Method for preparing semi-solid metal or alloy

A semi-solid metal and alloy technology, applied in the field of metal or alloy casting, can solve the problems of limited grain refiner, low efficiency, long preparation process, etc., to solve the problem of uneven crystal nucleus dispersion, short process flow and simple equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

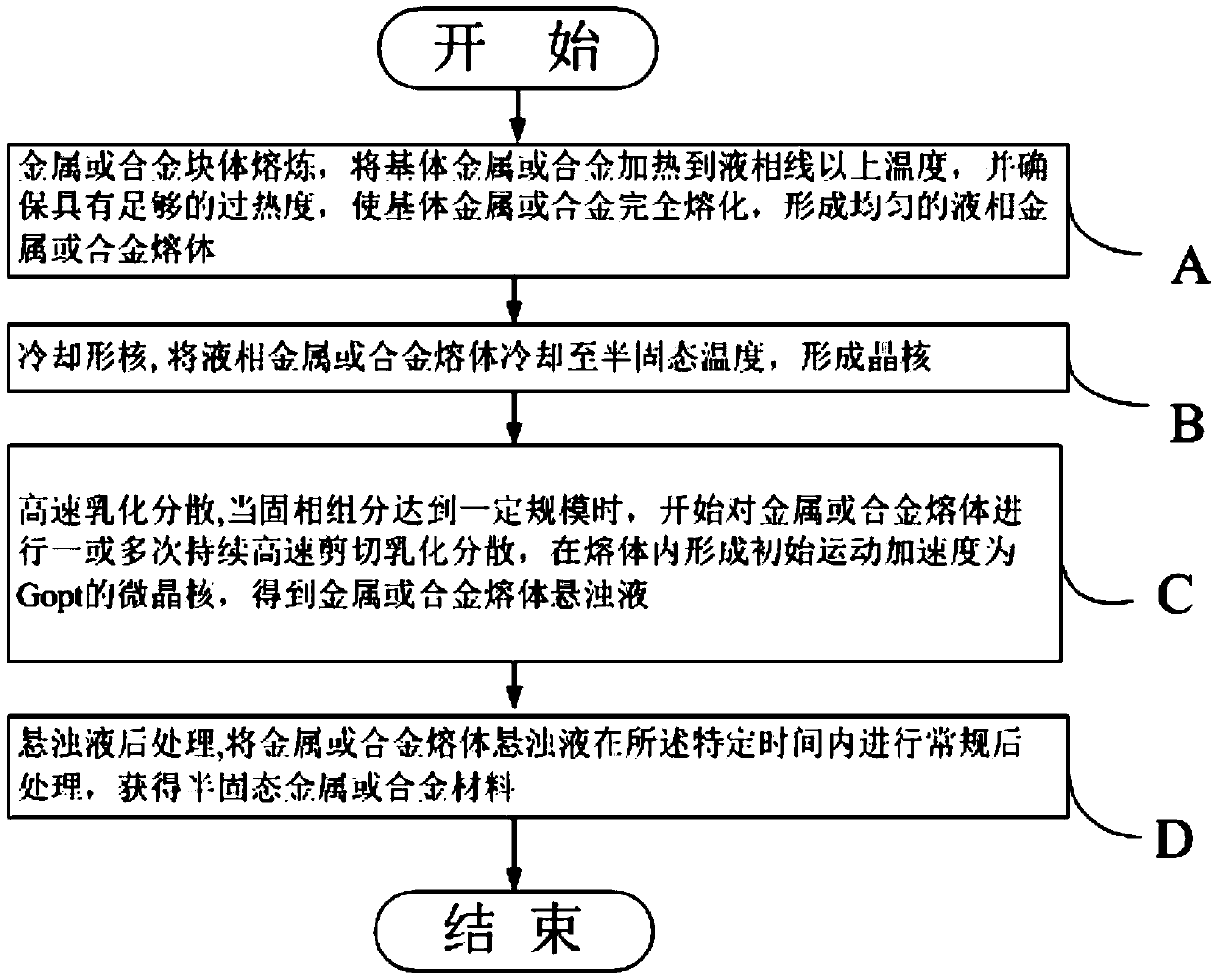

[0023] Such as figure 1 Shown, the present invention provides a kind of preparation method of semi-solid metal or alloy, comprises the following steps:

[0024] A. Metal or alloy bulk smelting, heating the base metal or alloy to a temperature above the liquidus line, and ensuring sufficient superheat to completely melt the base metal or alloy to form a uniform liquid metal or alloy melt; B. .Cooling nucleation: cooling liquid phase metal or alloy melt to semi-solid temperature, and start to form crystal nuclei; C. High-speed emulsification dispersion: when the solid phase components including crystal nuclei in metal or alloy melt (comprising When the crystal nuclei and the dendrites growing on the crystal nuclei) reach a certain scale, the melt is continuously subjected to high-speed shear emulsification and dispersion for one or more times to realize the crushing and dispersion of the newly formed crystal nuclei in the melt. Form the crystallite nuclei whose initial motion a...

Embodiment 1

[0033] The preparation method of embodiment 1 semi-solid aluminum-copper alloy X1

[0034] Place the aluminum-copper alloy ingot in a graphite melting furnace and heat it to 700°C under the protection of a nitrogen atmosphere; after the alloy ingot is completely melted, cool it to 630°C; when the solid phase component in the alloy melt reaches 40%, the graphite The emulsification head of the high-speed shear emulsification disperser extends into the melt, turns on and gradually increases the speed to a line speed of 60m / s, and continuously breaks up the formed crystal nuclei into microcrystalline nuclei with a diameter of 50-70nm within 30 minutes. And the initial acceleration of the de-emulsification and dispersion equipment of the microcrystalline nuclei reaches 30G; then the aluminum-copper alloy melt suspension is poured into the extrusion casting mold for rheological molding, and a semi-solid aluminum alloy special-shaped casting is obtained after 60 minutes.

[0035] Tes...

Embodiment 2

[0036] Embodiment 2 The preparation method of semi-solid magnesium aluminum alloy X2

[0037] Place 2kg of magnesium-aluminum alloy ingot in a graphite melting furnace and heat it to 650°C under the protection of argon atmosphere; after the alloy ingot is completely melted, cool it to 480°C; when the solid phase component in the alloy melt reaches 60%, Extend the emulsification head of the graphite high-speed shear emulsification disperser into the melt, turn it on and gradually increase the speed to a line speed of 40m / s, break up the formed crystal nuclei into microcrystalline nuclei with a diameter of 80-100nm, and make The initial acceleration of the de-emulsification and dispersion equipment for microcrystalline nuclei is 100G; after 20 minutes of high-speed shear emulsification and dispersion, the magnesium-aluminum alloy melt suspension is poured into the mold, and the circulating water is used for rapid cooling; the cooled ingot is passed through cutting, cleaning and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com