Backing type sizing feed gear and sizing feed method

A feeding device and feeding technology are applied in the field of retractable fixed-length feeding devices, which can solve the problems of slow speed, low precision, and inability to make full use of the material head.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

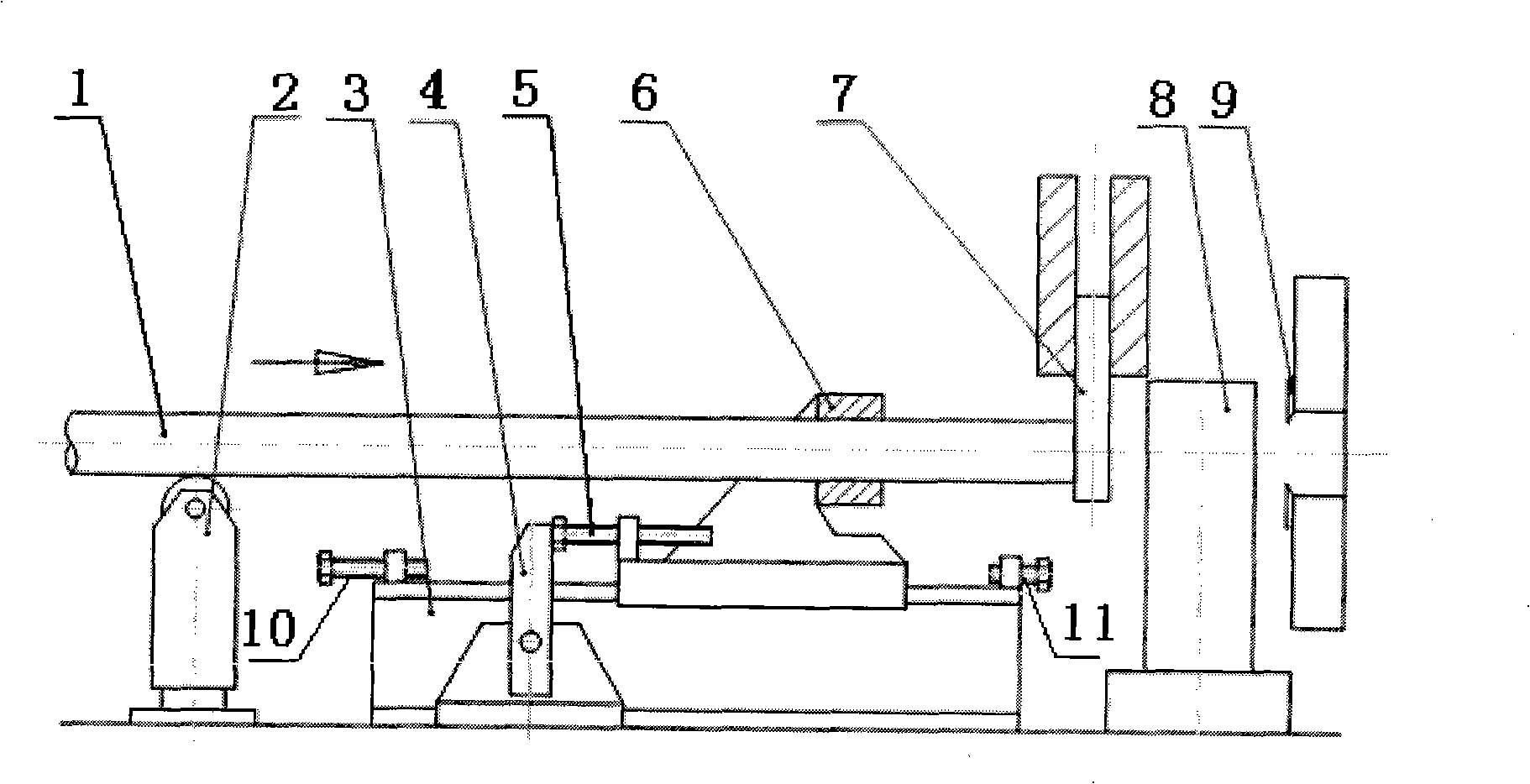

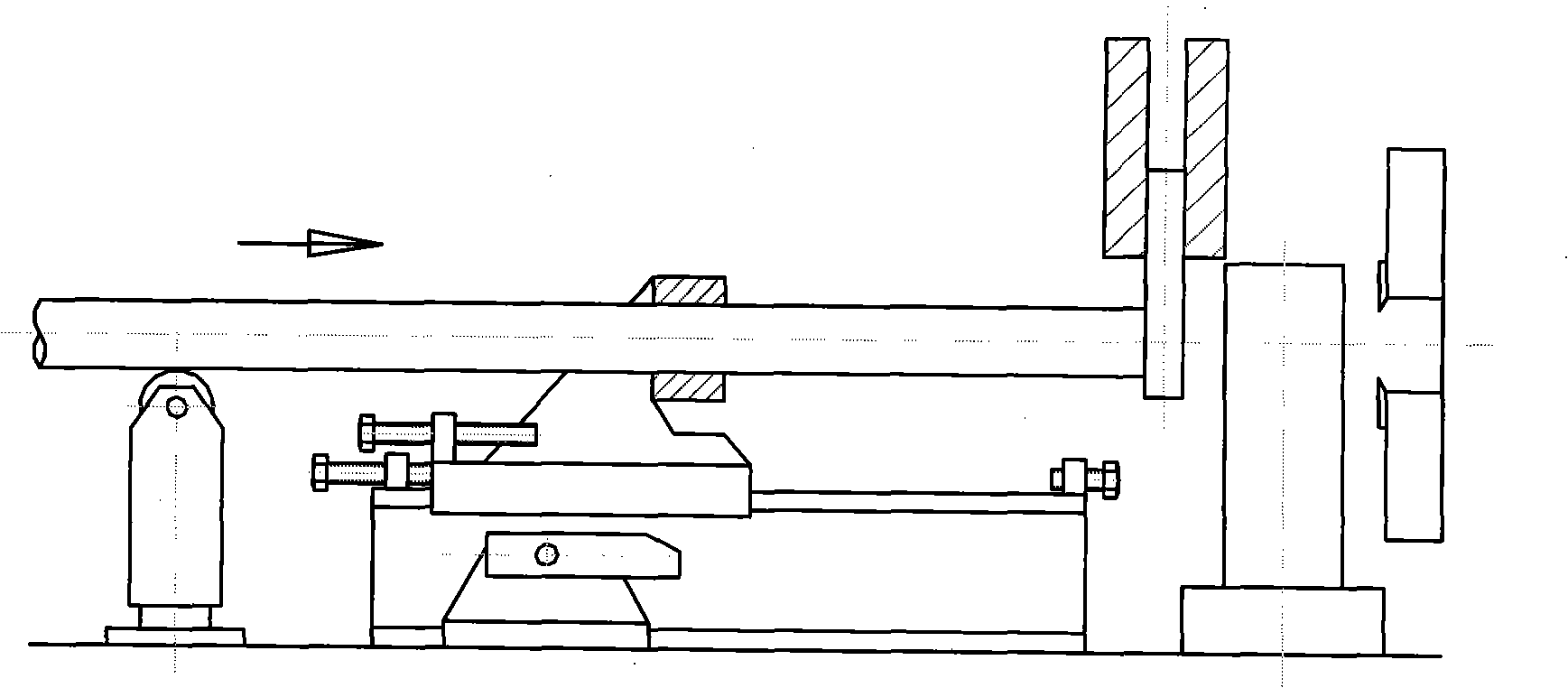

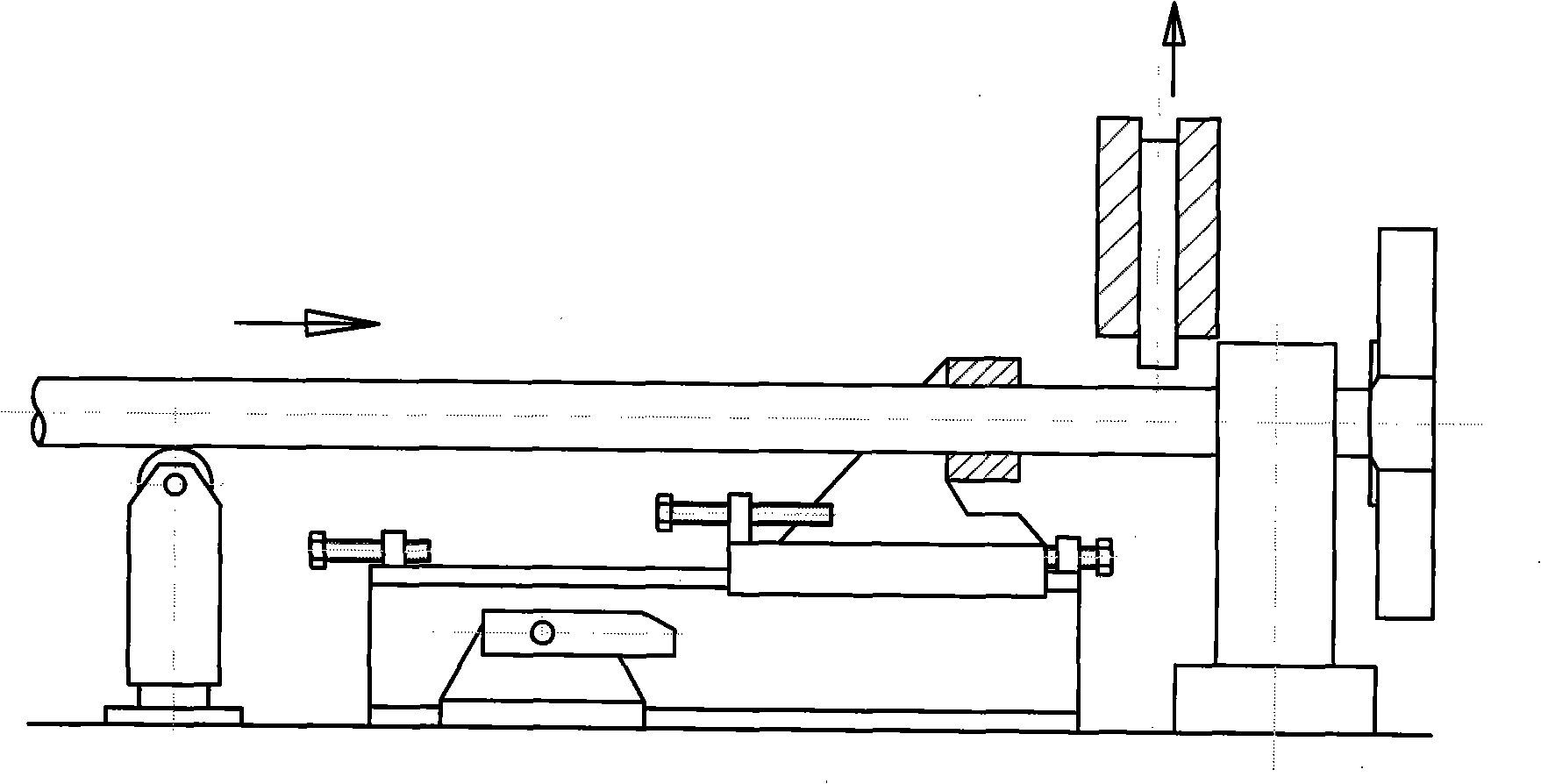

[0024] Example figure 1 As shown, the idler 2, the main clamp 8, the slideway 3, and the head baffle 7 are respectively fixed on one side of the cutting tool 9 of the cutting device and on the same axis, and the idler 2 and the main clamp 8 are fixed on the slideway 3 The two sides of the material head baffle plate 7 are between the slideway 3 and the main clamp 8, and the feeding clamp 6 is slidingly connected with the slideway 3, so that the pipe bar material 1 is transferred on the idler roller 2. There is a fixed-length baffle 4 on one side of the slideway seat, and the fixed-length baffle 4 can rotate 90 degrees along the fixed axis; when the fixed-length baffle 4 is in a vertical position, the fixed-length screw 5 will touch the fixed-length baffle 4 when moving on the horizontal axis ; When the fixed-length baffle 4 is in the horizontal position, the fixed-length screw 5 moves along the horizontal axis and will pass through the fixed-length baffle 4 positions in the ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com