Patents

Literature

45results about How to "High precision in sizing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

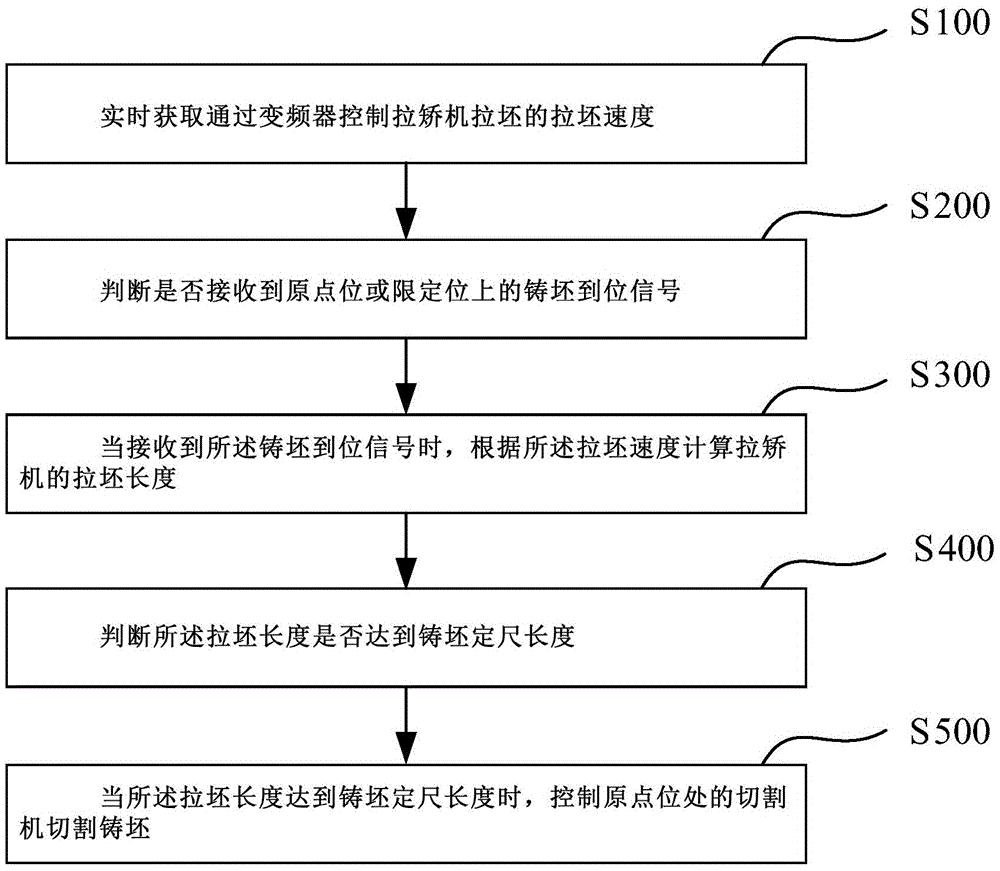

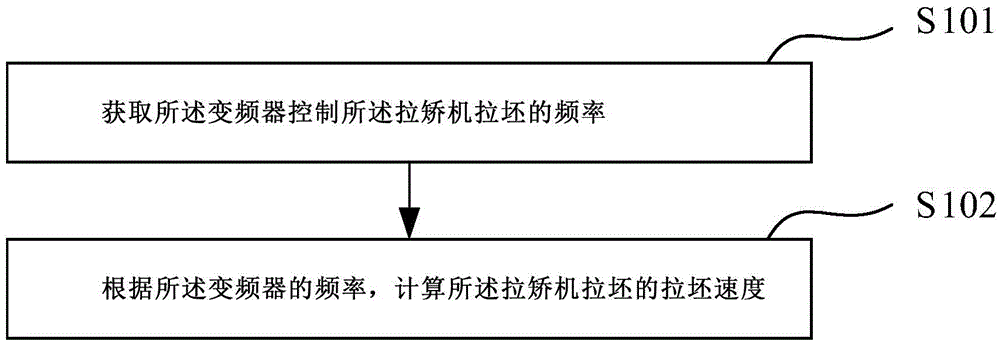

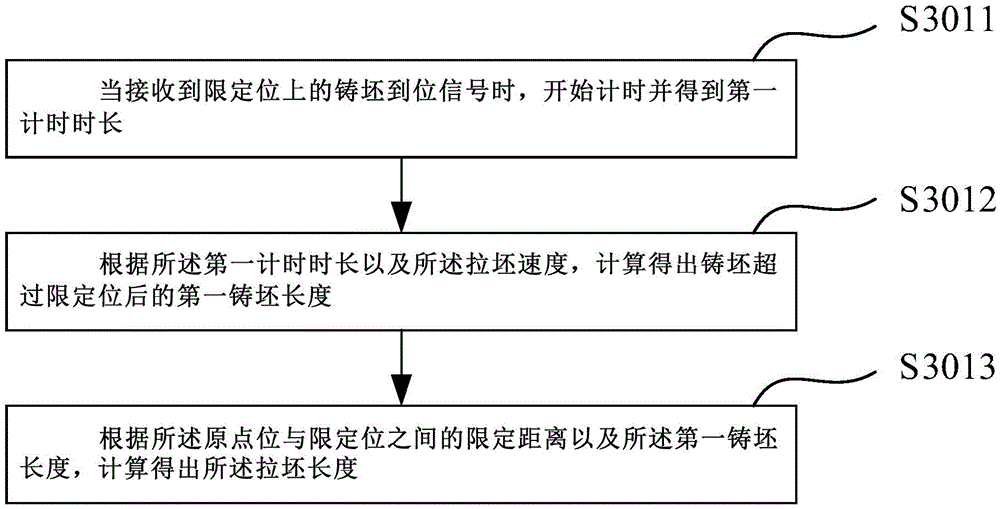

Continuous casting blank sizing method and system

The embodiment of the invention discloses a continuous casting blank sizing method and system. The method includes the steps that the withdrawing speed, controlled through a frequency converter, of withdrawing of a withdrawing and straightening machine is obtained in real time; whether a casting blank in-place signal on an original point position or a limiting position is received or not is judged; when the casting blank in-place signal is received, the withdrawing length of the withdrawing and straightening machine is calculated according to the withdrawing speed; whether the withdrawing length reaches the casting blank sizing length or not is judged; and if the withdrawing length reaches the casting blank sizing length, a cutting machine at the original point position is used for cutting a casting blank. By means of the continuous casting blank sizing method and system, the sizing precision of the casting blank is improved, and meanwhile the maintenance cost of the system is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

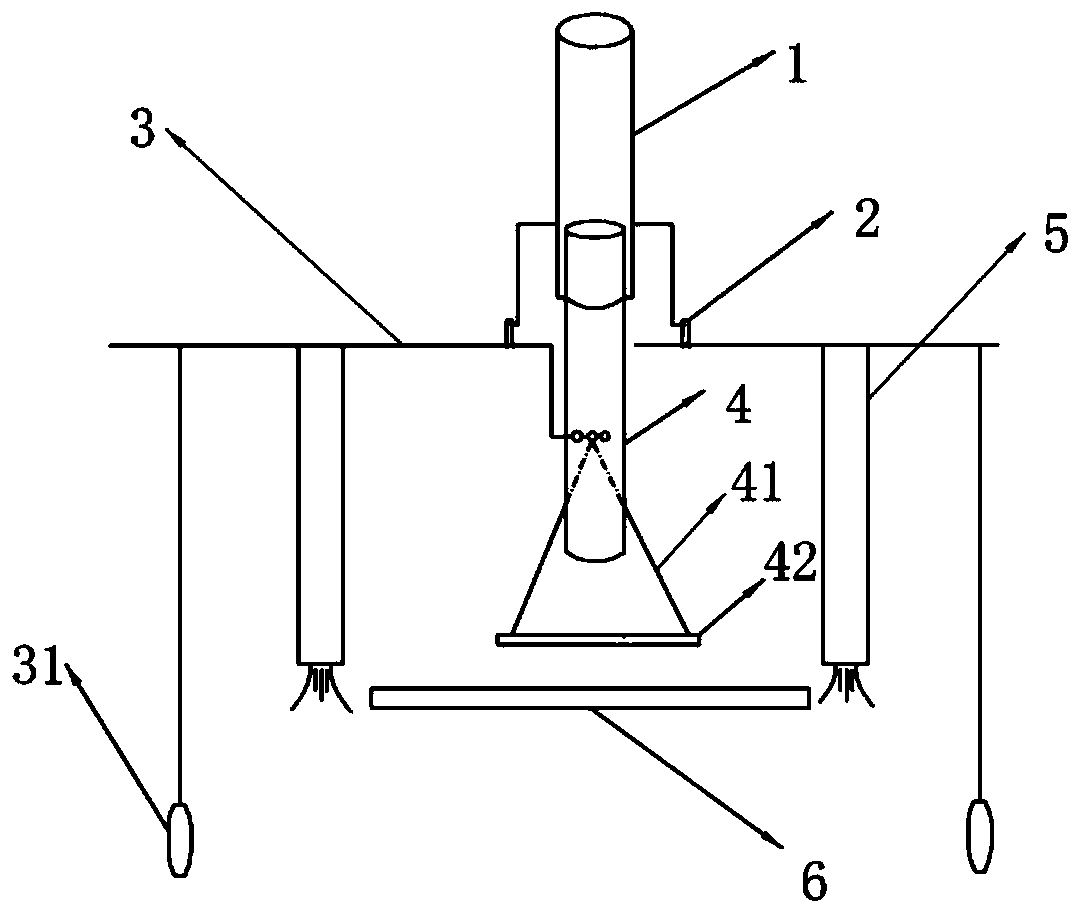

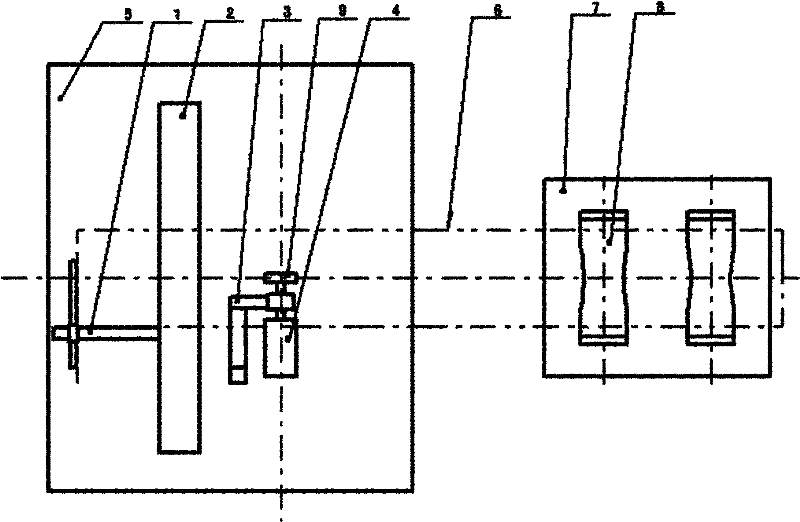

Continuous casting billet laser sizing system

ActiveCN103350200AHigh precision in sizingSimple installation and debuggingOptoelectronicsFlame cutting

The invention discloses a continuous casting billet laser sizing system. The continuous casting billet laser sizing system comprises a PLC unit, a laser detection unit, a display unit and a calculation unit, wherein the PLC unit controls a roller bed of a continuous casting machine and a flame cutting machine; the laser detection unit is connected with the PLC unit and is used for detecting relative positions of continuous casting billets; the display unit is connected with the PLC unit and is used for monitoring operating conditions of the whole system and allowing workers to input necessary data during debugging; the calculation unit is connected with the PLC unit and is used for converting the relative positions, detected by the laser detection unit, of end surfaces of the continuous casting billets into actual lengths of the continuous casting billets. The continuous casting billet laser sizing system has the advantages of being high in sizing precision, stable and simple in calibration, easy to install, debug, operate and maintain, low in operation cost and accurate in cutting, improves sizing rate and yield and reduces rejection rate.

Owner:江阴福盛自动化仪表有限公司

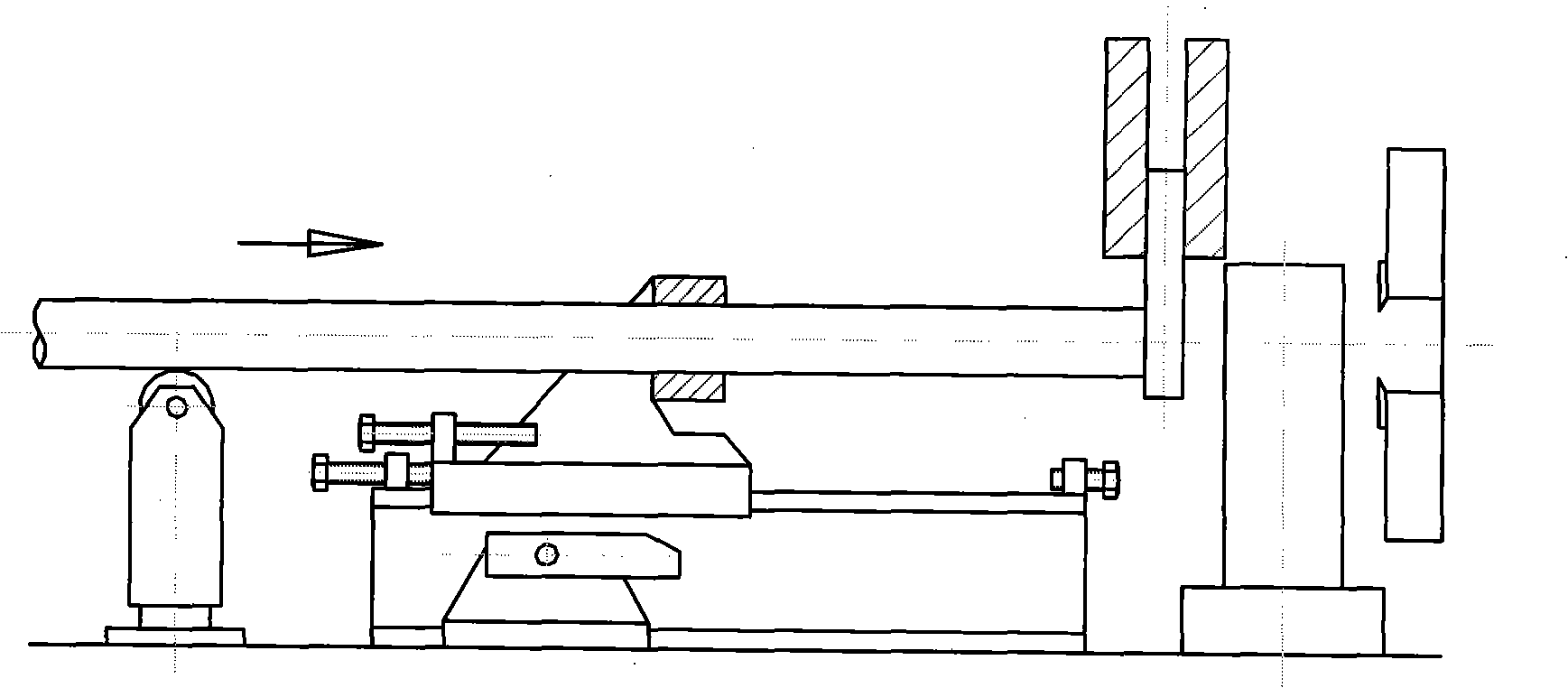

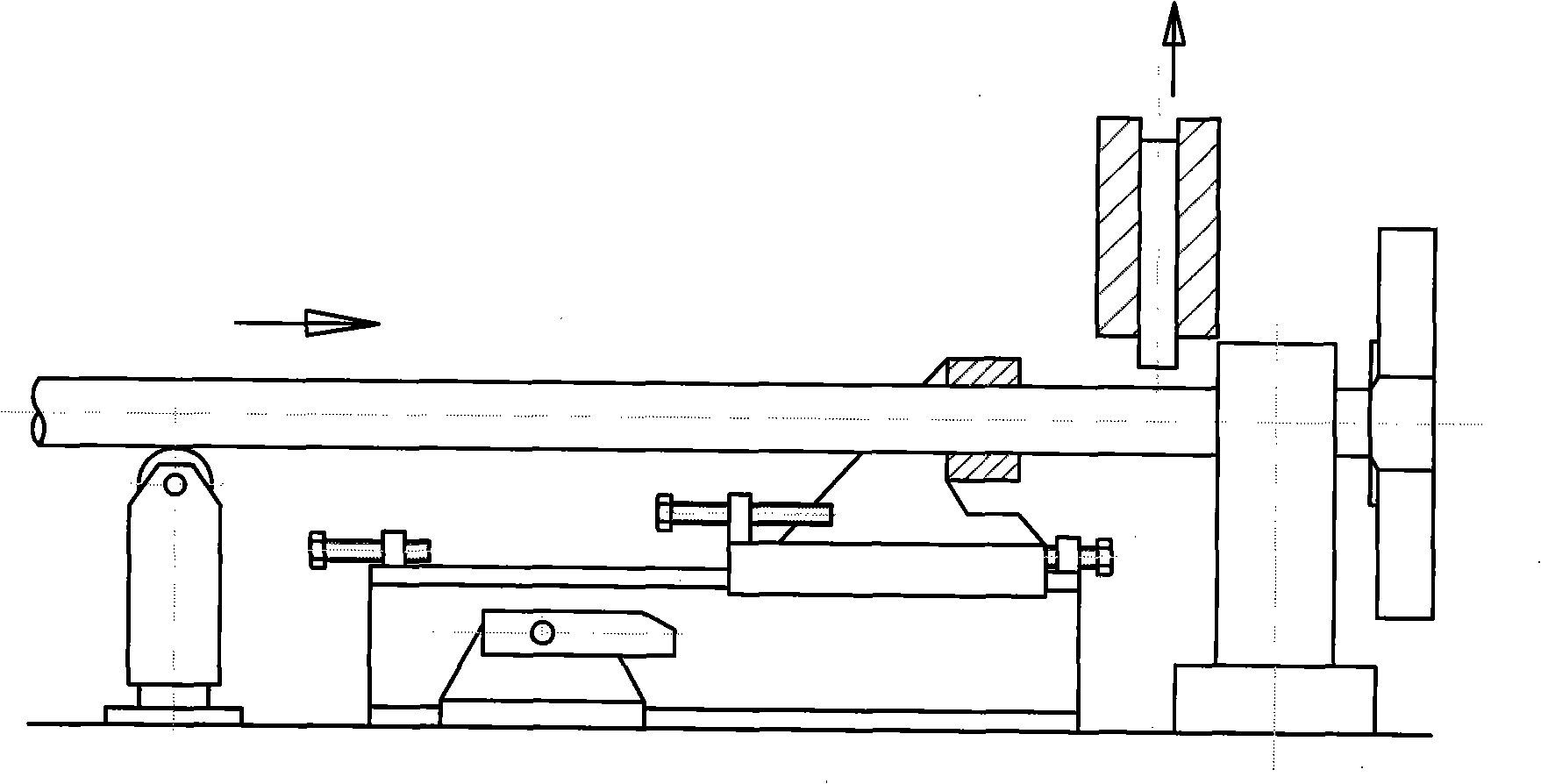

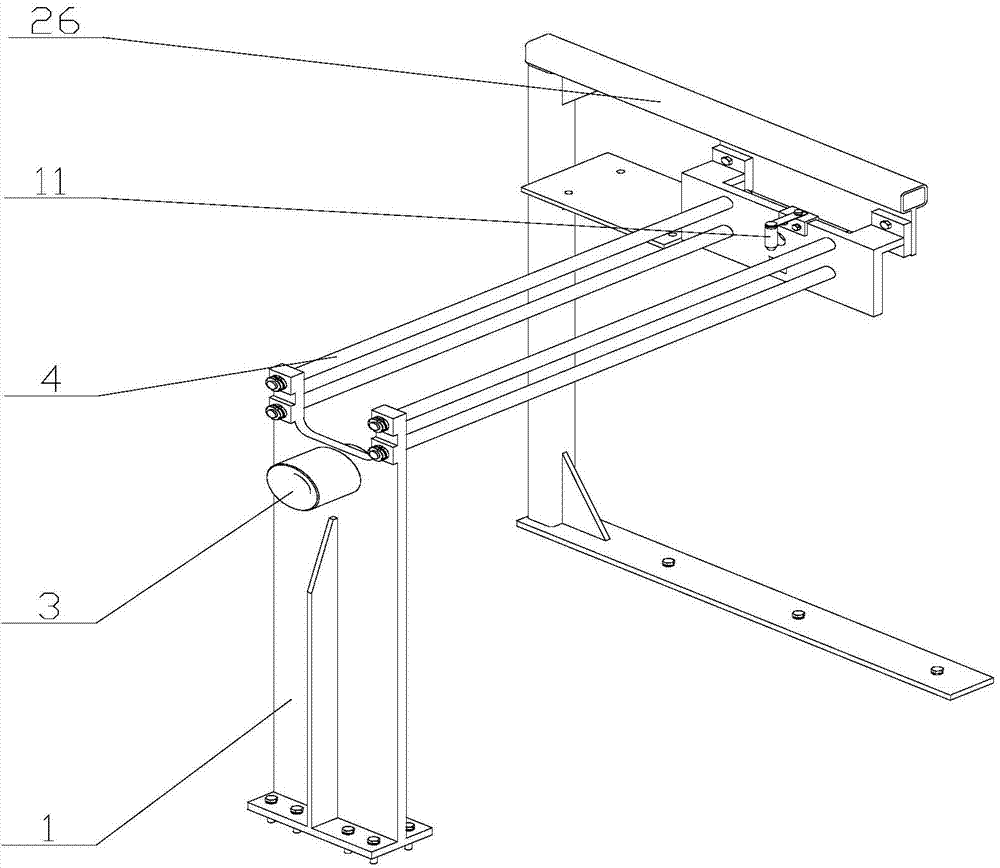

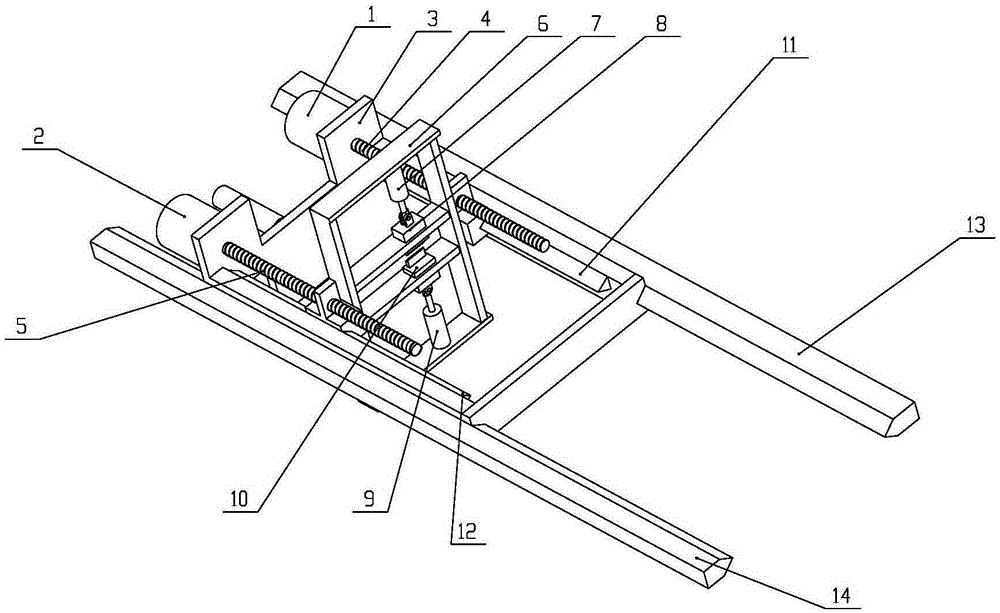

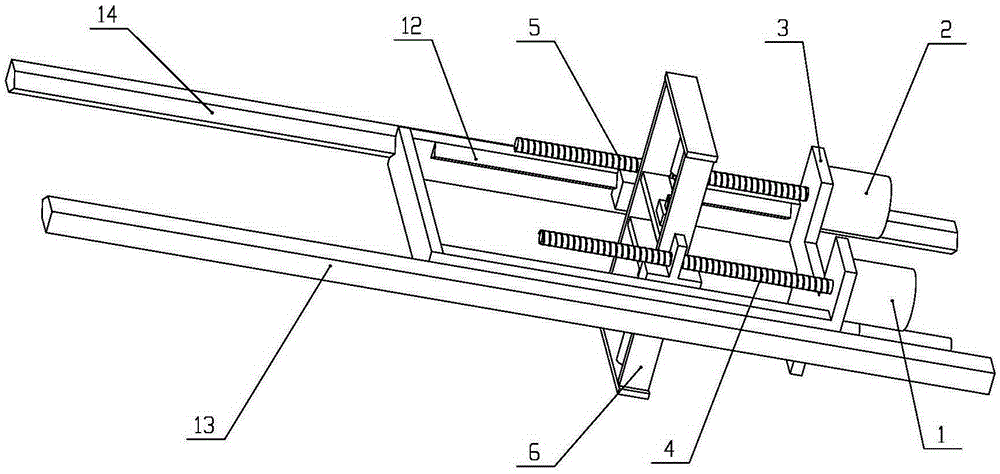

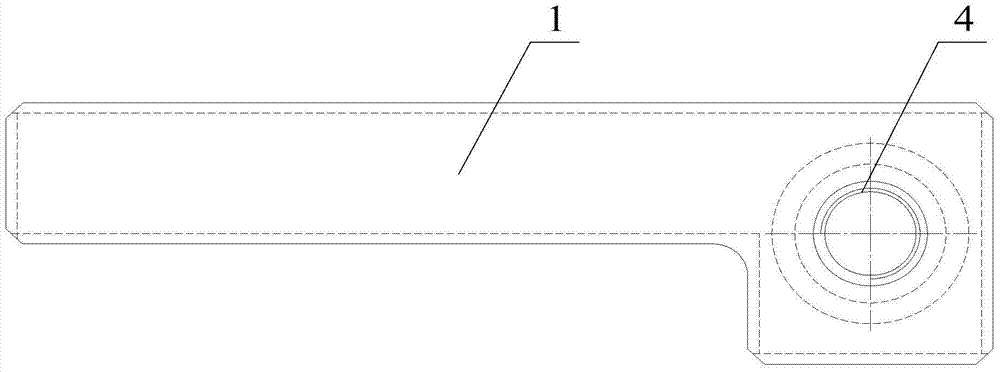

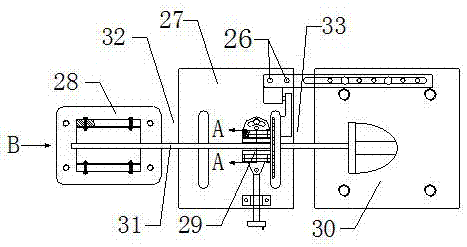

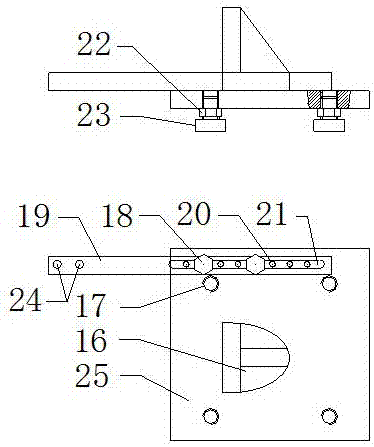

Backing type sizing feed gear and sizing feed method

InactiveCN101407029AHigh precision in sizingHigh speedMetal working apparatusHorizontal axisEngineering

