Multi-cutter disk type combined disk-shear

A technology of disc shears and multi-cutter discs, which is applied in the direction of shearing equipment, shearing devices, metal processing equipment, etc., can solve problems such as inability to shear, and achieve the effect of fast shearing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

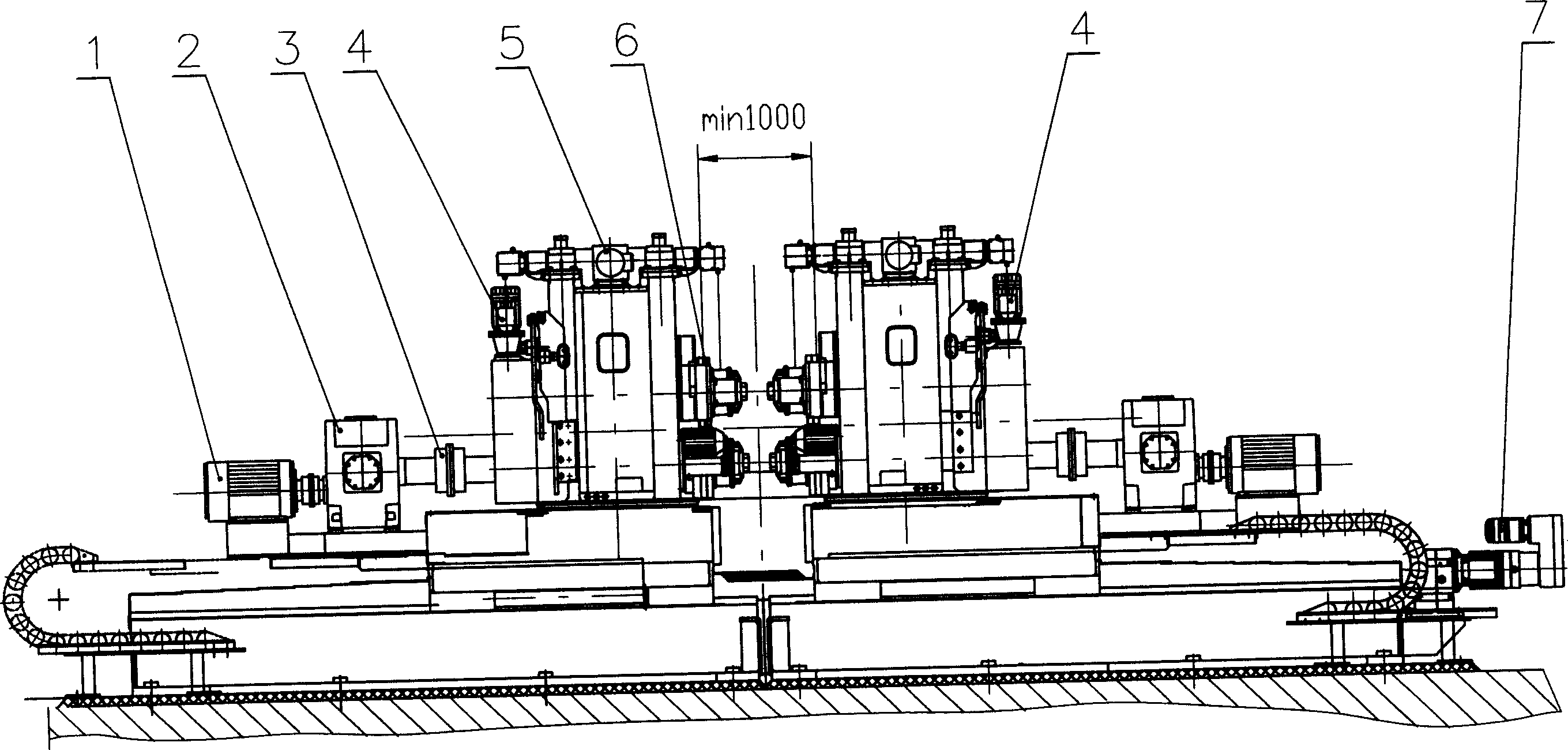

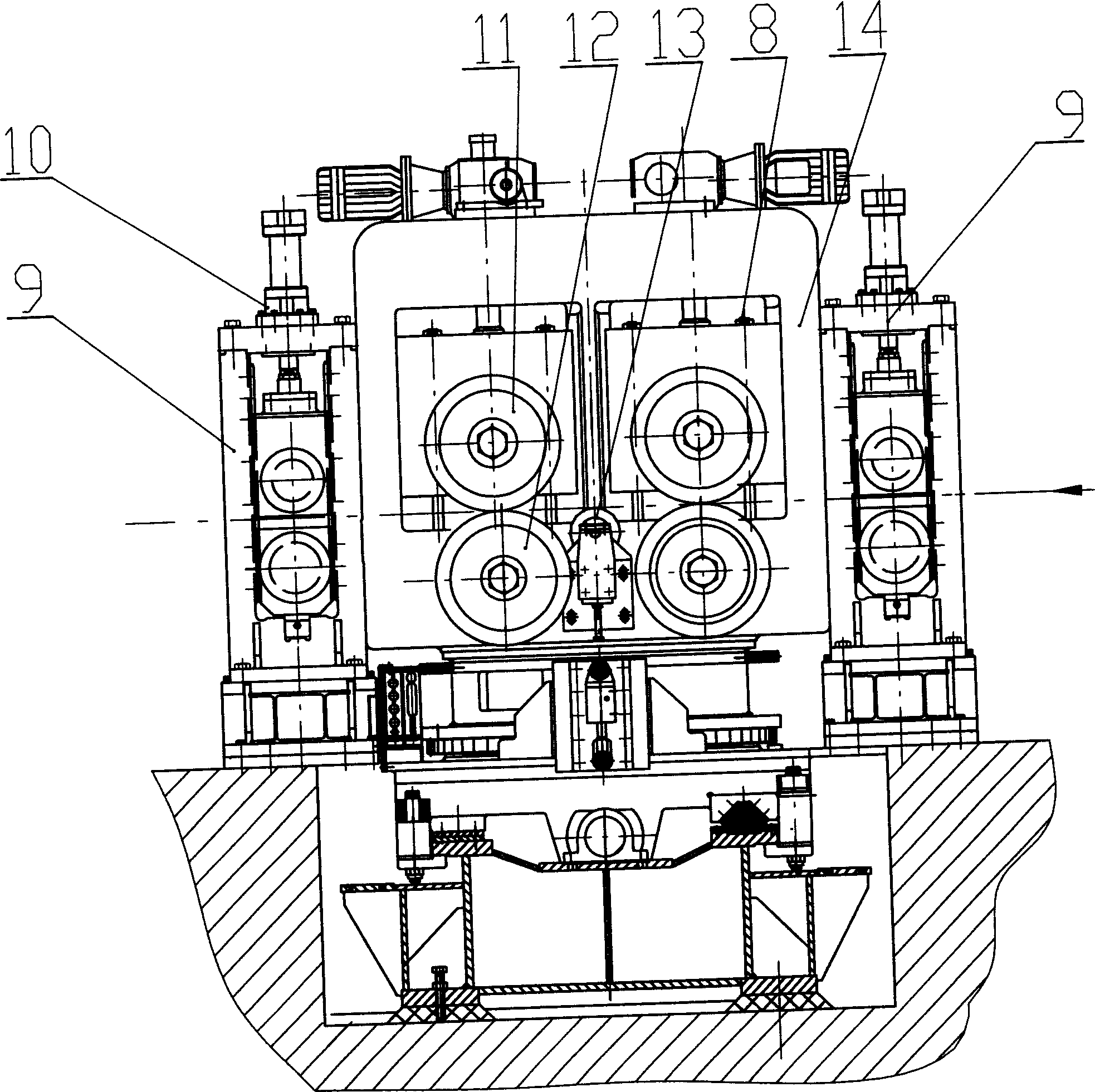

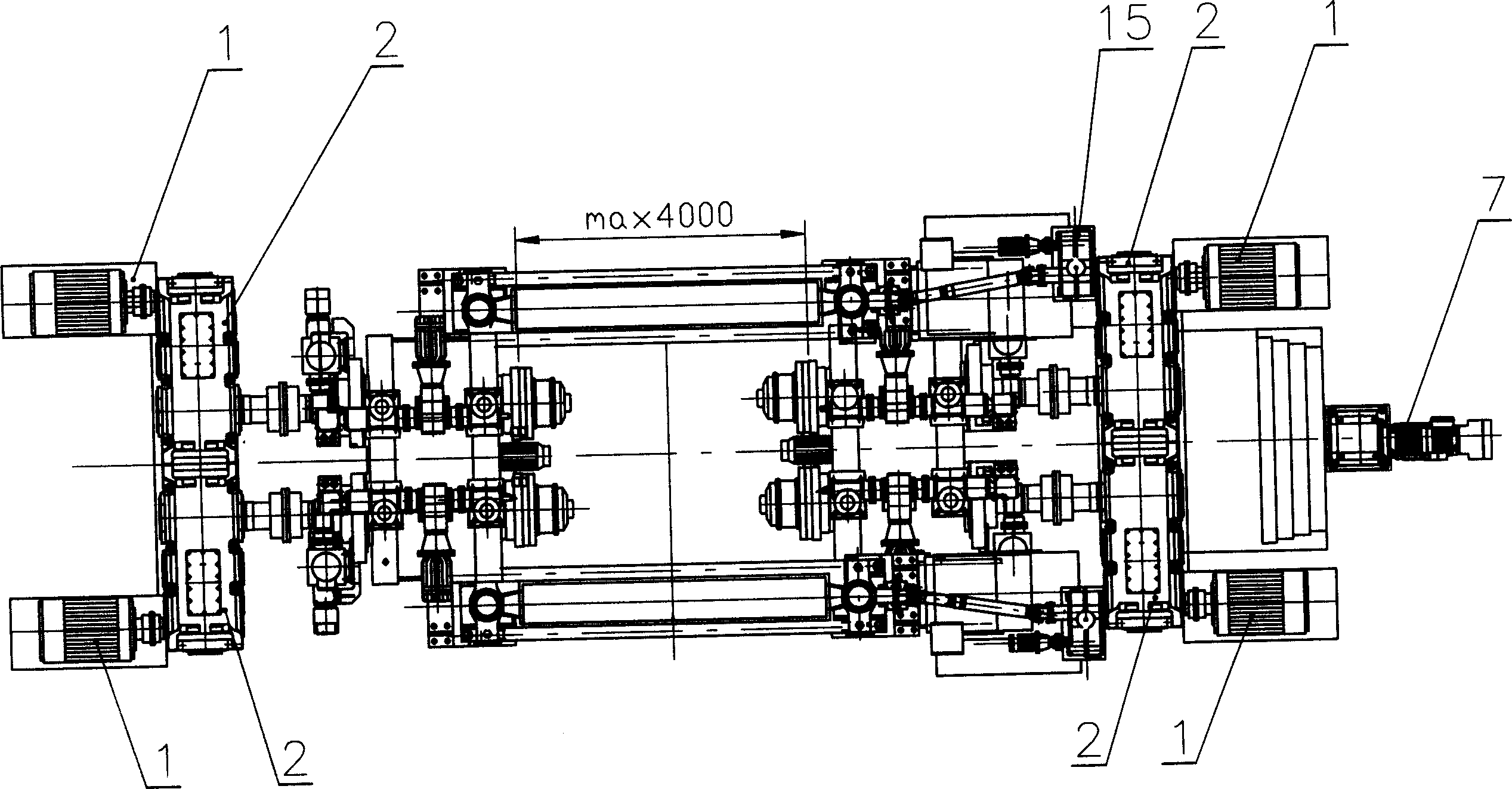

[0016] see figure 1 , figure 2 , image 3 , four pairs of cutterheads (upper cutterhead device 11 and lower cutterhead device 12) are installed in the disc shear frame 14 to cut the two sides of the steel plate together. Tangentially cut steel plate. Because the thickness of the sheared steel plate is relatively large, there are powerful pinch rollers 9 installed before and after the disc shears, which are hydraulically balanced and hydraulically depressed powerful pinch roller devices, and its function is to make the steel plate easily enter between the upper and lower cutter heads, It can also increase the rigidity during the movement of the steel plate so that the shearing process can be carried out stably. Each pair of cutterheads is provided with a pressure roller mechanism 6 at the upper cutterhead 11. The moving mechanism 7 of the left and right frames of the disc shears is equipped with an electric screw device, which is composed of a motor, a reducer, a screw nut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com