Welding rod shearing machine capable of adjusting shearing length

A technology for shearing machines and welding rods, which is applied in the direction of shearing devices, attachments of shearing machines, knives for shearing machines, etc. It can solve the problems of low shearing efficiency, inconvenient adjustment and operation, etc., and achieve high shearing efficiency , Easy to adjust and ensure the effect of reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

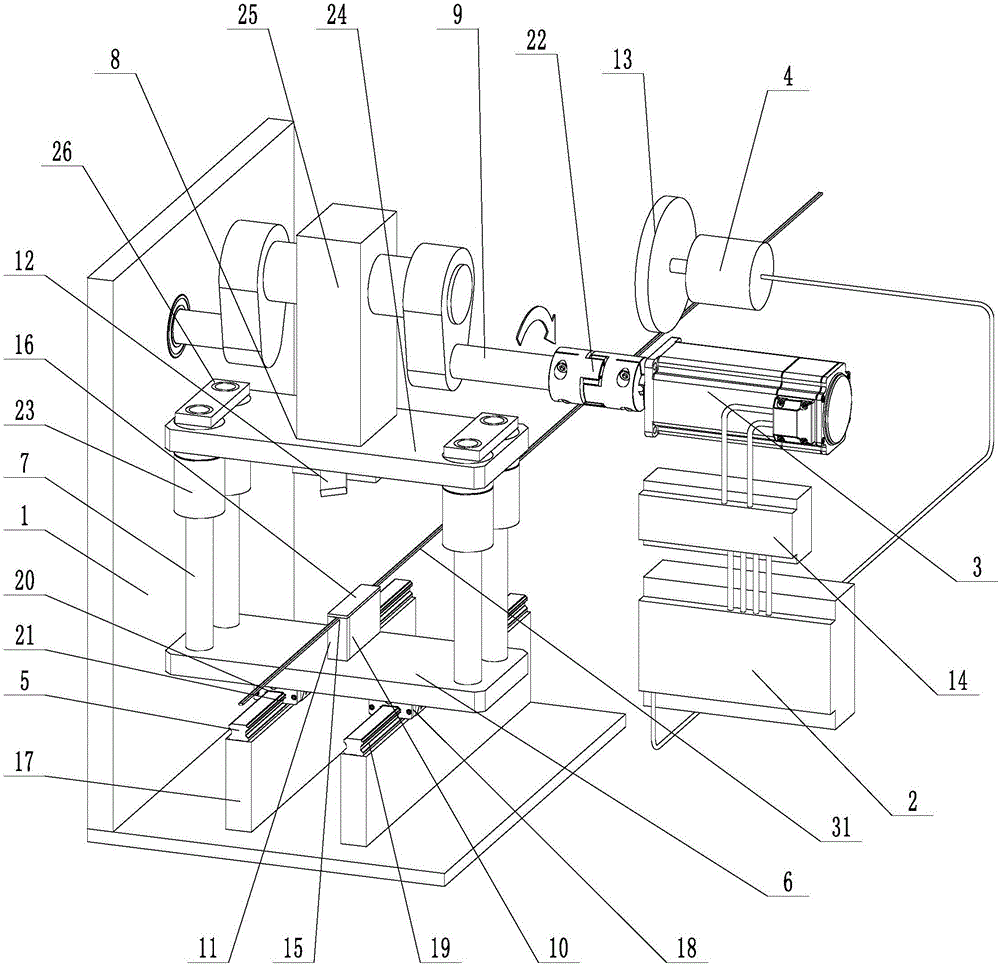

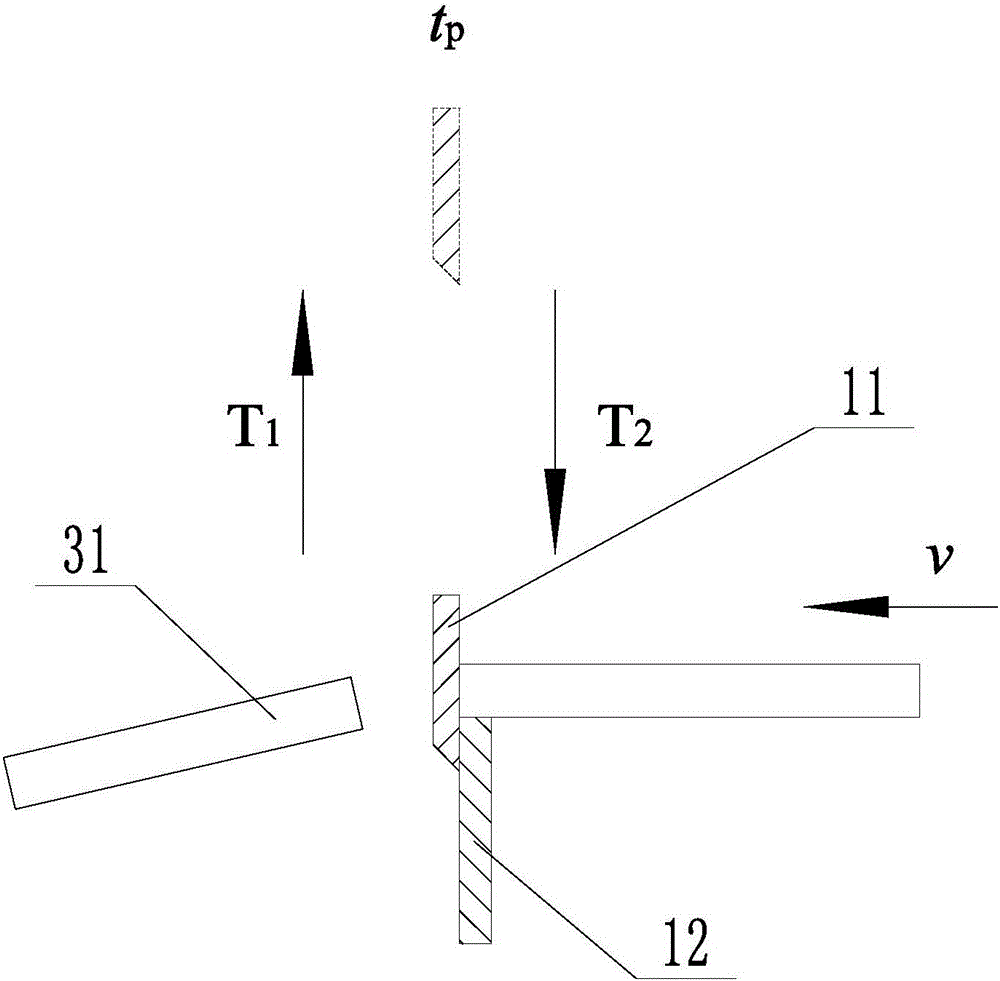

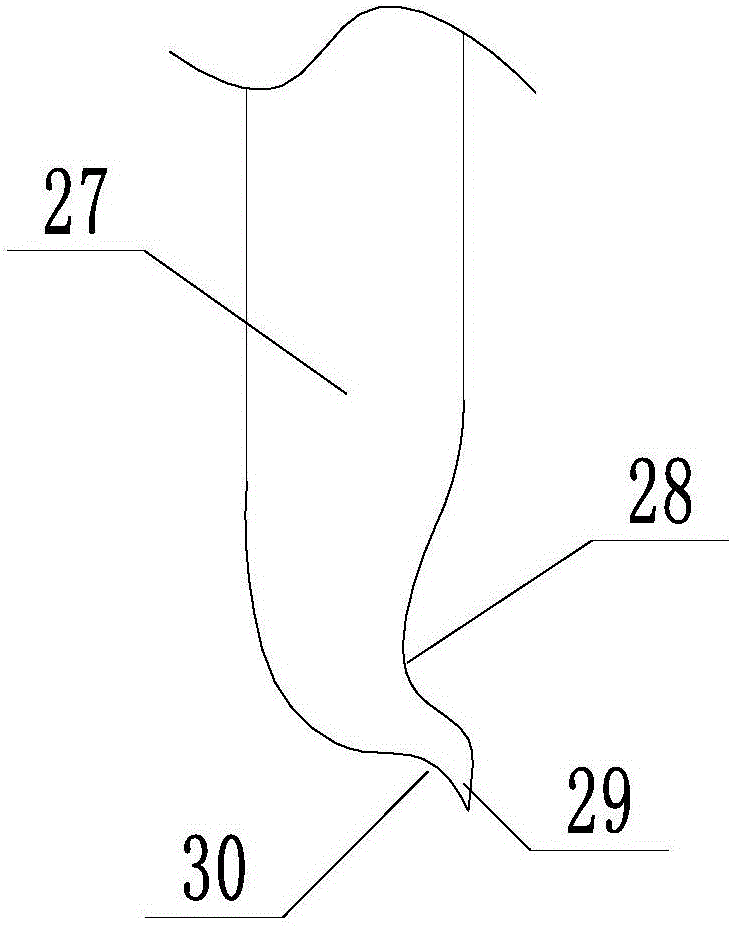

[0021] Embodiment: a kind of electrode cutter with adjustable cutting length (see attached figure 1 , attached figure 2 ), including frame 1, PLC controller 2, drive motor 3, and photoelectric encoder 4. The frame is in an L-shaped structure, and a linear guide rail 5 is installed on the frame. The linear guide rail is installed on the bottom surface of the frame, and the linear guide rail can be The sliding adapter is connected with the lower mounting seat 6, and the bottom surface of the frame is fixedly connected with two supporting vertical plates 17 arranged in parallel, and two linear guide rails are installed on the two supporting vertical plates respectively. There are two sliding guide bars 18 correspondingly connected to the linear guide rail on the lower surface of the lower mounting seat, and concave guide grooves 19 are provided on both outer surfaces of the linear guide rail, and sliding guide bars adapted to the linear guide rail are provided on the lower surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com