The invention belongs to a tube bar blanking device for metallurgical equipment and a method, in particular to a return type specified feeding device and a specified feeding method. The return type specified feeding device at least comprises a sliding support, a feeding clamp (6) for clamping a tube bar (1) to move forwards, and a main clamp (8) between a cutting tool (9) and the feeding clamp (6). The return type specified feeding device is characterized in that a movable stub bar baffle (7) is arranged between the feeding clamp (6) and the main clamp (8), and the feeding clamp (6) is glidingly connected with a slide way (3) through a feeding clamp seat; one side at the back end of the feeding clamp seat is provided with a specified leading screw rod(5), and one side of a slide way seat is provided with a specified baffle (4) which can rotate for 90 degrees along a fixed shaft; and when the specified baffle (4) is positioned at the vertical position, the specified leading screw rod(5) is moved in a horizontal axis through the specified baffle (4). The device has high specified precision and quick speed, is easy to achieve automation, and can be applied to various tube bars.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

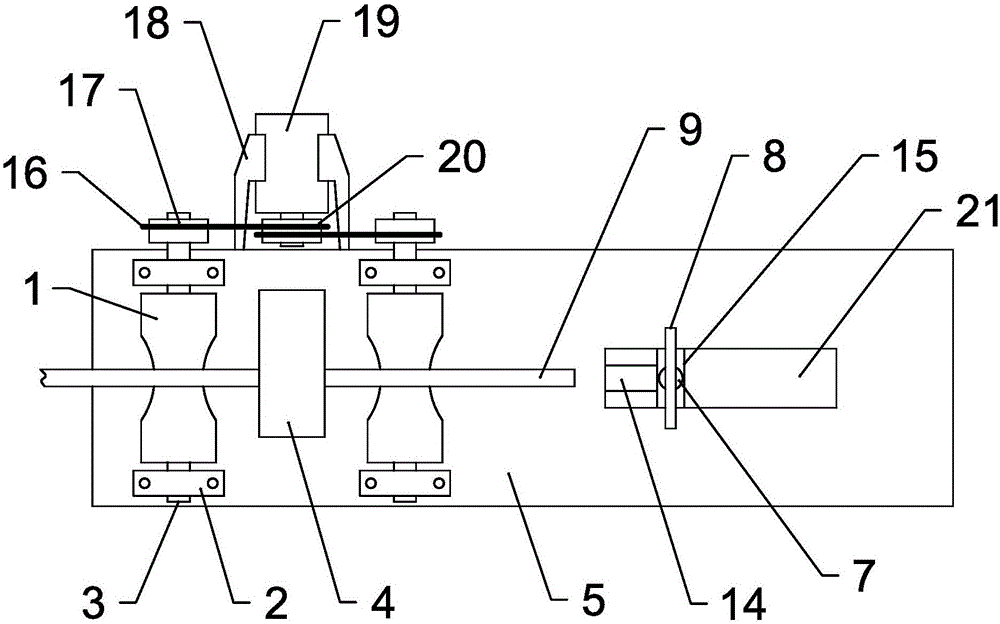

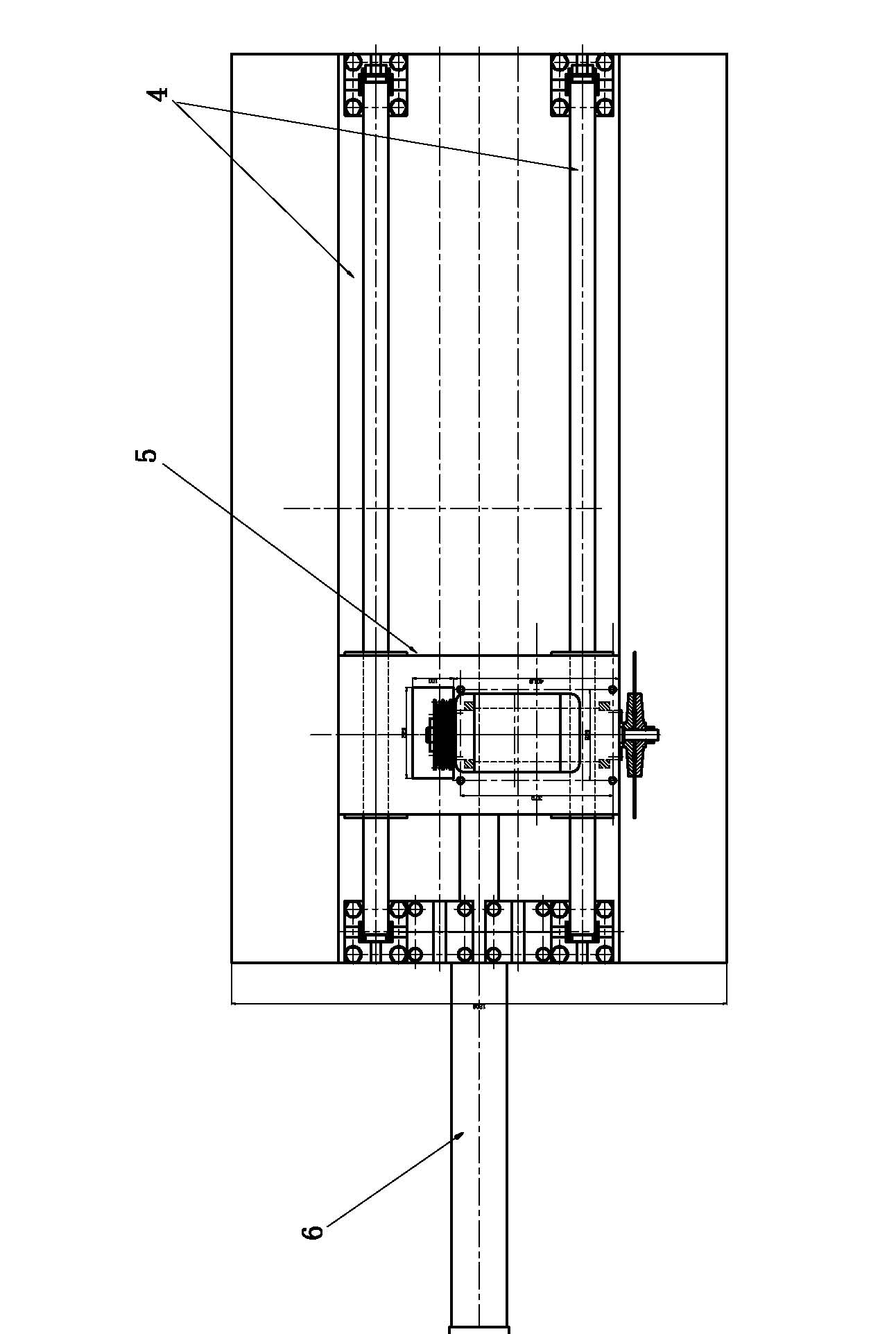

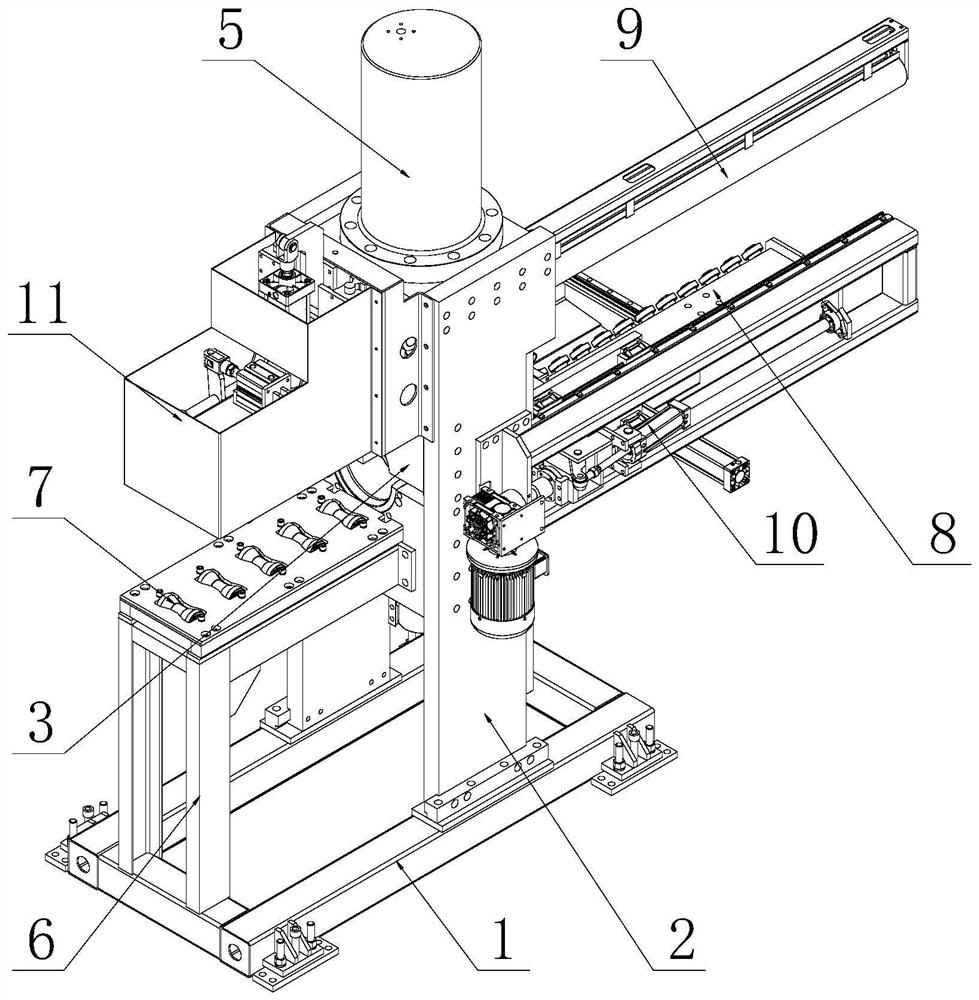

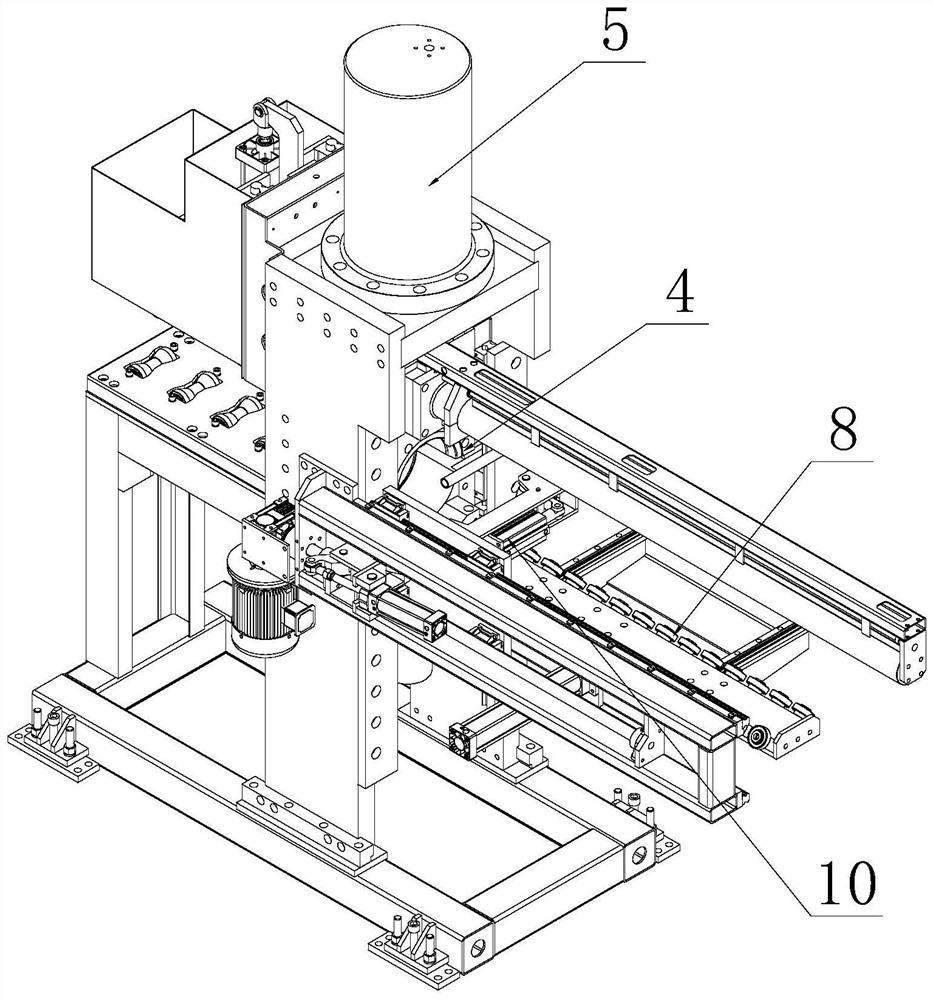

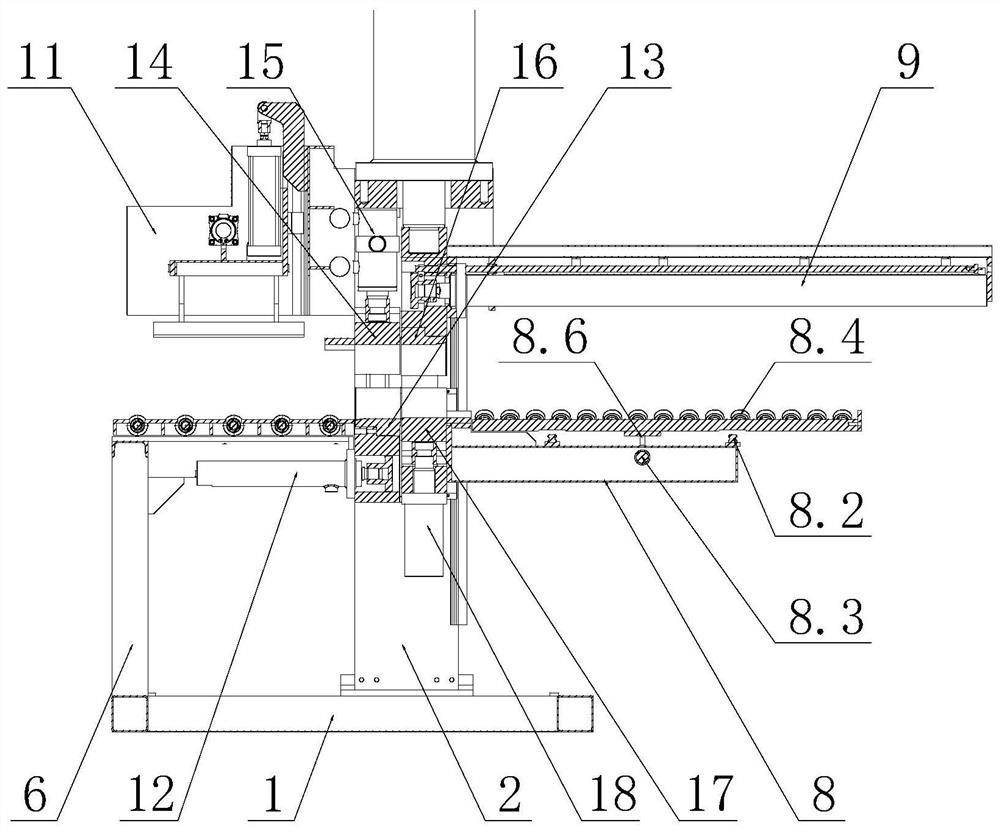

Steel plate shear gauge and gauging method thereof

InactiveCN104723172AHigh precision in sizingPrecise positioningMeasurement/indication equipmentsShearing machine accessoriesReducerControl theory

The invention provides a steel plate shear gauge. The steel plate shear gauge comprises a gauging trolley, a trolley driving motor and a conveying mechanism used for conveying steel plates, wherein two racks are arranged above the conveying mechanism in parallel in the steel plate conveying direction, a gear used for traveling is arranged at the lower end of the gauging trolley, the gear is meshed with the racks and is installed on an output shaft of the trolley driving motor through a speed reducer, an encoder is installed on the output shaft of the trolley driving motor which is connected with a frequency converter, and the frequency converter and the encoder are connected to a controller. The steel plate shear gauge further comprises a gauging baffle used for positioning the steel plates, wherein the gauging baffle is fixed to the gauging trolley through a lifting mechanism. The invention further discloses a gauging method of the steel plate shear gauge. Segmented control over the rotating speed of the trolley driving motor is achieved through segmented control over the output frequency of the frequency converter. According to the steel plate shear gauge and the gauging method thereof, the gauging precision of the shear gauge is improved greatly, and practicality is high.

Owner:SHANDONG IRON & STEEL CO LTD

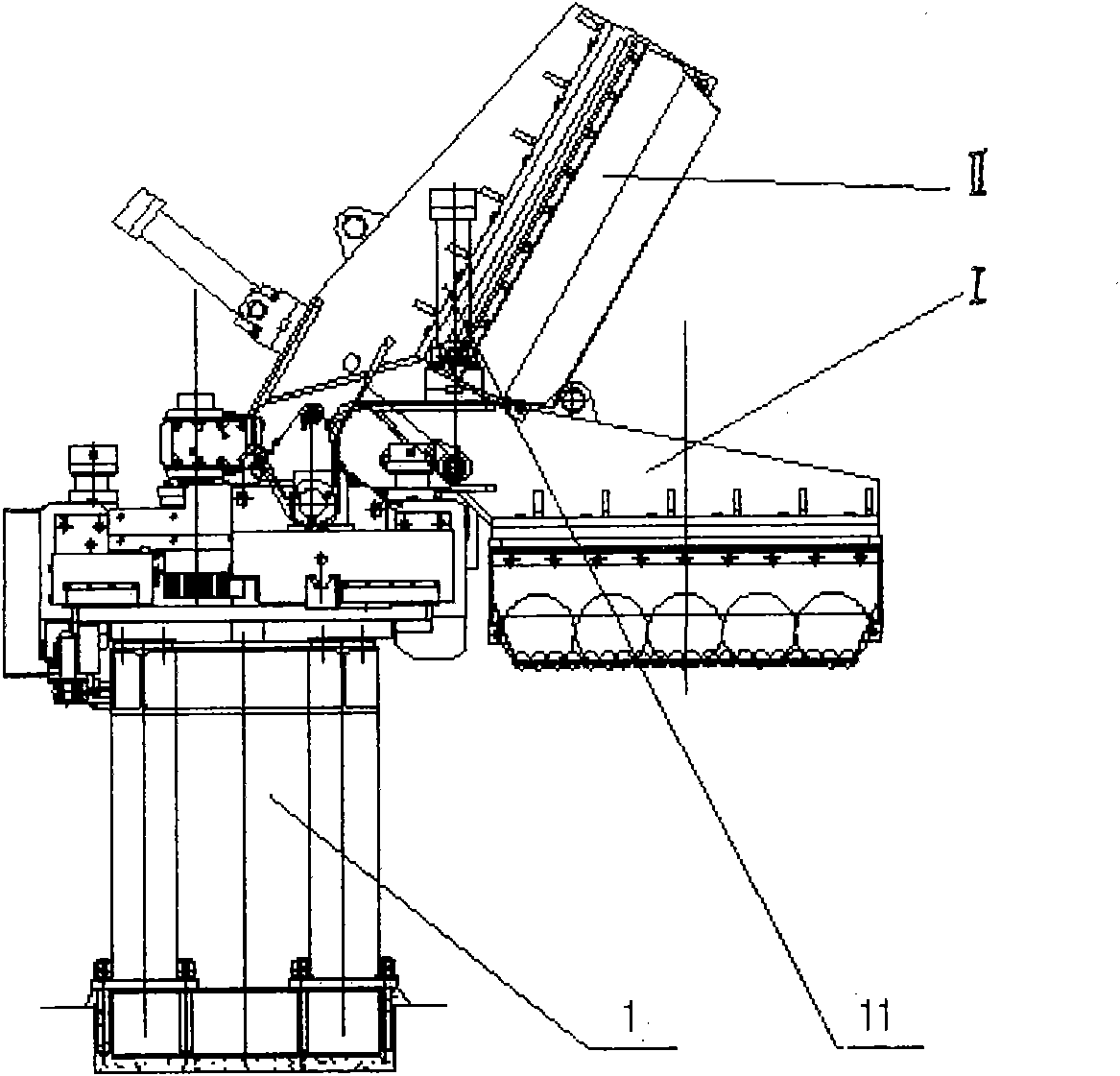

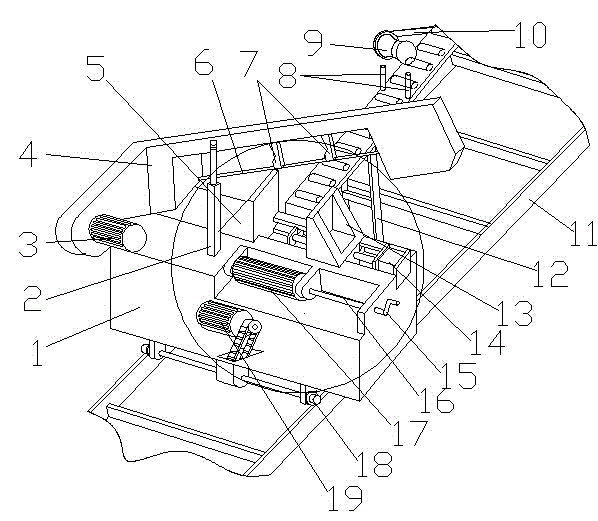

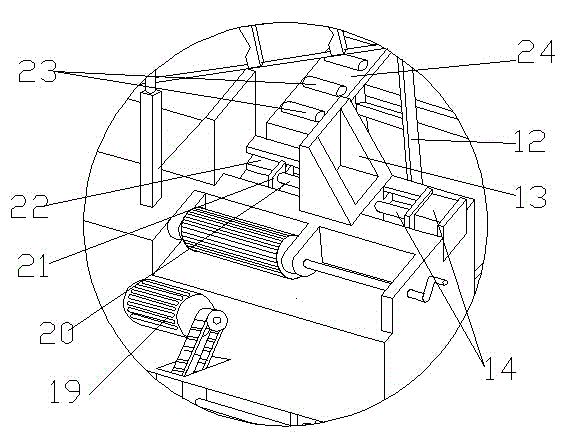

Saw cutting device for tube rows with positioned length

InactiveCN101590546ASimple controlHigh precision in sizingMetal sawing devicesShearing machine accessoriesSteel tubeVehicle frame

The invention belongs to the technical field of mechanical engineering, relates to a row saw cutting device, in particular to a saw cutting device for tube rows with positioned length. The saw cutting device mainly consists of a walking rail track and a row sawmill. A positioning device body consists of a car frame, a walking driving mechanism, a locking mechanism, a walking guide mechanism, a positioning mechanism, a buffering baffle plate and a swing mechanism of the buffering baffle plate, wherein the buffering baffle plate is connected with the car frame through an auxiliary sliding hinge point; two gas-liquid buffers and a response hydraulic cylinder are arranged in the baffle plate, and the gas-liquid buffers and the head of the hydraulic cylinder are simultaneously connected with the working face of the baffle plate. The invention has the advantages of elaborate structure, simple operation, simple control, high length positioning precision and energy saving. The lumber recovery of steel tubes can be increased, and the length positioning requirement of any length can be realized. The invention can be popularized to be applied to the saw cutting or cutting device with positioned length for sectional material, bar material and the like.

