Online servo large-diameter bar hydraulic follow-up fixed-length shearing mechanism

A technology of cutting to length and shearing machine, which is applied in the direction of shearing devices, shearing equipment, and attachments of shearing machines, etc., which can solve the problem of cutting accuracy and continuity discount, affecting the accurate entry of bars, and speed limitations and other issues, to achieve the effect of wide application range, efficiency and benefit improvement, and continuous improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings.

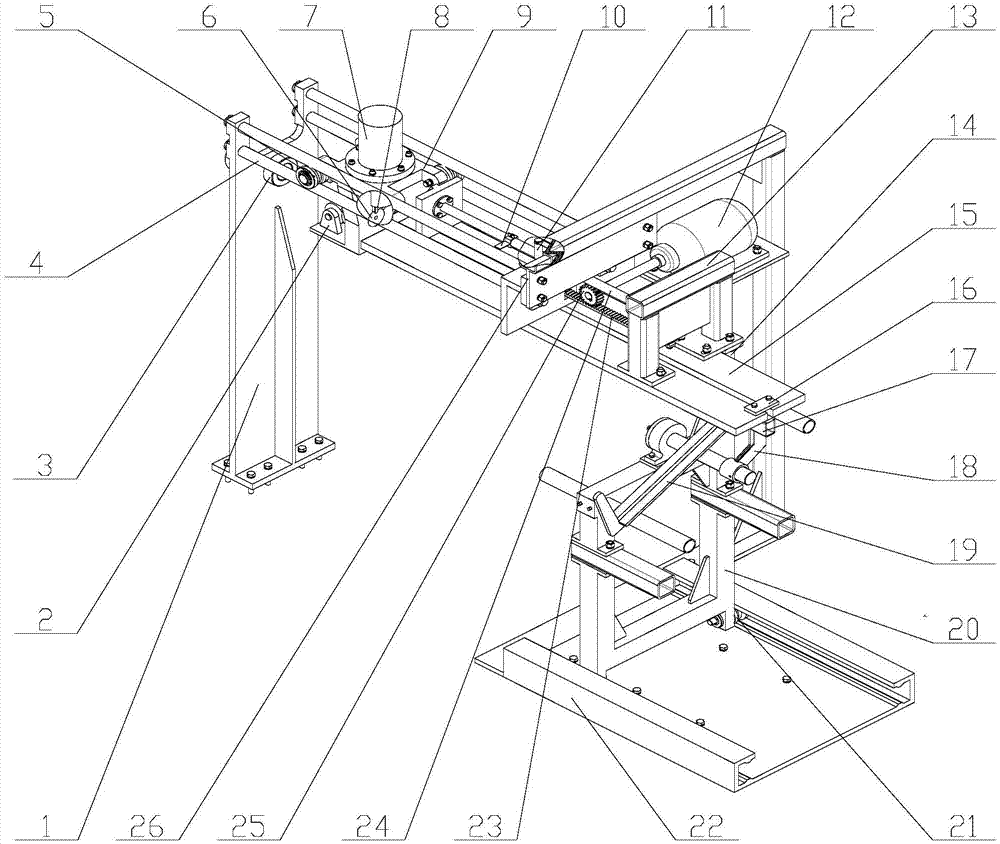

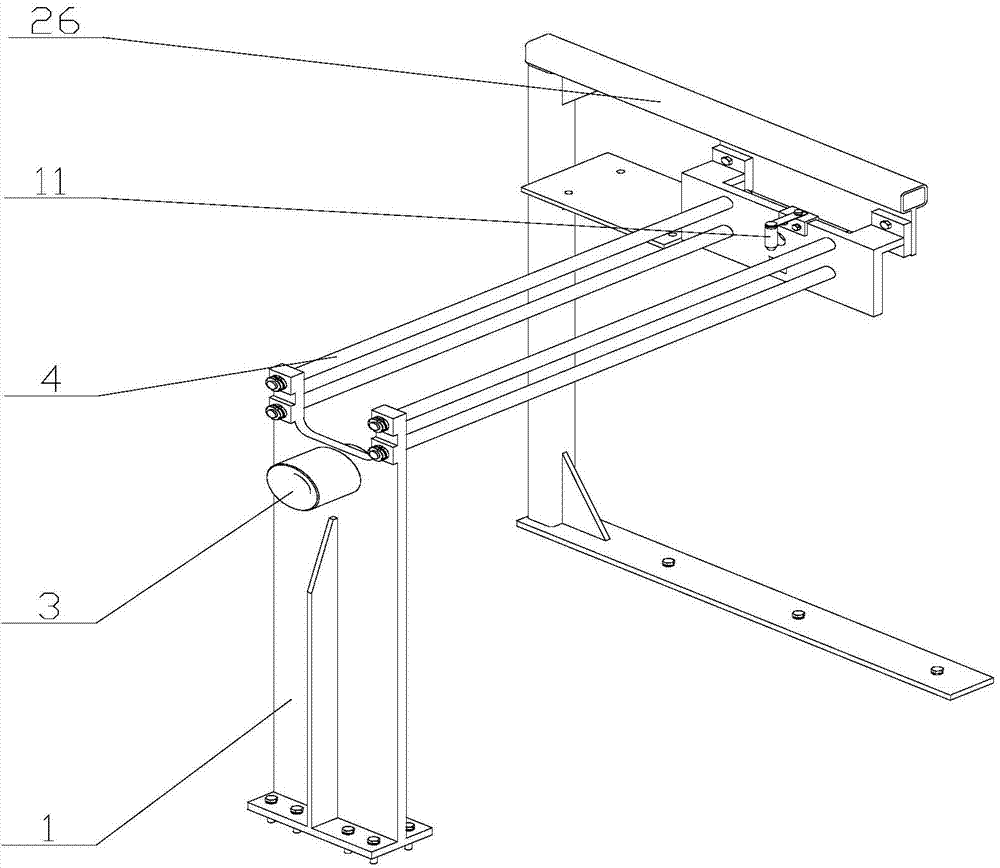

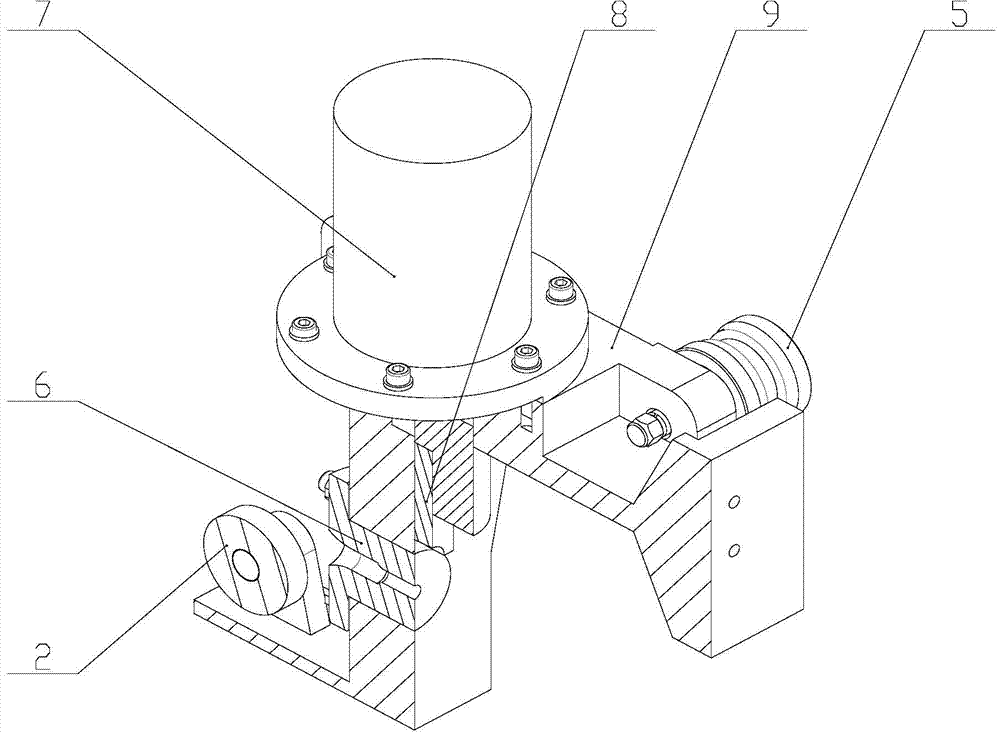

[0021] exist figure 1 In the three-dimensional schematic diagram of the online servo large-diameter bar hydraulic follow-up shearing mechanism shown, the present invention mainly includes a fixed support, a hydraulic shearing machine, a mechanical connection mechanism and a material receiving frame. Wherein, the fixed bracket mainly includes: left bracket (1), right bracket (26), shearer guide rail (4), guide sleeve (3), photoelectric sensor (11) etc.; figure 2 As shown, the lower end of the vertical plate type left bracket is fixed on the foundation, a through hole is provided in the middle of the upper end, and a guide sleeve with a horizontal axis is arranged inside, and two pairs of shearer guide rails parallel to each other are movably connected on both sides of the upper end of the left bracket. , the other end of the guide rail of the shearing machine is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com