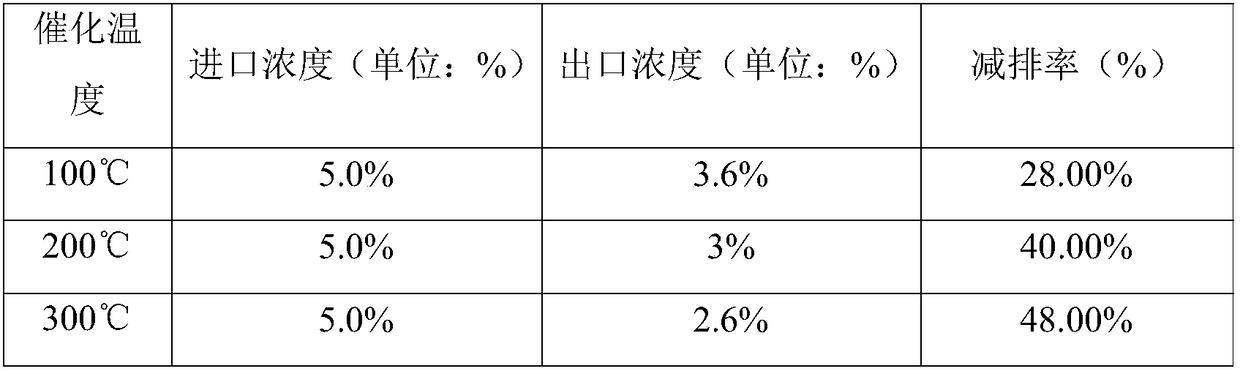

A technology for removing dioxins and v-ce-ti, which is applied in the field of V-Ce-Ti catalysts, can solve the problems of catalysts that are difficult to catalyze degradation of NOx and dioxins, and catalyst environmental pollution, so as to reduce emissions and reduce production cost, effect of avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A V-Ce-Ti catalyst for combined denitrification and dioxin removal of the present invention, the V-Ce-Ti catalyst is V a Ce b Ti c o x Catalyst is made by sol-gel method in one step, wherein the oxide mass ratio of V and Ce is 0.5 to 1, and the oxide mass ratio of Ce and Ti is 0.05 to 0.16. is measured, the measured V a Ce b Ti c o x The specific surface area of the catalyst is 95.7219m 2 / g; In the present embodiment, the mass ratio of V and Ce is 1, and the mass ratio of Ce and Ti is 18, V a Ce b Ti c o x The mass ratio of V, Ce, and Ti oxides in the catalyst is 1:1:18.

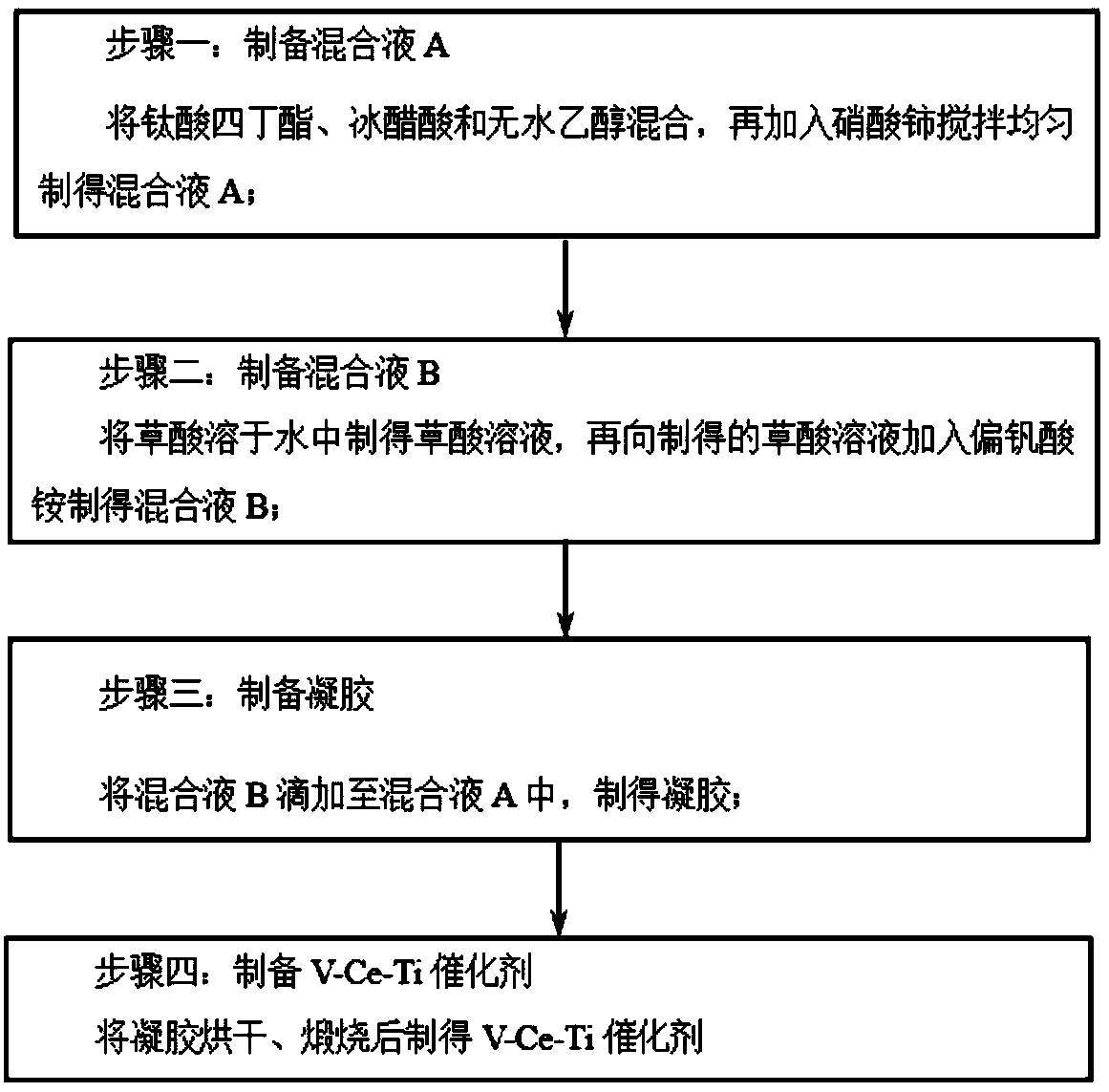

[0035] A kind of preparation method of the V-Ce-Ti catalyst of combined denitrification and dedioxin as described above comprises the steps:

[0036] Step 1, mixing tetrabutyl titanate, glacial acetic acid and absolute ethanol, then adding cerium nitrate and stirring evenly to obtain mixed solution A;

[0037] Step 2, dissolving oxalic acid in water to obtain an oxalic acid solution, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com