Owner:CISDI ENG CO LTD

Sizing mechanism of equipment in steel bar shearing process

InactiveCN106825334AImprove delivery stabilityEasy to controlMetal working apparatusArchitectural engineeringRebar

The invention discloses a sizing mechanism of equipment in a steel bar shearing process, comprising a driving roller, an L-shaped bracket, a workbench, a positioning baffle and a pressing roller; the left side of the top part of the workbench is provided with two groups of steel bar gliding rolling mechanisms, and each of the steel bar gliding rolling mechanism comprises the driving roller, the L-shaped bracket is fixedly between the two groups of the steel bar gliding rolling mechanisms and on the workbench; the lower side of a horizontal part of the L-shaped bracket is equipped and fixed with a second telescopic cylinder, and the lower end of a piston rod of the second telescopic cylinder is connected with a roller wheel frame through a buffer supporting mechanism; the lower end of the roller wheel frame is equipped with a pressing roller, and the right side of the top part of the workbench is provided with an installing base holding groove; an installing base is arranged in the installing base holding groove, the left side of the installing base is provided with a third telescopic cylinder, and the top part of the installing base is fixedly provided with a first telescopic base; the upper end of the piston rod of the first telescopic cylinder is fixedly equipped with a positioning baffle. The sizing mechanism can stably convey the steel bar, convenient to carry out the sizing operation, and high in both stability and precision.

Owner:康振智能装备(深圳)股份有限公司

Novel hot-rolled round steel cut-to-length system

InactiveCN104439492AConsistent travel speedConsistent feed rateStock shearing machinesShearing machine accessoriesHydraulic cylinderAutomatic control

The invention discloses a novel hot-rolled round steel cut-to-length system, and belongs to the technical field of mechanical engineering. The novel hot-rolled round steel cut-to-length system comprises a charging skip, a cutting frame, a supporting conveying device and guide rails. The cutting frame is hinged to one end of the charging skip, an automatic clamping mechanism and a manual supporting conveying structure are arranged at the other end of the charging skip, and the automatic clamping mechanism comprises a first clamping plate and a second clamping plate. The supporting conveying device is arranged in the discharging direction of the automatic clamping mechanism and comprises a conveying carrier roller support, a carrier roller base and carrier rollers, and a rotary encoder is installed on the carrier roller base. The cutting frame comprises a cutting saw rotation base, a first driving motor and a transmission device, a cutting saw is arranged at an opening of the cutting saw rotation base and guide wheels are arranged at the lower end of the charging skip and driven by a second motor. The novel hot-rolled round steel cut-to-length system can realize automatic control over fixed-length cutting through the combination of the driving motors, a hydraulic cylinder and the rotary encoder, and through the mobile length fixing mode of a shearing machine, the moving range is small, speed is high, cut-to-length accuracy is high and the working efficiency of the shearing machine can be obviously improved.

Owner:芜湖市海源铜业有限责任公司

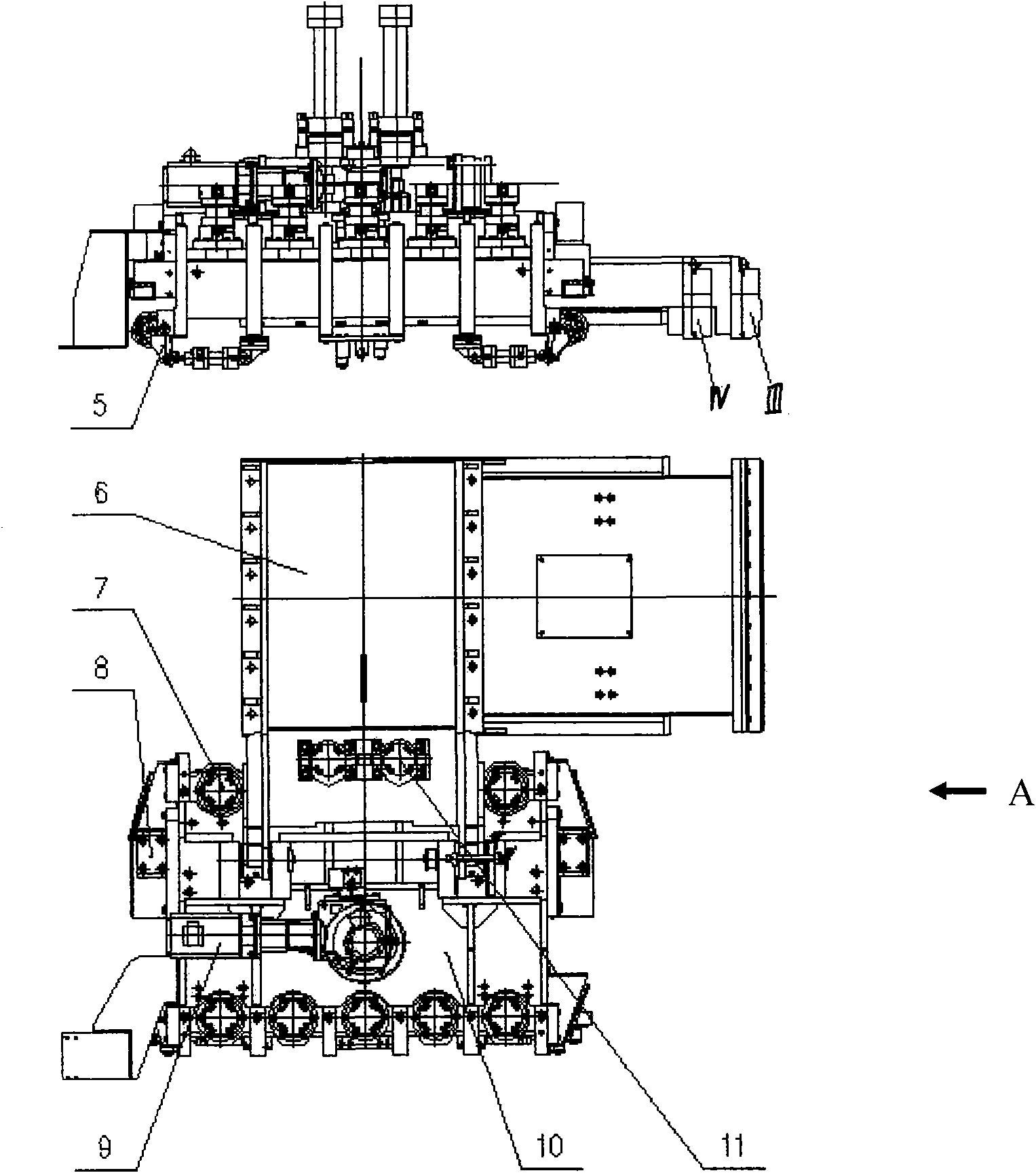

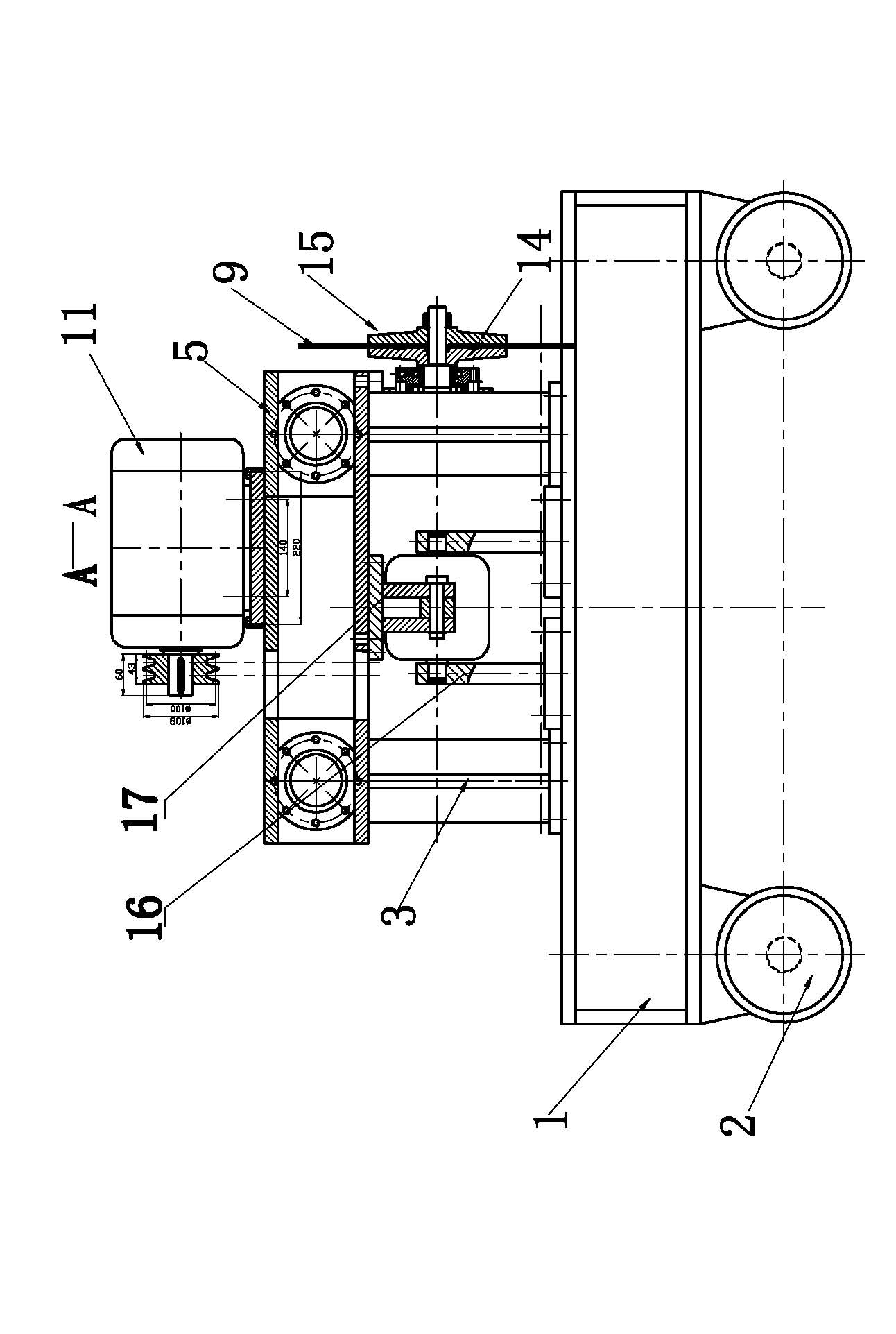

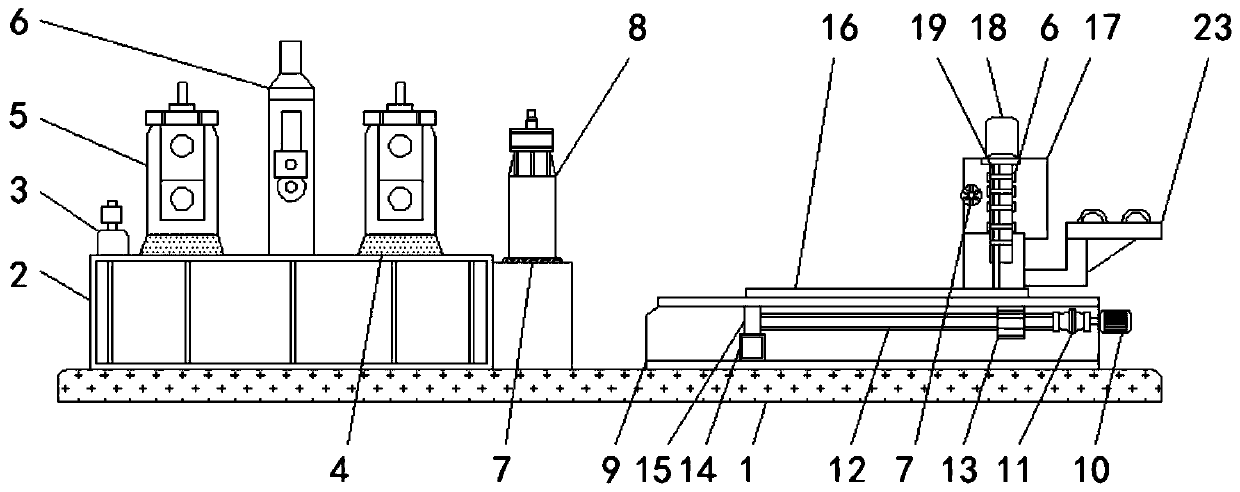

Online servo large-diameter bar hydraulic follow-up fixed-length shearing mechanism

InactiveCN104259548AImprove continuityHigh speed online shearingShearing machinesShearing machine accessoriesHydraulic cylinderEngineering

The invention discloses an online servo large-diameter bar hydraulic follow-up fixed-length shearing mechanism. The online servo large-diameter bar hydraulic follow-up fixed-length shearing mechanism mainly comprises a fixed bracket, a hydraulic shearing machine, a mechanical connecting mechanism and a bearing frame, wherein the fixed bracket mainly comprises a left bracket, a right bracket, a shearing machine guide rail, a guide sleeve, a photoelectric sensor and the like. The hydraulic shearing machine mainly comprises a hydraulic cylinder, an upper cutting knife, a lower cutting knife, a shearing machine roller, a speed measuring support wheel and a bracket. The bearing frame mainly comprises an upper bracket, a lower horizontal rod, a lower bracket, a lower bracket roller, a linear guide rail, a wide guide rail, a baffle rod, a turning arm, a bracket and a fixed-length baffle plate. The mechanical connecting mechanism comprises a servo motor, a gear, a rack, a connecting rod and a touch plate. The online servo large-diameter bar hydraulic follow-up fixed-length shearing mechanism can largely quicken the bar speed to realize high-speed online production, and prevents secondary processing and resource waste to achieve high practical value.

Owner:YANSHAN UNIV

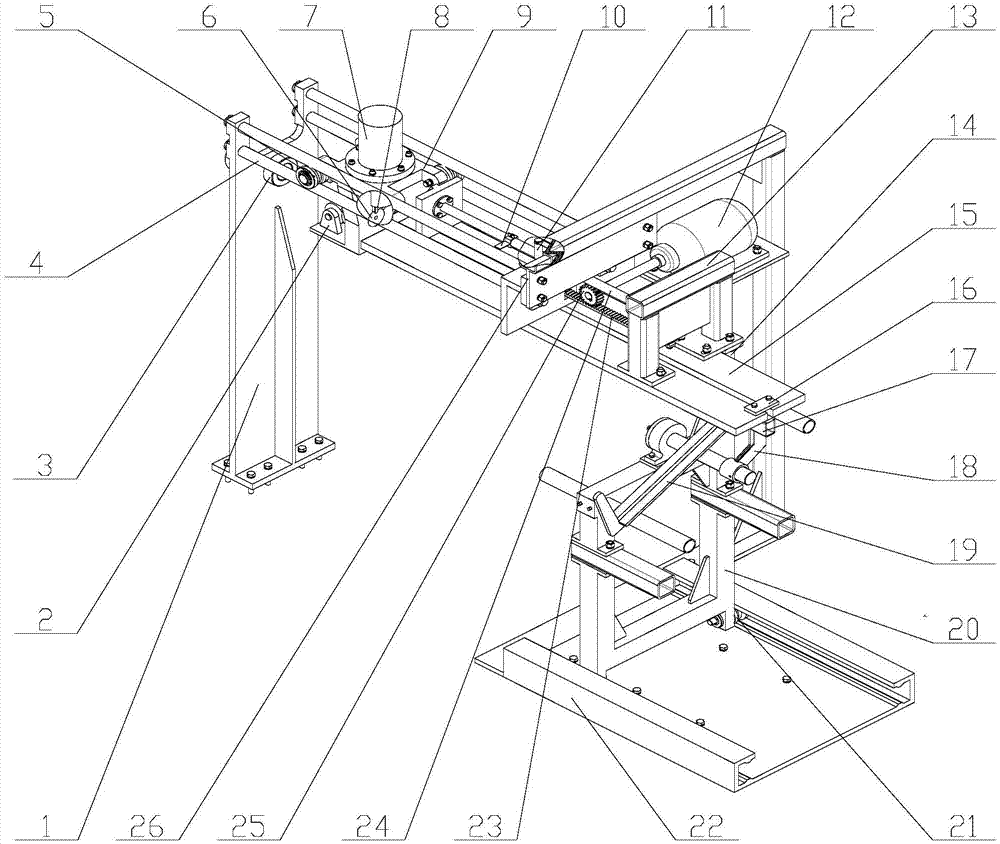

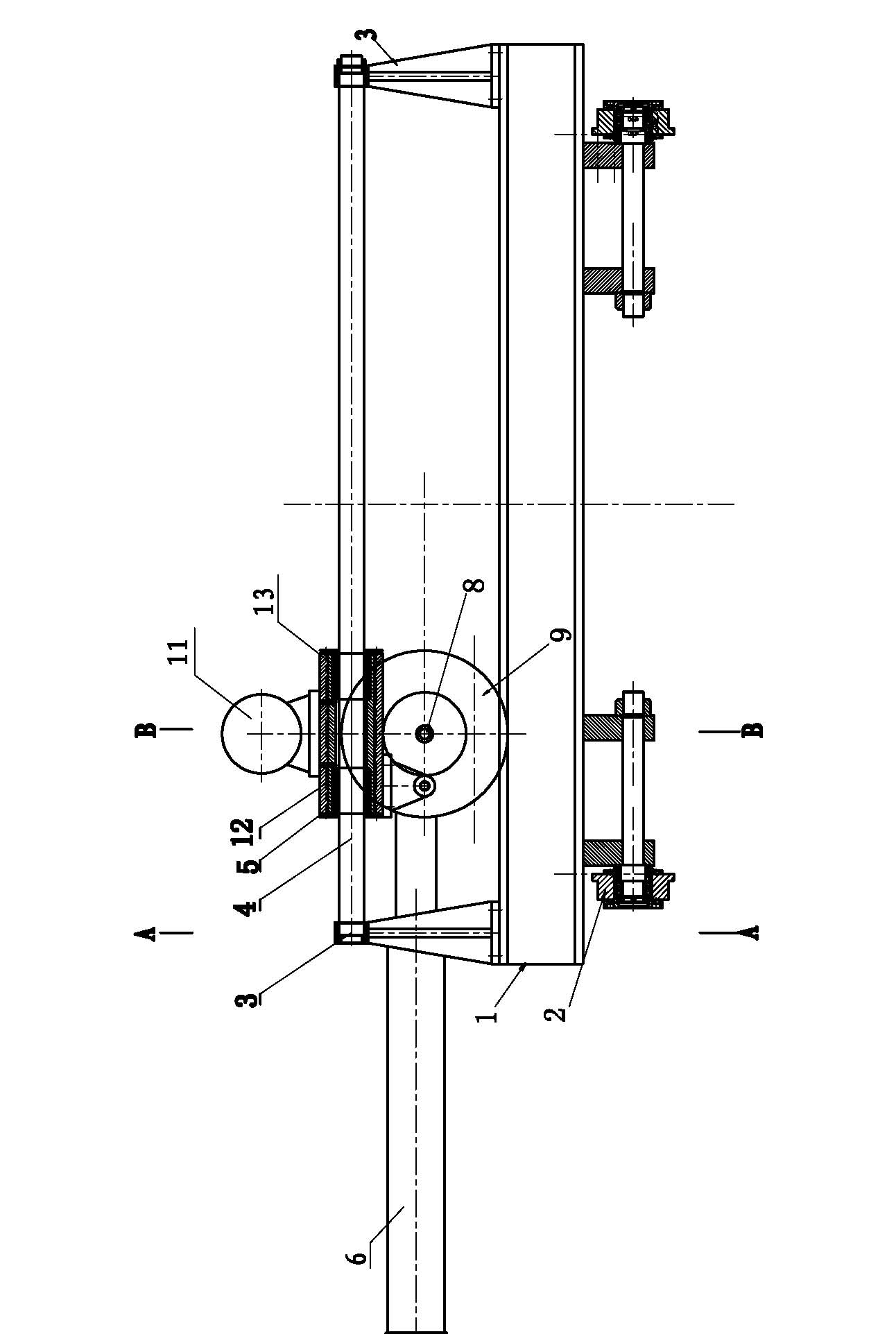

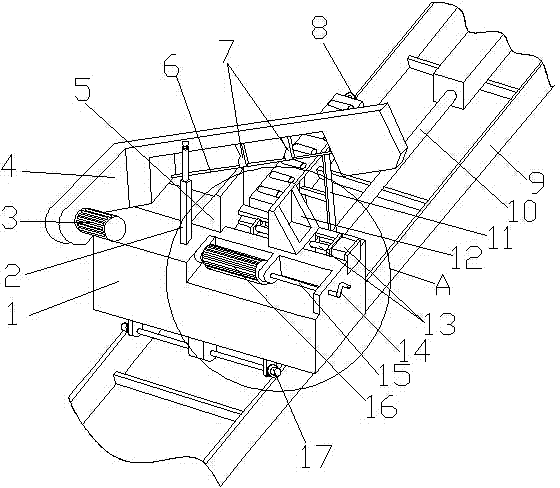

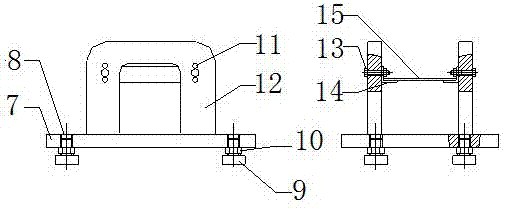

Wide stainless steel product cut-off device

InactiveCN102581373AHigh precision in sizingImprove equipment reliabilityMetal sawing devicesElectric machineryLeather belt

A wide stainless steel product cut-off device comprises a sawing trolley (1) and travelling wheels (2), wherein the sawing trolley (1) is mounted on the travelling wheels (2). The wide stainless steel product cut-off device is characterized in that guide rod supports (3) are mounted on the sawing trolley, two ends of a guide rod (4) are supported on the corresponding guide rod supports (3), a sliding sleeve (5) capable of moving back and forth on the guide rod (4) is mounted on the guide rod (4) and connected with a piston rod of a telescopic sleeve cylinder (6) mounted on the sawing trolley (1) through a connecting plate (17), a saw arm (7) is mounted on the lower portion of the sliding sleeve (5), a saw arm shaft (8) is mounted in the saw arm (7), a saw blade (9) is mounted at one end of the saw arm shaft (8), and a belt plate (10) driving the saw arm shaft (8) to rotate is mounted at the other end of the saw arm shaft (8) and connected with an output shaft of a motor (11) mounted on the upper portion of the sliding sleeve (5) through a transmission belt. The wide stainless steel product cut-off device is simple in structure, fine in precision and high in efficiency.

