Feather positioning and trimming device for badminton production

A trimming device and badminton technology, applied in the direction of sports accessories, etc., can solve the problems of unusable feathers, feathers that cannot be leveled, and low trimming efficiency, so as to achieve the effects of improving shearing efficiency, improving efficiency, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

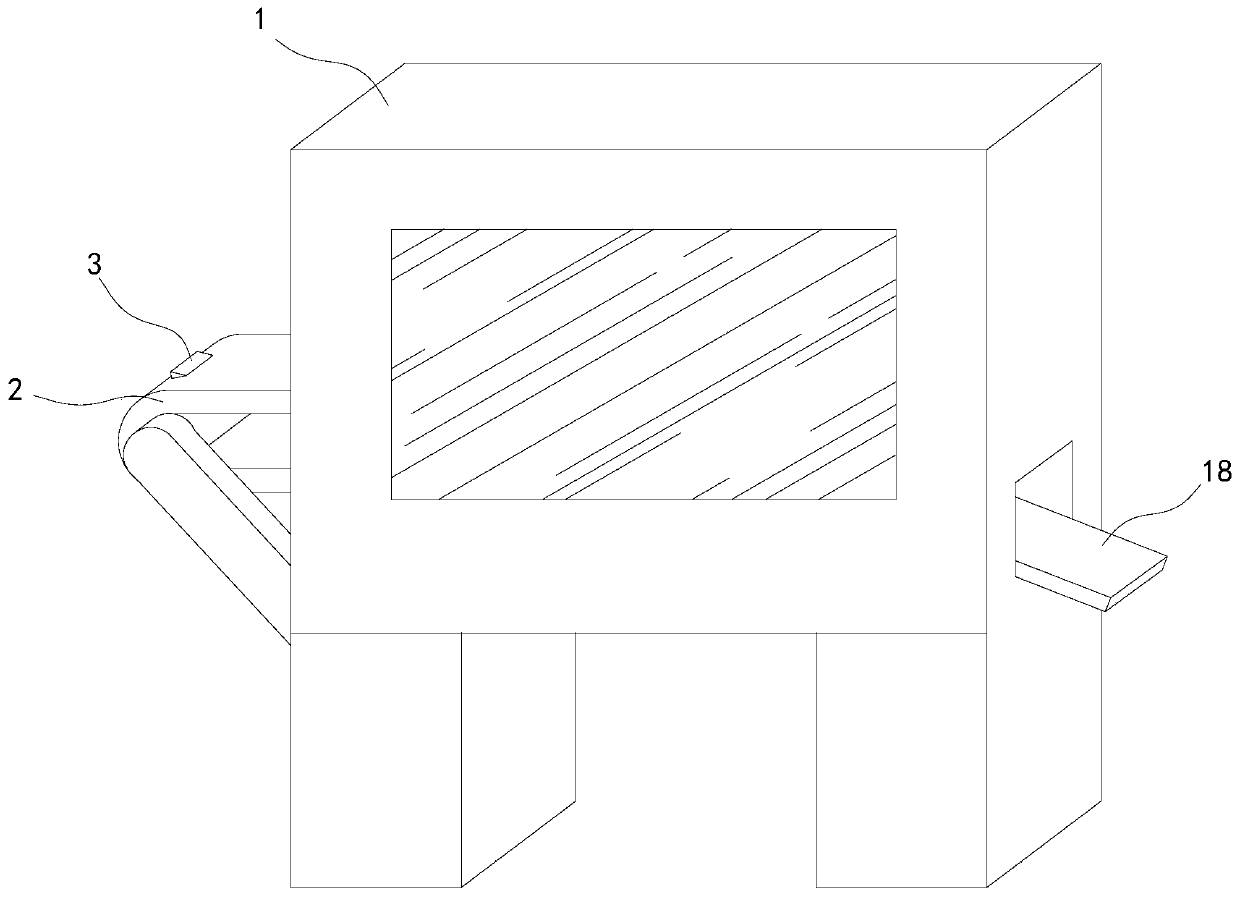

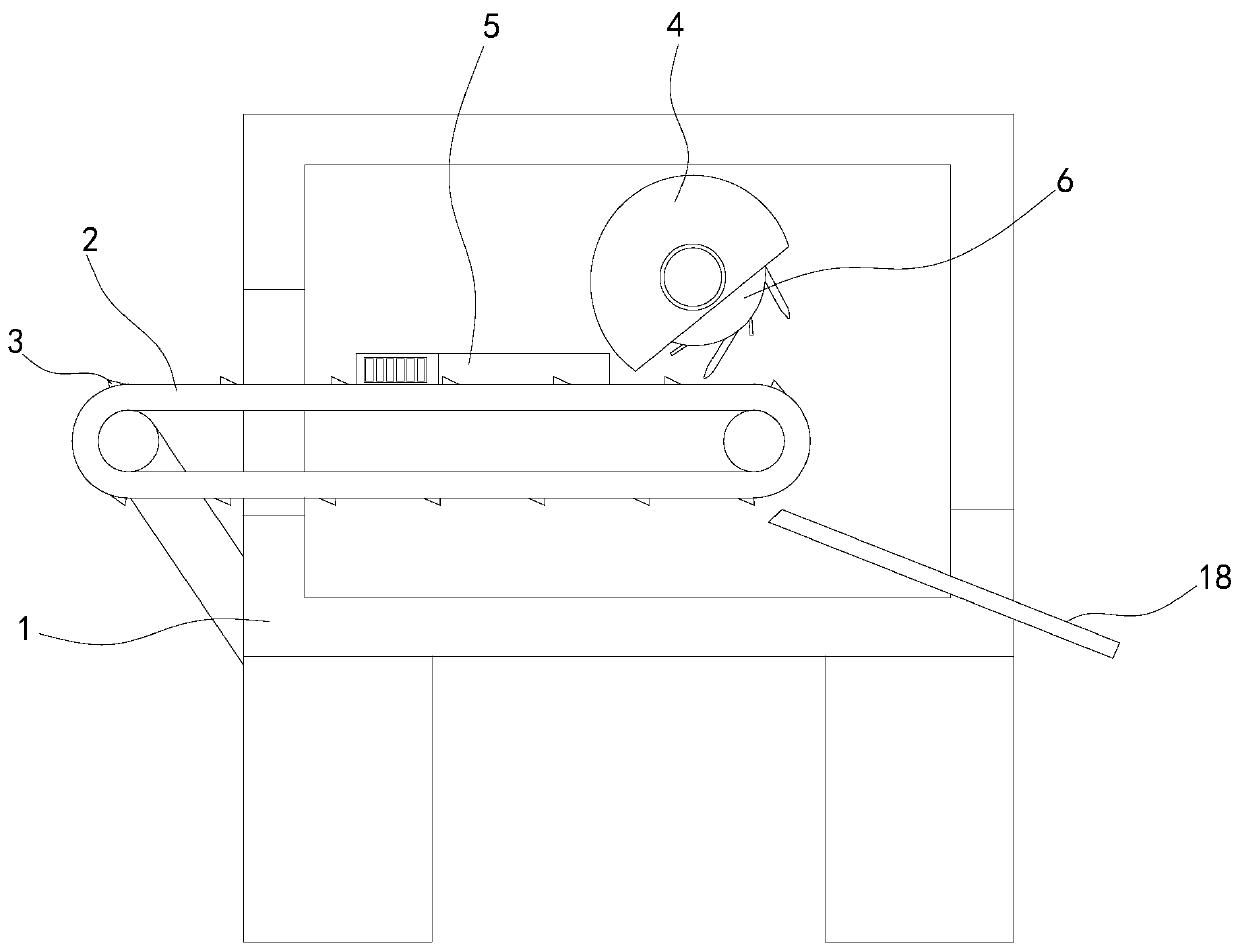

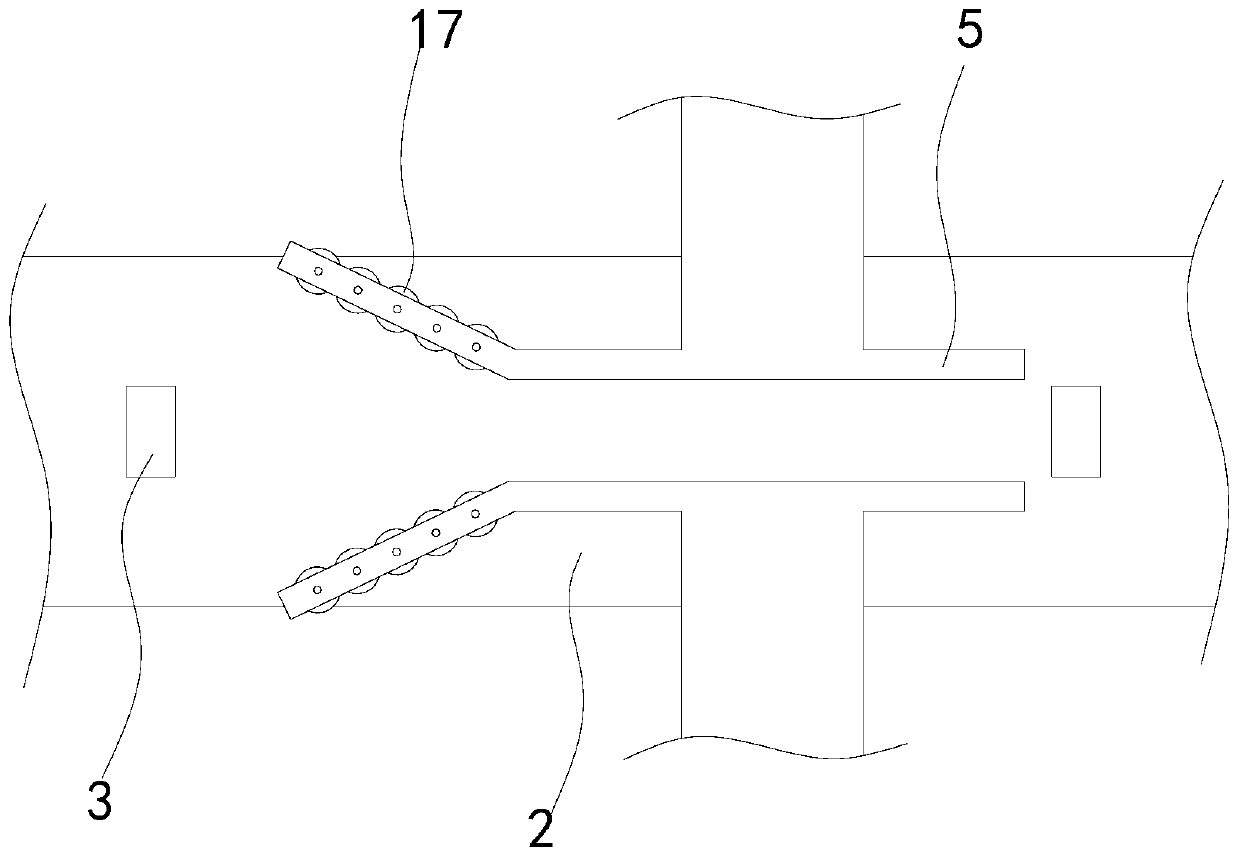

[0028] see Figures 1 to 8 , a plane structure schematic diagram and a three-dimensional structure schematic diagram of a feather positioning and trimming device for badminton production.

[0029] A feather positioning and trimming device for badminton production, comprising a device main body 1, a limiting plate 5 is fixedly installed on the left upper end of the device main body 1, a shearing device 4 is fixedly installed on the inner upper end of the device main body 1, and a shearing device 4 is fixedly installed on the inside. Shear runner6.

[0030] In a specific implementation, a conveyor belt 2 is fixedly installed on the upper end of the device main body 1, and the limiting plate 5 is arranged on the upper end of the conveyor belt 2, so that when the conveyor belt 2 brings the feathers into the device main body 1, the feathers on both sides of the feather can be passed through the limiting plate 5. Restrictions are made to avoid tilting displacement due to equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com