Sprue structure used for injection mold and injection mold

An injection mold and gate technology, applied in the field of mold injection technology, can solve the problems of inability to fill the molding cavity of molten plastic, poor plastic fluidity, flow marks of molded products, etc. The effect of reducing the generation of streaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

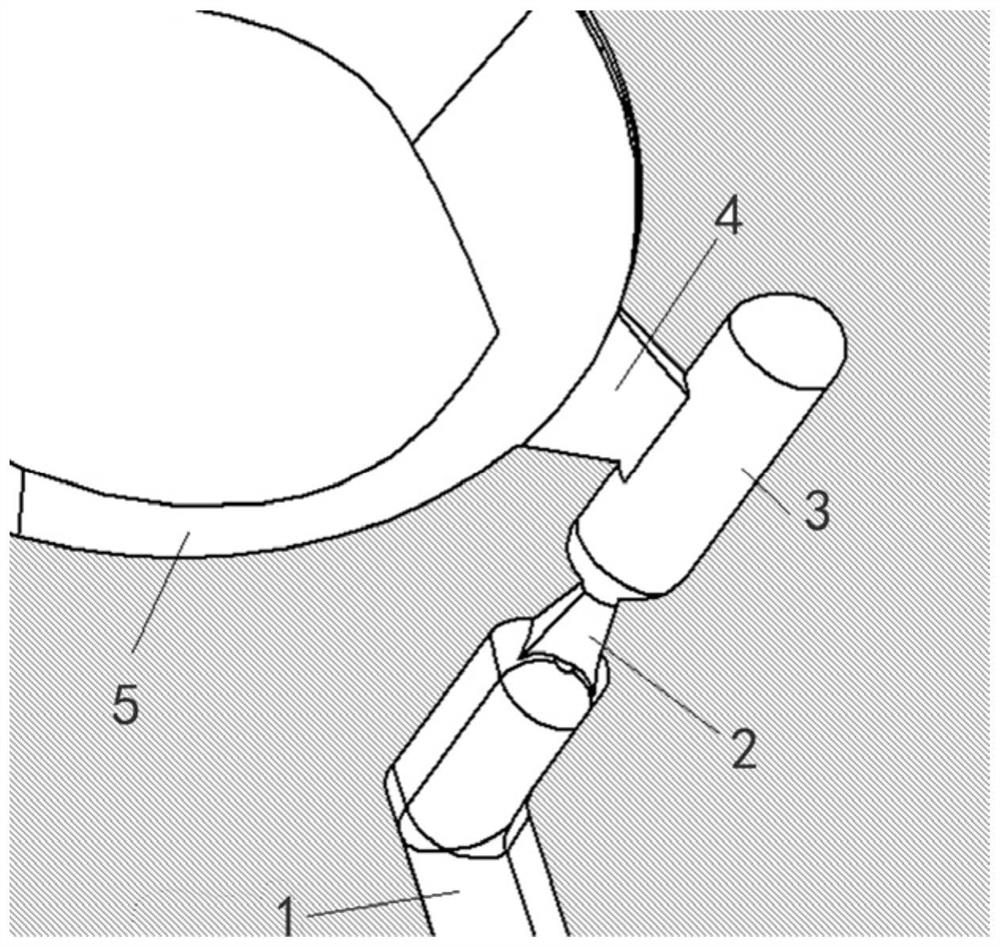

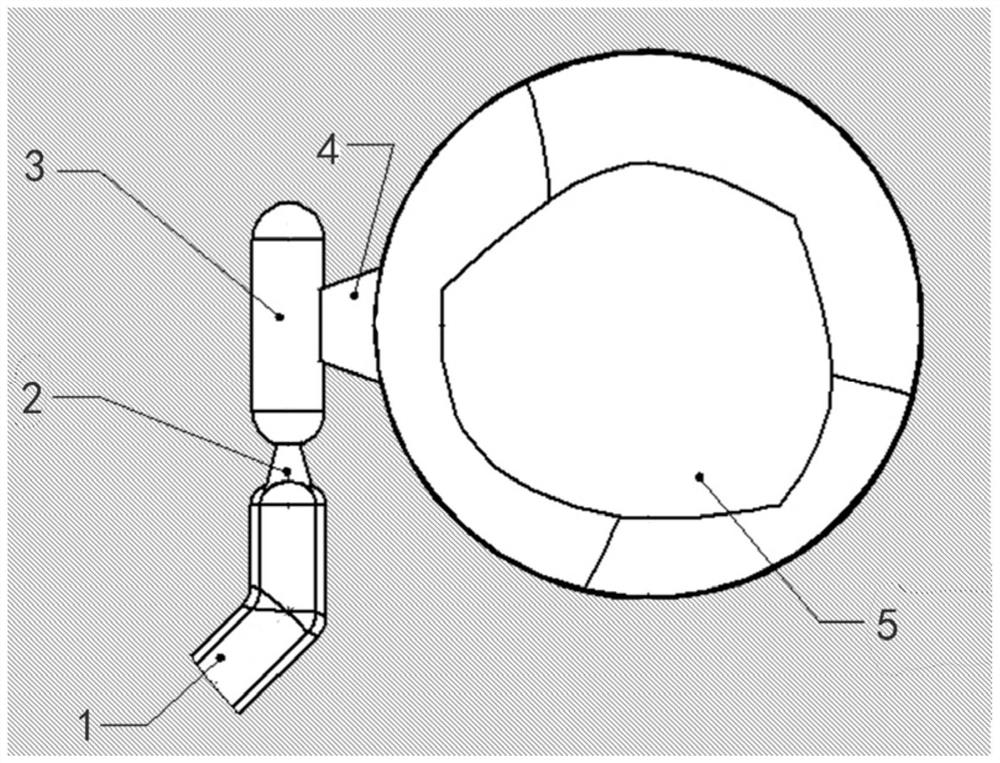

[0028] Such as figure 1 with figure 2 As shown, this embodiment provides a gate structure for an injection mold, which includes a primary runner 1, a restricted gate 2, a secondary runner 3, and an unrestricted gate 4. One end of the primary runner 1 is a pouring port, the other end is connected to the inlet of the restriction gate 2, and the outlet of the restriction gate 2 is connected to the secondary runner 3. The secondary runner 3 is connected to the molding cavity 5 through an unrestricted outlet. Specifically, the inlet of the unrestricted gate 4 is connected to the center of the side wall of the secondary runner 3 and the outlet is connected to the molding cavity 5.