Owner:NANJING WANHUI STEEL SHEET PILING

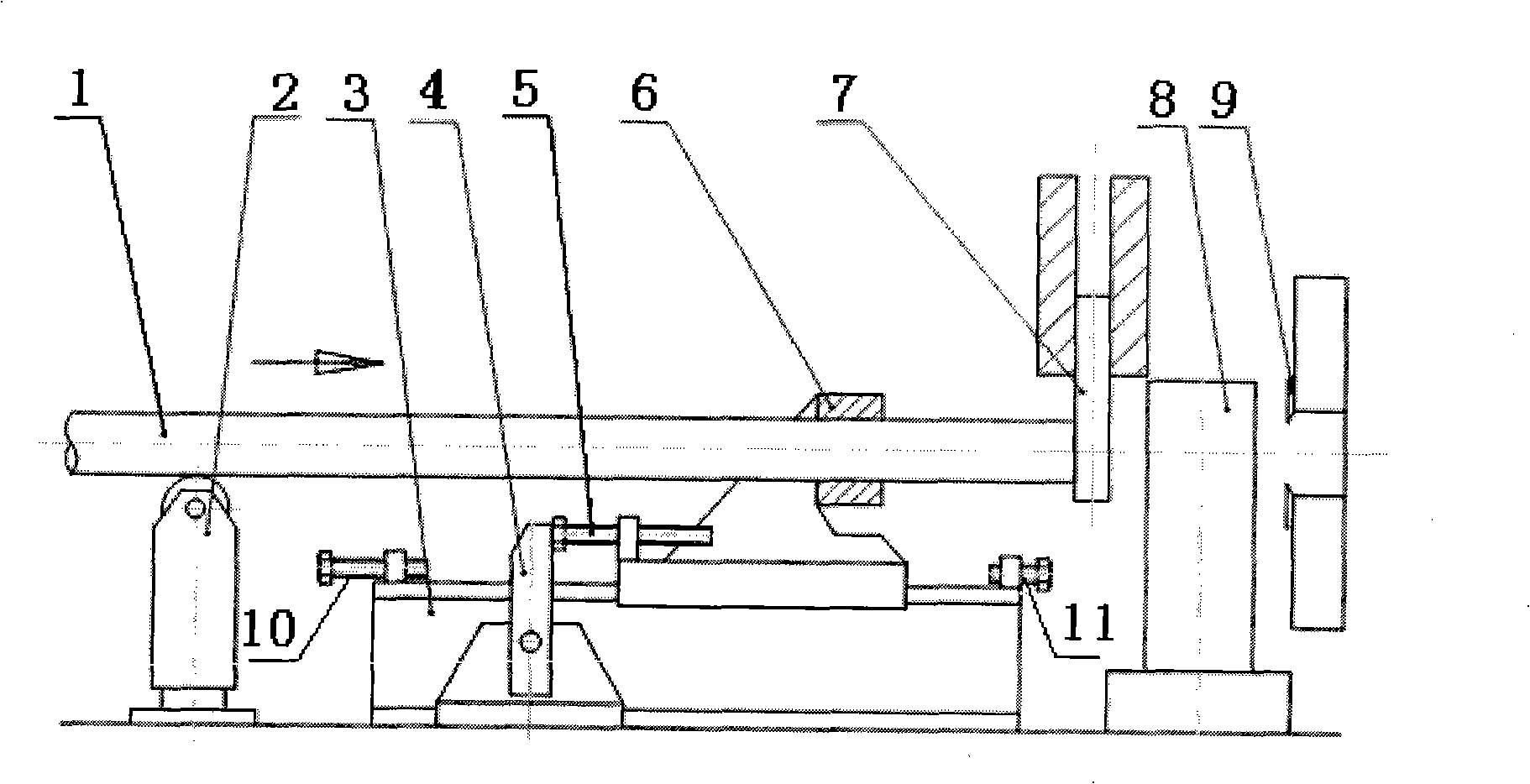

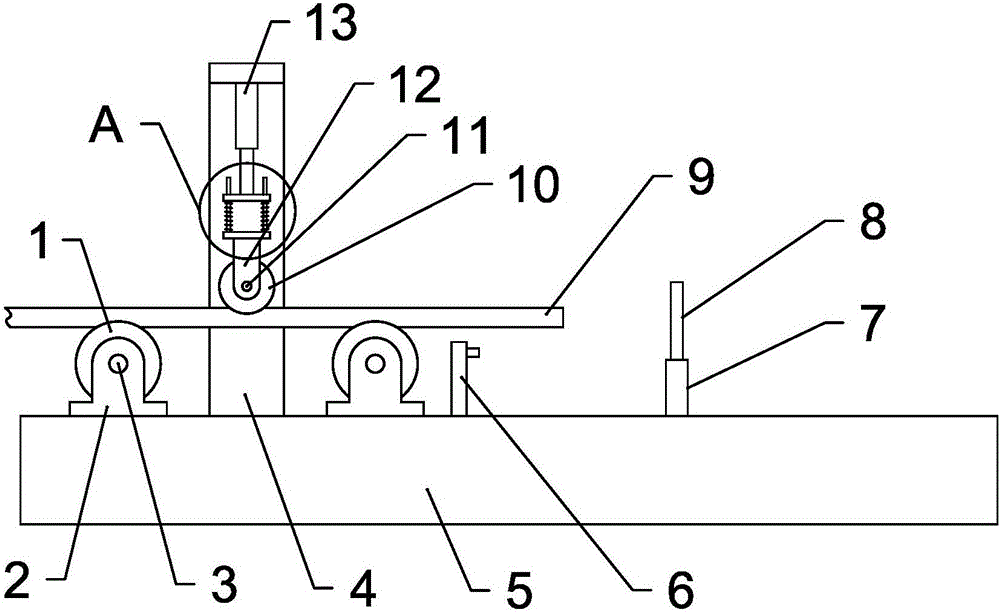

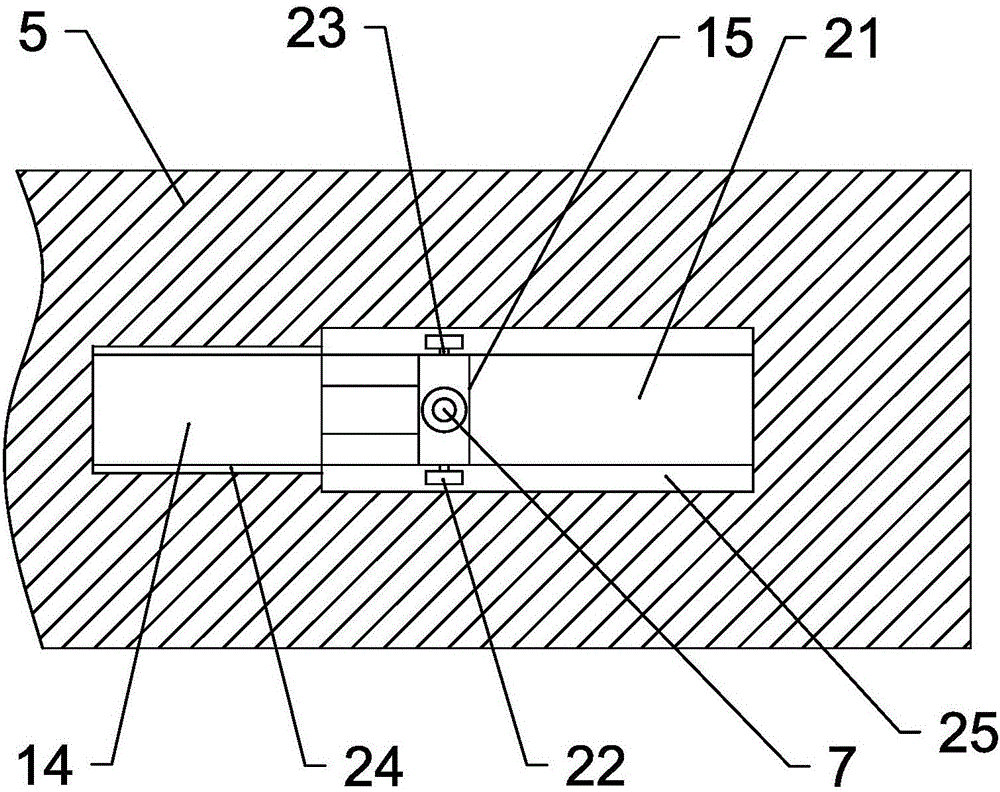

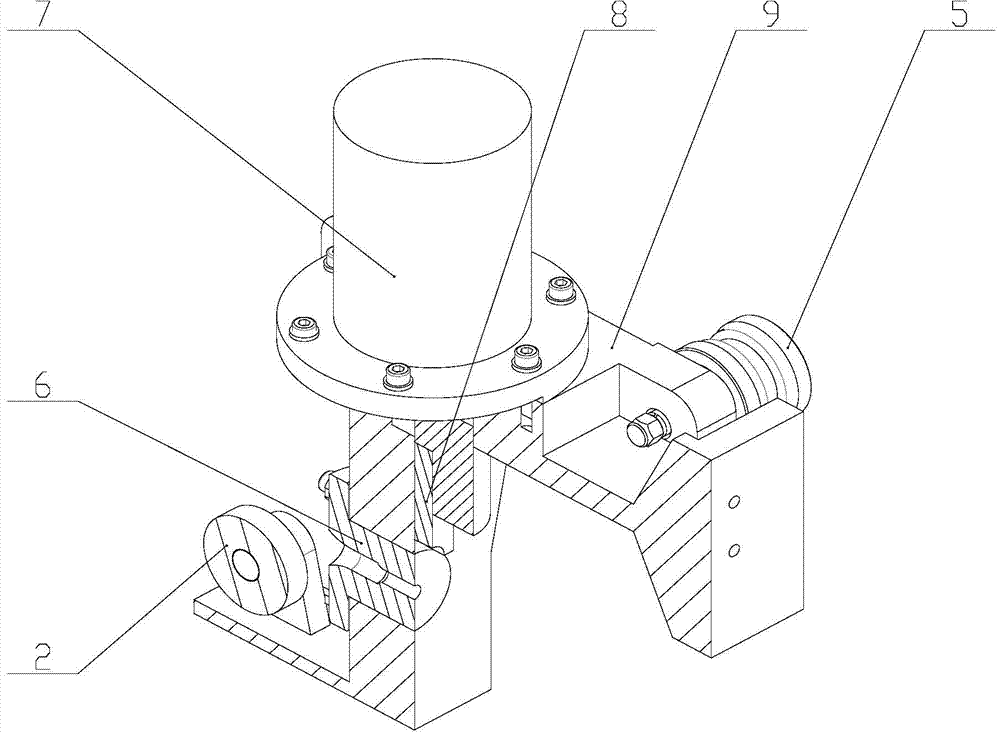

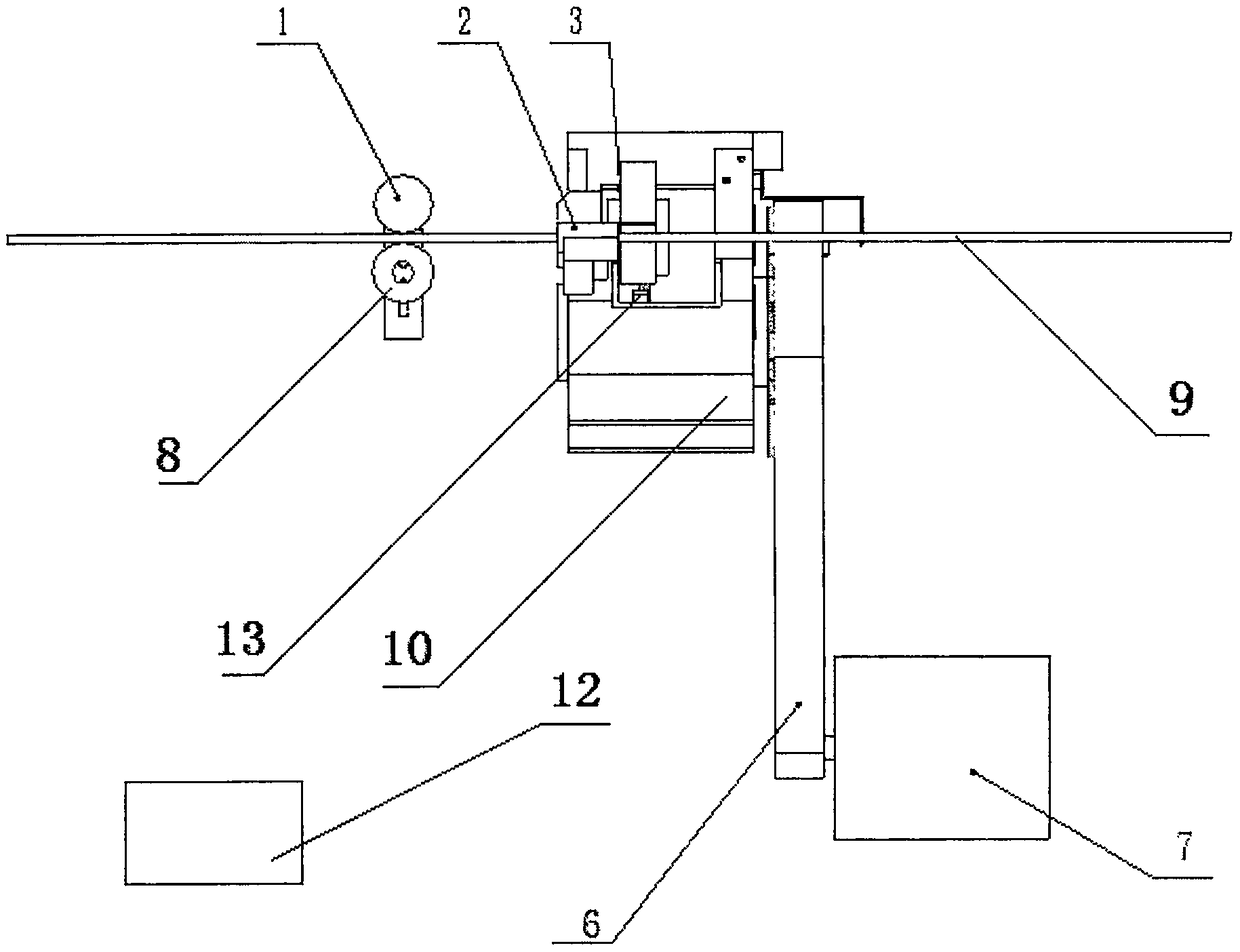

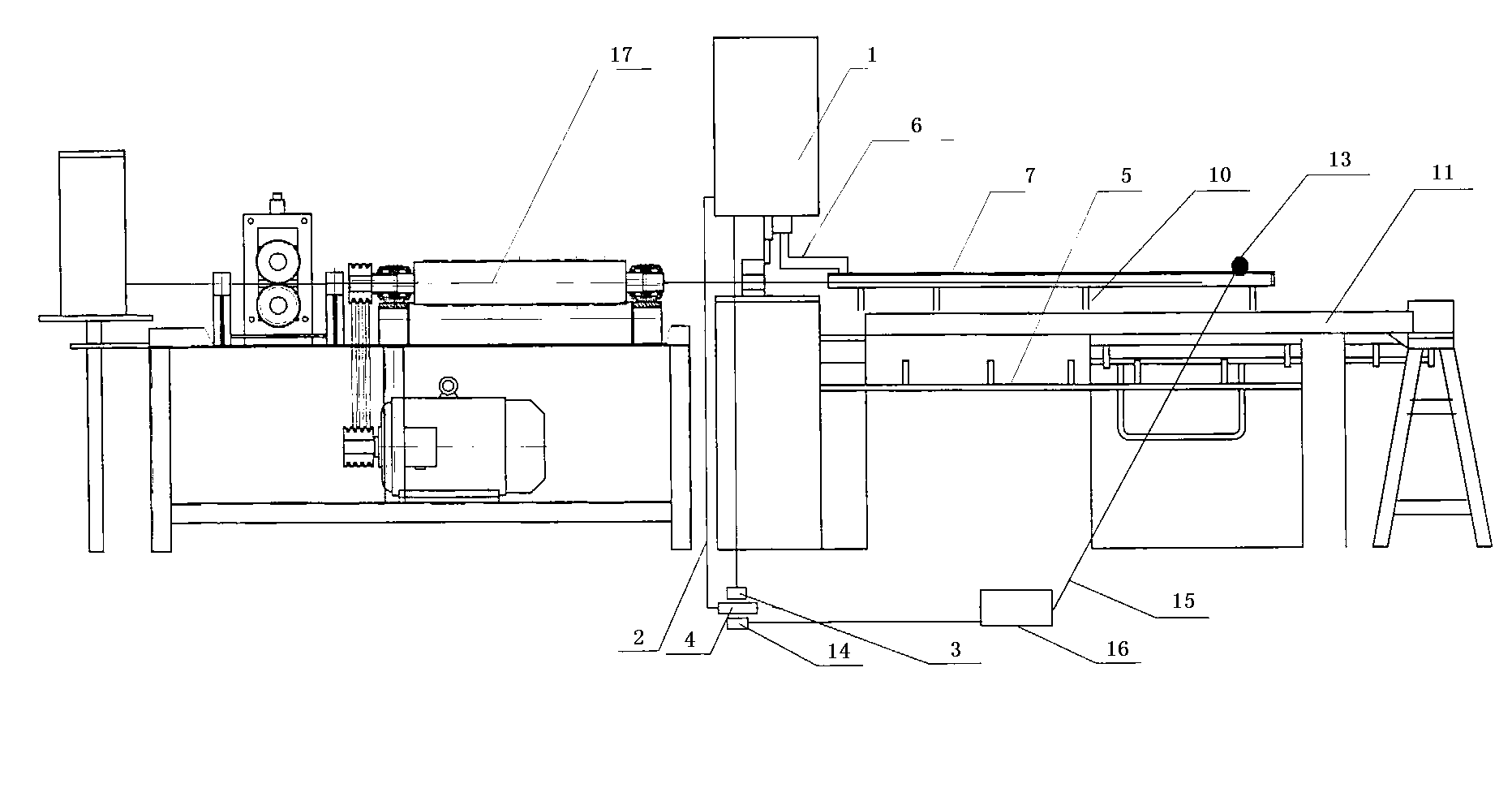

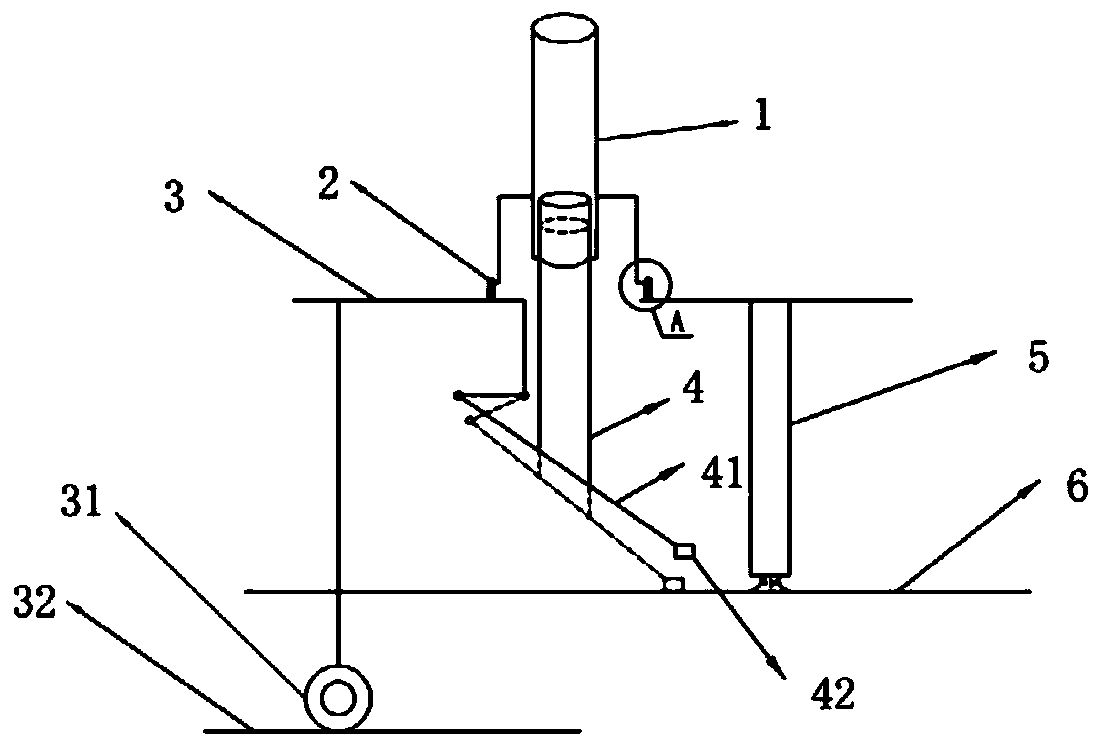

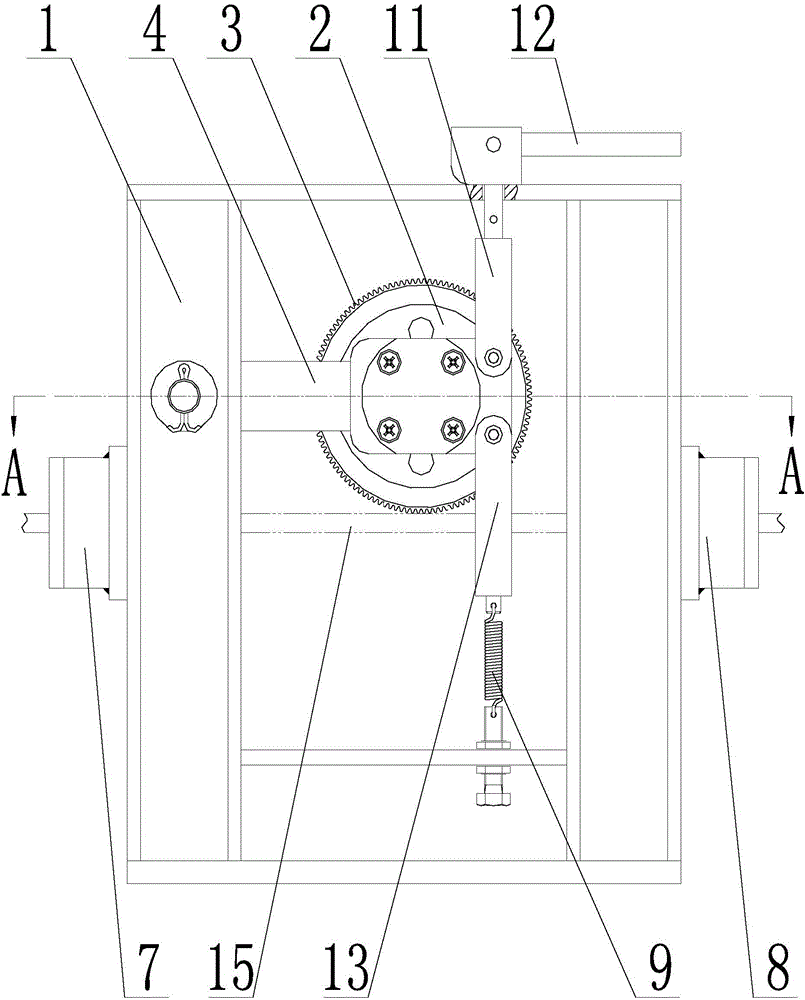

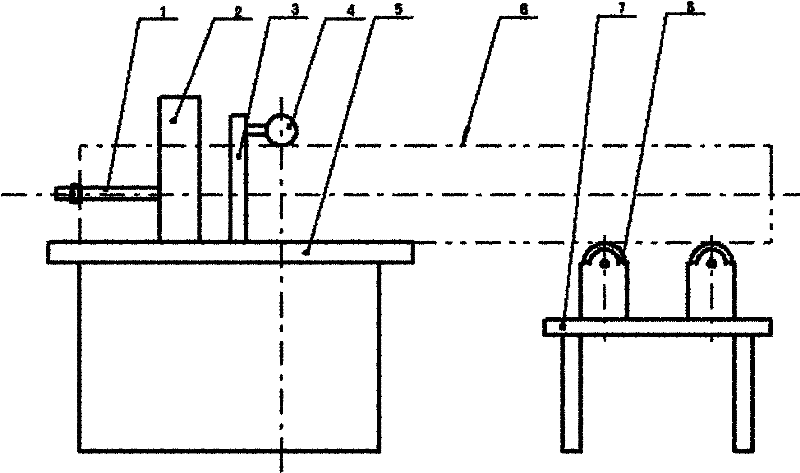

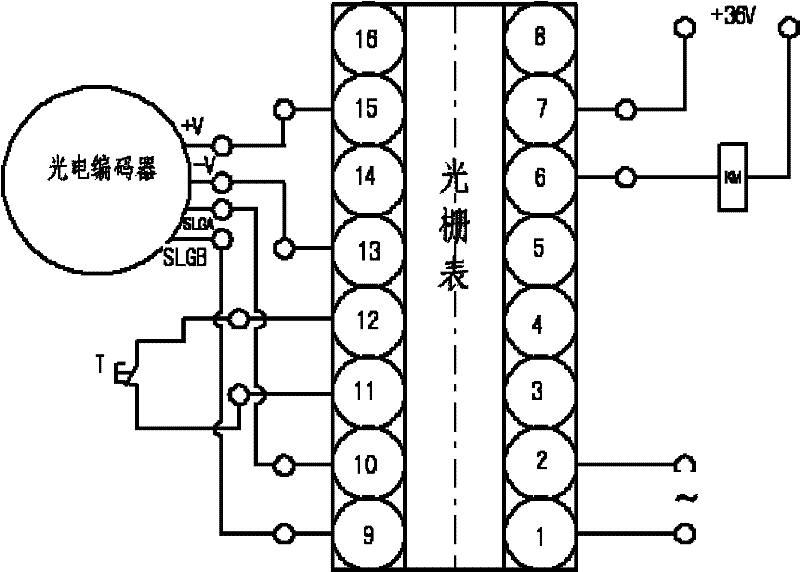

Control method for sizing accuracy of high-speed reinforcement bar straightening machine

