Continuous casting infrared camera shooting sizing error online continuous correction method

A technology of infrared camera and infrared camera, which is applied in the field of steelmaking and continuous casting, can solve the problems of manual adjustment, poor precision, waste, etc., and achieve the effect of improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

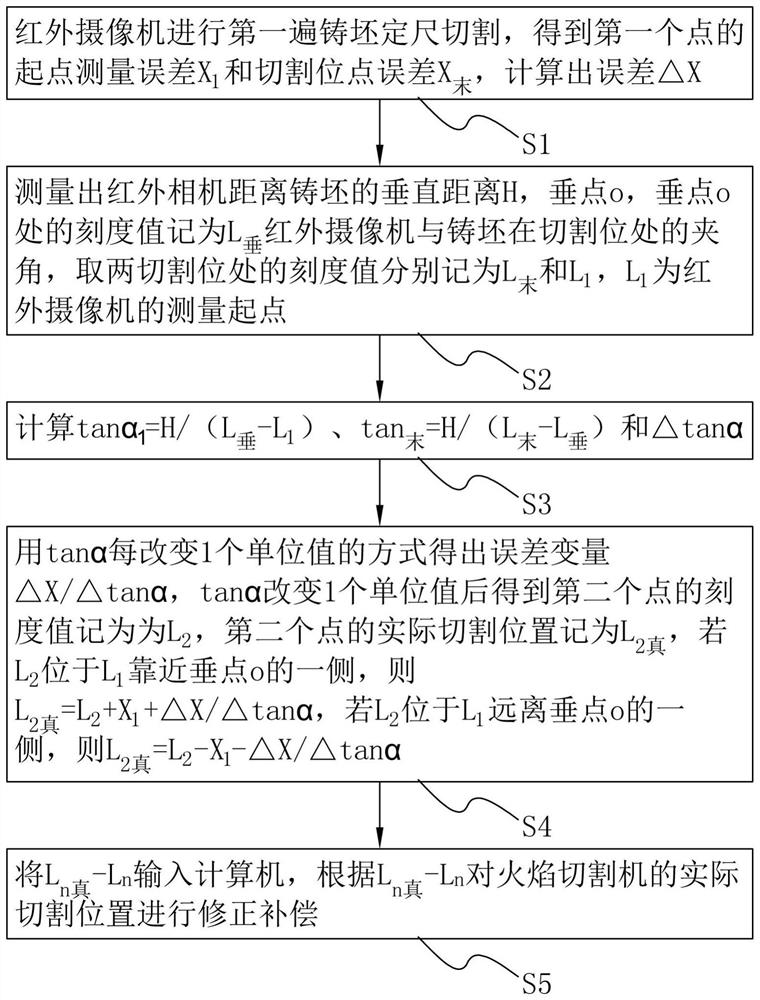

[0022] A method for online continuous correction of continuous casting infrared camera sizing error, such as figure 1 shown, including the following steps:

[0023] S1. The infrared camera conducts the first round of slab cut-to-length cutting, and obtains the measurement error X of the starting point of the first point. 1 and cleavage site error X 末 , calculate the error ΔX, and take the cutting site error X of the first point 末 Measurement error with starting point X 1 Calculate the difference of ΔX=X 末 -X 1 .

[0024] S2. Use an infrared camera to measure the vertical distance H between the infrared camera and the slab, the vertical point o, and the scale value at the vertical point o is recorded as L 垂 , The angle α between the infrared camera and the billet at the cutting position, take the scale values at the two cutting positions as L 末 and L 1 , L 1 It is the measurement starting point of the infrared camera.

[0025] S3, calculate tanα 1 =H / (L 垂 -L 1 ),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com