[0029] The restriction gate 2 is a cone, the outlet of the restriction gate 2 is arranged at the top end of the cone, and the inlet of the restriction gate 2 is arranged at the bottom end of the cone. The cross-sectional area of the inlet of the gate 2 is restricted to be larger than the cross-sectional ...

Embodiment 2

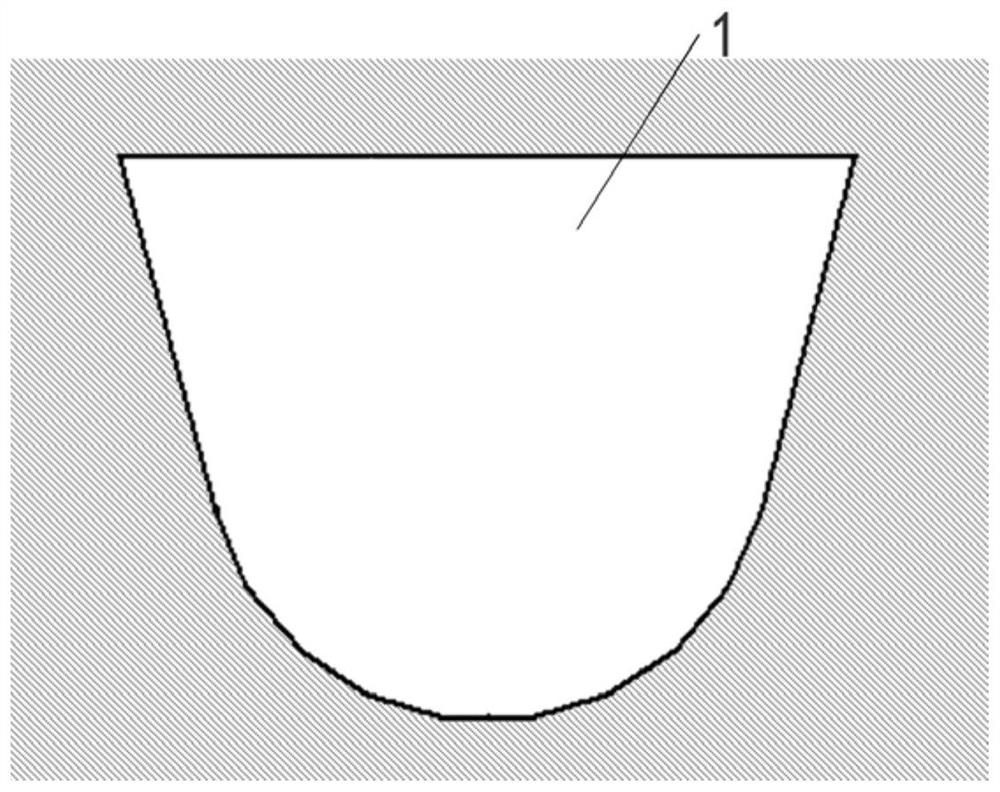

[0033] Such as Figure 5 As shown, this embodiment provides an injection mold, which includes four gate structures disclosed in the first embodiment. The product geometry of the injection mold is irregular wall thickness, the outer diameter is round, and 100% PMMA is used. Therefore, the product has requirements for transparency, high quality requirements for appearance, and no appearance problems such as flow marks, bubbles and cold materials.

[0034] In this embodiment, the four molding cavities are arranged in a row and the four gate structures are arranged in a cross shape to achieve overall flow channel balance. The pouring ports of the primary runners of all gate structures are connected and located in the center of the mold, so that the melt can evenly enter each gate structure through a pouring port, so that the plastic melt can be quickly and evenly filled into the molding cavity. Get qualified products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com