InactiveCN108326200AHigh precision in sizingHigh precisionMetal working apparatusDrive wheelControl manner

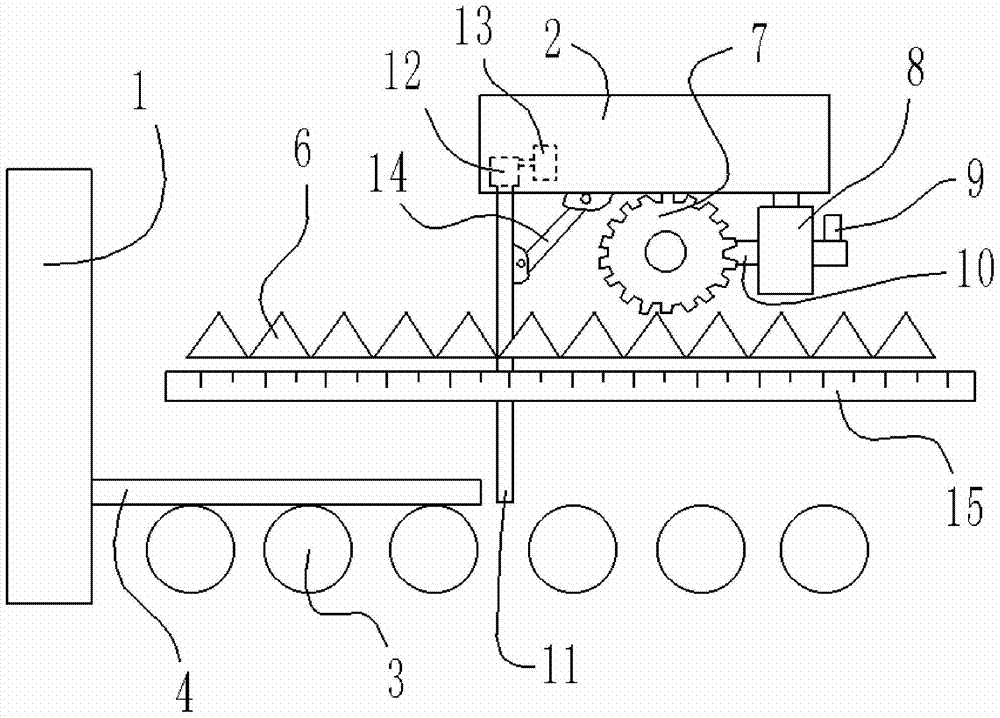

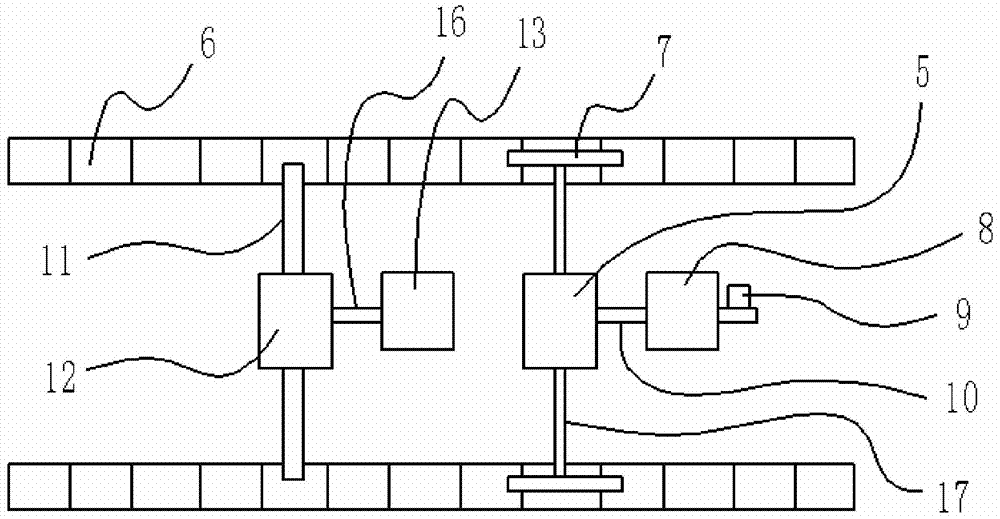

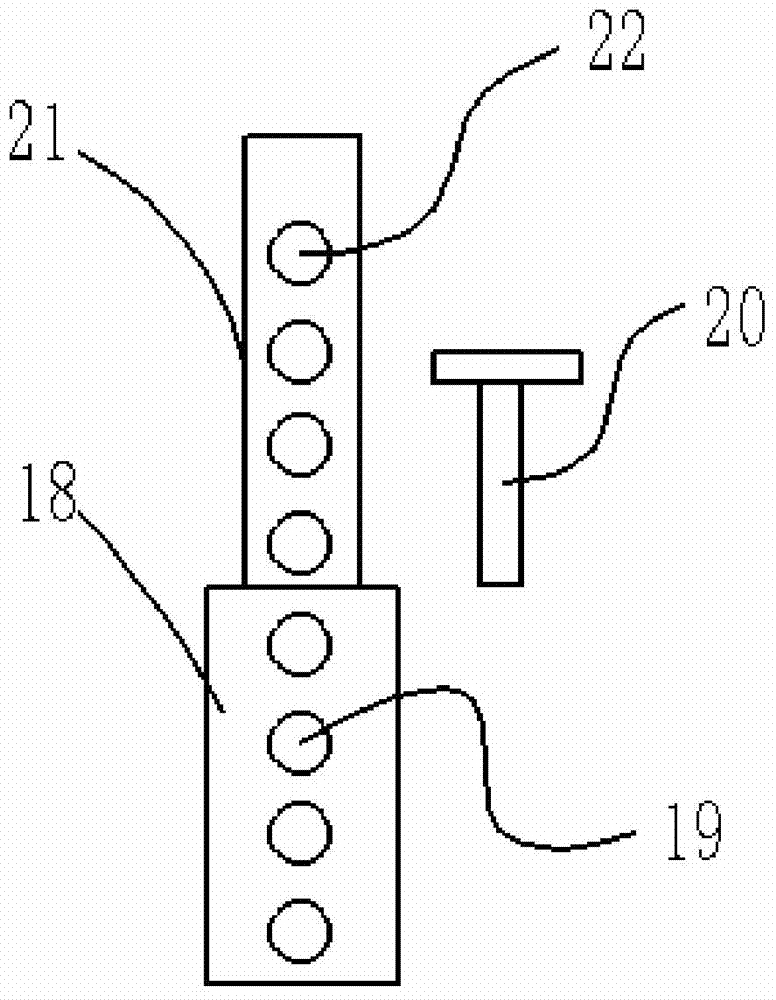

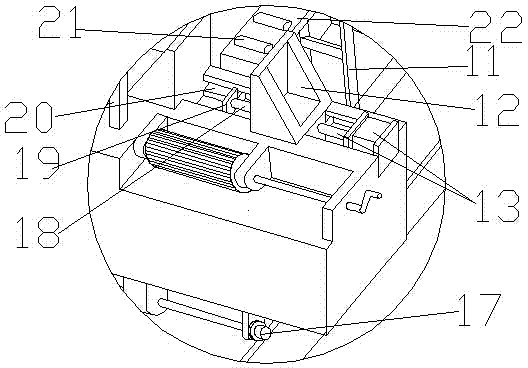

The invention provides a control method for sizing accuracy of a high-speed reinforcement bar straightening machine. The reinforcement bar straightening machine comprises an encoder (1), a fixed cutter (2), a moving cutter (3), an initial position signal sensor (4), a synchronous pulley (5), a synchronous belt (6), a servo motor (7), a driven wheel (8), a reinforcement bar (9), a shear box (10), adrive shaft (11), a PLC (programmable logic controller) (12), a cam (13) and a signal plate (14). With adoption of encoder sizing and servo shear, electrical control instead of mechanical control isadopted in the whole process from signal receiving to shear execution by a control system, time is basically consistent for different times of shear from signal receiving to shear execution by the control system, errors are avoided, and sizing accuracy of the reinforcement bar is improved effectively.

Owner:LUOYANG TIHOT RAILWAY MACHINERY MFG

Cutting-to-length system of hot-rolled round steel

InactiveCN104493288AImprove work efficiencyReduced range of movementStock shearing machinesShearing machine accessoriesHydraulic cylinderAutomatic control

The invention discloses a cutting-to-length system of hot-rolled round steel and belongs to the technical field of mechanical engineering. The cutting-to-length system comprises a trolley, a cutting rack, a carrier unit and a guide rail; the cutting rack is hinged to one end of the trolley; the other end of the trolley is provided with an automatic clamping mechanism and a manual carrying structure; the automatic clamping mechanism comprises a first clamp plate and a second clamp plate; the carrier unit is disposed in a discharging direction of the automatic clamping mechanism and comprises a conveying carrier roller support, a carrier roller base and carrier rollers; the carrier roller base is provided with a photoelectric sensor; the cutting rack comprises a cutting saw rotor base, a drive motor and a transmission device; an opening of the cutting saw rotor base is provided with a cutting saw; a second hydraulic cylinder is fixed on the guide rail; the moving end of the second hydraulic cylinder is fixedly connected with the trolley. The cutting-to-length system has the advantages that cutting-to-length is automatically controlled through the combination of the hydraulic cylinders and the trolley, the length is fixed during moving, the moving range is narrow, the speed is high, length precision is high, and operating efficiency of a shearing machine is evidently improved.

Owner:芜湖市海源铜业有限责任公司

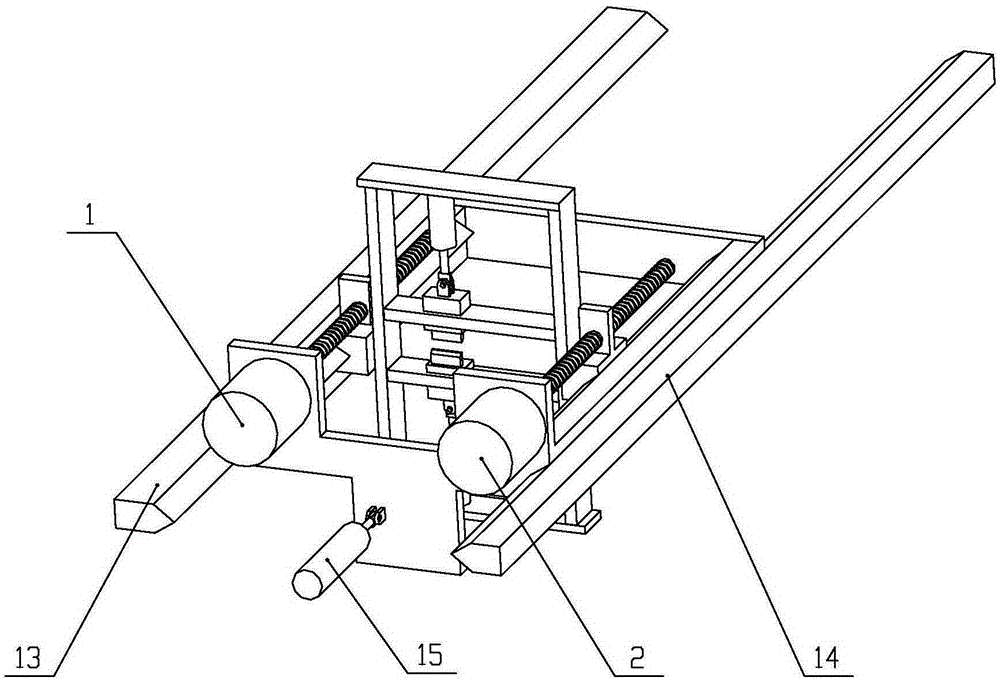

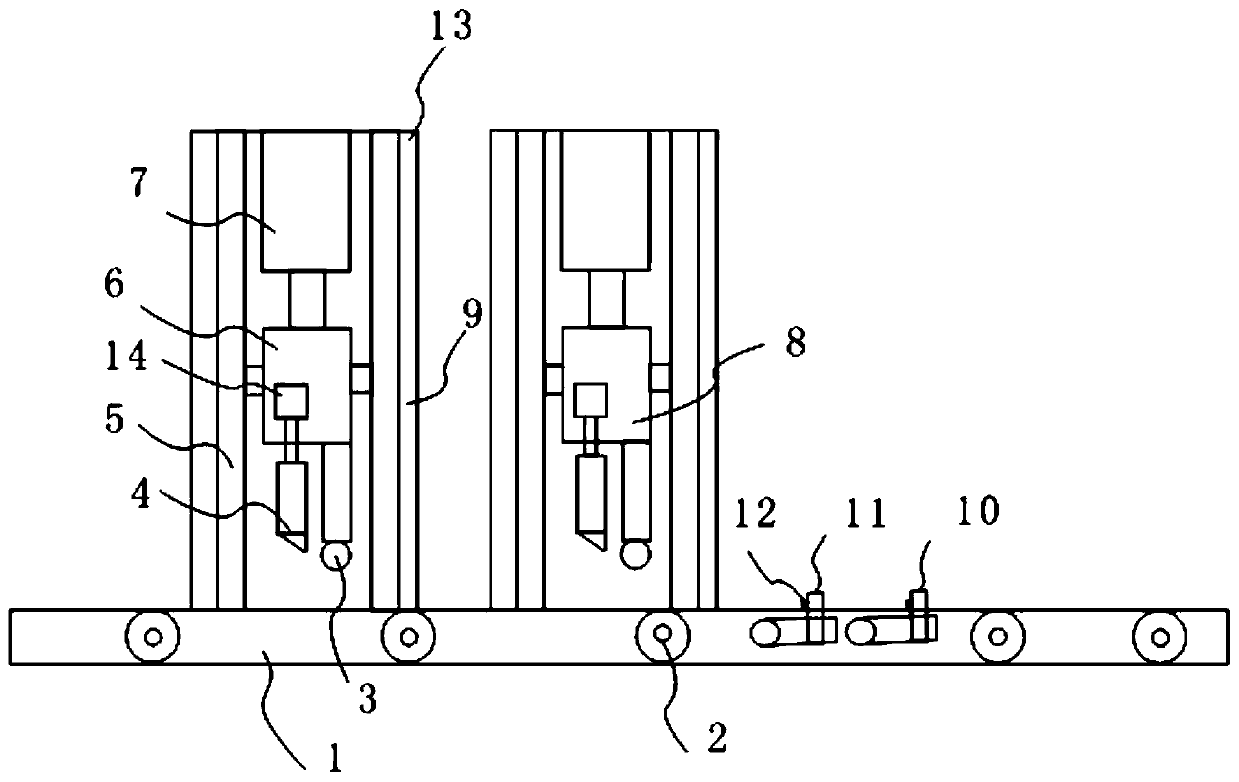

Double-acceleration synchronous tracking fixed-length flying shear

InactiveCN105252063AImprove response speedHigh precision in sizingStock shearing machinesProduction lineHydraulic cylinder

A double-acceleration synchronous tracking fixed-length flying shear is composed of a first servo motor, a second servo motor, a first sliding support, a first lead screw, a second lead screw, a second sliding support, a first hydraulic cylinder, a first shear module, a second hydraulic cylinder, a second shear module, a first guide rail, a second guide rail, a third guide rail, a fourth guide rail, a third hydraulic cylinder, a first rotary encoder, a control unit and a second rotary encoder. By the adoption of the hydraulic driving method for quick acceleration and the servo motor driving lead screw method for accurate positioning, responding speed and length setting accuracy can be effectively improved. Meanwhile, due to the adoption of a hydraulic driving shear device, the size of the whole machine can be effectively reduced. By the adoption of the flying shear, fixed-length shearing of workpieces can be achieved without stopping the machine on the whole production line, working efficiency can be improved effectively, and cost can be reduced effectively.

Owner:SHANDONG JIAOTONG UNIV

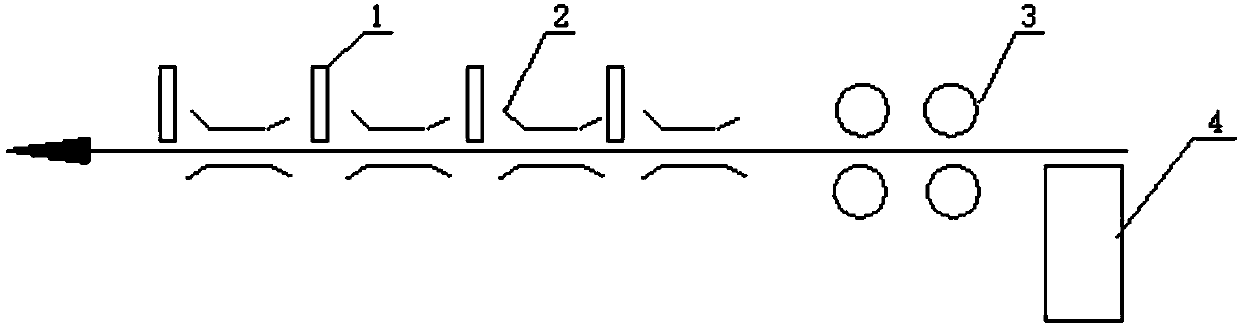

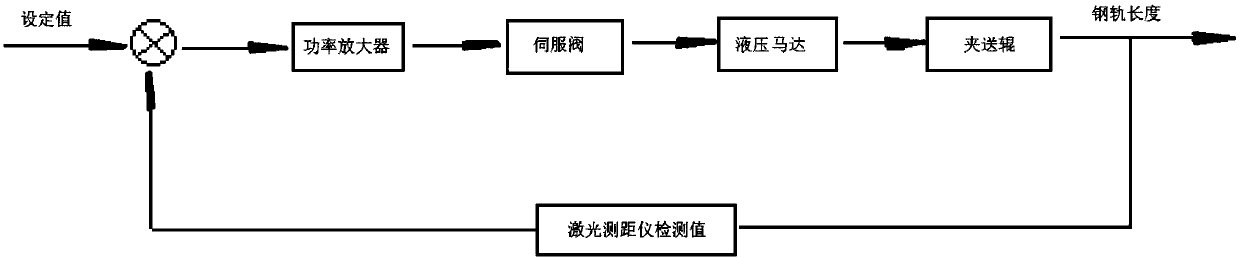

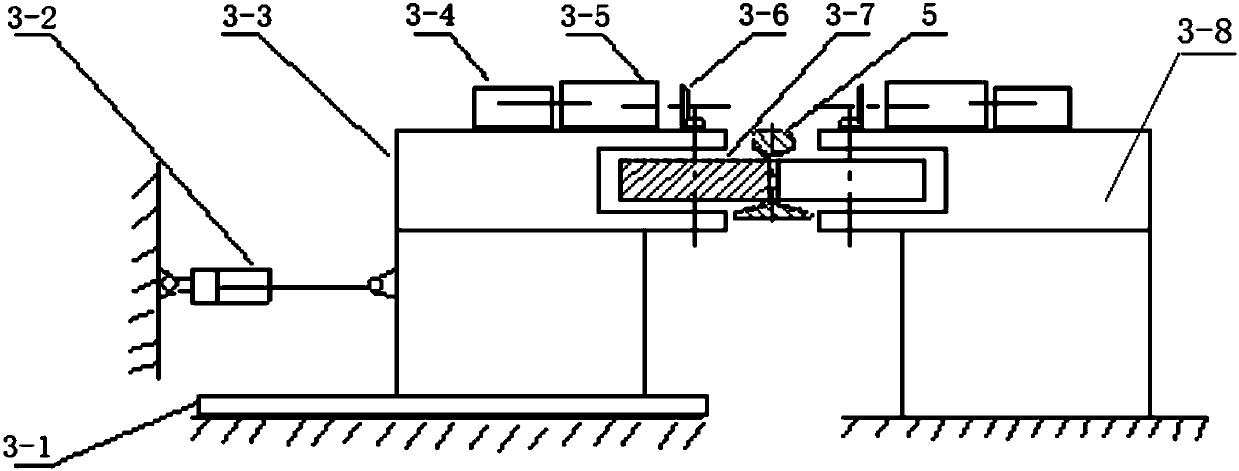

Method and device for realizing arbitrary fixed-length of steel rail

InactiveCN107598274AHigh precision in sizingEasy to change the sizeMetal sawing accessoriesLaser rangingData information

The invention provides a method and device for realizing the arbitrary fixed-length of a steel rail. The device comprises laser range finders and pinch rollers. The laser range finders are mounted ina sectioned mode on a track on the rear side of a sawing machine according to the fixed-length setting value, and the pinch rollers are mounted on the rear side of the sawing machine and the two sidesof the steel rail. Compared with the prior art, the method and device have the beneficial effects that the steel rail is subjected to whole process fixed-length monitoring through a non-contact laserfixed-length system on line, the system conducts anti-interference recognition processing on laser data information, operation information is formed and converted into an electrical signal of the prescribed form, and the steel rail is subjected to length control through an executing mechanism. The method and device have the advantages that the non-contact mode is achieved, the fixed-length precision is high, and fixed-length changing is convenient and fast.

Owner:ANSTEEL BEIJING RES INST

Automatic sizing, cutting off and blanking device for high-strength metal wire straightener

The invention discloses an automatic sizing, cutting and blanking device for a high-strength metal wire straightener. The device comprises a high-pressure cut-off machine, a blanking frame, a movable contact head and a fixed contact head, and further comprises a sizing pressing handle and a sizing guide frame, wherein the opening and closing of the sizing guide frame are in linkage with the high-pressure cut-off machine, the sizing guide frame opens when the high-pressure cut-off machine presses down, the sizing guide frame closes automatically when the high-pressure cut-off machine is lifted, a sensing joint is arranged in the sizing guide frame, an electromagnet is arranged under the movable contact head and connected with the sensing joint through wires, and an automatic control unit is connected between the wires. The device has the advantages of being simple in structure, low in cost, high in efficiency, automatic in sizing, cutting off and blanking, high in sizing accuracy and low in labor intensity of workers.

