A device for improving the production efficiency of a profile cutting machine and a method of using the same

A production efficiency and cutting machine technology, which is applied to the attachments of sawing machines, positioning devices, metal sawing equipment, etc., can solve the problem of inability to efficiently and accurately ensure the quality and accuracy of cutting workpieces, high labor intensity, low efficiency, and dimensional accuracy. It can reduce the cutting operation time, simplify the structure and reduce the measurement time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementations.

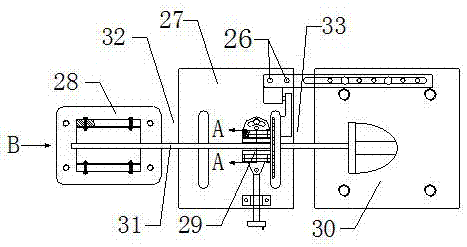

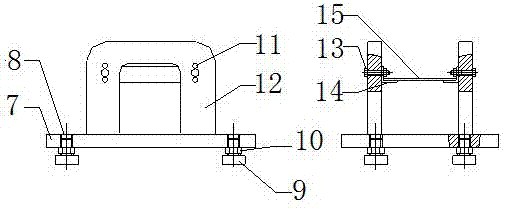

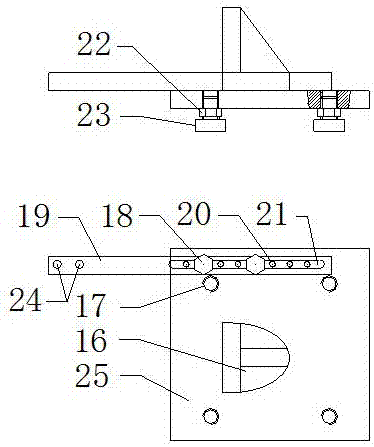

[0024] Refer to the attached Figure 1-5 Shown: a device for improving the production efficiency of a profile cutting machine is used in conjunction with the profile cutting machine 27. The device includes a "V"-shaped groove fixture 29 located on the profile cutting machine 27, and the device also includes a feeding support 28 and a fixed Ruler mechanism 30, the feeding bracket 28 is located at the feeding end 32 of the profile cutting machine 27, and the feeding bracket 28 includes: a bracket base 7, an adjusting bolt 9, a locking nut 10, a rib plate 12, a fixing bolt 13, The angle steel 14 and the tray 15 are formed; the rib plate 12 is welded on both sides of the bracket base 7, and the rib plate 12 has height adjustment holes 11, which is convenient for adjusting the horizontal height of the cutting piece; the tray 15 is we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com