Owner:JIANGSU SHENYUAN SPECIAL STEEL

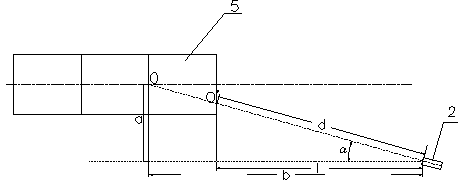

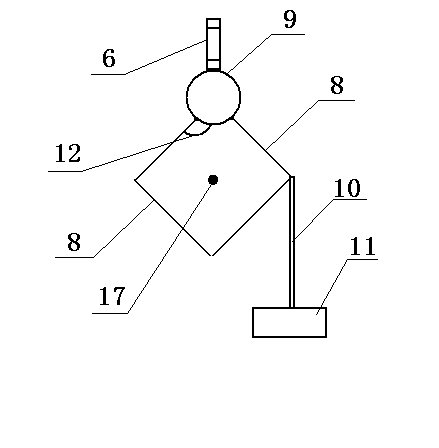

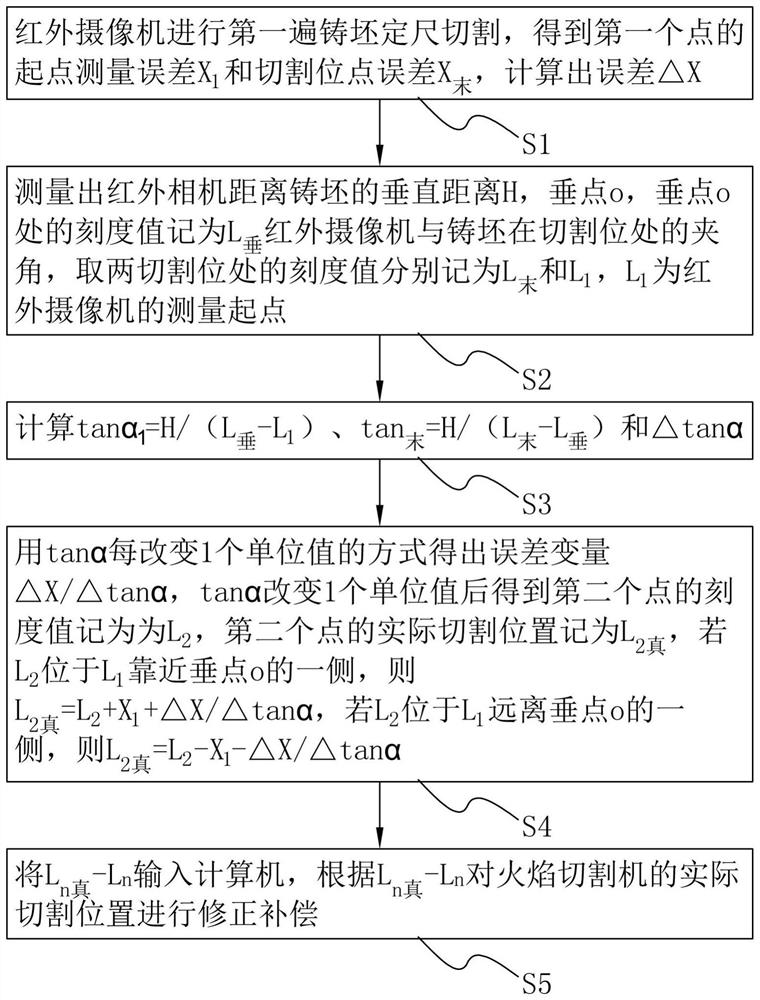

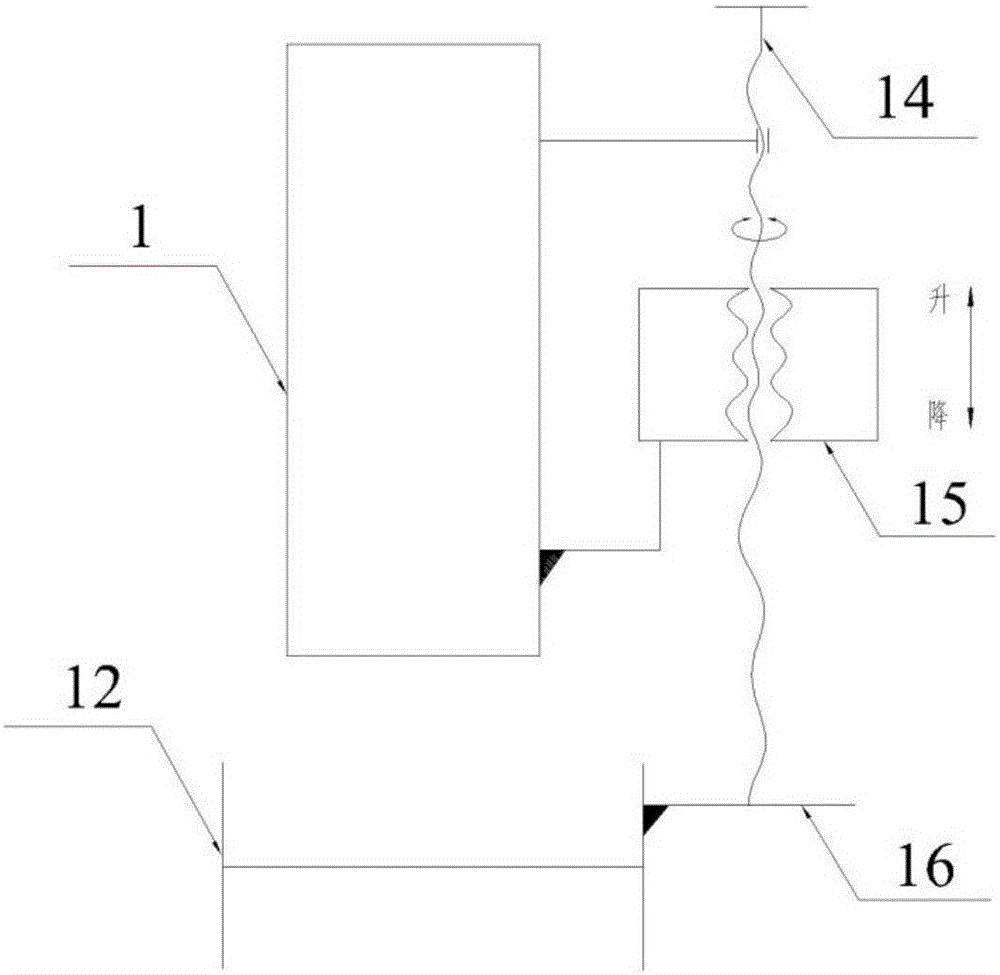

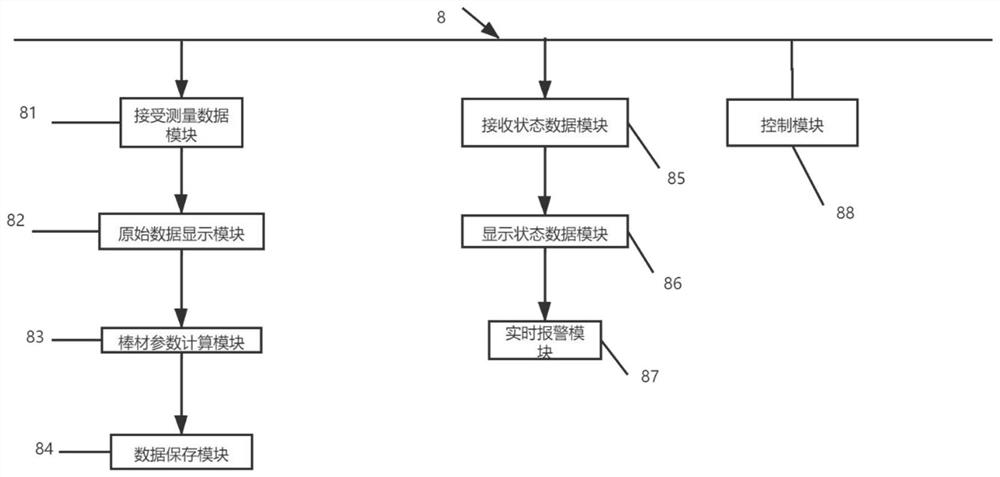

Continuous casting infrared camera shooting sizing error online continuous correction method

ActiveCN113084109AHigh precisionHigh precision in sizingCasting parameters measurement/indication devicesEngineeringSteelmaking continuous casting

The invention discloses a continuous casting infrared camera shooting sizing error online continuous correction method, relates to the technical field of steelmaking continuous casting, and solves the problem that precision is poor. According to the technical key points, the continuous casting infrared camera shooting sizing error online continuous correction method comprises the following steps that an infrared camera carries out casting blank sizing cutting for the first time, and an error delta X is calculated; the vertical distance H between the infrared camera and a casting blank is measured, and scale values at the two cutting positions are marked as Ltail and L1 respectively; and after the tan alpha is changed by one unit value, the obtained scale value of a second point is recorded as L2, and the actual cutting position of the second point is recorded as L2 true = L2 + / -X1 + / -delta X / delta tan alpha. According to the actual cutting length of the continuous casting blank, an error correction value is dynamically adjusted on line, so that the measured value is closer to an actual sizing value, the sizing precision of the continuous casting blank is improved, and important support is provided for accurately controlling the length and the weight of the continuous casting blank.

Owner:YANGCHUN NEW STEEL CO LTD +1

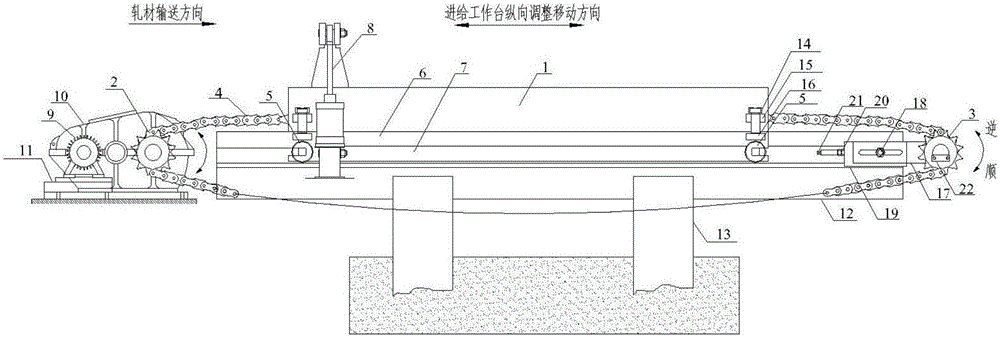

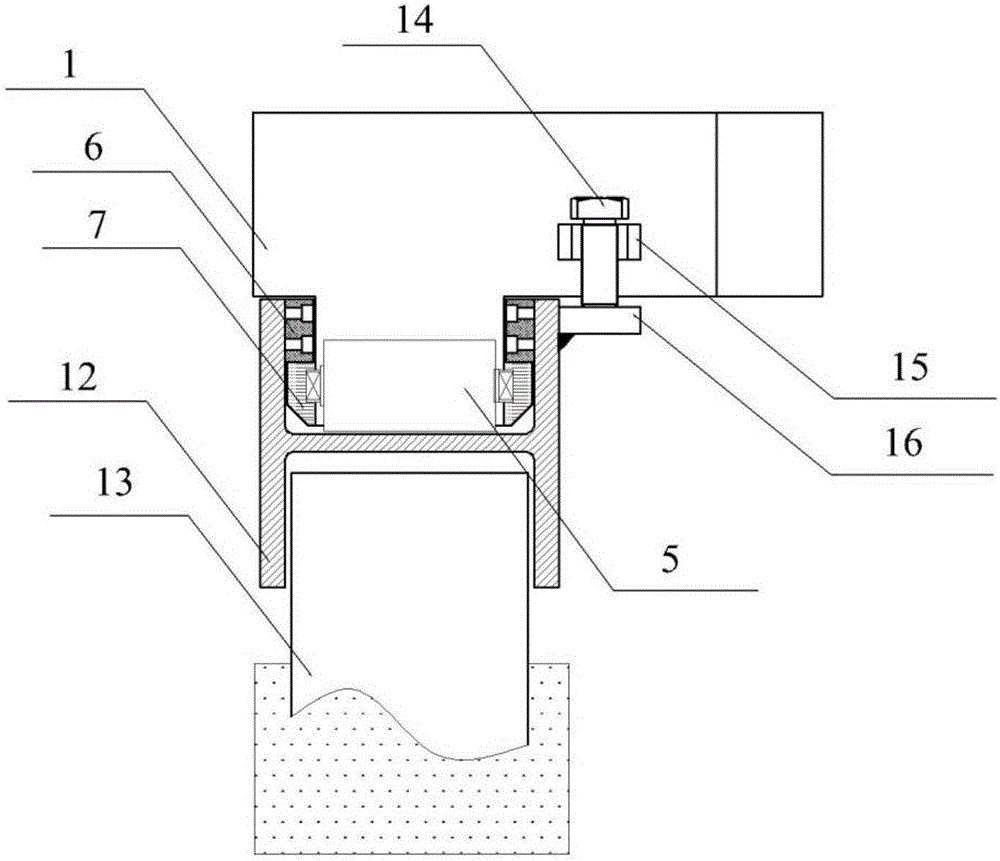

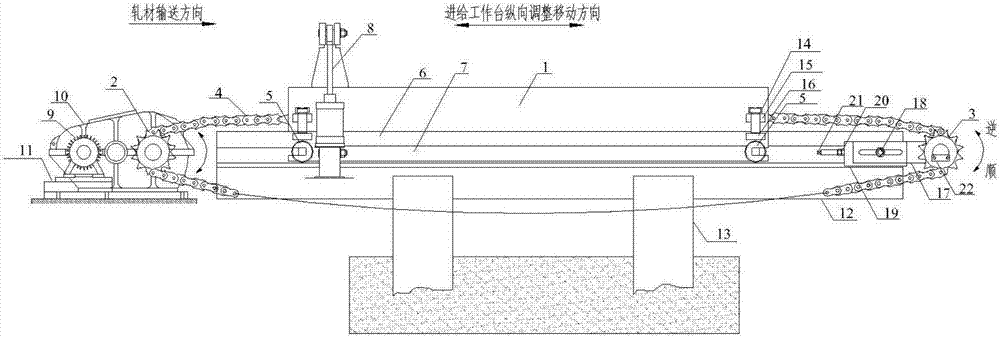

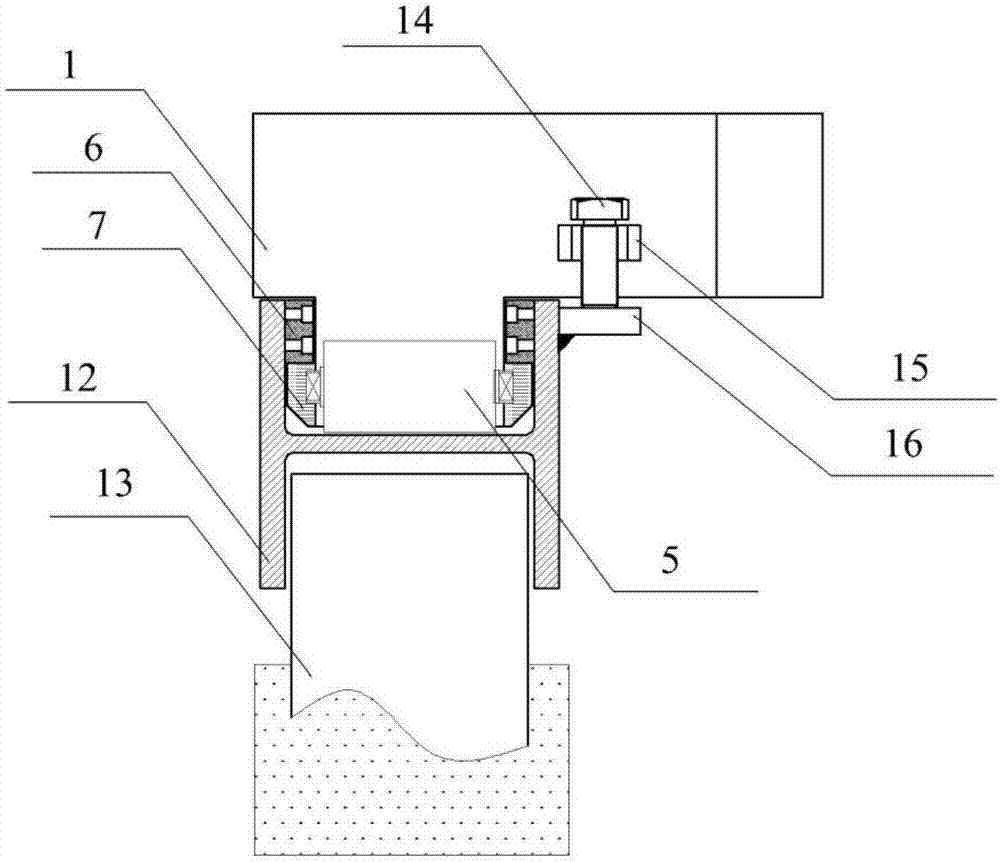

Shear gauge system and use method thereof

ActiveCN105921518AImprove transmission efficiencyHigh precisionMetal rolling arrangementsShearing machine accessoriesStatic frictionEngineering

The invention relates to a shear gauge system and a use method thereof. The shear gauge system comprises a feeding worktable, a chain wheel mechanism, a bearing mechanism, sliding screw mechanisms and a shear gauge, wherein the bearing mechanism comprises a guide groove, supporting plates and an upper friction plate; the feeding worktable is arranged on the guide groove in a slidable manner through vertical roll assemblies; a lower pressing plate is fixedly connected onto the feeding worktable; the upper surface of the lower pressing plate is in contact with the lower surface of the upper friction plate; each sliding screw mechanism comprises a welding nut fixed on the feeding worktable and a fastening bolt which are matched with each other, and the bottom of the fastening bolt is in contact with the corresponding supporting plate; the chain wheel mechanism comprises a roller chain and a first chain wheel and a second chain wheel which are meshed with the roller chain; and the shear gauge is fixedly connected onto the feeding worktable. During a use process, the sliding screw mechanisms are adjusted, so that the upper friction plate is matched with the lower pressing plate; high static friction force is provided, so that the shear gauge does not deflect under high-load impact, and the sizing precision is improved; and furthermore, the chain wheel mechanism has the advantages of high precision, abrasion-resistance, small spatial size and the like.

Owner:SHANDONG IRON & STEEL CO LTD

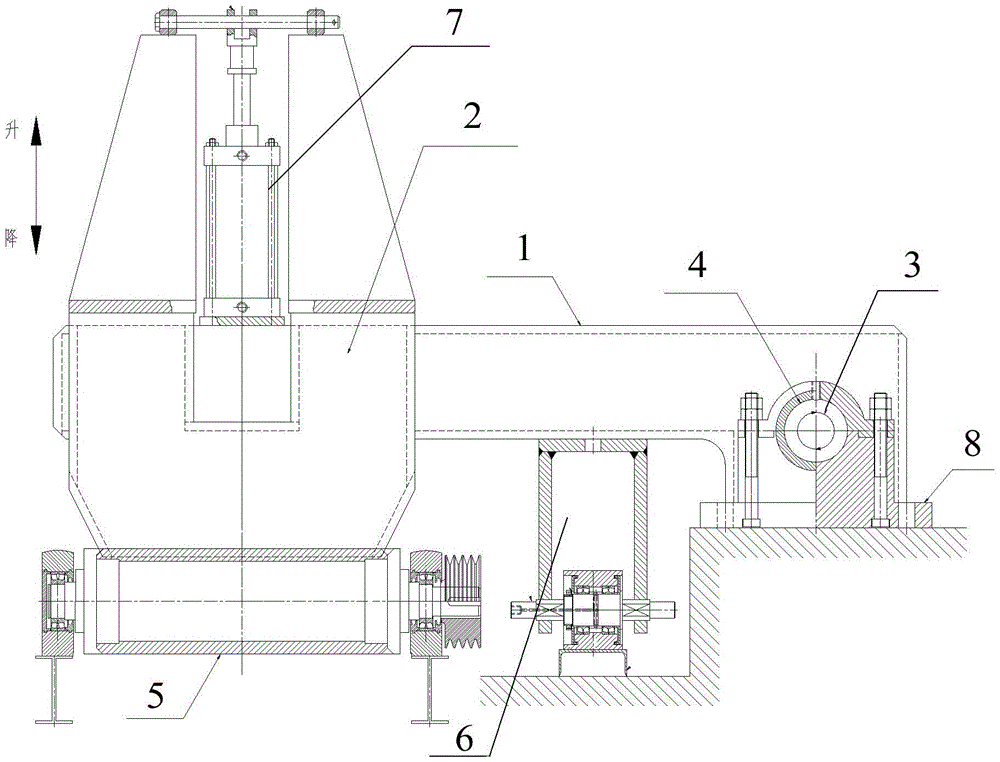

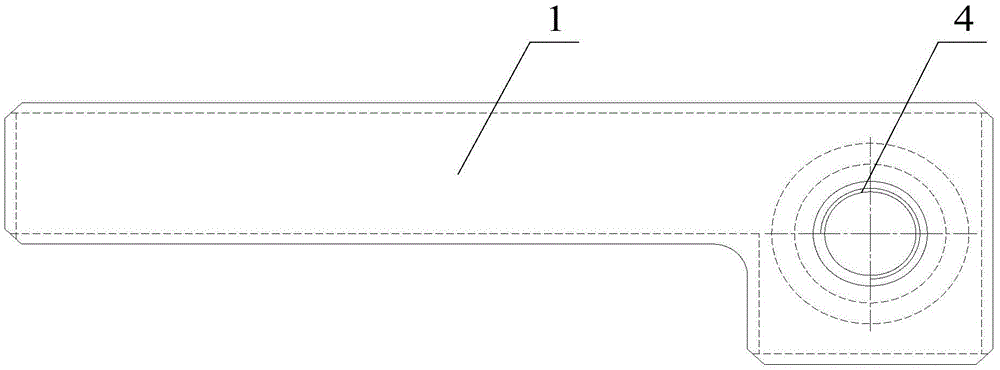

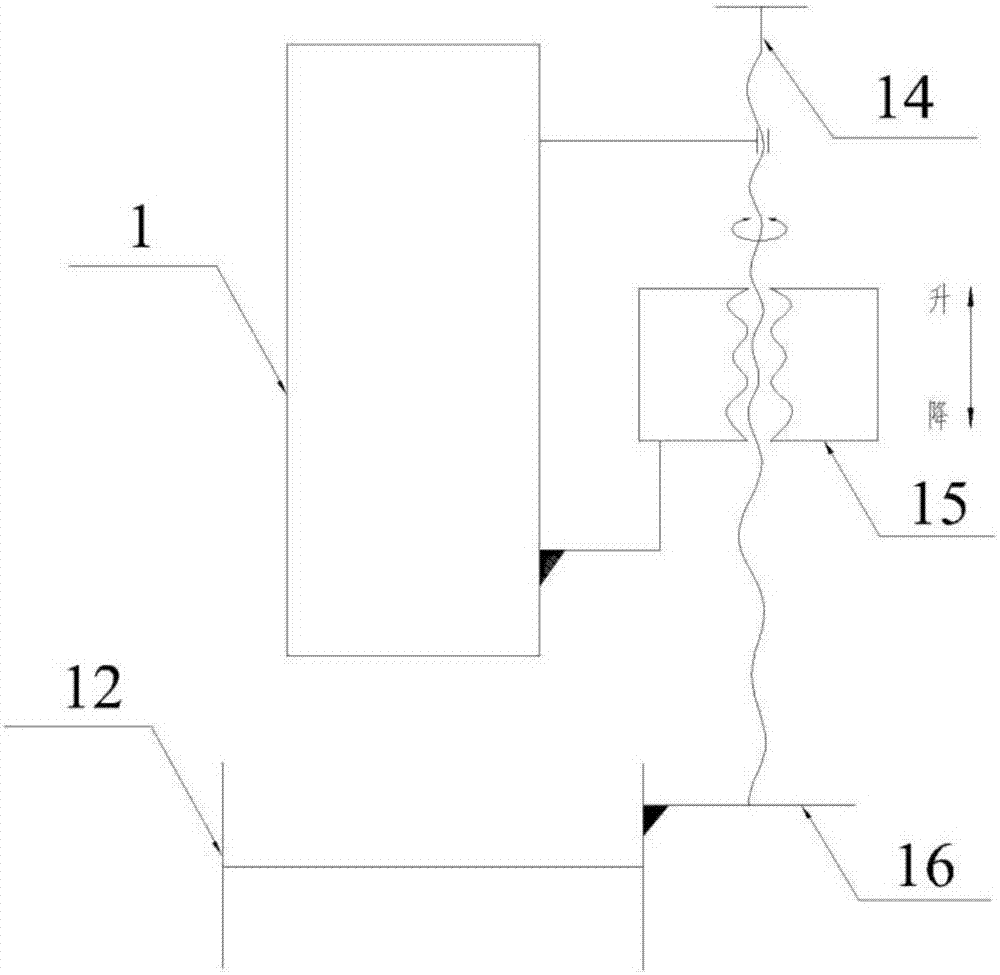

Fixed size machine and application method thereof

ActiveCN105478889ASimple structureReduce flex deformationShearing machine accessoriesAutomatic controlMechanical engineering

The embodiment of the invention discloses a fixed size machine and an application method thereof. According to the fixed size machine, a sliding screw pair structure comprising a sliding spiral lead screw and a sliding spiral nut is adopted, the parameters of a thread, the screw pitch and the like of a sliding spiral pair are set in a matched manner, and it is guaranteed that the fixed size machine cannot move when bearing the large axial horizontal impact load, so that the fixed size accuracy is high, and the sliding screw pair has the beneficial effects of being simple in structure, stable in operation, low in noise, high in screwing accuracy, large in transmission ratio and the like. A guide device is arranged, a feeding workbench can be supported effectively through the guide device, and the situation that the fixed size machine rotates along with rotation of the sliding spiral lead screw is prevented, so that flexibility deformation is lowered; and in addition, a pneumatic device is adopted for the fixed size machine and arranged on the top face of the feeding workbench, the compactness of the fixed size machine is further guaranteed, space is saved, and the fixed size machine has the beneficial effects of being simple in structure, convenient to maintain, high in automatic control level and short in response time.

Owner:SHANDONG IRON & STEEL CO LTD

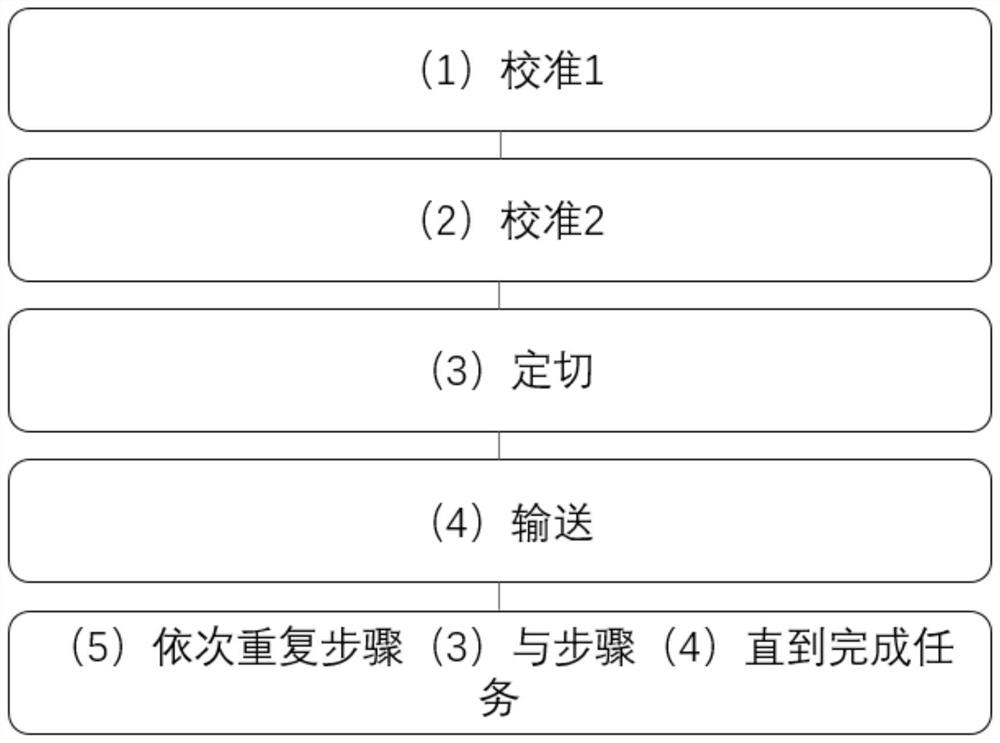

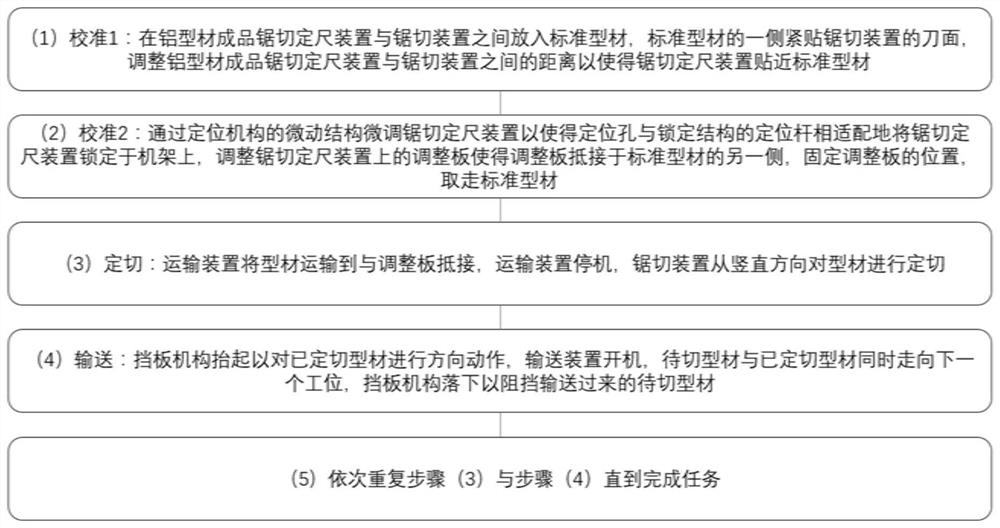

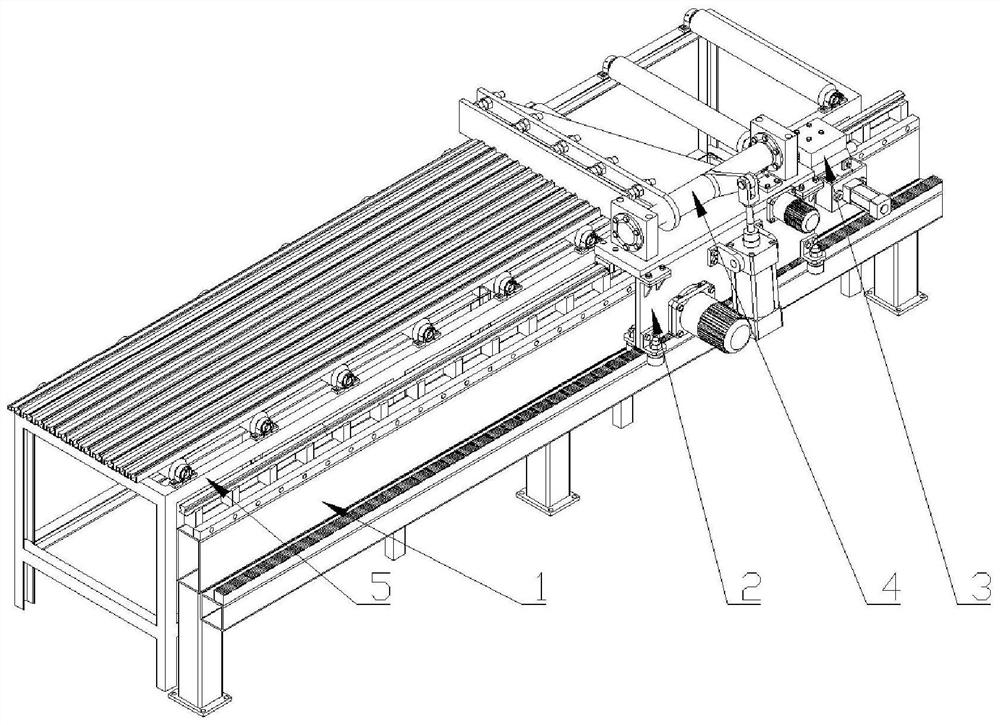

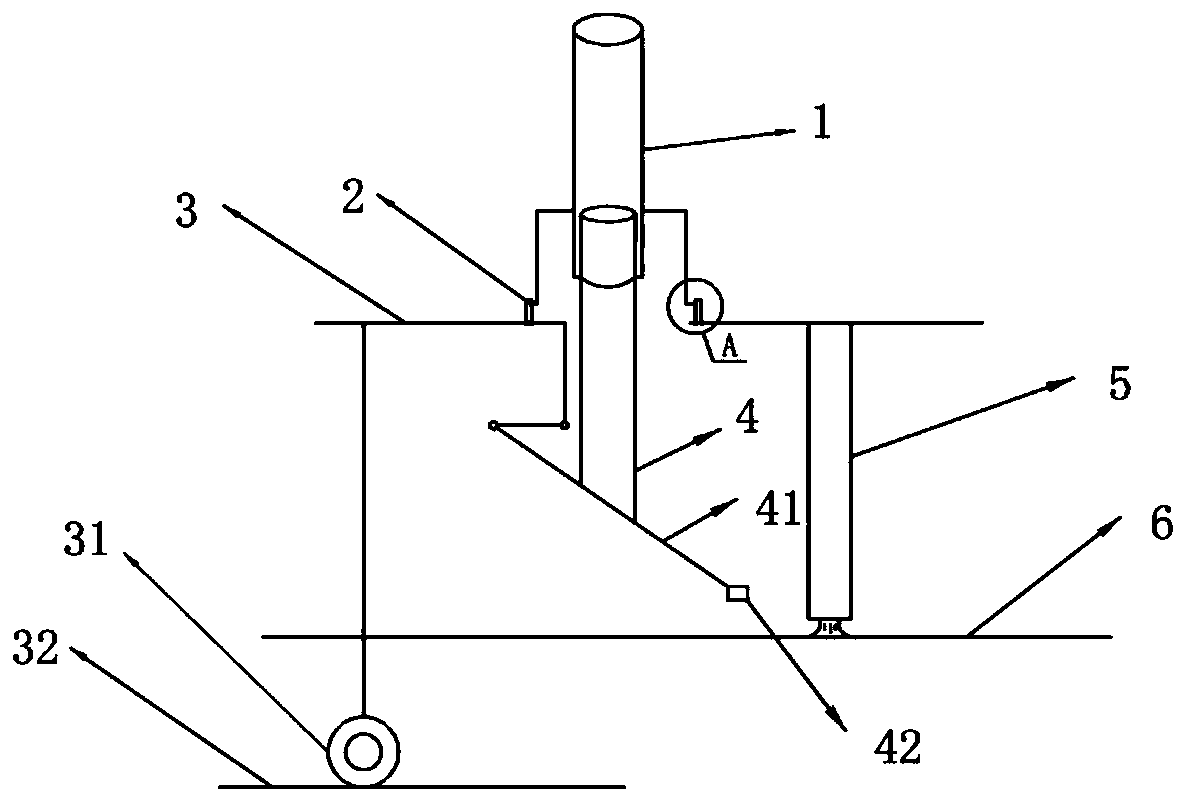

Aluminum profile finished product saw cutting sizing device and aluminum profile fixed cutting process

ActiveCN111975107APrecise sizing operationImprove work efficiencyMetal sawing devicesMetal sawing accessoriesMechanical engineeringIndustrial engineering

The invention provides an aluminum profile finished product saw cutting sizing device. The device comprises a rack, a traveling mechanism, a positioning mechanism and a baffle mechanism, wherein the rack is arranged on one side, in the conveying direction, of the conveying device, the traveling mechanism is used for moving on the rack in the length direction of the rack, the positioning mechanismis connected with the traveling mechanism and used for adjusting the position of the traveling mechanism and fixing the traveling mechanism and the rack through the positioning mechanism, the baffle mechanism is connected with the traveling mechanism and used for stopping a profile to be sawn and releasing the sawn profile, and meanwhile the aluminum profile fixed cutting process is provided. According to the device and the process, accurate sizing operation can be achieved, large-batch multi-time cutting can be conducted uninterruptedly, the working efficiency is improved, waste caused by inaccurate positioning is reduced, the overall structure is high in automation degree, the sizing precision is greatly improved, the operation intensity of workers is reduced, the stability and durability of the overall structure are greatly improved, and the service life of the device is prolonged.

Owner:GUANGDONG HAOMEI ALUMINUM

Sizing cutting device for thick plate continuous casting machine and method for improving sizing accuracy

The invention provides a sizing cutting device for a thick plate continuous casting machine and a method for improving the sizing accuracy. The method includes the following steps: (a) for casting blanks with different thicknesses, the time of a pressing head of a pressing rod of the continuous casting machine from receiving a pressing signal to pressing the casting blanks are the same; (b) the actual position of a flame cutting trolley is corrected by adopting a laser positioning method, and thus the positioning error of the flame cutting trolley is controlled to be within 2 mm; (c) a gun body of a flame cutting gun is protected, and the gun body is prevented from deforming after being heated; (d) according to weighing results returned by a casting blank weighing system, a cutting sizingcorrection value is dynamically corrected; and (e) a rollertable weighing system is checked for 1-2 times a day, and a roller table correction system is corrected, so that the weighing accuracy of a roller table is improved. According to the sizing cutting device for the thick plate continuous casting machine and the method for improving the sizing accuracy, the fluctuation of the sizing accuracyof the casting blanks with the different thicknesses is effectively reduced, the sizing length accuracy of the casting blanks with the different thicknesses can be the same, and the sizing accuracy ofthe casting blanks with the different thicknesses can be improved stably.

Owner:SHANDONG IRON & STEEL CO LTD

High-precision and high-efficiency fixed-length shearing control method and device for bars

PendingCN111482663AReasonable control of production costsHigh precisionFeeding apparatusPositioning apparatusStructural engineeringIndustrial engineering

Owner:盐城市联鑫钢铁有限公司

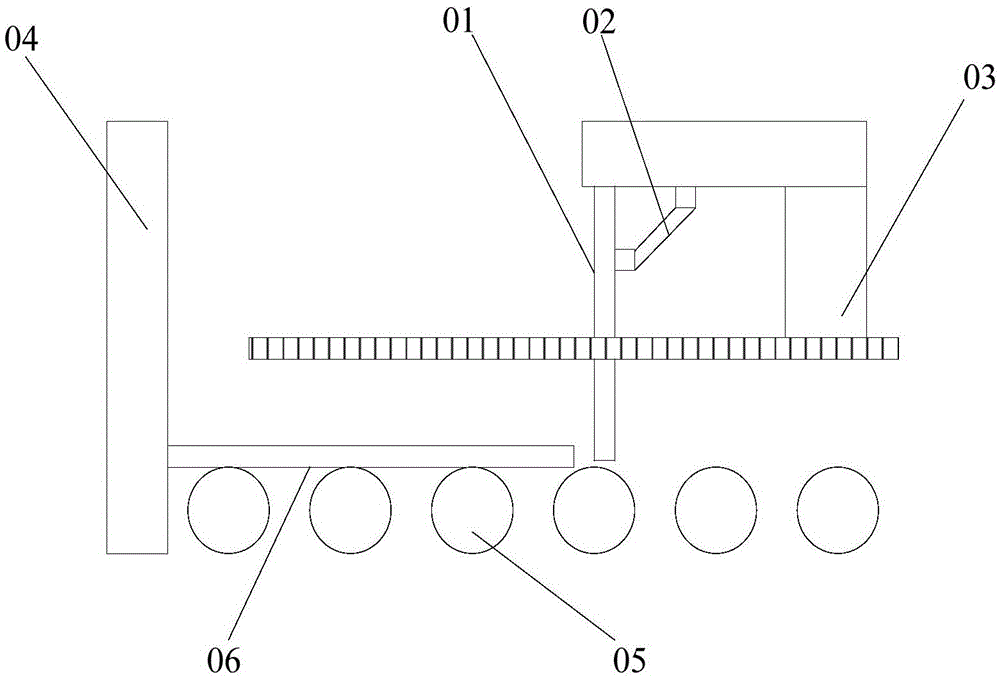

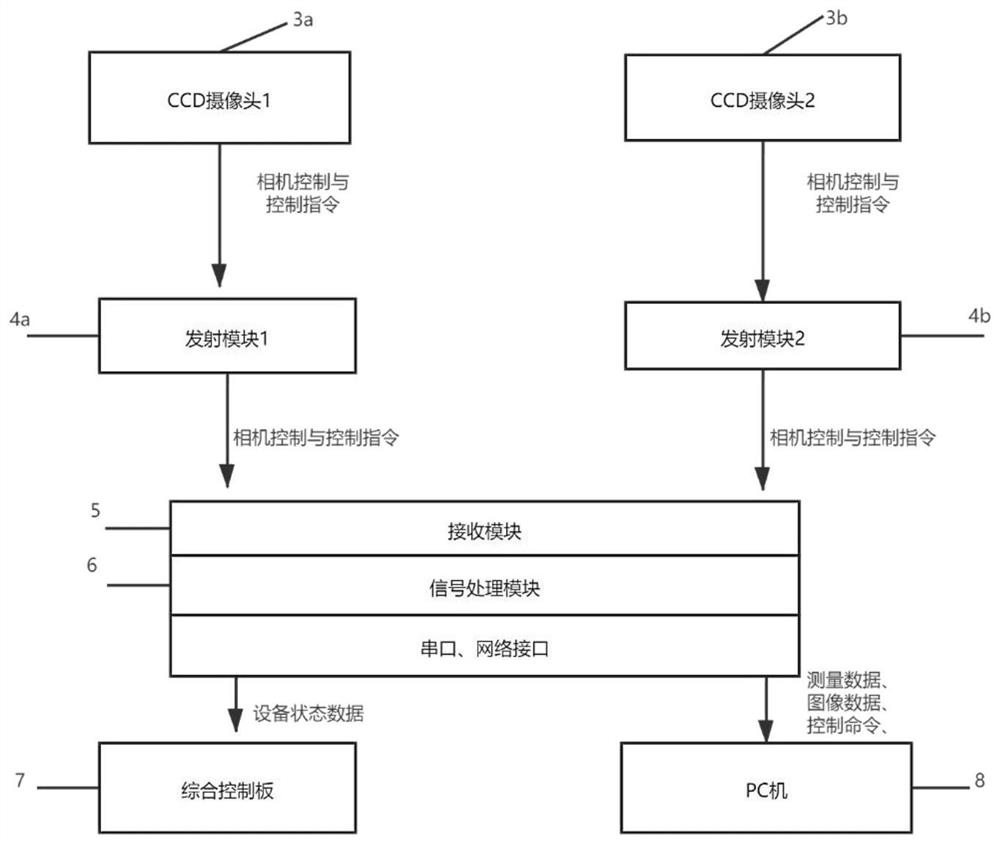

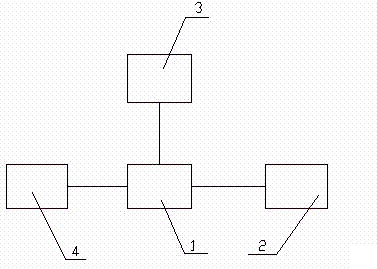

Efficient and accurate round steel automatic sizing system

PendingCN113103069AAvoid non-compliance with standard requirementsAvoid wastingAutomatic control devicesMeasurement/indication equipmentsLogistics managementControl system

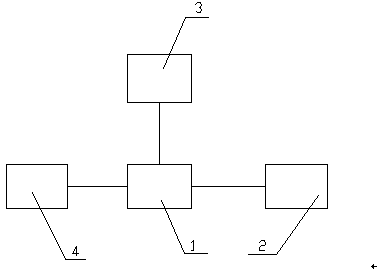

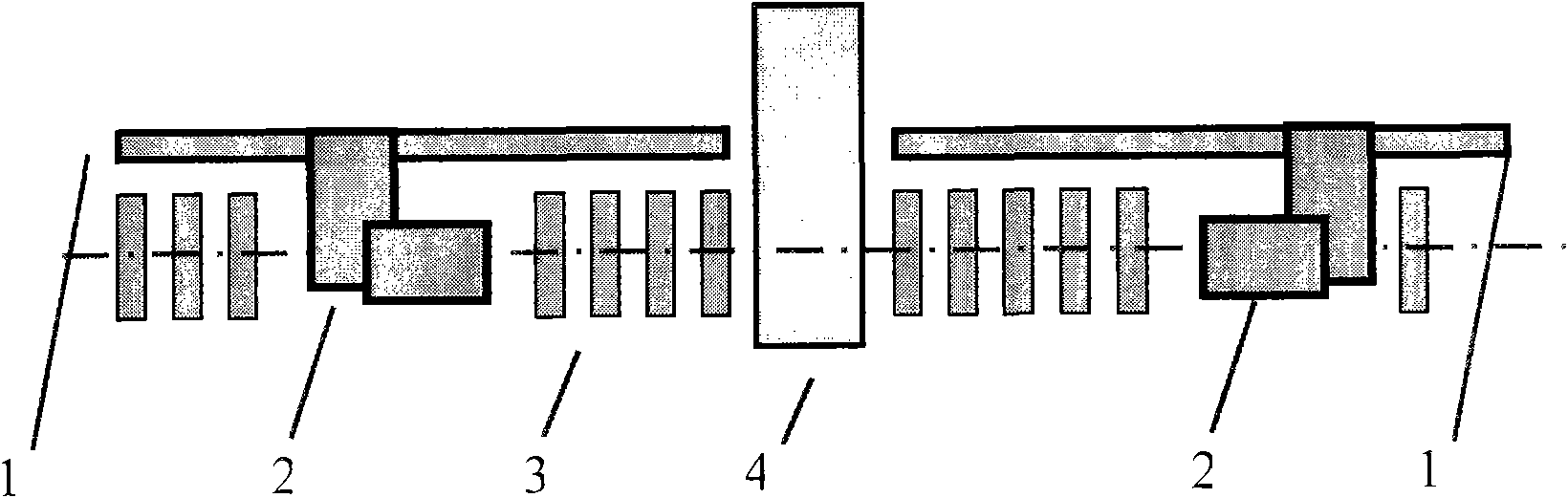

The invention discloses an efficient and accurate round steel automatic sizing system, and relates to the technical field of metal bar sizing. The method comprises the specific steps that first, machine vision distance measurement is conducted, and the length of a steel bar is measured by adopting a machine vision system; second, automatic sizing is carried out, algorithm compiling operation is designed in a C language programming environment, and the requirements for the qualification rate and the yield of sizing of a steel ball blank are met; and third, system control is performed, the related production technologies and processes include length measurement, material turning, calculation and cutting, and press breaking and alignment, and the round steel automatic sizing system is composed of a PLC unit (1), a machine vision detection unit (2), a display unit (3), a calculation unit (4), a power supply system, a production workshop logistics scheme, matters needing attention and the like. By optimizing the steel bar length measurement and steel bar automatic sizing control system, the sizing precision is high, the sizing is stable, calibration is simple, installation, debugging, operation and maintenance are easy, the operation cost is low, cutting is accurate, the sizing rate and the yield are increased, and the rejection rate is lowered.

Owner:TONGLING UNIV

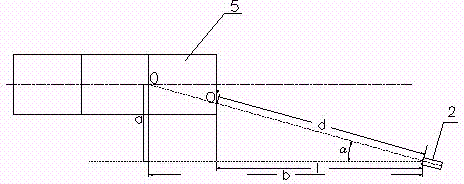

Continuous casting slab laser sizing system

ActiveCN103350200BHigh precision in sizingSimple installation and debuggingOptoelectronicsFlame cutting

The invention discloses a continuous casting billet laser sizing system. The continuous casting billet laser sizing system comprises a PLC unit, a laser detection unit, a display unit and a calculation unit, wherein the PLC unit controls a roller bed of a continuous casting machine and a flame cutting machine; the laser detection unit is connected with the PLC unit and is used for detecting relative positions of continuous casting billets; the display unit is connected with the PLC unit and is used for monitoring operating conditions of the whole system and allowing workers to input necessary data during debugging; the calculation unit is connected with the PLC unit and is used for converting the relative positions, detected by the laser detection unit, of end surfaces of the continuous casting billets into actual lengths of the continuous casting billets. The continuous casting billet laser sizing system has the advantages of being high in sizing precision, stable and simple in calibration, easy to install, debug, operate and maintain, low in operation cost and accurate in cutting, improves sizing rate and yield and reduces rejection rate.

Owner:江阴福盛自动化仪表有限公司

Container bottom side beam and cold roll forming special-shaped beam servo tracking fixed-length cutting device

PendingCN111036978AHigh precision in sizingAutomatic control devicesMetal-working feeding devicesSizingServo

The invention relates to the technical field of bottom side beam production and discloses a container bottom side beam and cold roll forming special-shaped beam servo tracking fixed-length cutting device. The device comprises a bottom plate. The device is characterized in that a measuring base and a cutting-off device base are supported through the bottom plate, a to-be-machined material enters from the top of the left side of the measuring base, and the material can only move forwards and backwards in the direction of the measuring base under the guiding effect of a vertical guide roller andthe correcting effect of a correcting roller machine, the material can only move back and forth along the direction of the measuring base when the material passes through the length measuring device,the length measuring device detects the length of the material, length data is converted into an electric signal to be sent to a servo motor control cutting device for cutting, a servo motor is adopted to replace an original air cylinder to follow up, the length is measured through an external encoder on the length measuring device, signals are fed back to the servo motor, the servo motor drives ahydraulic cutting-off shearing machine to walk along with materials, the cutting-off process is completed, and a purpose of high sizing precision is achieved.

Owner:南通通和机床科技有限公司

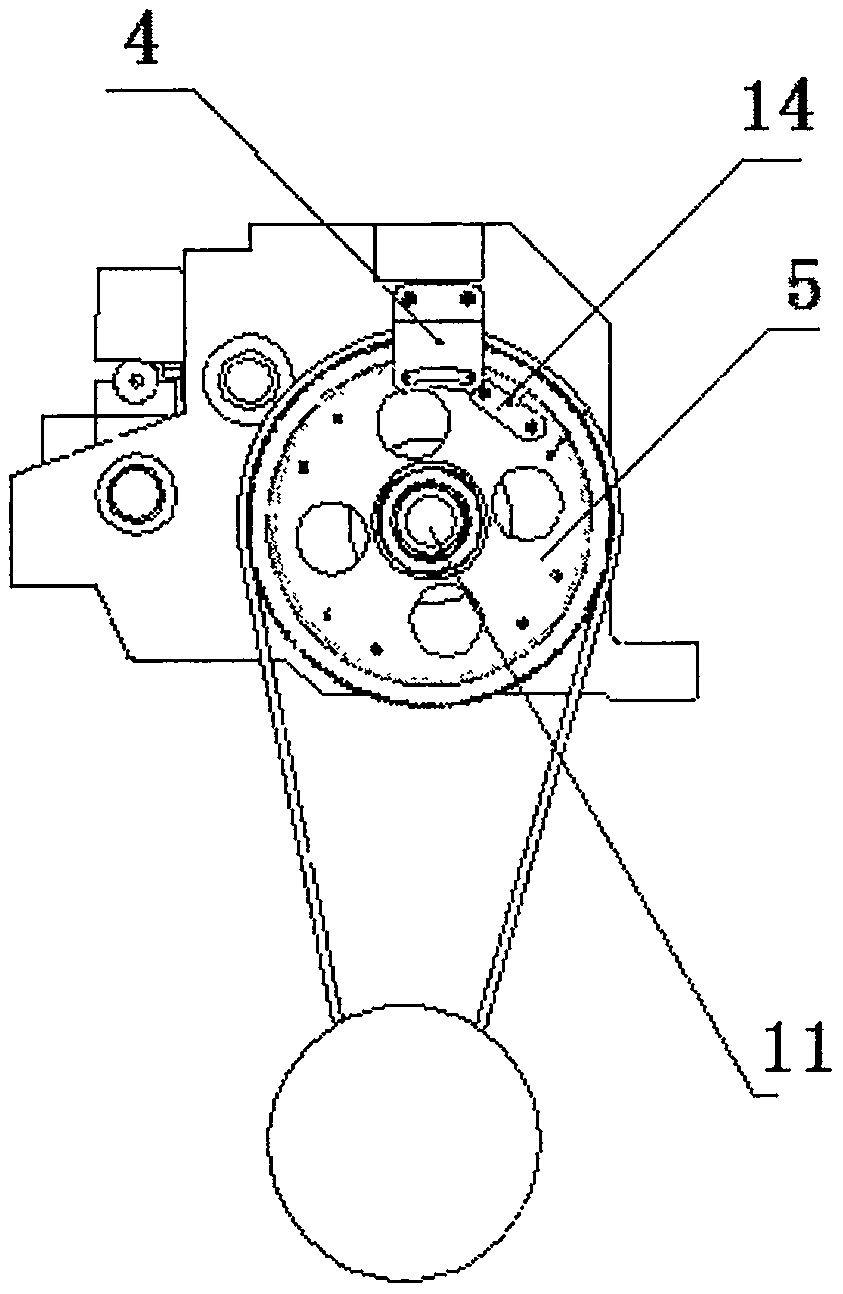

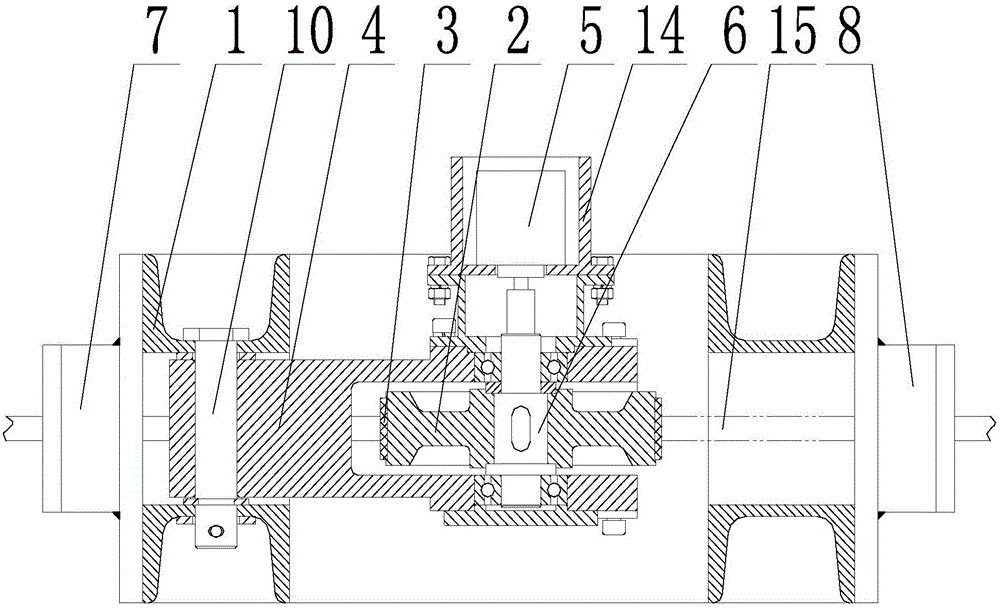

An automatic measuring mechanism for steel bar straightening and cutting equipment

ActiveCN103785710BWear fastHigh precision in sizingMetal working apparatusMetallic materialsEngineering

The invention discloses an automatic scale measure mechanism for steel bar straightening and cutoff equipment, belonging to the technical field of automatic strengthening and cutoff of disc steel bars. A scale measure wheel of the automatic scale measure mechanism is connected in a flexible fixation manner, the selection direction of a single steel material at the present stage is abandoned, the habitual thoughts about material selection of the traditional scale measure wheel are overcome, and a dismountable structure which adopts combination of a soft nonmetal material friction sleeve belt and a hard base wheel is creatively provided; during work, the friction sleeve belt can be rapidly replaced in the case of abrasion, which is not like the manner that the overall traditional scale measure wheel needs to be replaced in the case of abrasion, thus the use cost of the scale measure wheel is greatly lowered; when the friction sleeve belt is in contact with a steel bar moving at high speed, a high friction coefficient between the friction sleeve belt and the steel bar can be guaranteed, thus slip phenomenon is farthest reduced, and the automatic scale measure mechanism has a quite high sizing accuracy. The automatic scale measure mechanism disclosed by the invention solves the problems of abrasion, slip and sizing accuracy that cannot be solved by the existing high-cost technologies with low cost, and changes the development direction of the technical field of the current steel bar strengthening and cutoff.

Owner:沈阳建筑大学工厂

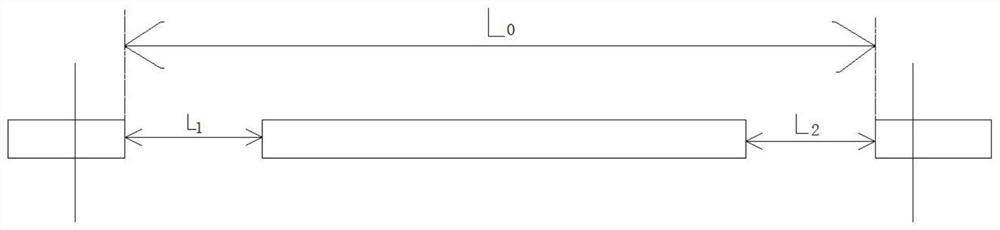

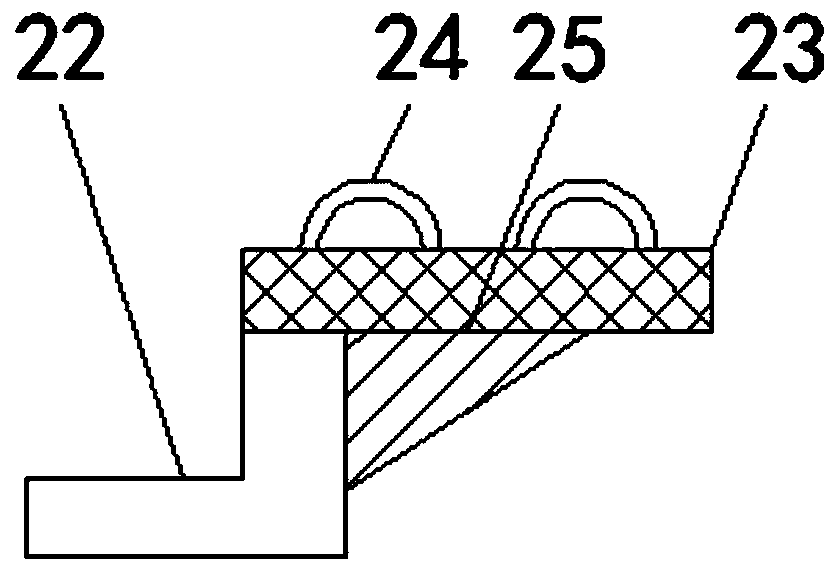

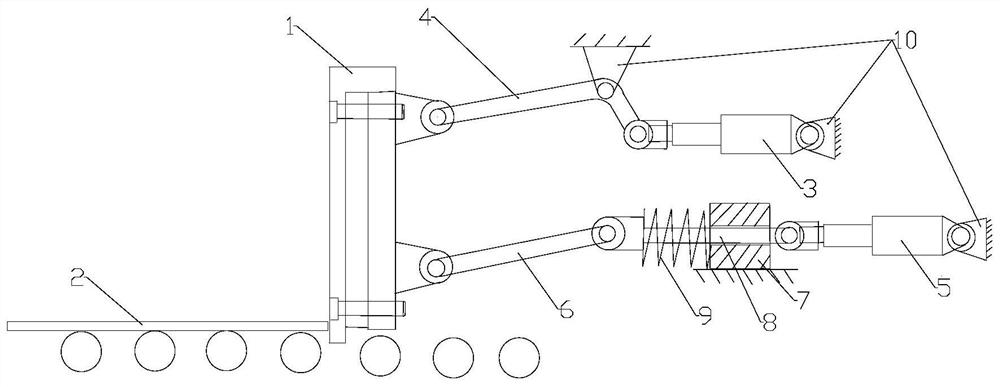

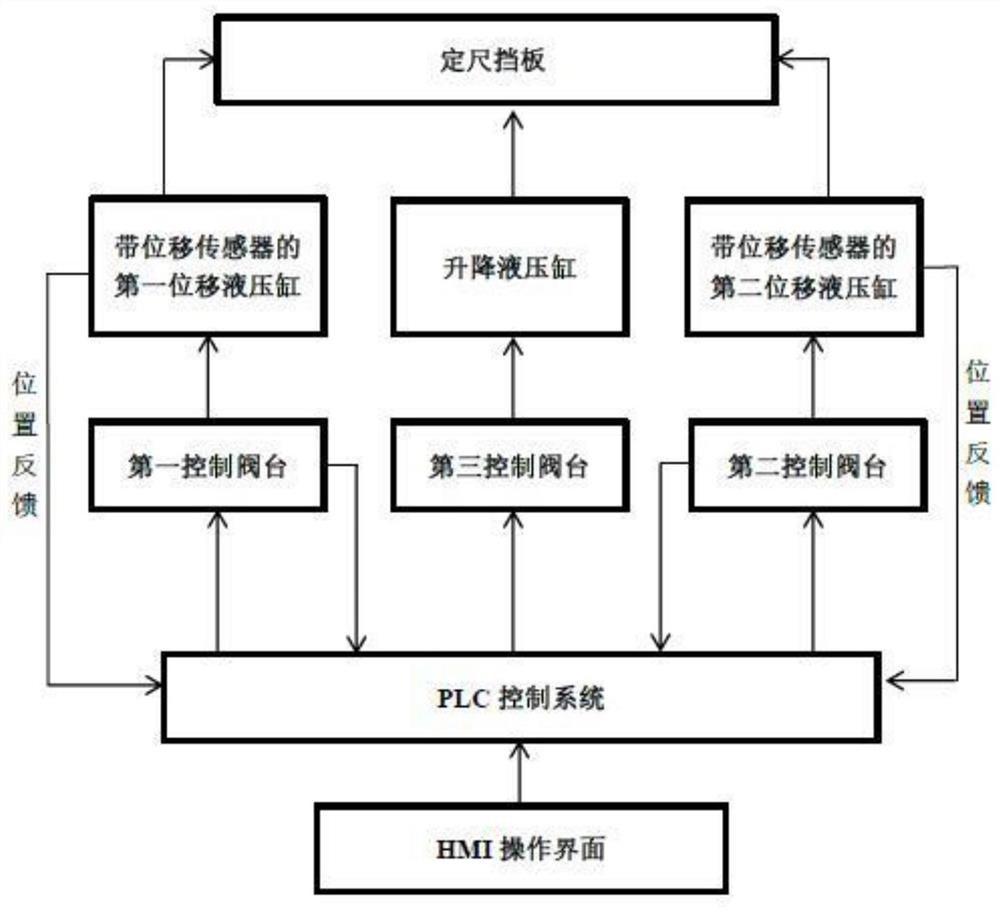

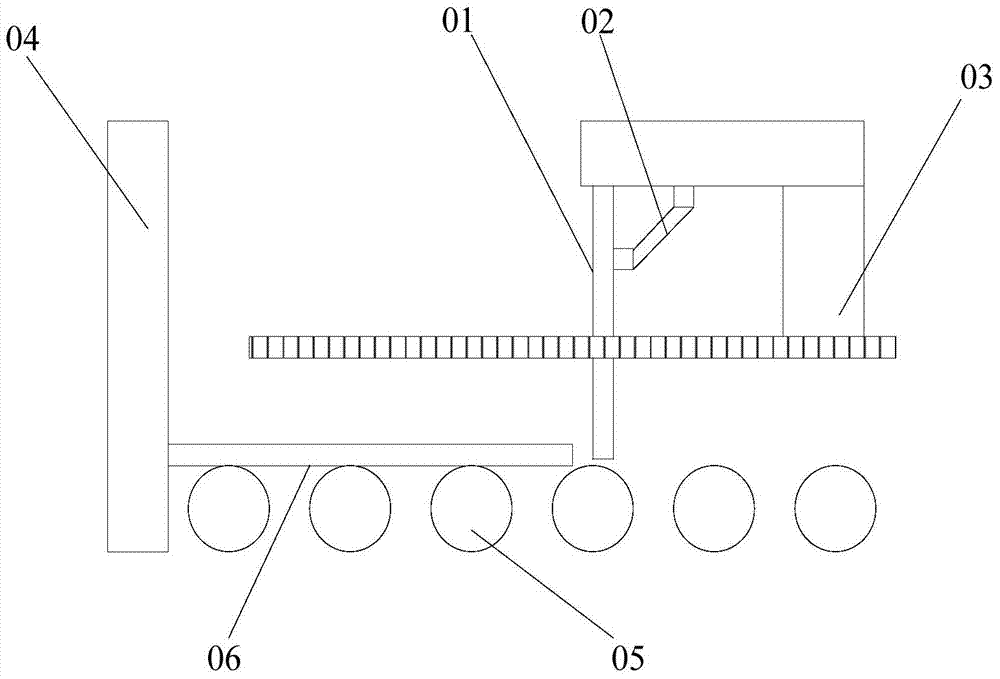

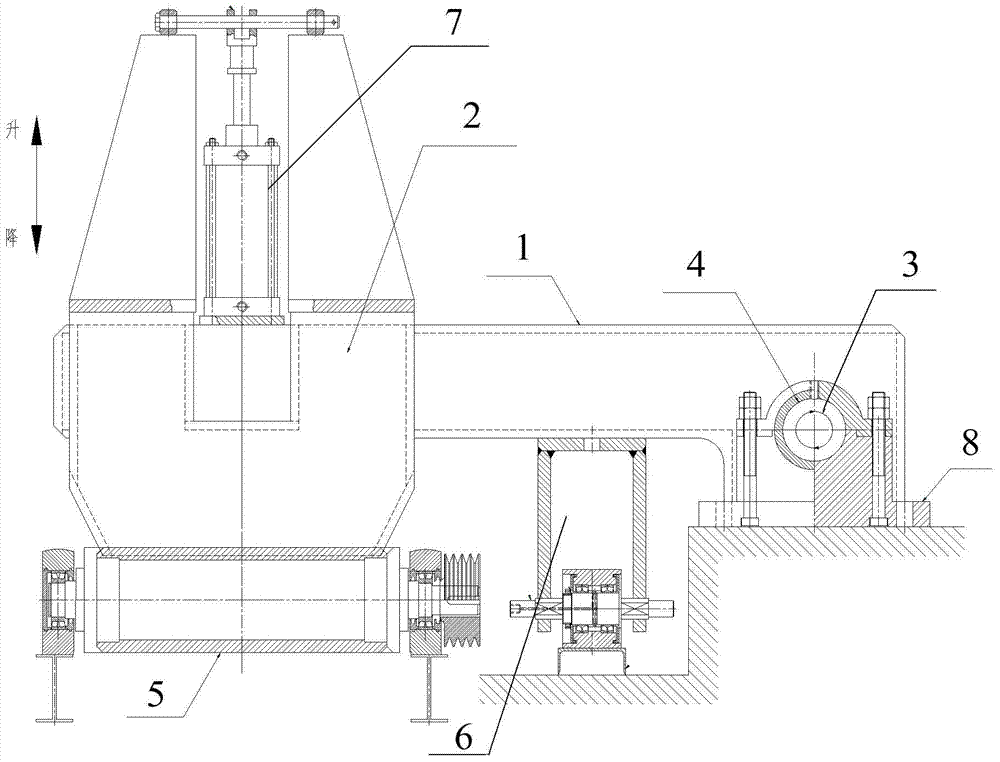

A device and method for improving the precision of special steel bar marshalling and sizing

ActiveCN113102509BEnables lateral temperature compensation for offsetAvoid uneven lengthMetal sawing accessoriesMetal rolling arrangementsHydraulic cylinderControl system

The invention relates to a device for improving the precision of special steel bar grouping and sizing, which includes a sizing frame, a sizing baffle mounted on the sizing frame, a baffle lifting device and a baffle displacement device, the baffle lifts The device includes a lifting hydraulic cylinder and a crank connecting rod. One end of the crank connecting rod is hinged with the piston rod of the lifting hydraulic rod, and the other end is hinged with the baffle plate. Hinged; the baffle plate displacement device includes two push mechanisms, both of which are hinged with the fixed-length baffle, and the push mechanism includes a displacement hydraulic cylinder and a connecting rod, and one end of the connecting rod is connected to the displacement hydraulic cylinder The piston rod is hinged, and the other end is hinged with the fixed-length baffle; both the lifting hydraulic cylinder and the displacement hydraulic cylinder are controlled by a PLC control system. The invention compensates the transverse temperature deviation and the longitudinal temperature deviation of the grouped multiple-length parent materials, and greatly improves the length-setting accuracy of the length-setting machine.

Owner:BAOSTEEL SPECIAL STEEL SHAOGUAN CO LTD

A sizing machine and method of use thereof

ActiveCN105478889BSimple structureReduce flex deformationShearing machine accessoriesAutomatic controlEngineering

The embodiment of the invention discloses a fixed size machine and an application method thereof. According to the fixed size machine, a sliding screw pair structure comprising a sliding spiral lead screw and a sliding spiral nut is adopted, the parameters of a thread, the screw pitch and the like of a sliding spiral pair are set in a matched manner, and it is guaranteed that the fixed size machine cannot move when bearing the large axial horizontal impact load, so that the fixed size accuracy is high, and the sliding screw pair has the beneficial effects of being simple in structure, stable in operation, low in noise, high in screwing accuracy, large in transmission ratio and the like. A guide device is arranged, a feeding workbench can be supported effectively through the guide device, and the situation that the fixed size machine rotates along with rotation of the sliding spiral lead screw is prevented, so that flexibility deformation is lowered; and in addition, a pneumatic device is adopted for the fixed size machine and arranged on the top face of the feeding workbench, the compactness of the fixed size machine is further guaranteed, space is saved, and the fixed size machine has the beneficial effects of being simple in structure, convenient to maintain, high in automatic control level and short in response time.

Owner:SHANDONG IRON & STEEL CO LTD

A kind of measuring machine system and using method thereof

ActiveCN105921518BImprove transmission efficiencyHigh precisionMetal rolling arrangementsShearing machine accessoriesStatic frictionRoller chain

The invention relates to a shear gauge system and a use method thereof. The shear gauge system comprises a feeding worktable, a chain wheel mechanism, a bearing mechanism, sliding screw mechanisms and a shear gauge, wherein the bearing mechanism comprises a guide groove, supporting plates and an upper friction plate; the feeding worktable is arranged on the guide groove in a slidable manner through vertical roll assemblies; a lower pressing plate is fixedly connected onto the feeding worktable; the upper surface of the lower pressing plate is in contact with the lower surface of the upper friction plate; each sliding screw mechanism comprises a welding nut fixed on the feeding worktable and a fastening bolt which are matched with each other, and the bottom of the fastening bolt is in contact with the corresponding supporting plate; the chain wheel mechanism comprises a roller chain and a first chain wheel and a second chain wheel which are meshed with the roller chain; and the shear gauge is fixedly connected onto the feeding worktable. During a use process, the sliding screw mechanisms are adjusted, so that the upper friction plate is matched with the lower pressing plate; high static friction force is provided, so that the shear gauge does not deflect under high-load impact, and the sizing precision is improved; and furthermore, the chain wheel mechanism has the advantages of high precision, abrasion-resistance, small spatial size and the like.

Owner:SHANDONG IRON & STEEL CO LTD

A sizing mechanism of aluminum rod hot shearing machine

ActiveCN110253068BAvoid deflectionHigh precisionShearing machinesShearing machine accessoriesVehicle frameClassical mechanics

The invention relates to a sizing mechanism of aluminum bar hot shears. The sizing mechanism comprises a sizing rack (10.1). The sizing rack (10.1) is provided with a sizing frame (10.2) which can move forward and backward, a fixed support base (10.3) is arranged on the front side of the sizing frame (10.2), a sizing stop bar assembly (10.4) is hinged to the fixed support base (10.3), a cylinder frame (10.5) is arranged on the back side of the sizing frame (10.2) and provided with a cylinder base (10.6), a first cylinder (10.7) is hinged to the cylinder base (10.6), and the first cylinder (10.7) and the sizing stop bar assembly (10.4) are connected through a connecting rod mechanism (10.8). When the sizing stop bar assembly is collided by an aluminum bar, and a first connecting rod and a second connecting rod are located at dead point positions so that the sizing stop bar assembly in the sizing process can be effectively prevented from being deflected, and the positioning accuracy of aluminum bar sizing is greatly improved.

Owner:JIANGYIN GIANSUN ALUMINUM PROFILE COMPLETE PLANT MFG

Sawing machine with automatic cut-to-length control function

InactiveCN102004465BHigh precision in sizingIncrease productivityProgramme controlComputer controlEngineeringRejection rate

The invention relates to a sawing machine with automatic cut-to-length control function. The sawing machine comprises a sawing machine workbench, a sawing machine support arm, a photoelectric encoder, a sawing machine feed frame, a guiding rule and a control circuit, wherein a workpiece to be detected is arranged on a roll of the sawing machine feed frame, the front end of the workpiece passes through the sawing machine support arm and is placed on the workbench; the guiding rule is arranged at the front end of the workpiece to be detected; an encoder bracket is fixed at the radial side of the workpiece on the workbench; the photoelectric encoder and a depended wheel are fixed on the cantilever at the front end of the encoder bracket; the photoelectric encoder and the depended wheel are coaxially arranged, and the depended wheel is arranged on the top end of the periphery of the workpiece to be detected. The cut-to-length device is controlled by a counter and detected by adopting the photoelectric encoder, and is assisted by the guiding rule, so that the cut-to-length accuracy of the sawing machine is greatly improved, the production efficiency is improved, and the rejection rate is reduced.

Owner:天津丰亿达通用机械有限公司

A device for improving the production efficiency of a profile cutting machine and a method of using the same

ActiveCN105728845BReduce cutting operation timeSimple structureMetal sawing accessoriesMeasurement/indication equipmentsEngineeringSizing

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com